Near-bit circumferential resonance impacter

A technology of impactor and near-drill bit, which is applied in drilling equipment, earthwork drilling, driving devices for drilling in boreholes, etc. It can solve problems such as intermittent sticking, stick-slip effect, etc., to ensure stable rock breaking and reduce torsion Oscillation, the effect of short structural dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

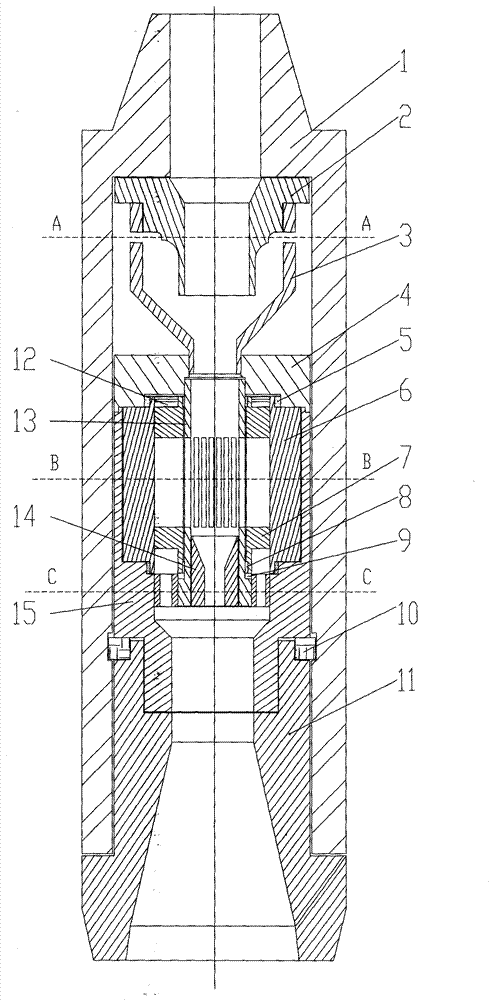

[0022] Such as figure 1 As shown, this kind of circumferential resonant impactor near the drill bit includes a shell short 1, a flow guide part, a resonant impactor, and a transmission short 11, and the upper end of the shell short 1 is connected to the female end of the upper drill collar through an API standard thread , the lower end of the shell short 1 is connected to the positioning snap ring 10 and the transmission short 11 with a gap, and the guide part and the resonant impactor are installed between the shell short 1 and the drive short 11, and the shell short 1 is outside, and the flow guide, Resonant shocks included.

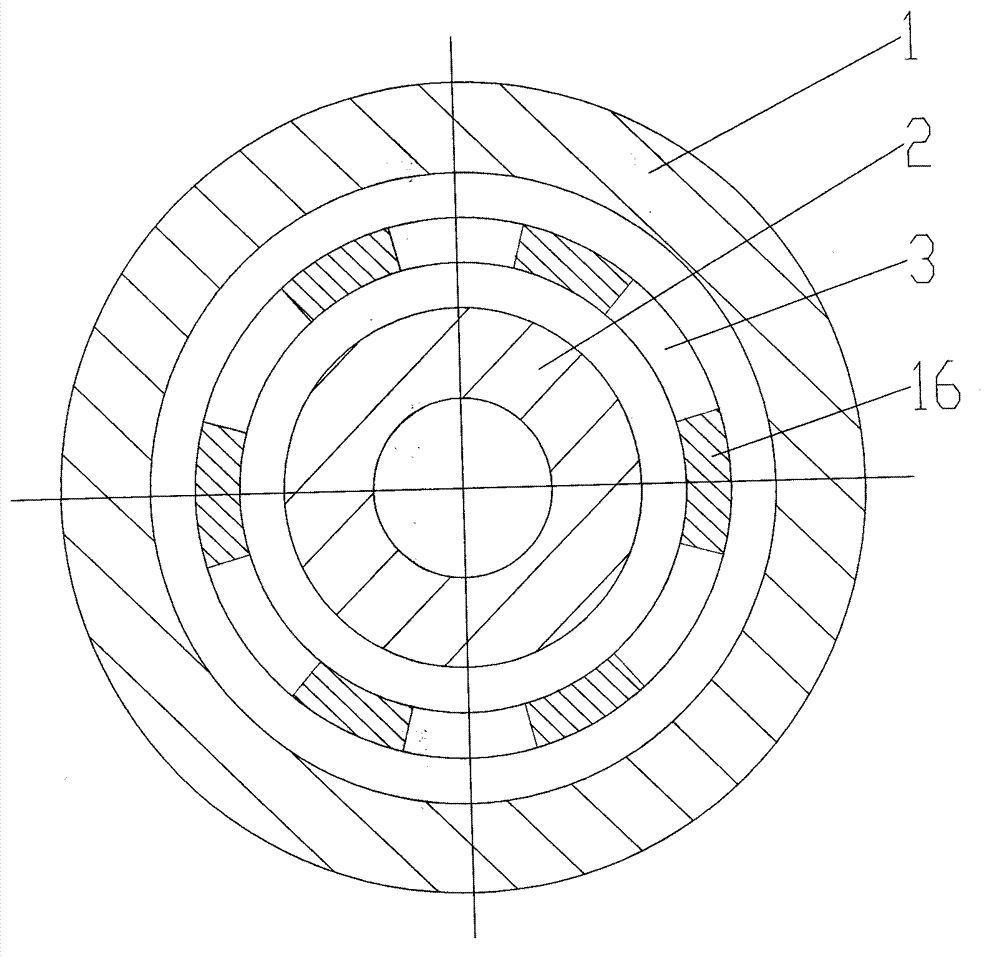

[0023] combine figure 2 As shown, the flow guiding part is composed of a T-shaped inner liner 2 and a V-shaped outer sleeve 3. The outer edge of the T-shaped inner liner 2 is seated on the upper port of the V-shaped outer sleeve 3, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com