Method and device of liquid power impact motor

A liquid power and motor technology, applied in the direction of drilling with vibration, can solve the problems of wear, slow ROP, etc., to achieve the effect of improving ROP, full power, and solving repeated cutting and stick-slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

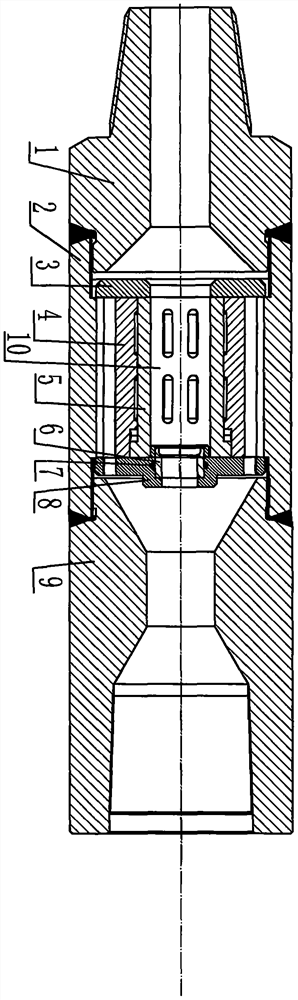

[0012] figure 1 Shown in: liquid power impact motor: including: upper joint 1, start valve 5, impact seat 2, impact hammer 4 and lower joint 9; figure 1 As shown in : the two ends of the impact seat 2 are provided with an upper joint 1 and a lower joint 9; figure 1 Shown in: the impact hammer 4 inside the impact seat 2, wherein: the upper shunt cover 3 is set between the impact hammer 4 and the upper joint 1, and the shunt load-bearing cover 8 is set between the impact hammer 4 and the lower joint 9. figure 1 Shown in: the impact hammer 4 and the inner chamber 10 of the motor are provided with a starting valve 5 . figure 1 Shown in: a sealing ring 7 and a nozzle 6 are provided between the starting valve 5 and the lower shunt load-bearing cover plate 8 .

[0013] During drilling operations, when the drilling fluid circulates at high pressure, when the fluid passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com