Drilling tool with spinning coupling function and operating method of drilling tool

A technology for drilling tools and working methods, applied in drilling equipment and methods, driving devices for rotary combined drilling, drilling equipment, etc. Drilling and other problems to achieve the effect of increasing the ROP, reducing the stick-slip phenomenon, and improving the rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

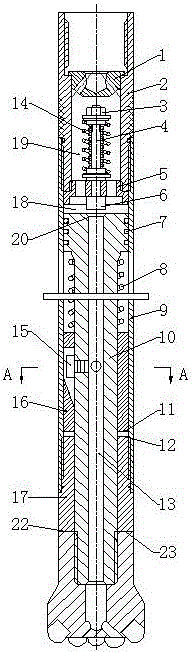

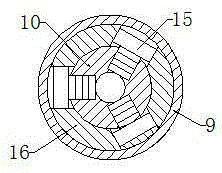

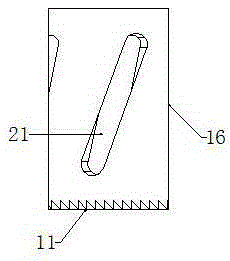

[0012] like figure 1 , figure 2 , image 3 As shown, the present invention is a drilling tool with rotary impact coupling action and its working method, which mainly includes an overflow valve 1, an upper joint 2, a flow controller 3, a spring rod 4, an overflow baffle 5, a valve head 6, and a seal 7. Spring 8, shell 9, mandrel 10, lower ratchet 11, upper ratchet 12, center hole 13, valve spring 14, follower 15, rotary sleeve 16, lower joint 17, adjustment chamber 18 , control valve 19, valve seat 20, screw hole 21, upper bearing surface 22 and lower bearing surface 23; it is characterized in that: the upper joint 2 is connected to the upper part of the shell 9 by threads, and an overflow valve 1 is installed inside it; The valve 19 is installed at the lower end of the upper joint 2, and together with the upper end surface of the shell 9 and the mandrel 10, it forms the regulating chamber 18; , and valve spring 14; the upper outer surface of the mandrel 10 forms a clearanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com