Mixed type downhole drilling bit

A kind of drilling bit, hybrid technology, applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problems of low cutting efficiency of roller cone bit cutting teeth, fixed cutting teeth are vulnerable to impact damage, PDC bit mechanical penetration rate is slow, etc. , to achieve the effect of improving the overall cutting efficiency and ROP, eliminating stick-slip phenomenon, and improving cutting efficiency and ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

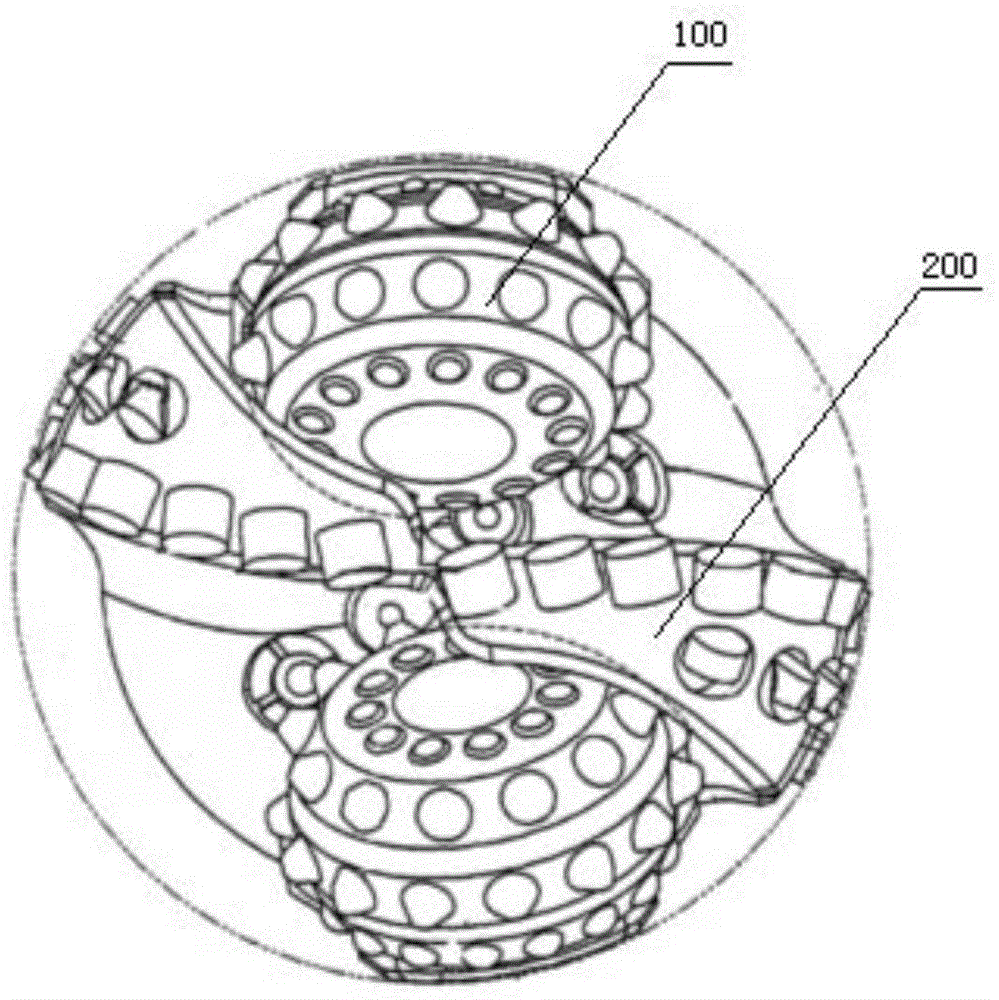

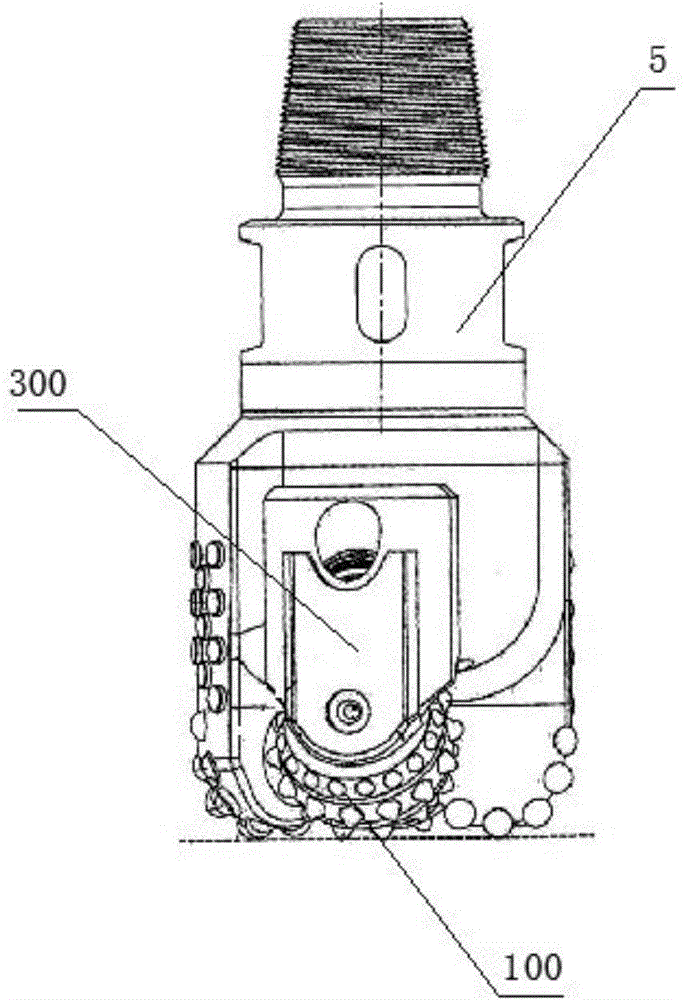

[0047] Such as Image 6 with Figure 7 As shown, a hybrid downhole drilling bit is disclosed, comprising a drill body 5, the drill body 5 includes two blades 13 with only conical teeth 8 and two other blades 32 and two palms 10, the palms The lower end of 10 is welded together with the drill bit body 5, the upper end of the palm 10 is provided with a journal, and the cone 11 is set on the journal; The chisel-shaped teeth 3 and flat-head teeth 2 are located on the nose and shoulder of the blade profile. When drilling, they not only rotate around the axis of the cone 11, but also revolve around the central axis of the downhole drill bit, wherein the axis of the cone 11 is aligned with the center of the bit body 5 There is an angle between 35 degrees and 65 degrees between the lines, two blades 13 with only conical teeth 8 and two blades 32 with front row disc shear teeth 7, only The exposed height of the front row of tapered teeth 8 of the blade 13 of the tapered teeth 8 is gr...

Embodiment 2

[0049] Such as Figure 8 As shown, another hybrid downhole drilling bit is disclosed, including a drill bit body 5, and the drill bit body 5 includes two blades 60 provided with front row disc shearing teeth 77 and two blades with only conical teeth 88 Wing 83, two tooth palms and two cones 61; the cone chisel teeth 66 and flat teeth 63 distributed in rows on the cone 61, the chisel teeth 66 and flat teeth 63 on the cone are located at the blade 60 The nose and the shoulder of the profile, wherein the axis of the cone 61 and the centerline of the downhole drilling bit body 5 have an angle between 25 degrees and 68 degrees; the two front rows are arranged with disc shears The blade 60 of the tooth 77 has a rear row of teeth, and the rear row of teeth is a conical tooth 75, and the rear row of conical teeth 75 is distributed on the nose and the shoulder of the blade contour at the position of the blade contour. The exposure height of the upper and front disc shearing teeth 77 i...

Embodiment 3

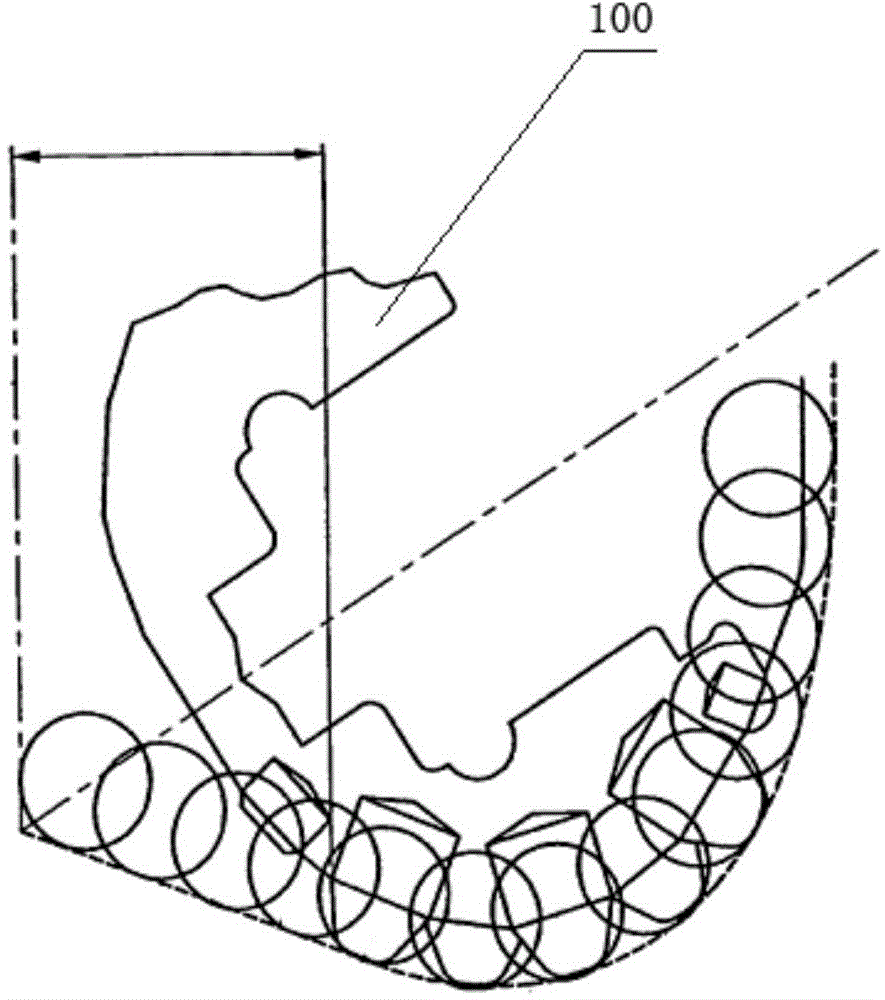

[0051] Such as Figure 9 with Figure 10 As shown, another hybrid downhole drilling bit is disclosed, including a drill bit body 5, and the drill bit body 5 includes two blades 52 with disc shearing teeth 44 in the front row and a blade 53 with only conical teeth 45 , two tooth palms 33 and two cones 35, tooth palms 33 one ends are welded into one with the drill body 5, the other end of the tooth palms 33 is provided with a journal, and the cones 35 are sleeved on the journal (refer to Figure 4 ); chisel-shaped teeth 20 and flat-head teeth 22 are distributed in rows on the cone 35, and the chisel-shaped teeth 20 and flat-head teeth 22 on the cone 35 are located at the nose and shoulder of the blade profile. The 35 axis rotates on its own axis and revolves around the central axis of the downhole drill bit; there is an angle between the axis of the cone 35 and the center line of the downhole drilling bit body 5, which is between 35 degrees and 65 degrees; the bit body 5 includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com