Patents

Literature

183 results about "Tapered teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

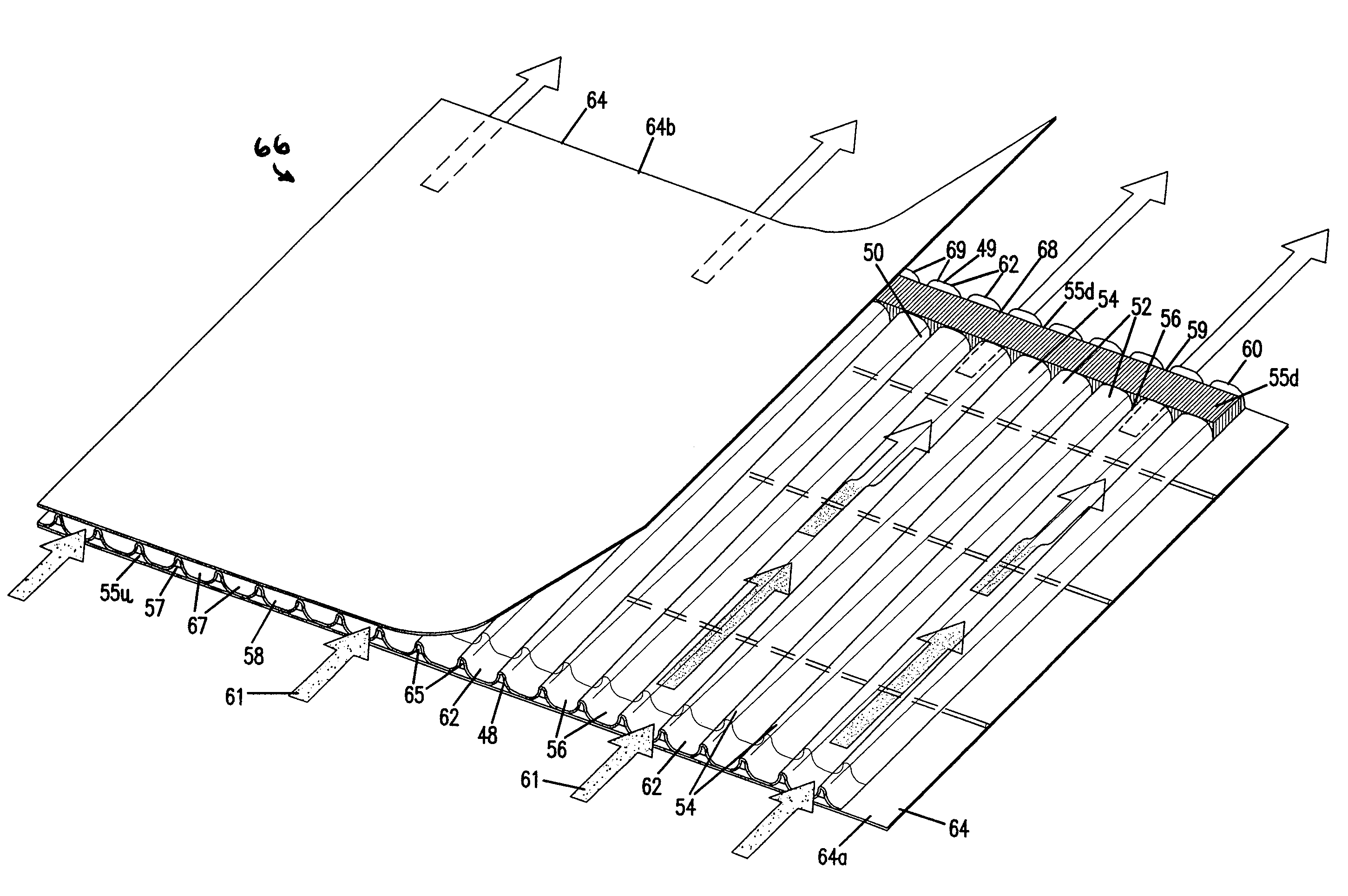

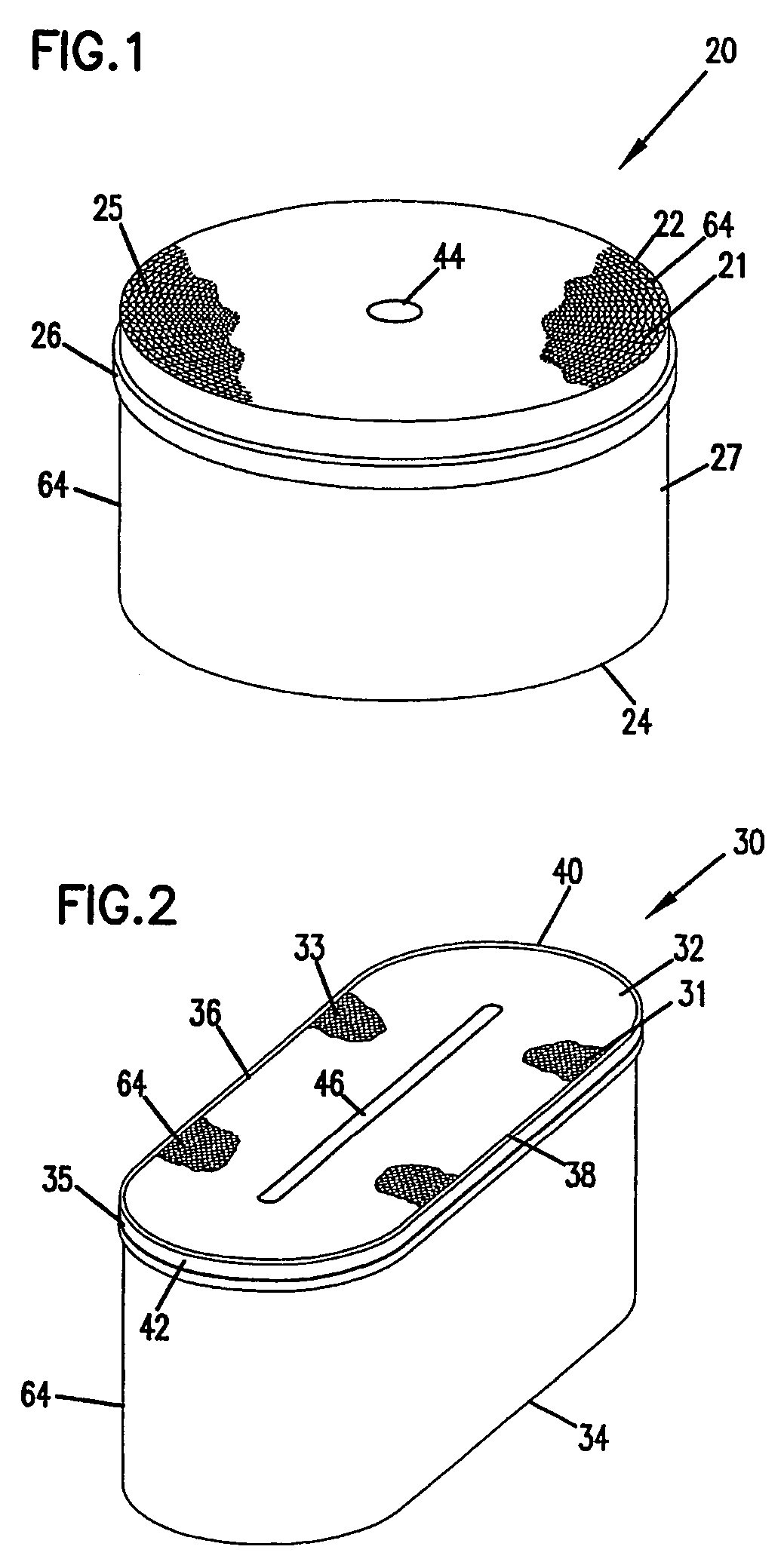

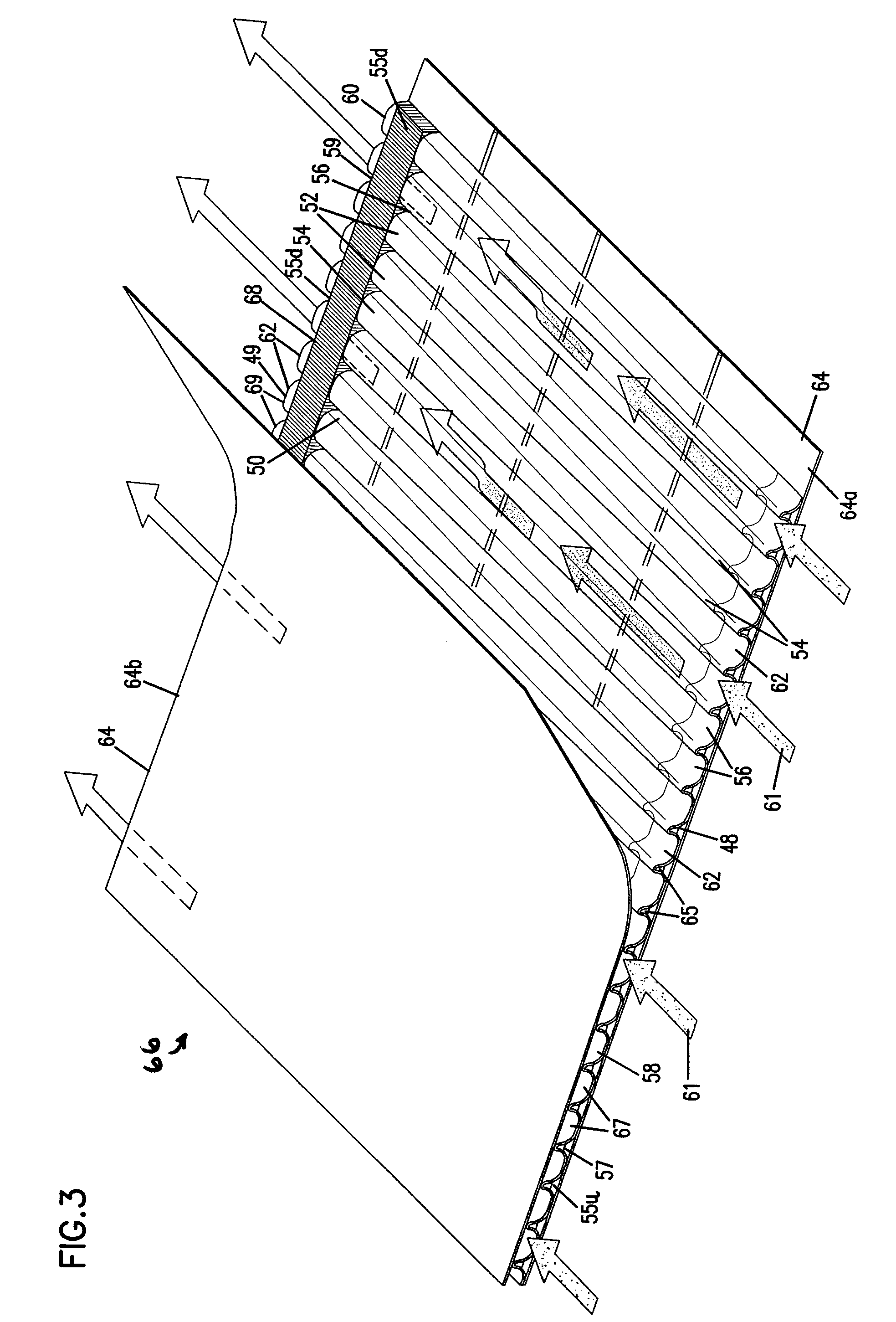

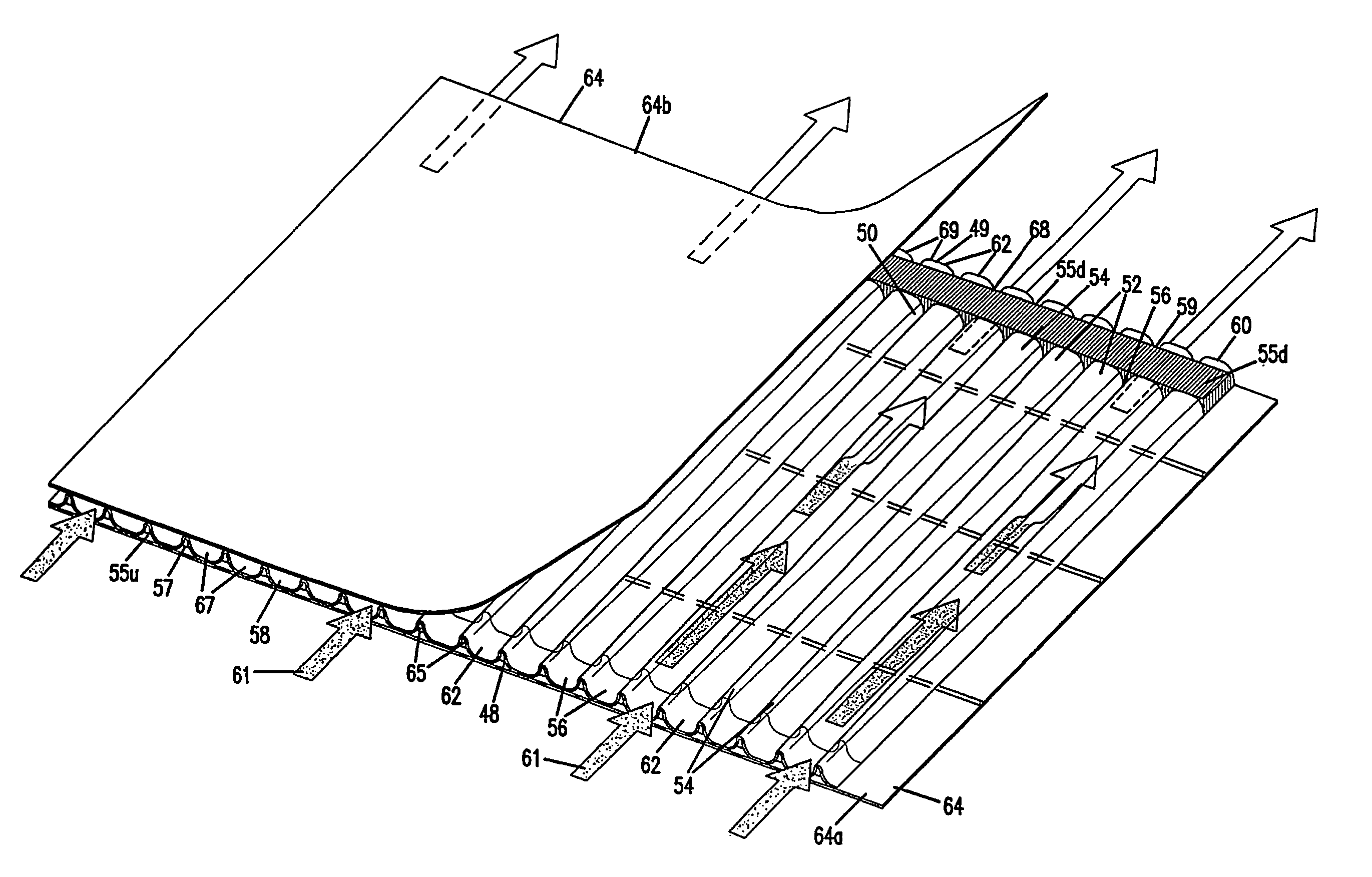

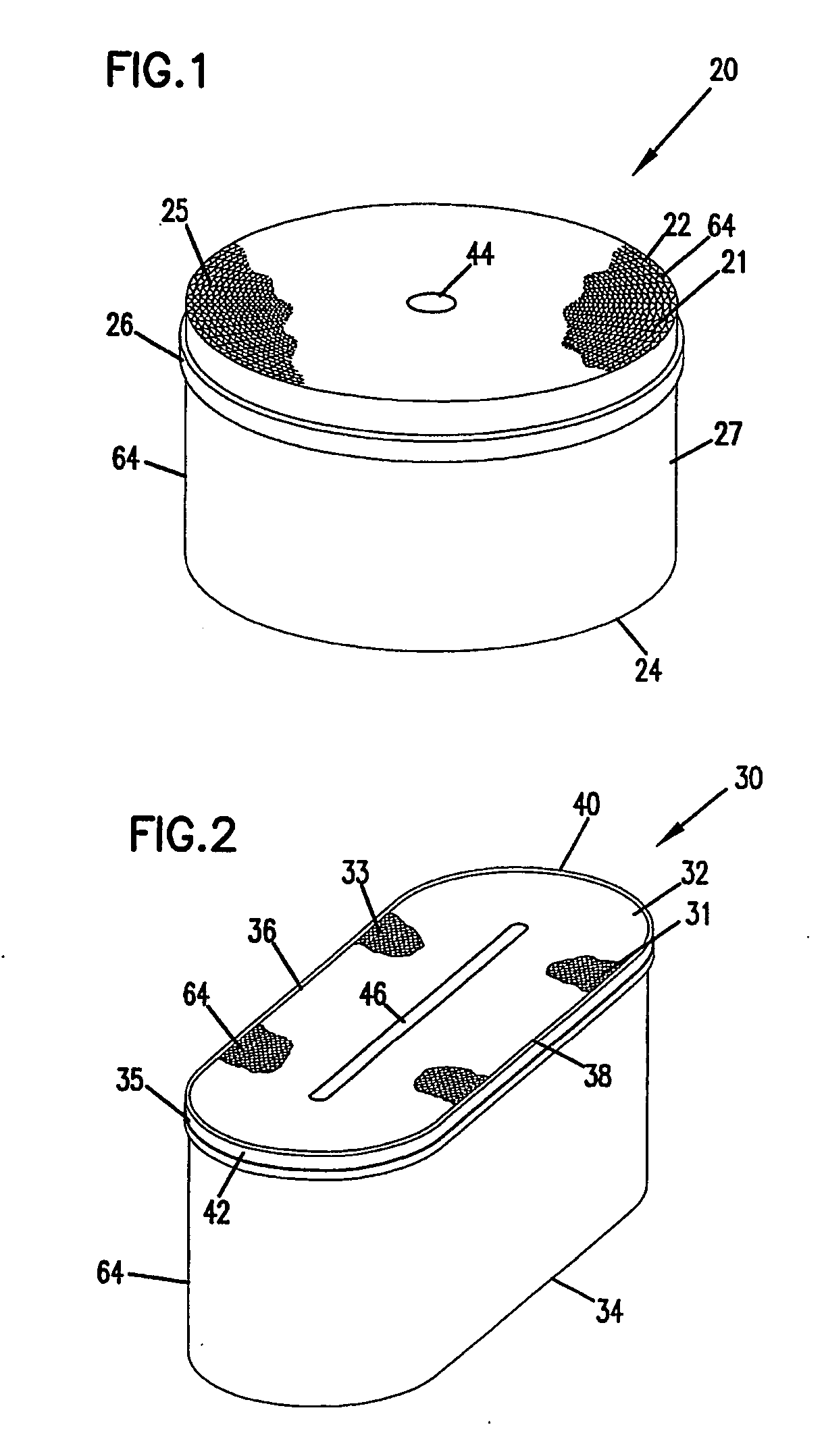

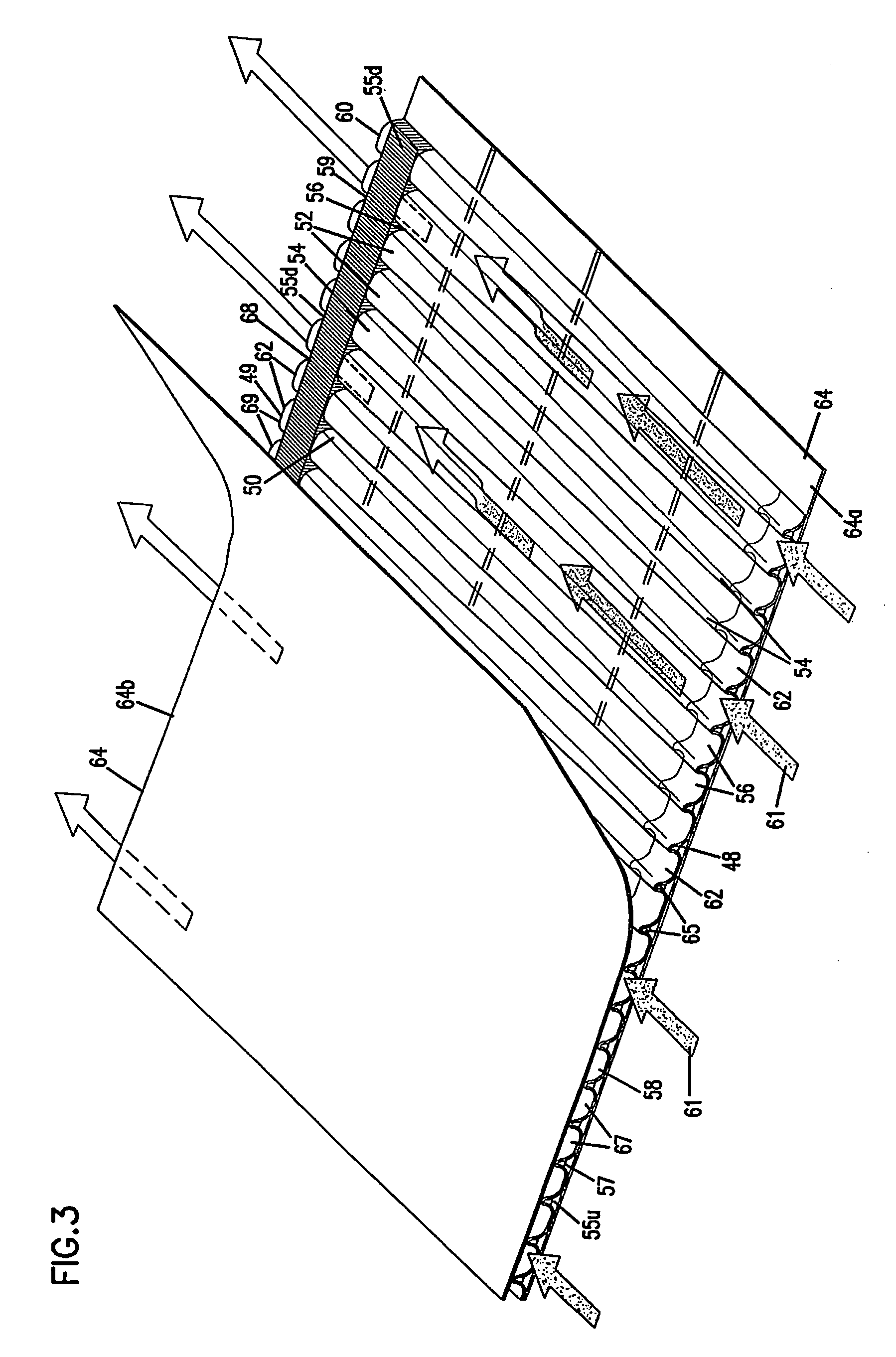

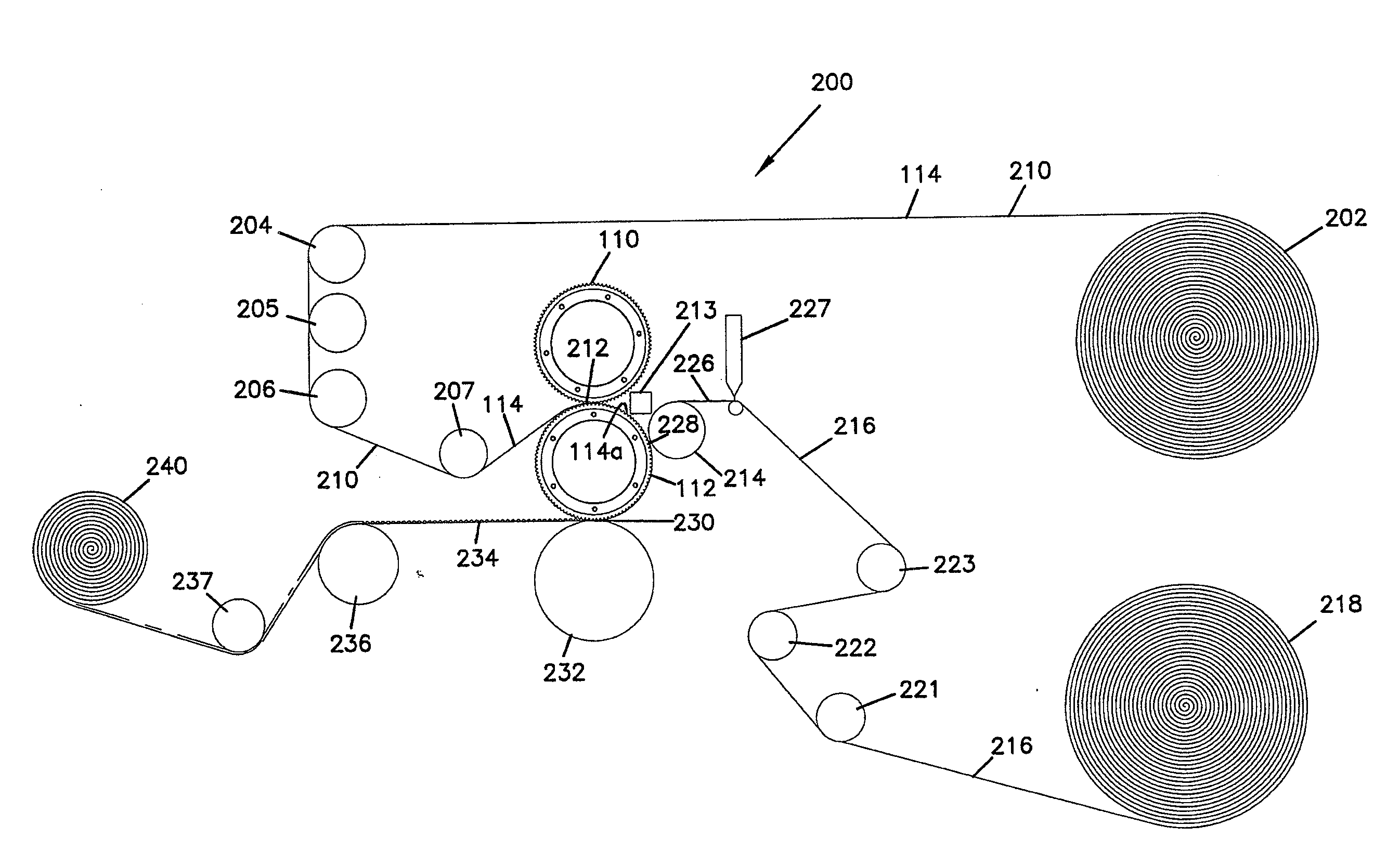

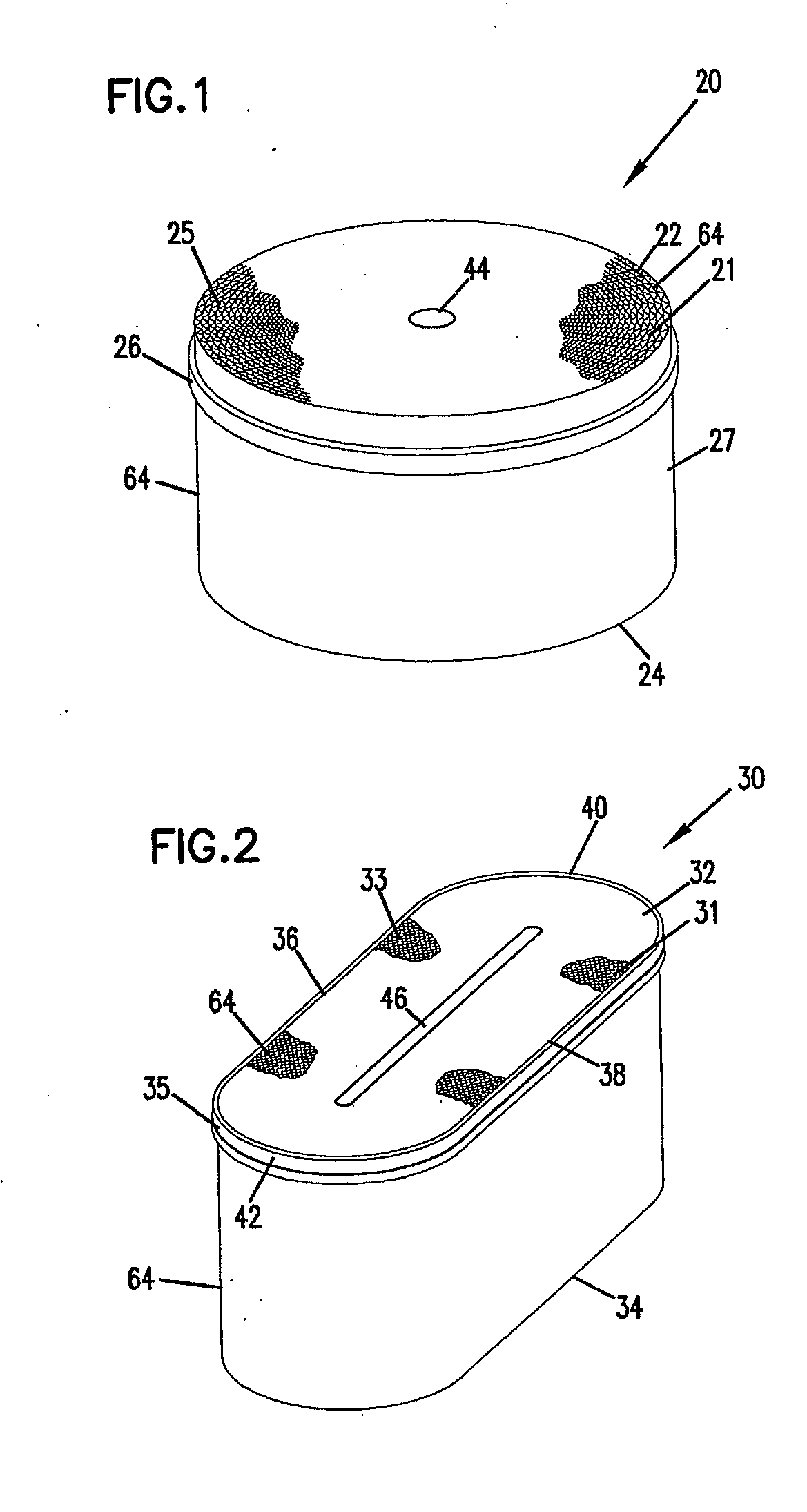

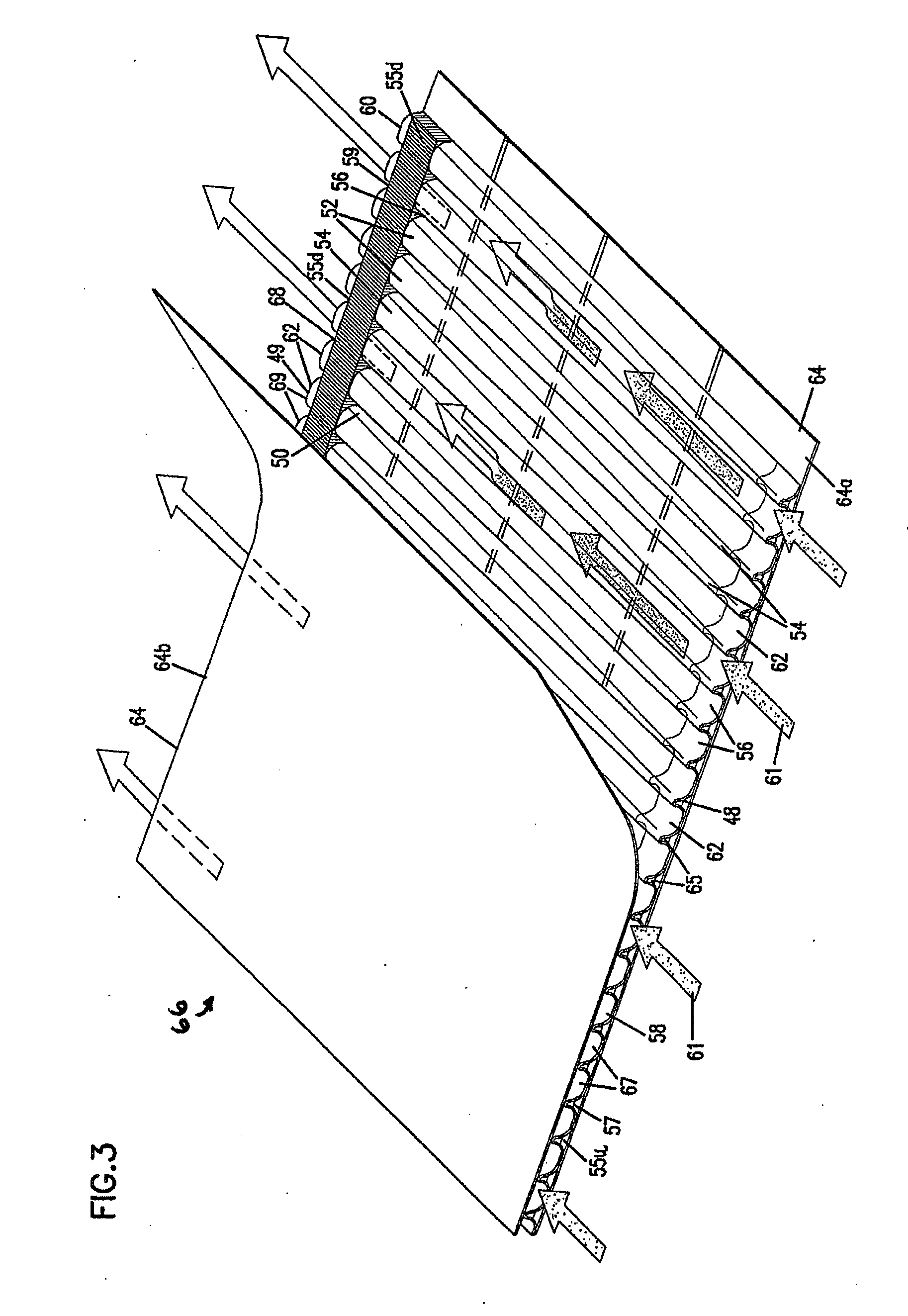

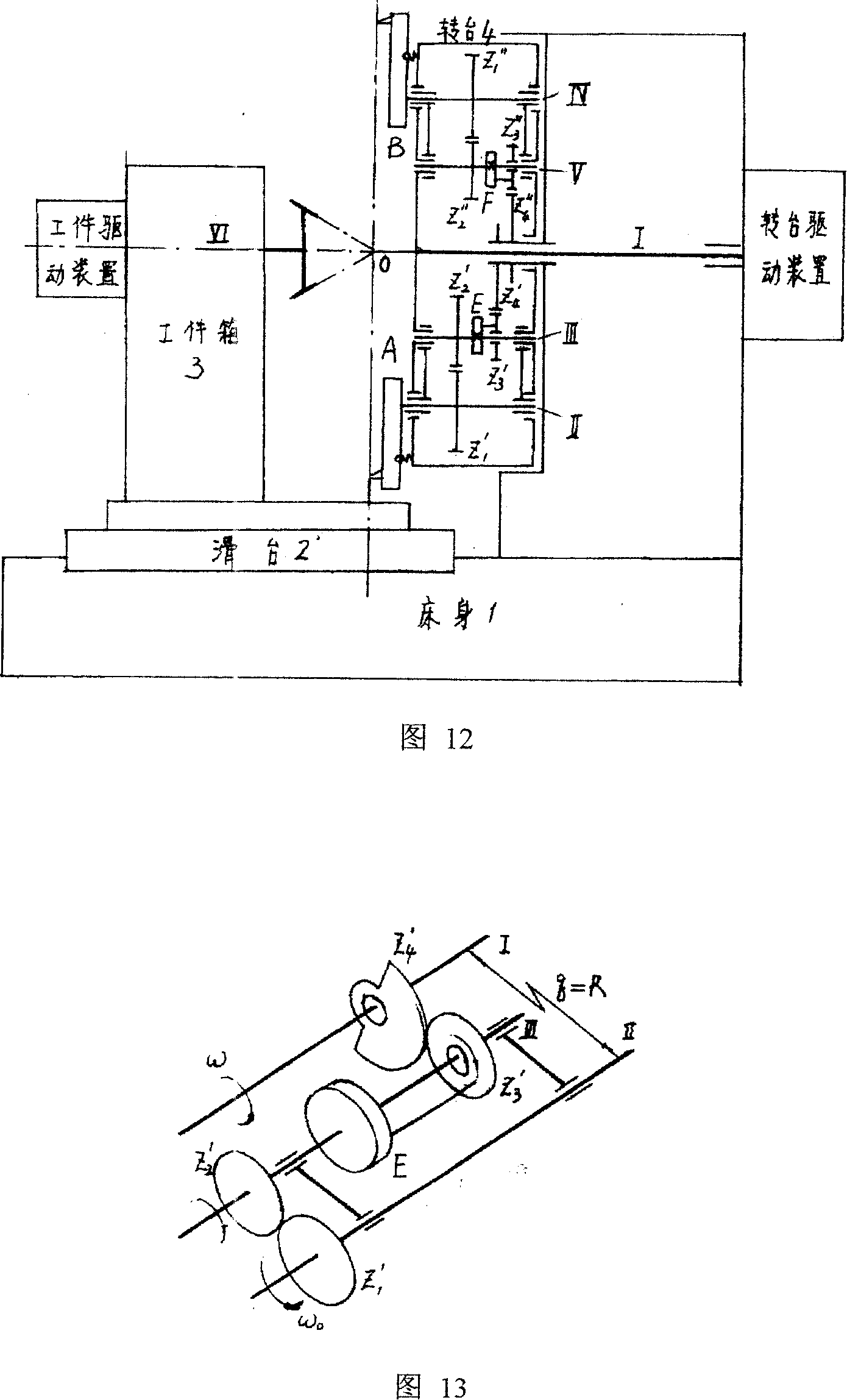

Filter element using corrugated media sheet

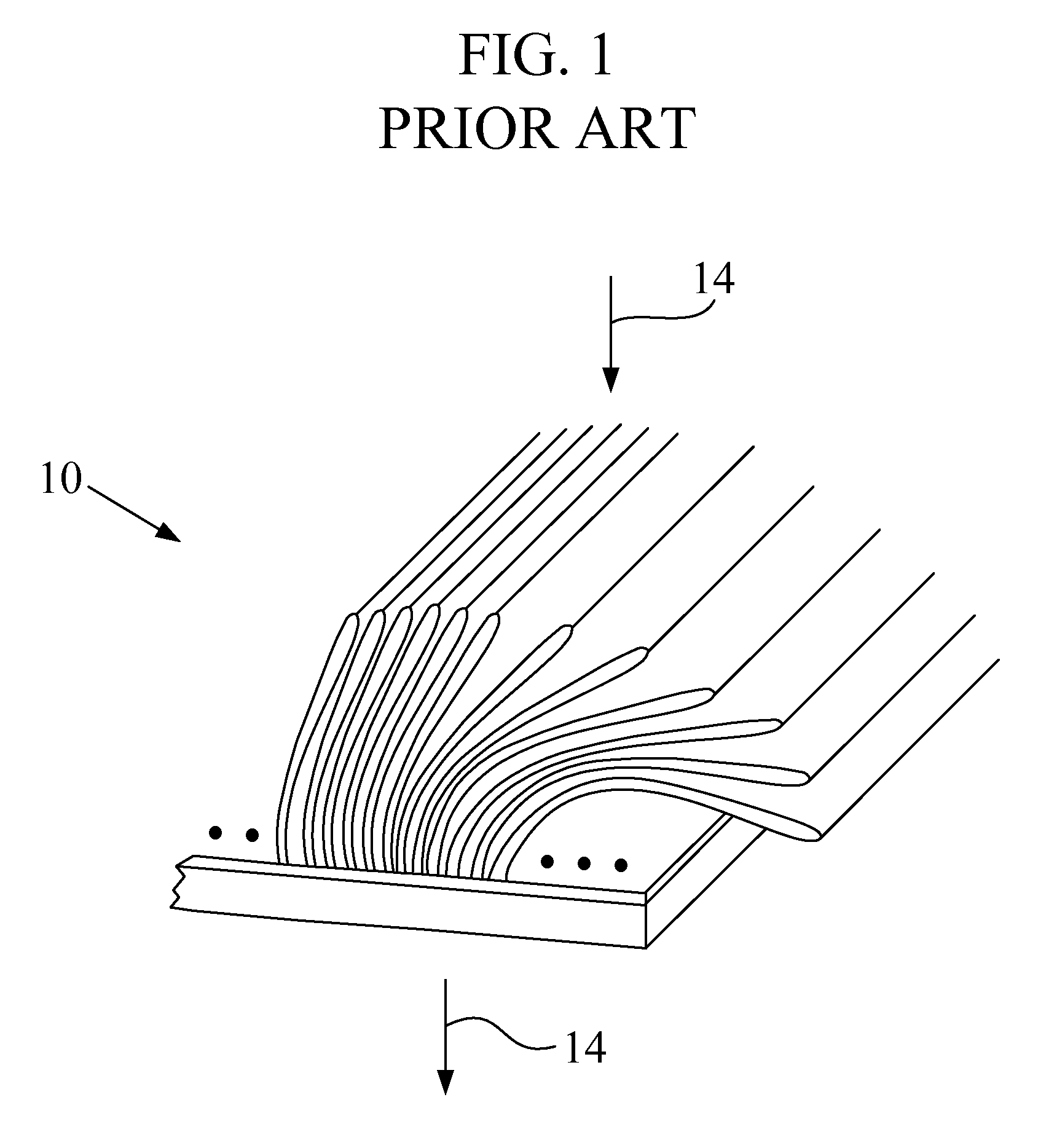

A corrugated web having tapered flutes is usable in straight-through flow filter elements. The corrugated web can be made by passage between a pair of corrugated rollers having tapered teeth. Methods of making usable corrugated rollers include methods for generating the tapered teeth at the end points and the extension between the end points. Corrugated webs may be made from a variety of media, including certain media that stretches in the machine direction. Methods of forming the corrugated web into filter elements (e.g., air filter elements) includes forming filter media by securing a flat sheet to the corrugated web. The filter media may then be wound into a filter element, including application of sealant during the winding process to close selected flutes.

Owner:DONALDSON CO INC

Filter element using corrugated media sheet

A corrugated web having tapered flutes is usable in straight-through flow filter elements. The corrugated web can be made by passage between a pair of corrugated rollers having tapered teeth. Methods of making usable corrugated rollers include methods for generating the tapered teeth at the end points and the extension between the end points. Corrugated webs may be made from a variety of media, including certain media that stretches in the machine direction. Methods of forming the corrugated web into filter elements (e.g., air filter elements) includes forming filter media by securing a flat sheet to the corrugated web. The filter media may then be wound into a filter element, including application of sealant during the winding process to close selected flutes.

Owner:DONALDSON CO INC

Media, filter element using corrugated media sheet, corrugated sheet, and methods

A corrugated web having tapered flutes is usable in straight-through flow filter elements. The corrugated web can be made by passage between a pair of corrugated rollers having tapered teeth. Methods of making usable corrugated rollers include methods for generating the tapered teeth at the end points and the extension between the end points. Corrugated webs may be made from a variety of media, including certain media that stretches in the machine direction. Methods of forming the corrugated web into filter elements (e.g., air filter elements) includes forming filter media by securing a flat sheet to the corrugated web. The filter media may then be wound into a filter element, including application of sealant during the winding process to close selected flutes.

Owner:DONALDSON CO INC

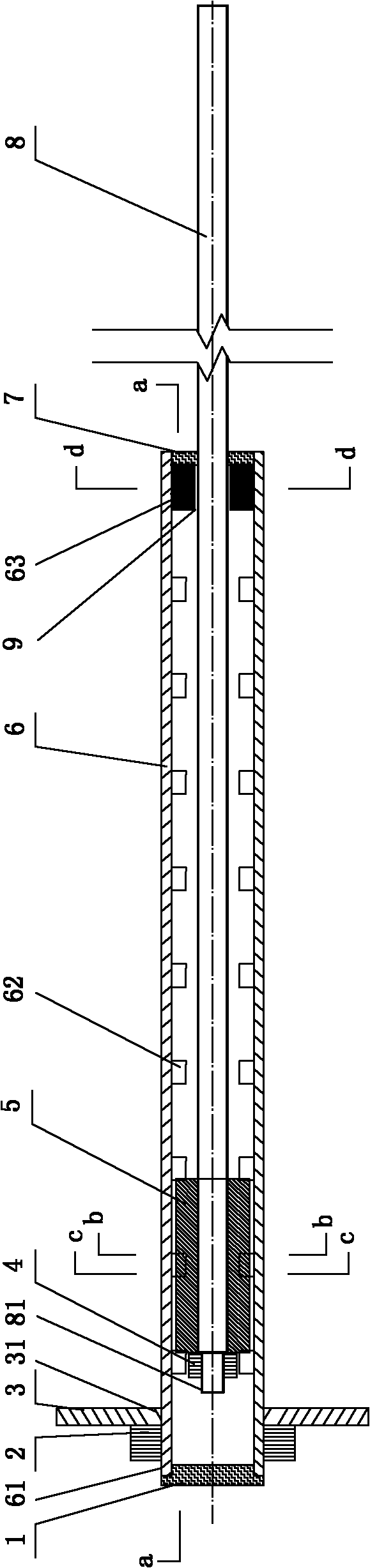

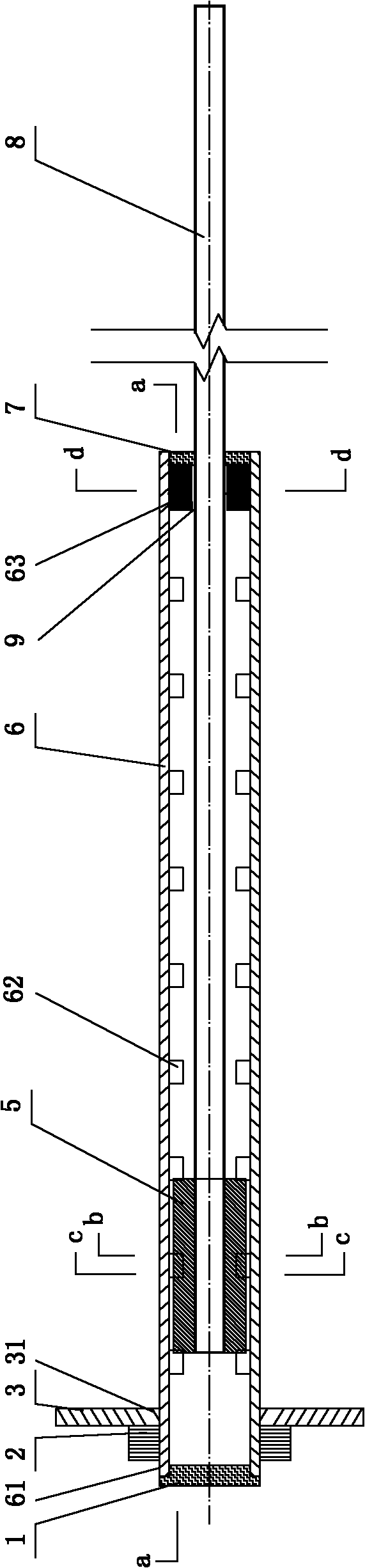

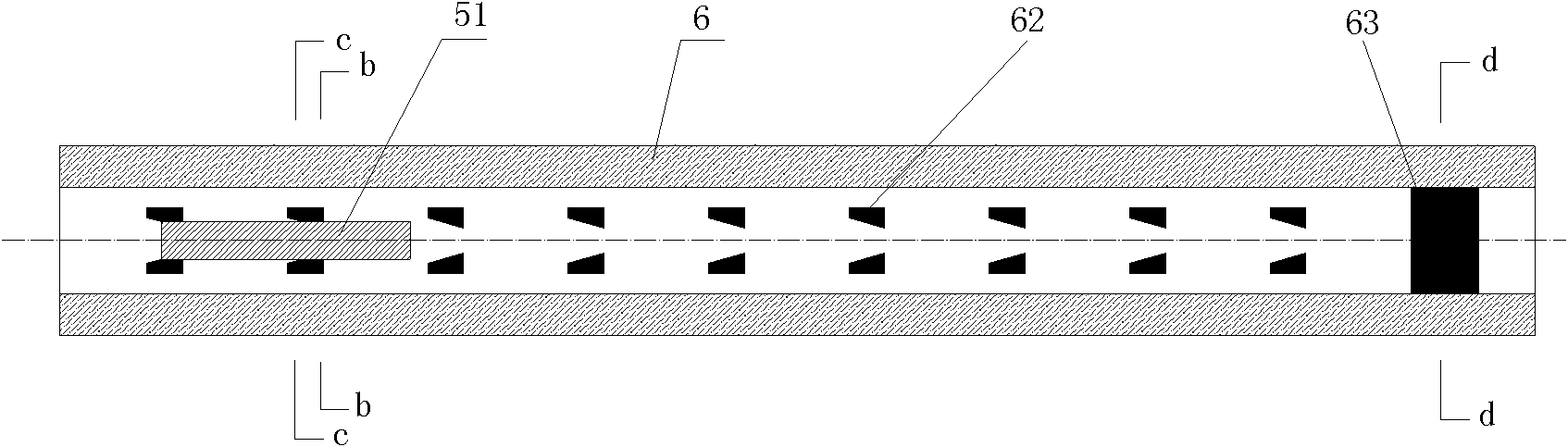

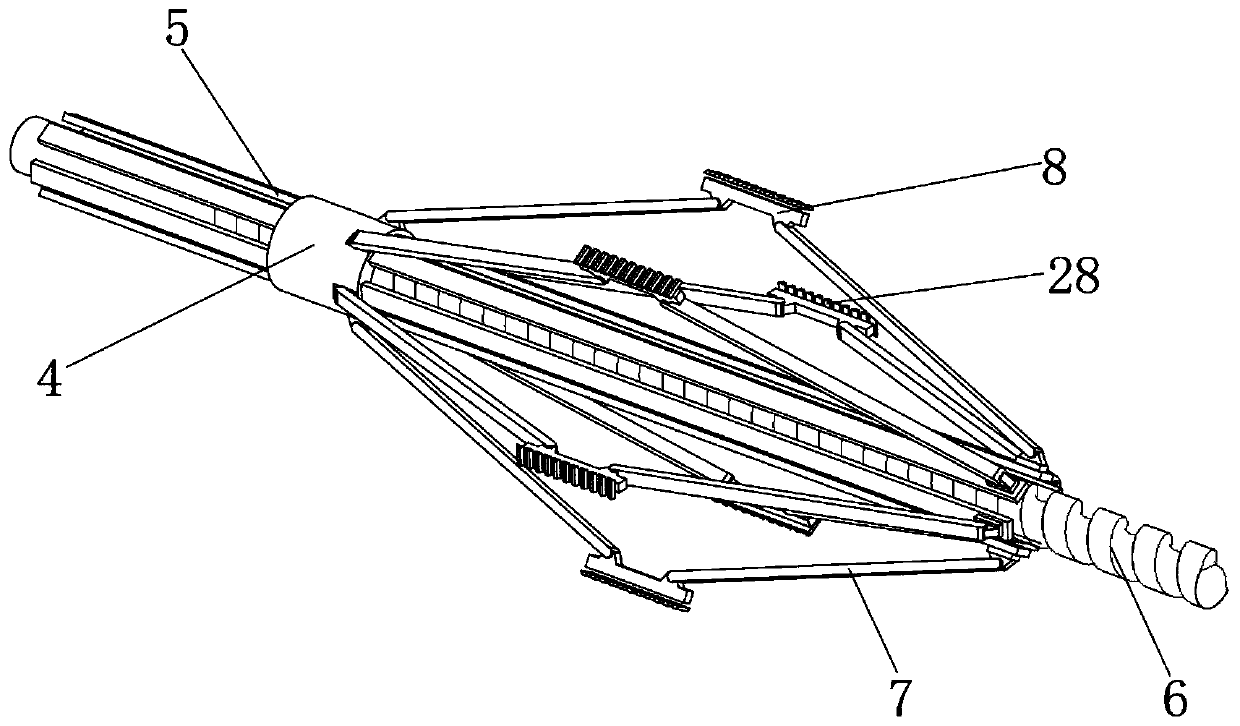

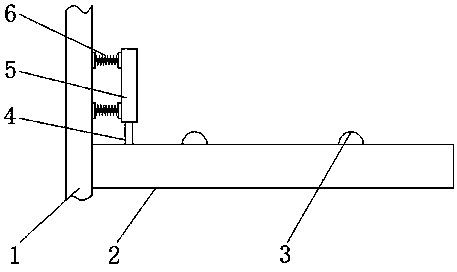

Cone resistive friction sleeve large-deformation anchor rod

The invention belongs to the field of geotechnical engineering anchoring, and relates to a supporting structure of a large-deformation rock-soil body, in particular relates to an anchor rod. The anchor rod comprises an external nut (2), a base plate (3), a cone-type-tooth friction body (5), a friction sleeve (6) and a rod body (8), and is characterized in that the inner wall of the friction sleeve (6) is provided with a plurality of sleeve friction grooves (62) along a longitudinal direction; and the cone-type-tooth friction body (5) is arranged on the rod body (8). The anchor rod provided bythe invention has the beneficial effects that large deformation of surrounding rock can be automatically adapted so as to automatically extend, and simultaneously the deformation energy of the surrounding rock can be absorbed in the deforming process, thus ensuring the supporting effects of the supporting structure.

Owner:UNIV OF SCI & TECH BEIJING

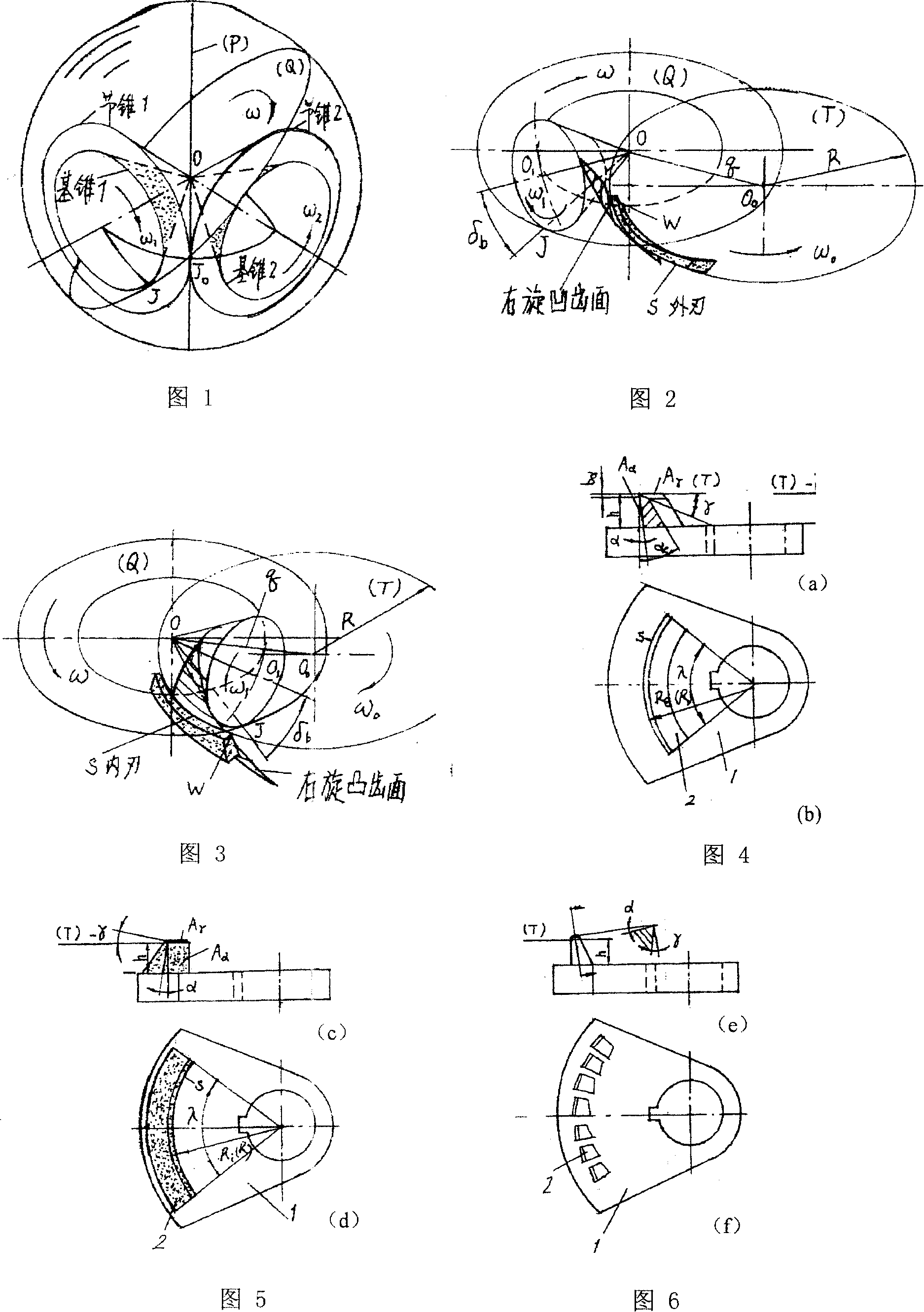

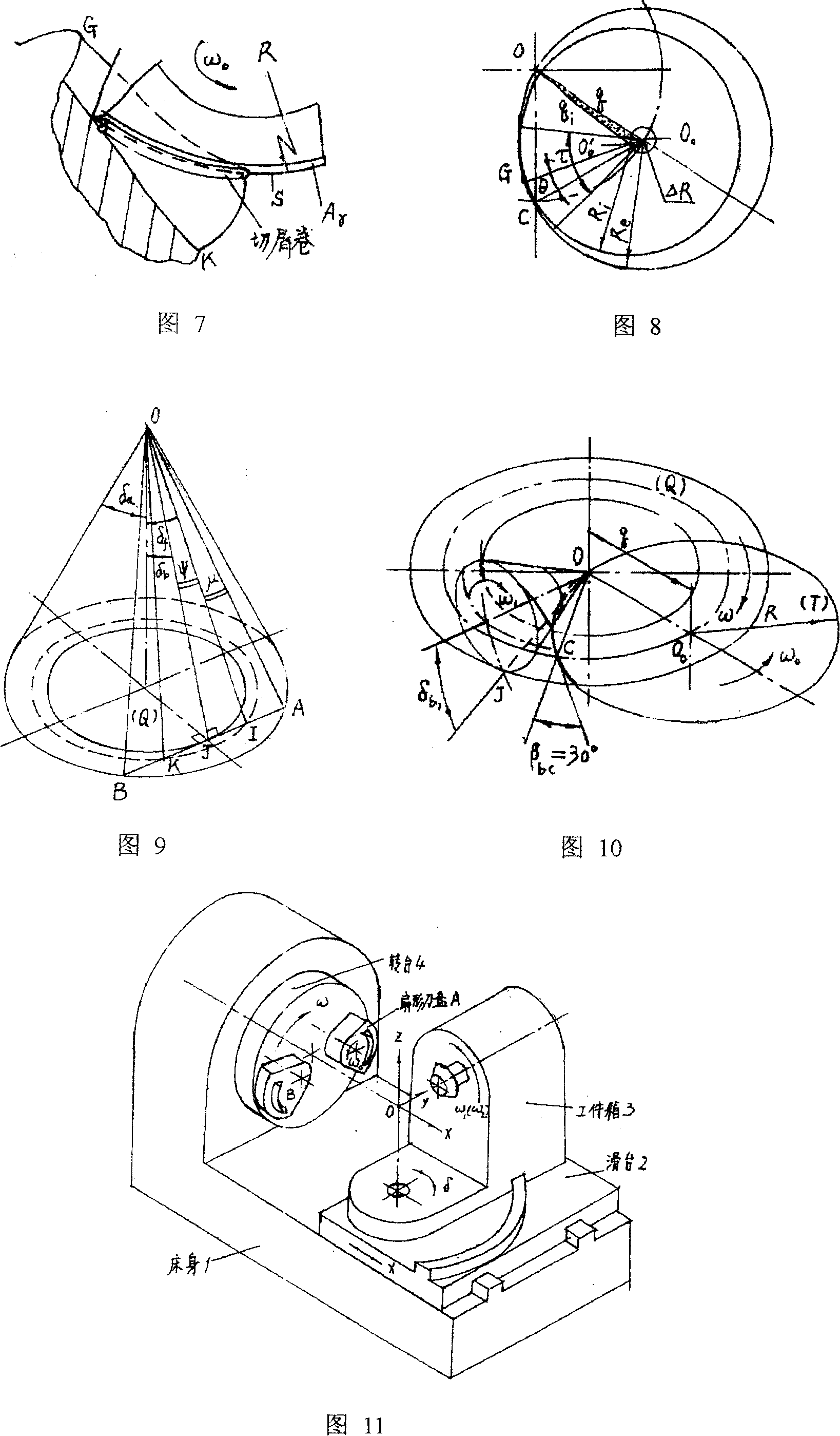

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

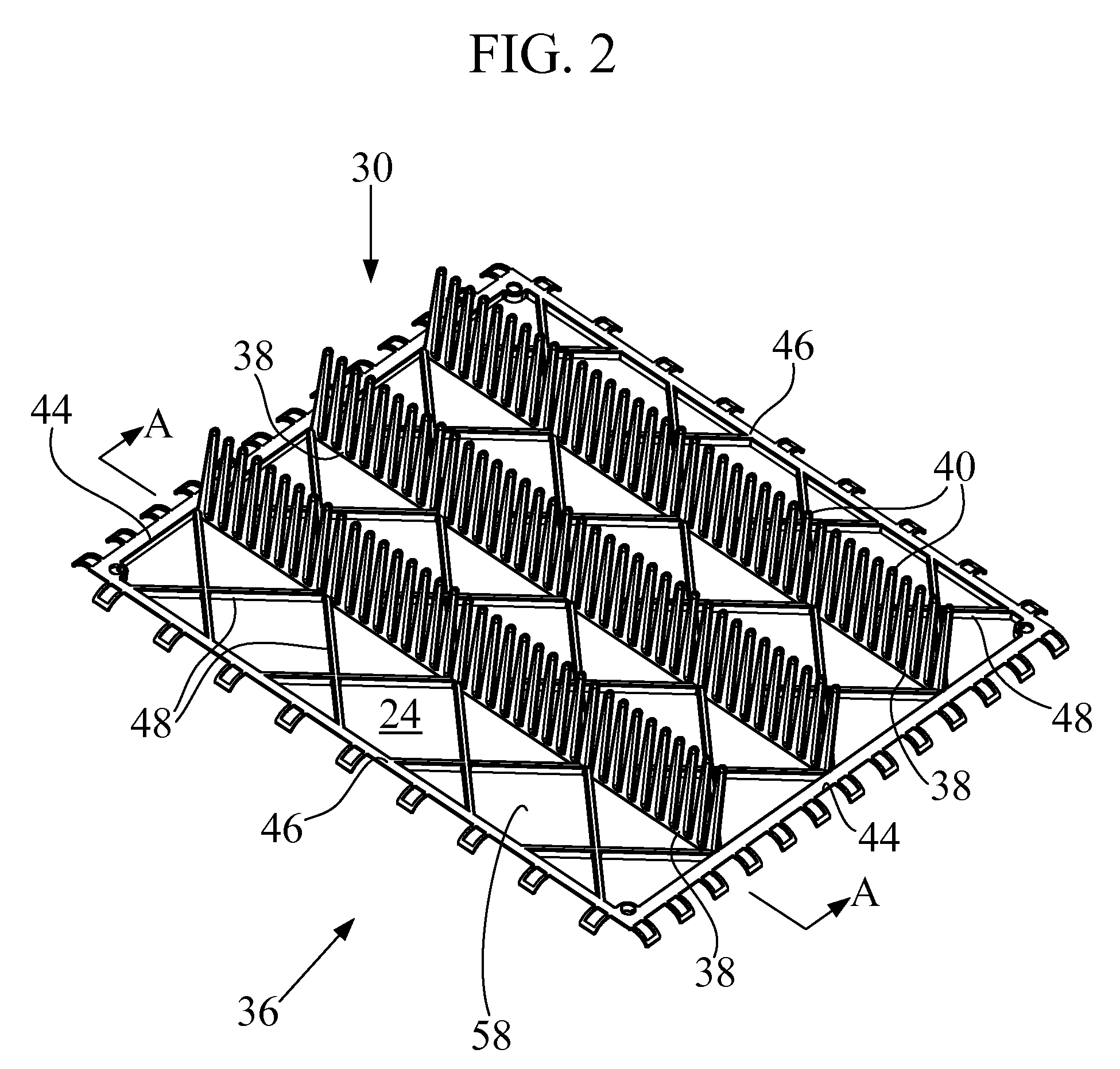

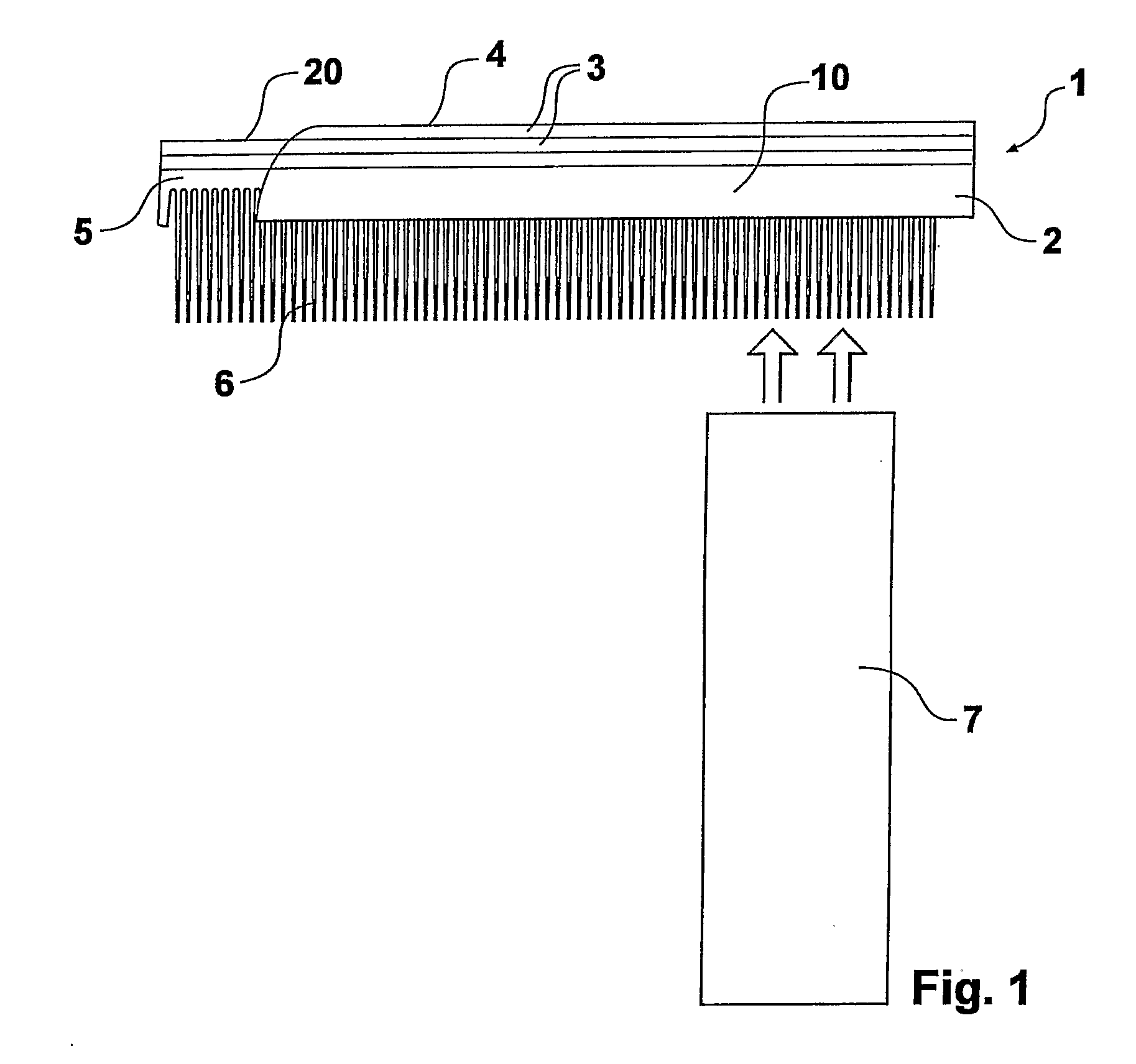

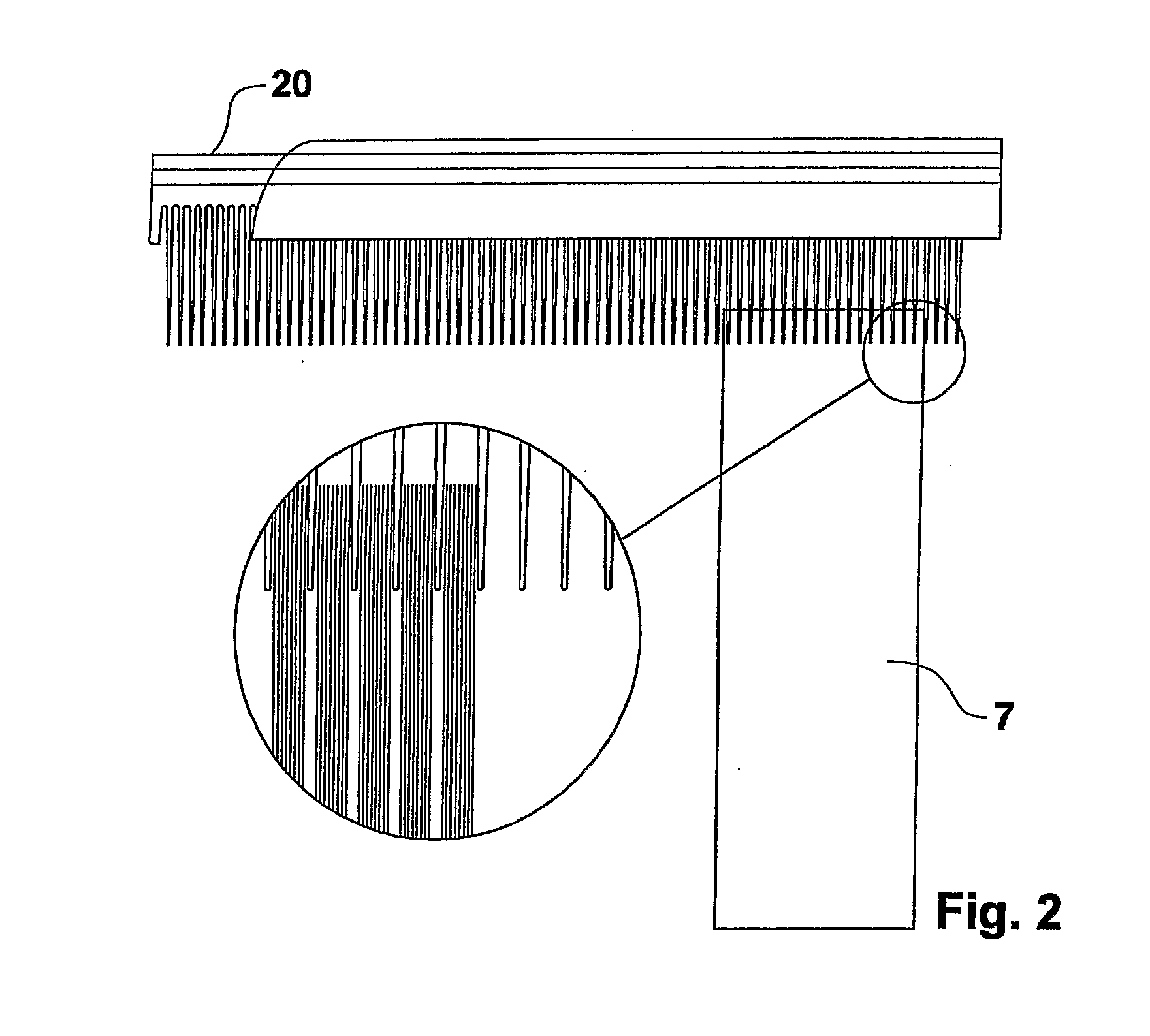

Filter element with pleat support combs

ActiveUS20100236204A1Add supportIncrease capacityDispersed particle filtrationUsing liquid separation agentFilter mediaTapered teeth

A filter element includes support grid secured about its periphery edges to a periphery frame member. A pleated filter media is secured to the frame member and is sized and positioned to fully cover the filter fluid aperture. The support grid is positioned such that it is effective in providing support to the filter media against fluid forces. At least one elongated comb member is provided and includes a plurality of spaced tapered teeth protruding outwards towards the filter media. The teeth are sized and spaced to be received into at least a portion of grooves present between the pleats of the filter media. The teeth of the comb member are sized and spaced to regulate filter media pleat separation and spacing.

Owner:MANN HUMMEL GMBH

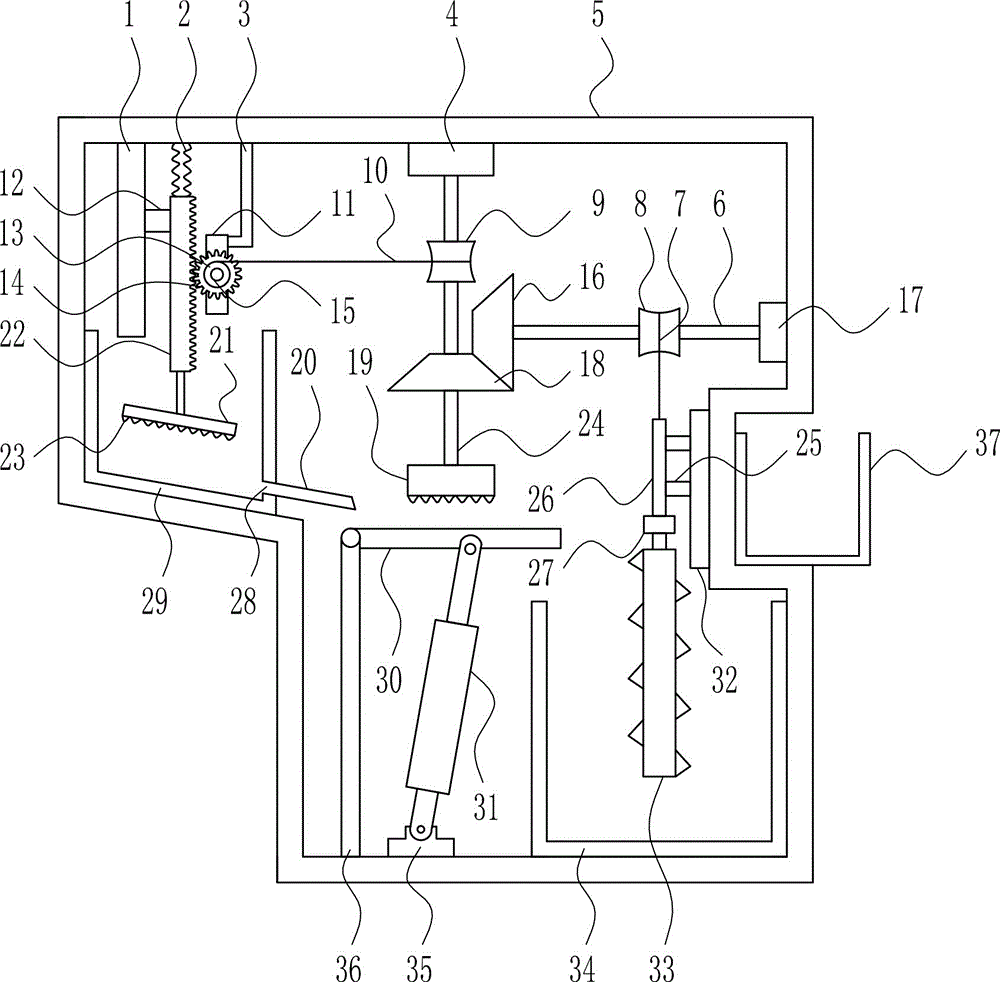

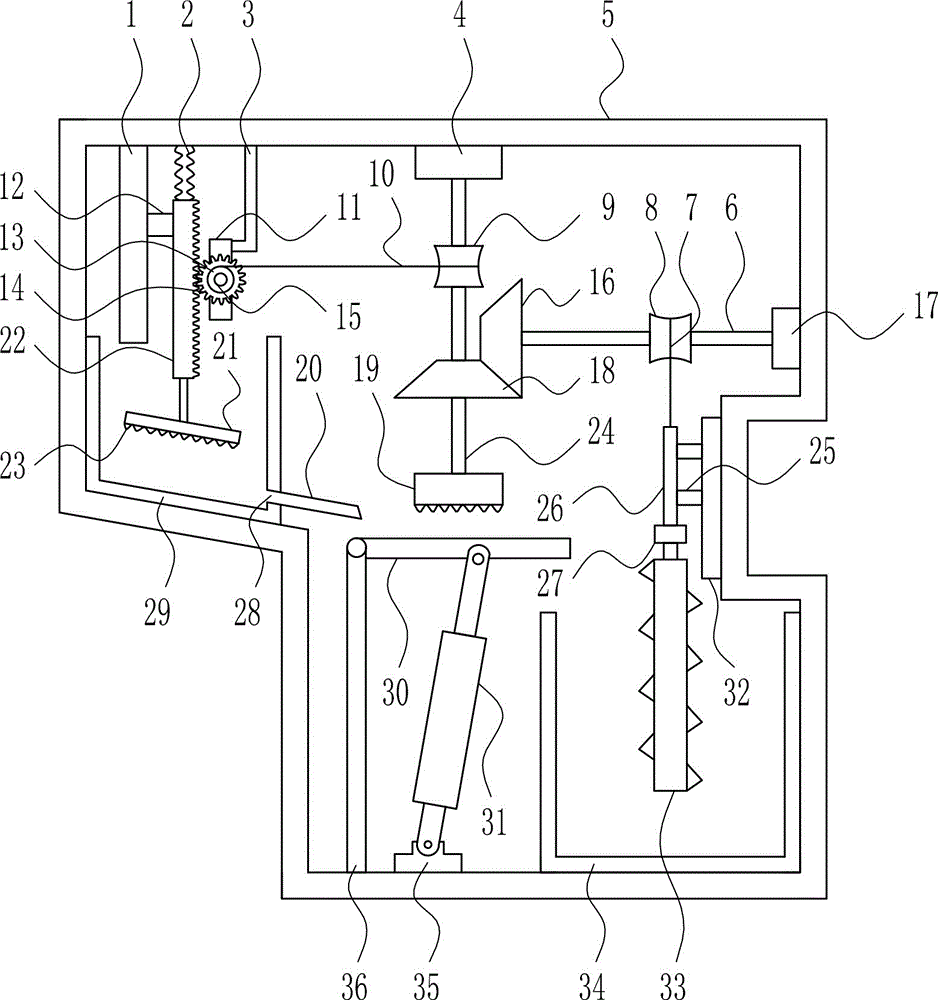

Part clamping device for automobile production

The invention belongs to the technical field of automobile production, and particularly relates to a part clamping device for automobile production. According to the problems that most traditional automobile part clamping devices have relatively simple structures, and the clamping effect for tubular parts is relatively general, the following scheme is put forward, the part clamping device comprises a base with four bottom corners being welded with supporting legs and a fixing plate vertically welded to one end of the top of the base, a fixing bracket is welded to one side of the fixing plate,and a circular plate is welded to the other end of the fixing bracket. A rotary table is arranged on the outer wall of the circumference of the circular plate, and a driving mechanism is installed onthe side, opposite to the fixing bracket, of the rotary table. According to the part clamping device for the automobile production, by arranging an external-pressure fixing mechanism, a driving gear can be driven by a servo motor to rotate, a screw rod is driven to rotate at the same time through the sequence rotation among a first inner gear ring, a second inner gear ring, a driven gear and tapered teeth, so that a thread barrel moves along the screw rod, and the tubular parts are further fixed and processed through clamping legs matching with an arc groove.

Owner:王晶晶

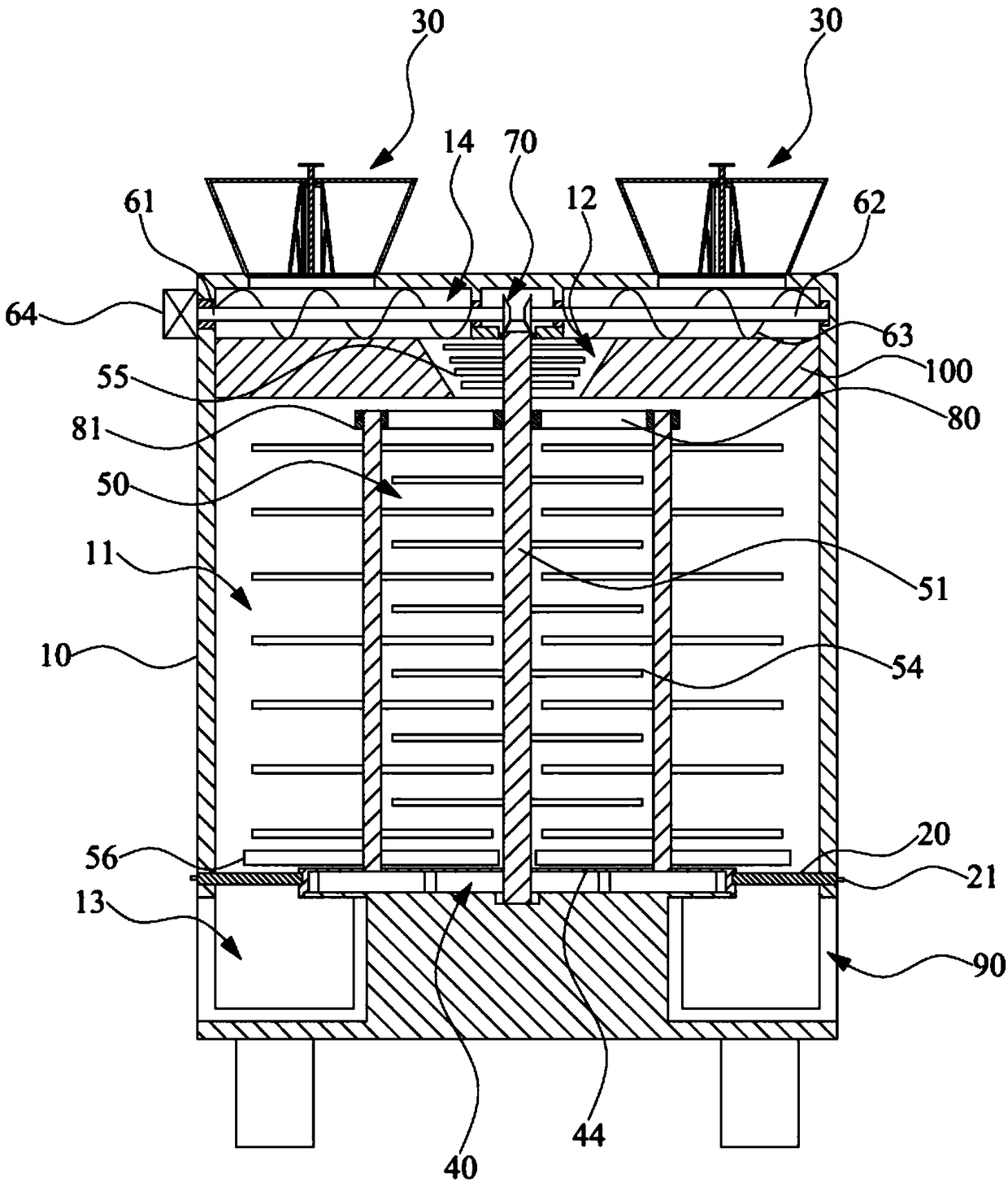

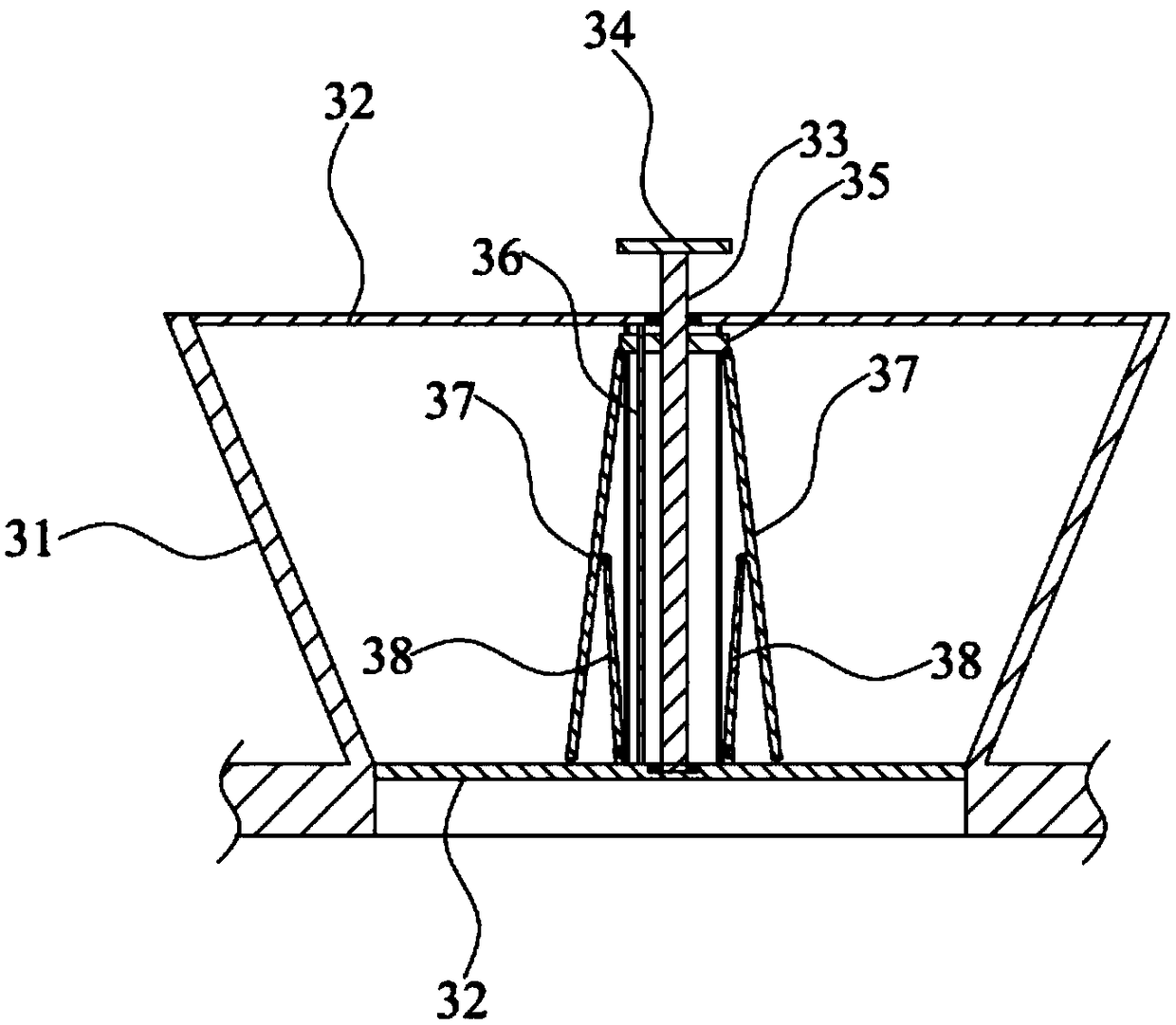

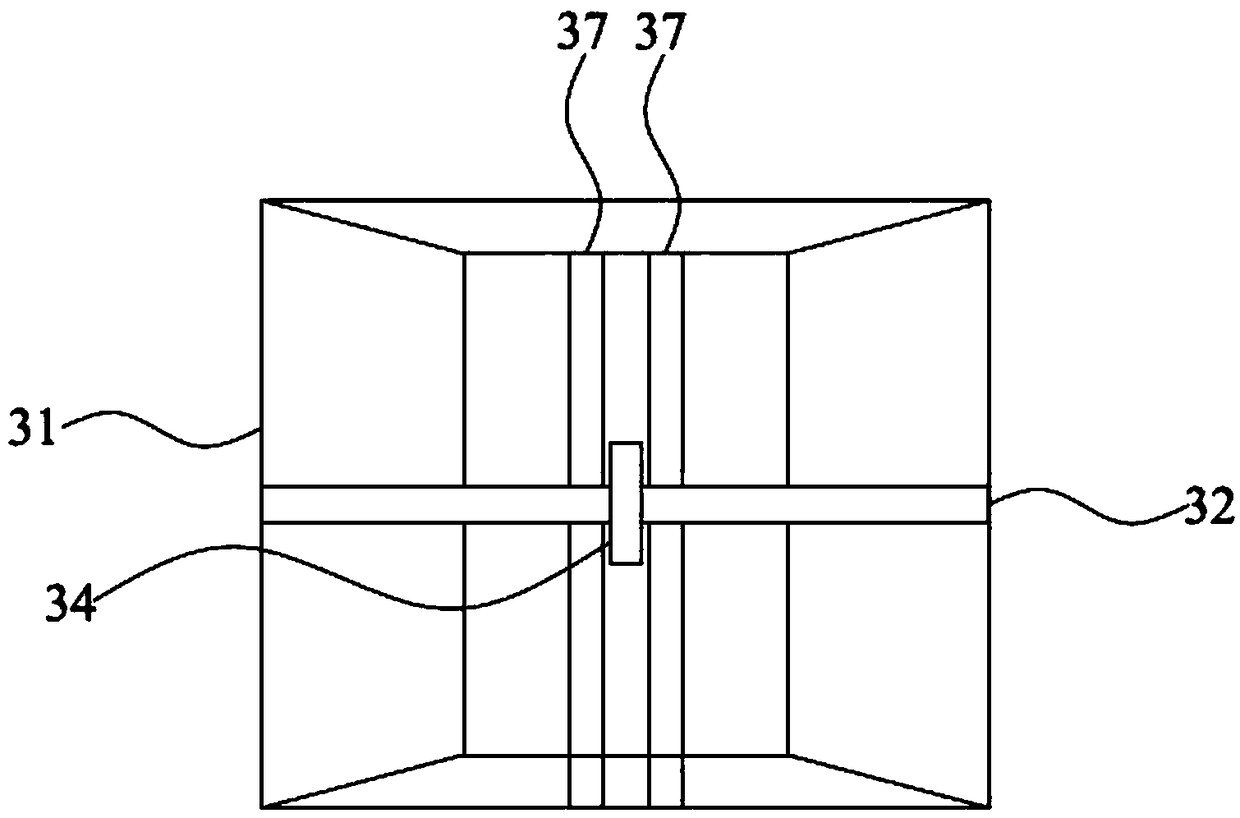

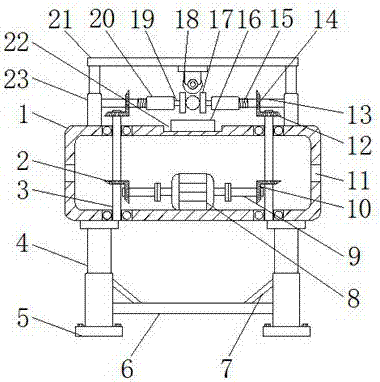

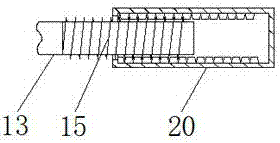

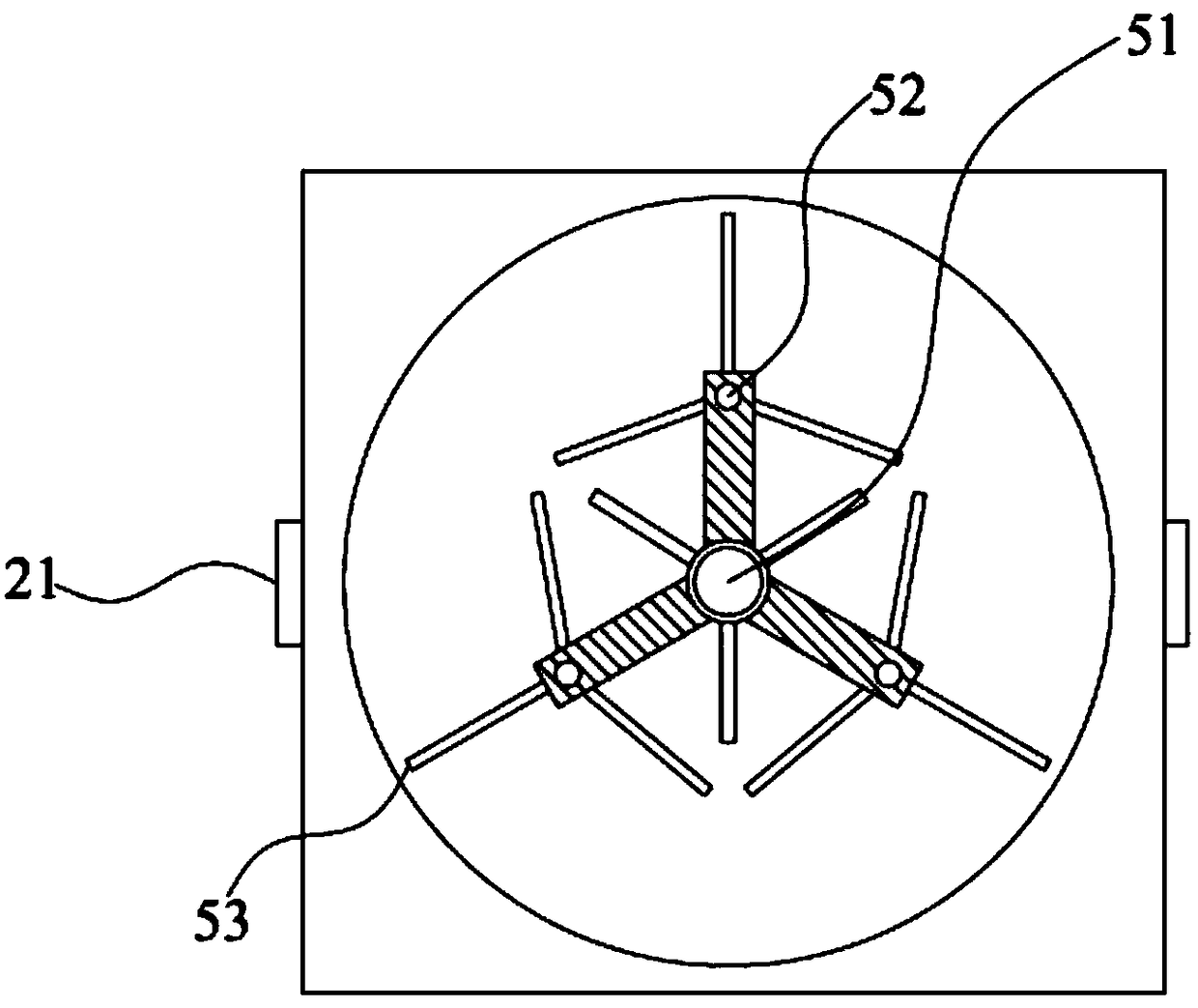

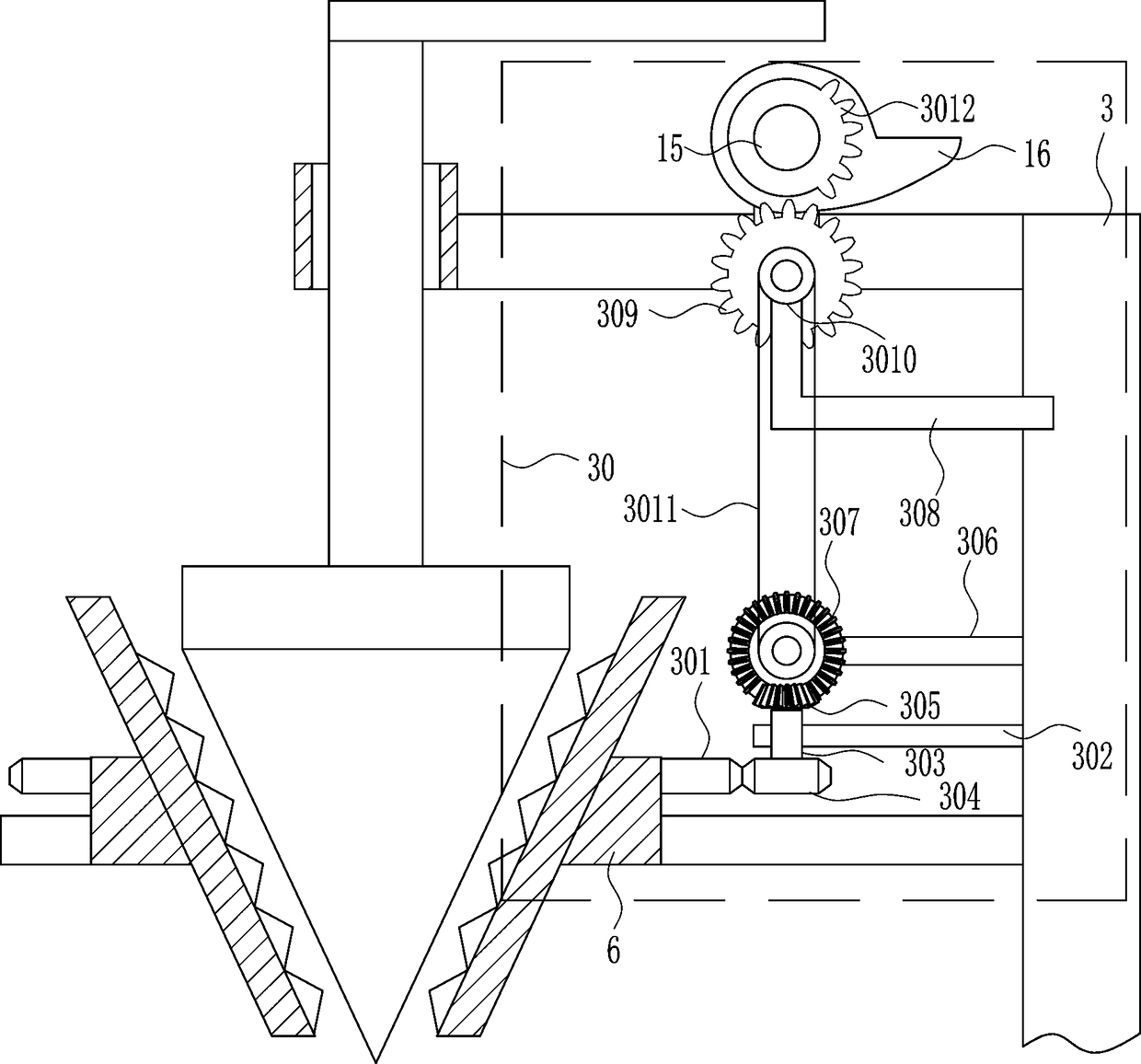

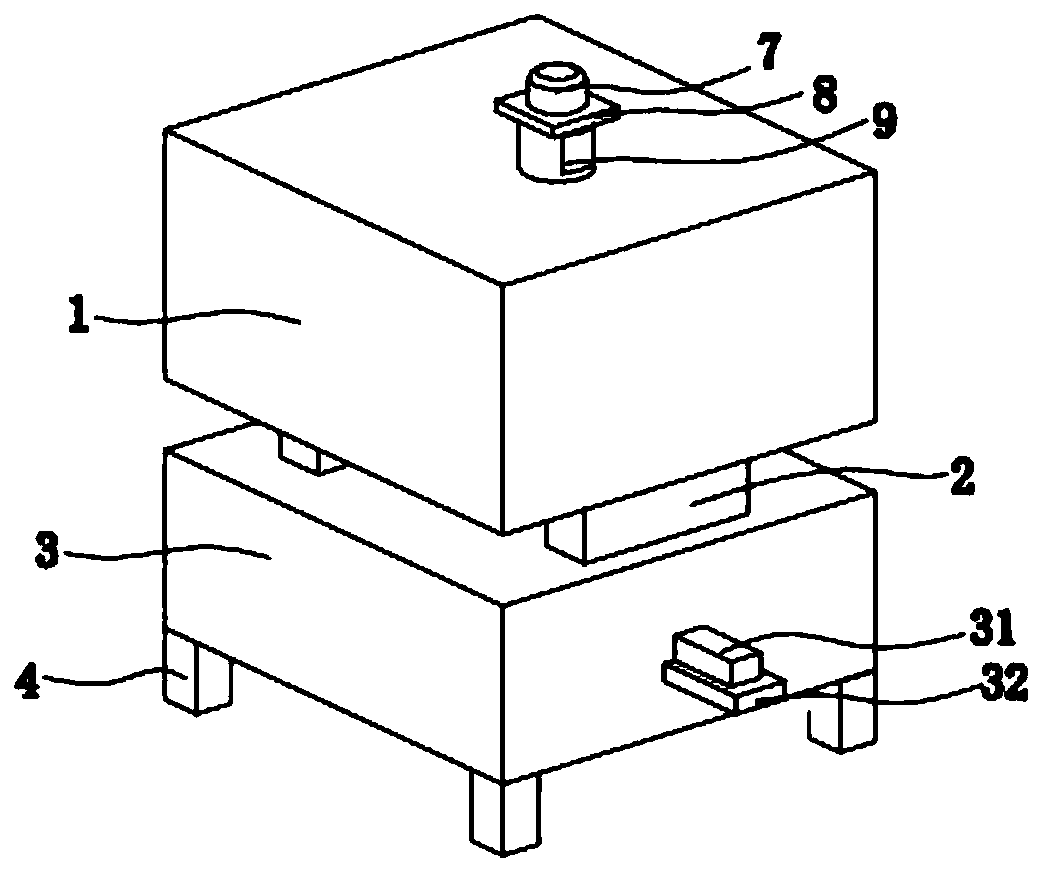

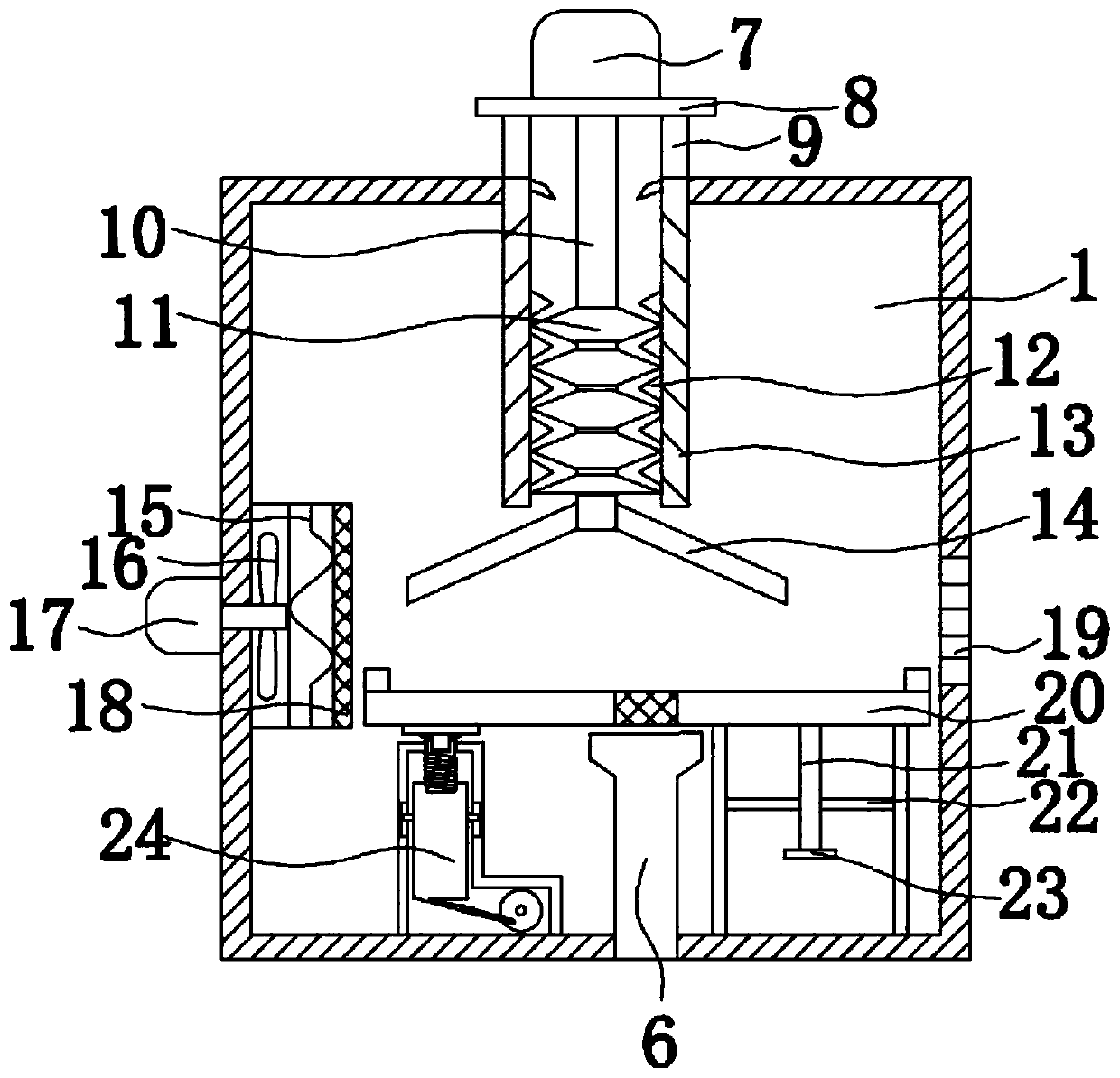

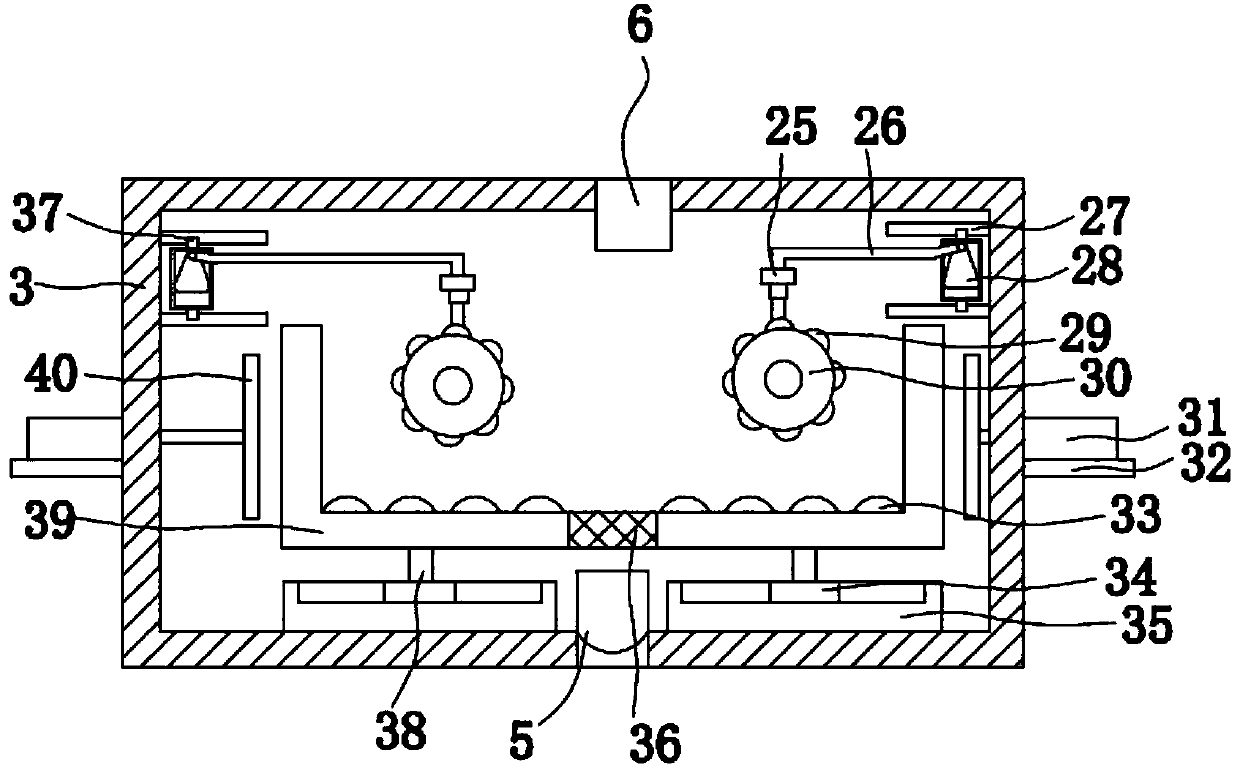

Energy-saving graphene blending stirrer

InactiveCN108355565AAchieving stirringStir wellRotary stirring mixersTransportation and packagingHelical bladeSlurry

The invention discloses an energy-saving graphene blending stirrer. The energy-saving graphene blending stirrer comprises a shell body, two feeding assemblies, a planetary gear assembly, a stirring assembly, a left rotary shaft and a right rotary shaft, spiral blades and a motor, wherein the shell body is provided with a main stirring cavity, an auxiliary stirring cavity, a discharging cavity anda feeding cavity; the two feeding assemblies are arranged at left and right sides of the feeding cavity; the planetary gear assembly is mounted at the bottom of the main stirring cavity; the stirringassembly penetrates through the planetary gear assembly; a stirring main shaft of the stirring assembly penetrates through the auxiliary stirring cavity into the feeding cavity from the main stirringcavity; the left rotary shaft and the right rotary shaft are arranged in the feeding cavity and are located at two sides of the stirring main shaft respectively; the spiral blades are arranged on theleft rotary shaft and the right rotary shaft; the motor is mounted on the shell body and is used for driving the left rotary shaft; the left rotary shaft and the right rotary shaft are engaged with the stirring main shaft through tapered teeth. According to the energy-saving graphene blending stirrer disclosed by the invention, the rotary shafts are driven through the motor and graphene slurry isspirally conveyed into the stirring cavities; meanwhile, the rotary shafts drive the main shaft and further drive the stirring assembly through the planetary gear assembly, so that the graphene slurryis stirred; finally, the graphene slurry is discharged from the discharging cavity; the energy-saving graphene blending stirrer has the advantages of energy saving and convenience, and uniformity instirring.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

Efficient washing equipment for reaction kettle

InactiveCN107617612AIncrease the areaSolve problems that require flushing of different locationsHollow article cleaningEngineeringHigh pressure water

The invention discloses efficient washing equipment for a reaction kettle. The efficient washing equipment comprises a reaction kettle body. One side of the side surface of the reaction kettle body isfixedly connected with the bottom of a positive and negative rotating motor through a loading plate. The output end of the positive and negative rotating motor is fixedly connected with the bottom ofa first bevel gear. One side of the top of the reaction kettle body is fixedly connected with the bottom of a fixing block. A rotating rod is inserted in the fixing block in a penetrating mode. According to the efficient washing equipment, by the improvement of the positive and negative rotating motor, the first bevel gear, a second bevel gear, a tapered tooth disc, a threaded lifting cylinder and a threaded rod are matched with one another, the first bevel gear and the second bevel gear are matched with each other to drive the tapered tooth disc, and meanwhile, a threaded rotating cylinder can ascend or descend the threaded lifting cylinder on the threaded rod, thus two wiping cloth can be driven to wash the inner wall of the reaction kettle body, the problem that a traditional high-pressure water pipe needs to flush the different positions can be solved, the area of washing of the inner wall of the reaction kettle body is increased, and the washing efficiency is improved.

Owner:江门市新会区崖门工业总公司

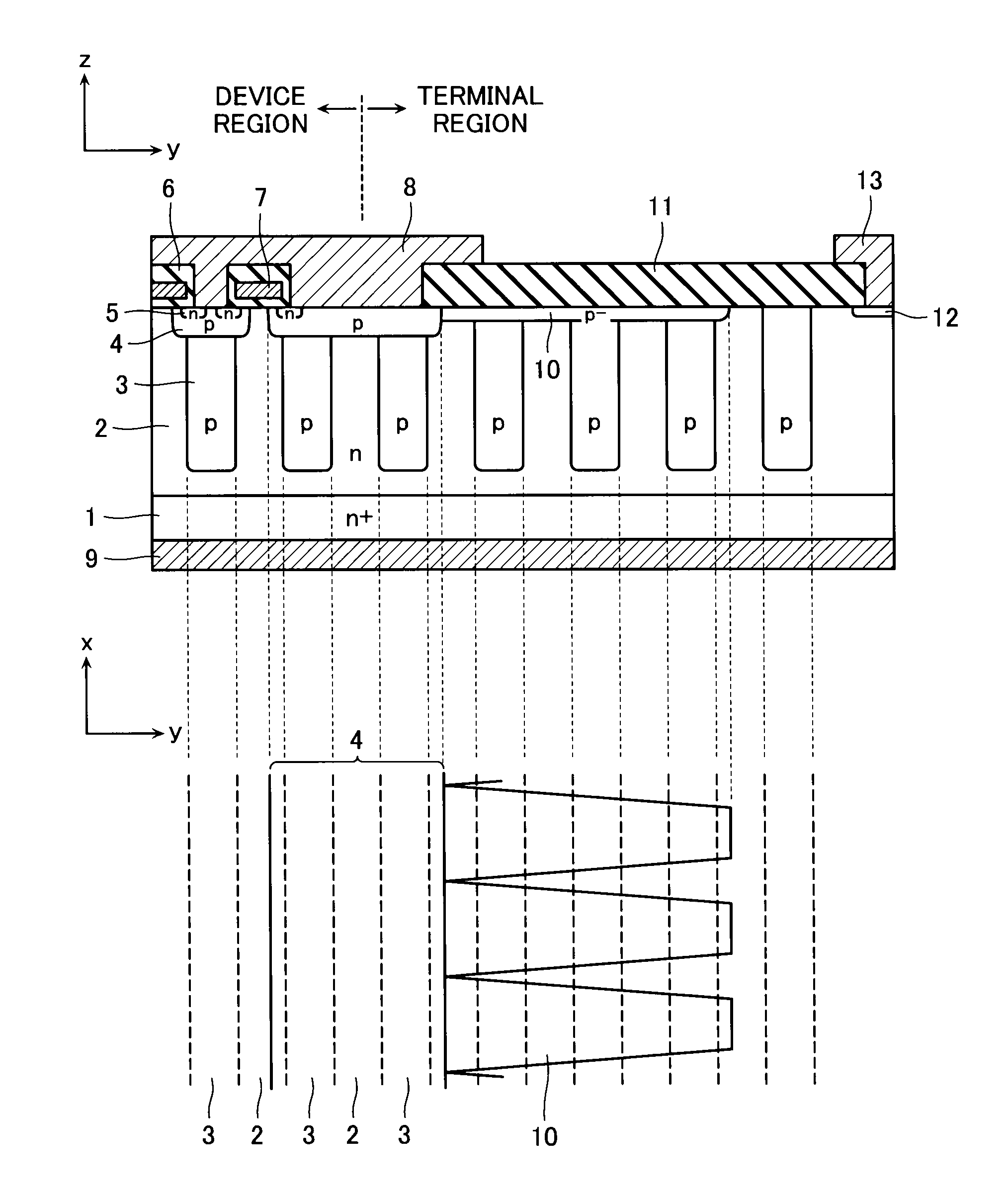

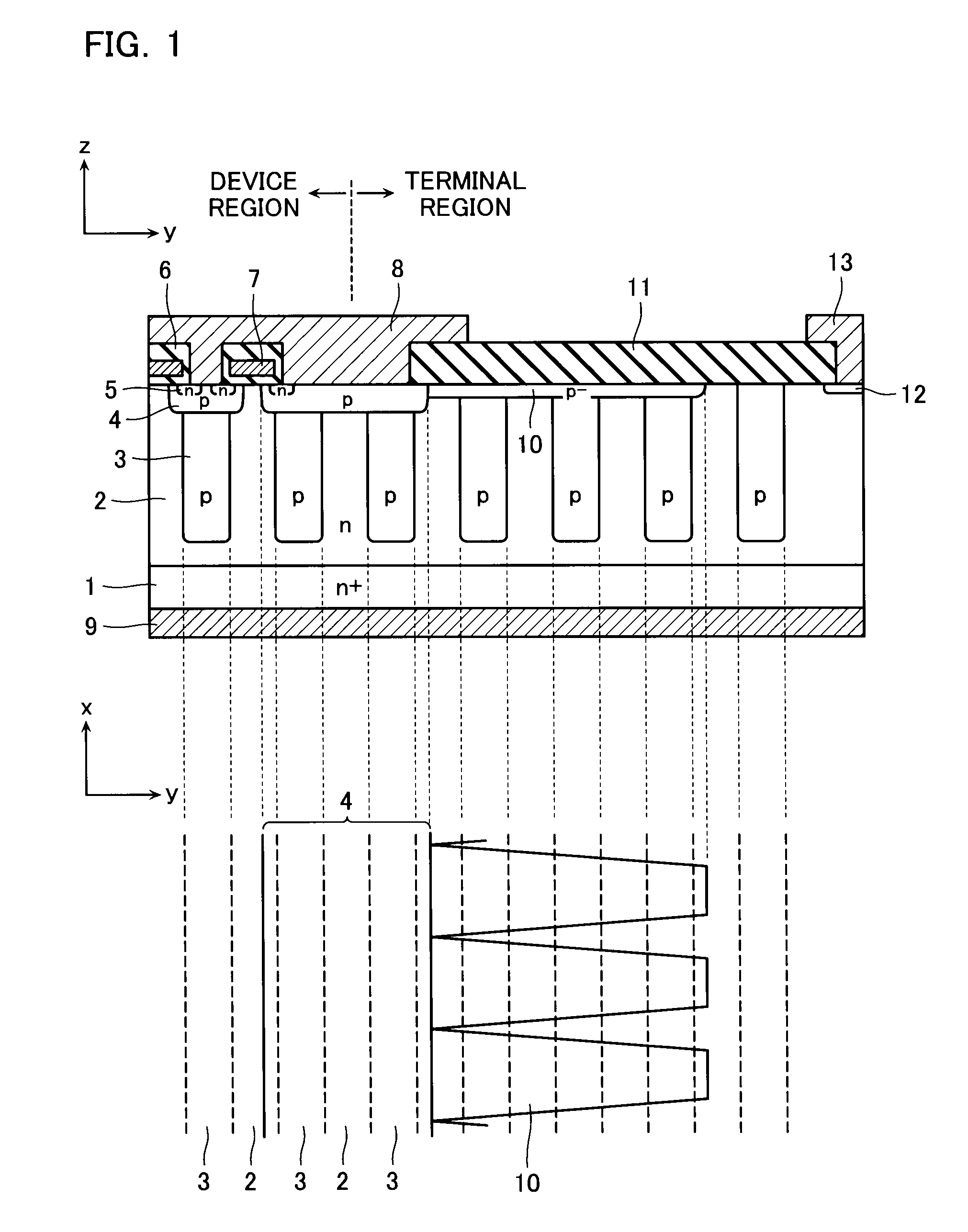

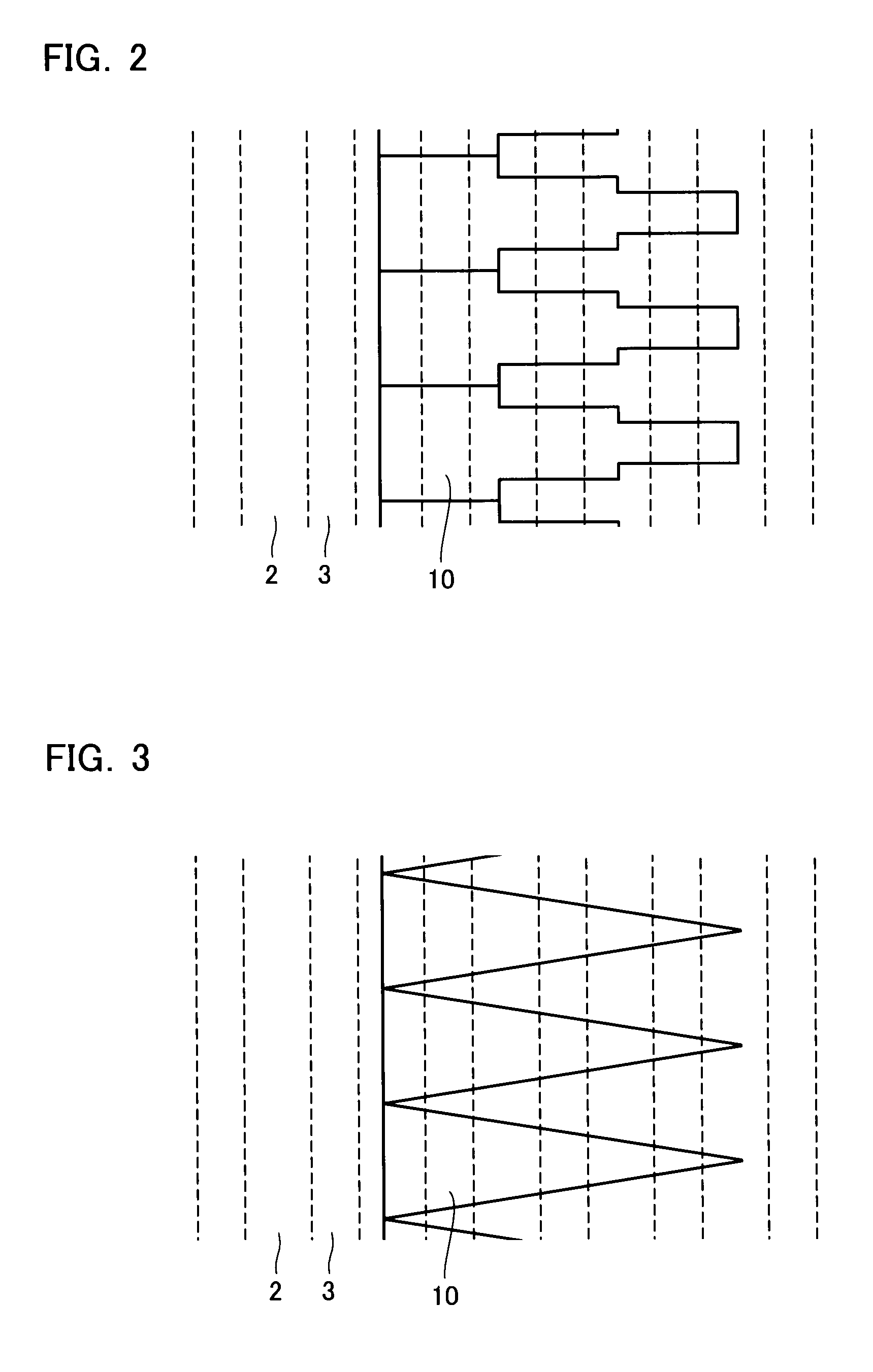

Semiconductor device including a resurf region with forward tapered teeth

ActiveUS7989910B2Semiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A semiconductor device includes an n+ type semiconductor substrate 1 and a super junction region that has, on the top of the substrate 1, an n and p type pillar regions 2 and 3 provided alternately. The device also includes, in the top surface of the super junction region, a p type base region 4 and an n type source layer 5. The device also includes a gate electrode 7 on the region 4 and layer 5 via a gate-insulating film 6, a drain electrode 9 on the bottom of the substrate 1, and a source electrode 8 on the top of the substrate 1. In the top surface of the super junction region in the terminal region, a RESURF region 10 is formed. The RESURF region has a comb-like planar shape with repeatedly-formed teeth having tips facing the end portion of the terminal region.

Owner:KK TOSHIBA

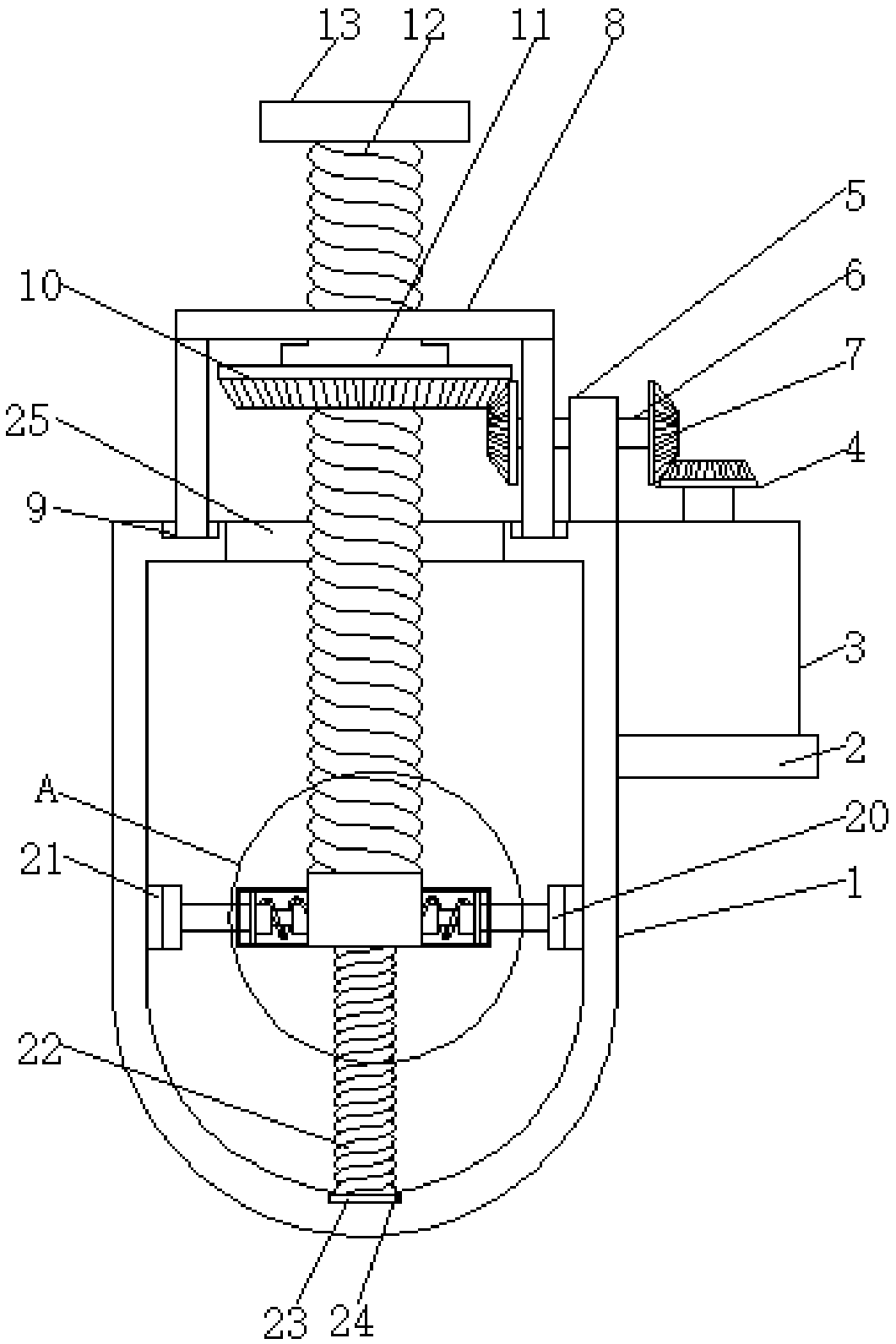

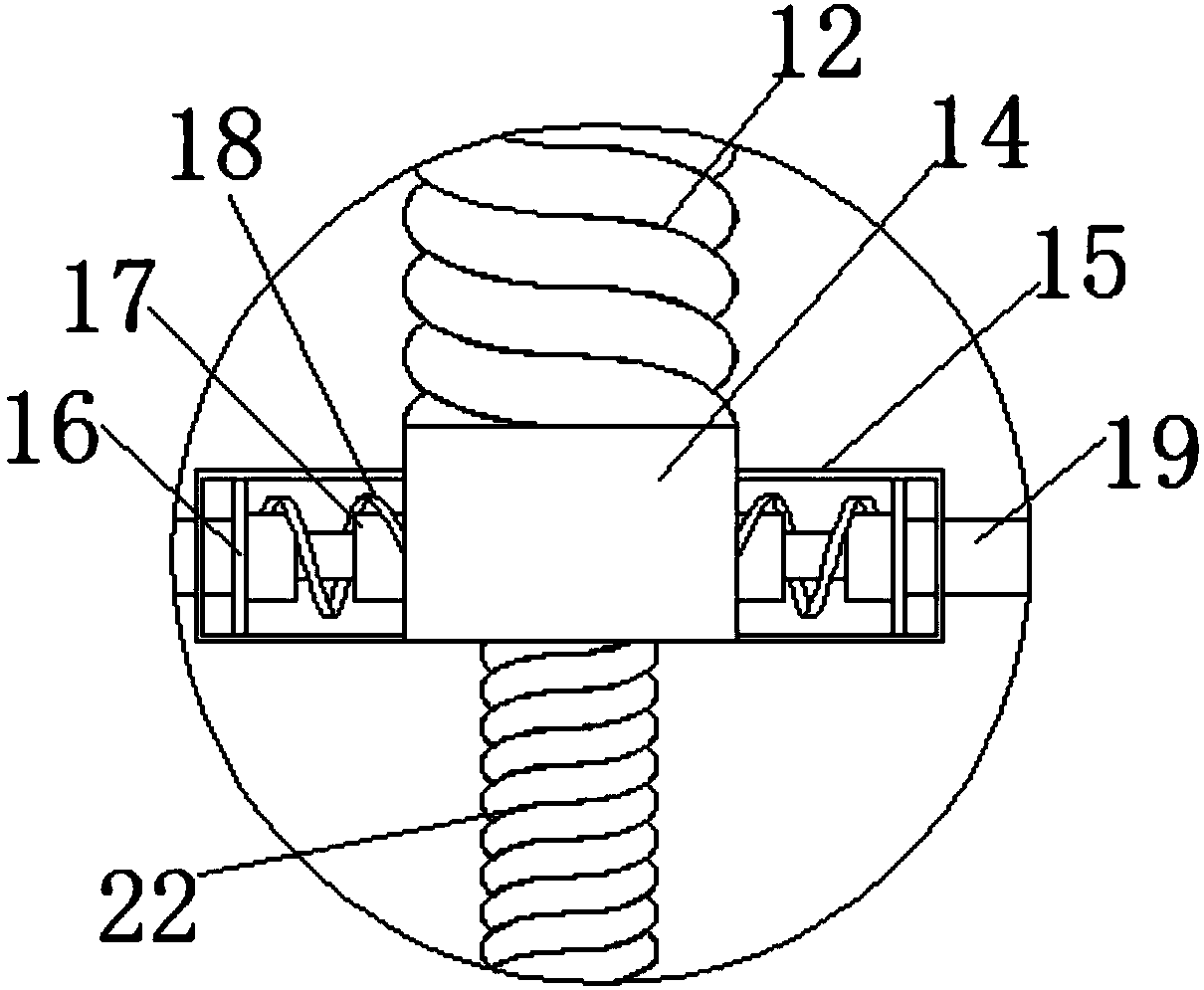

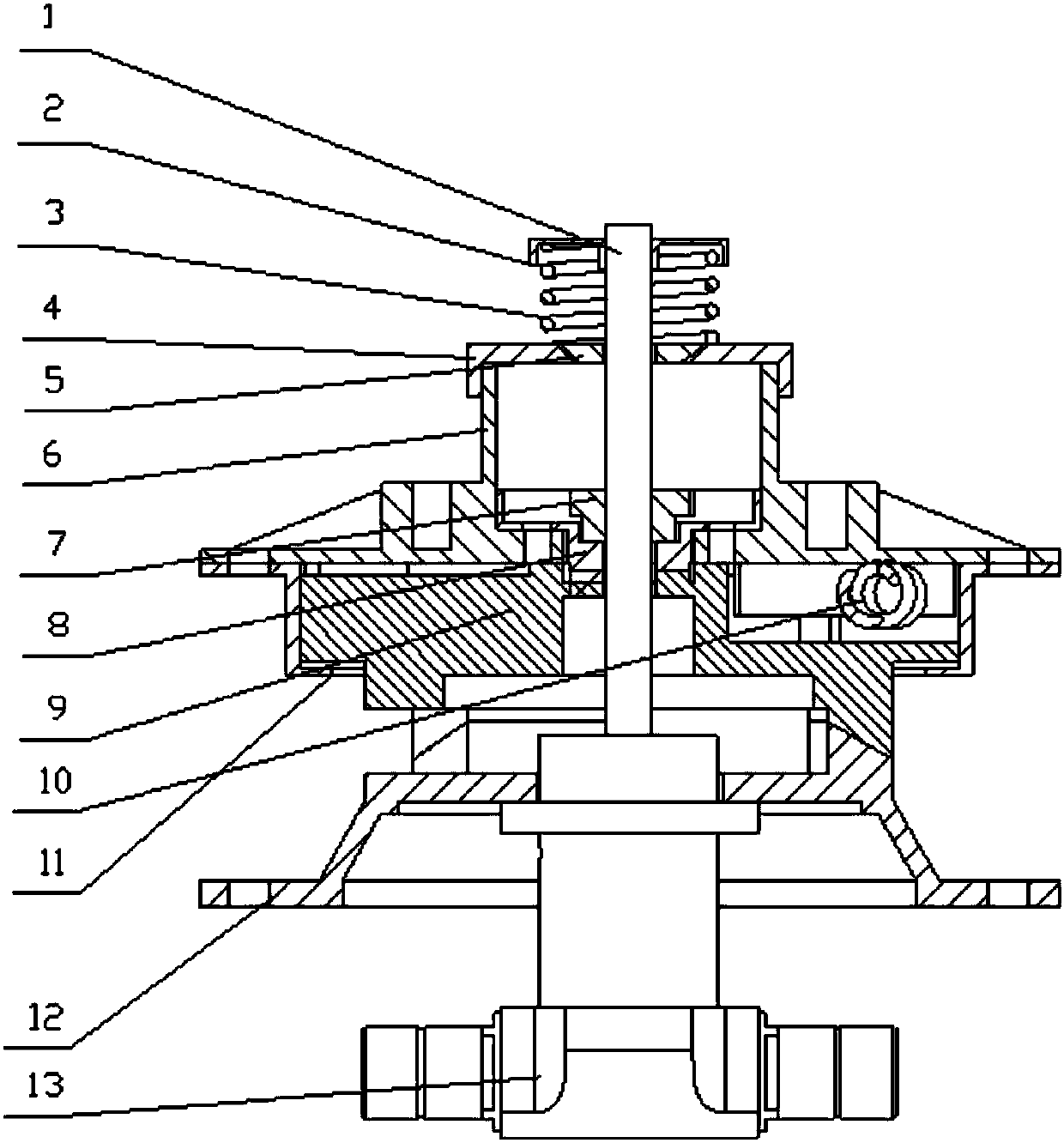

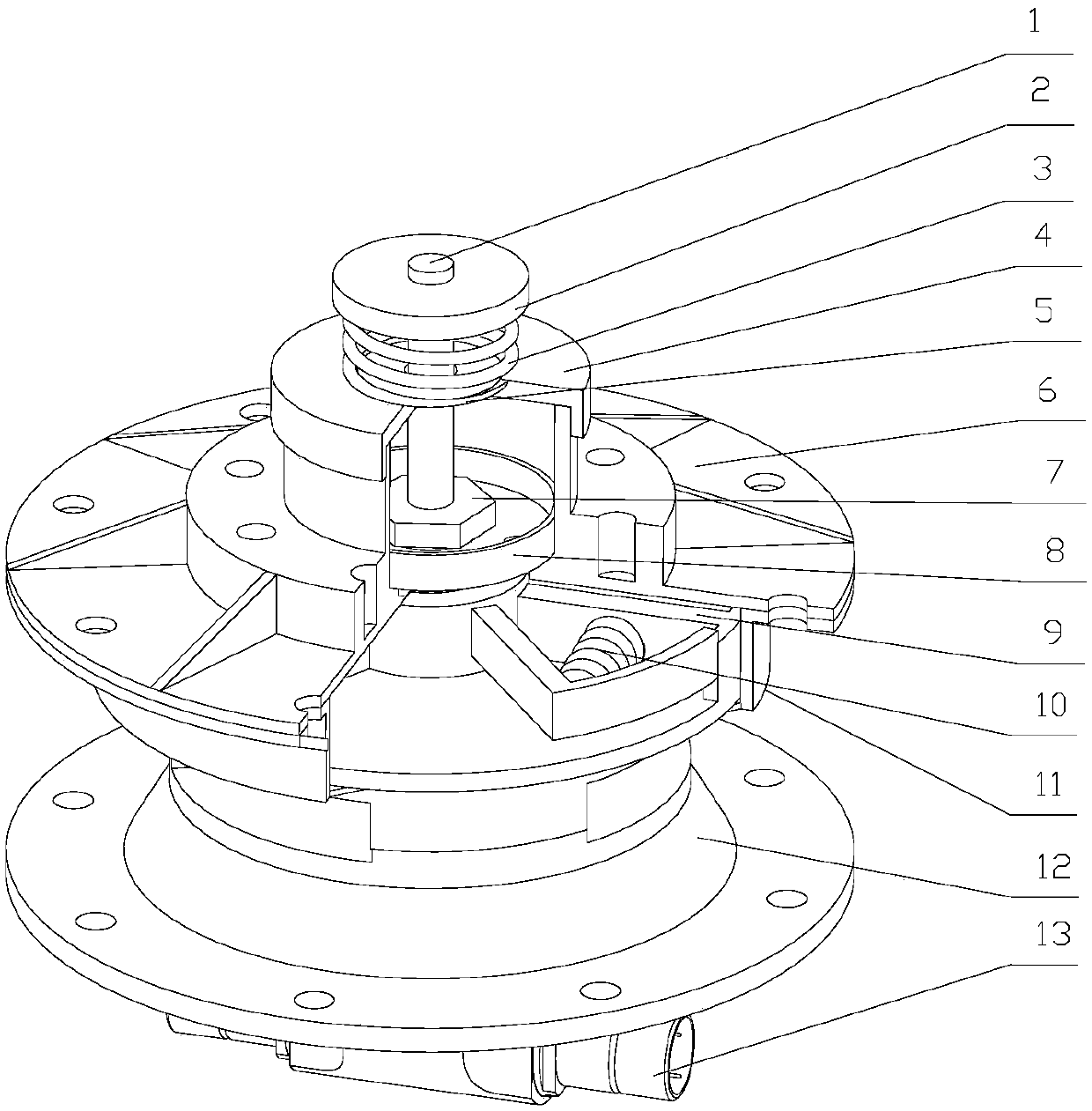

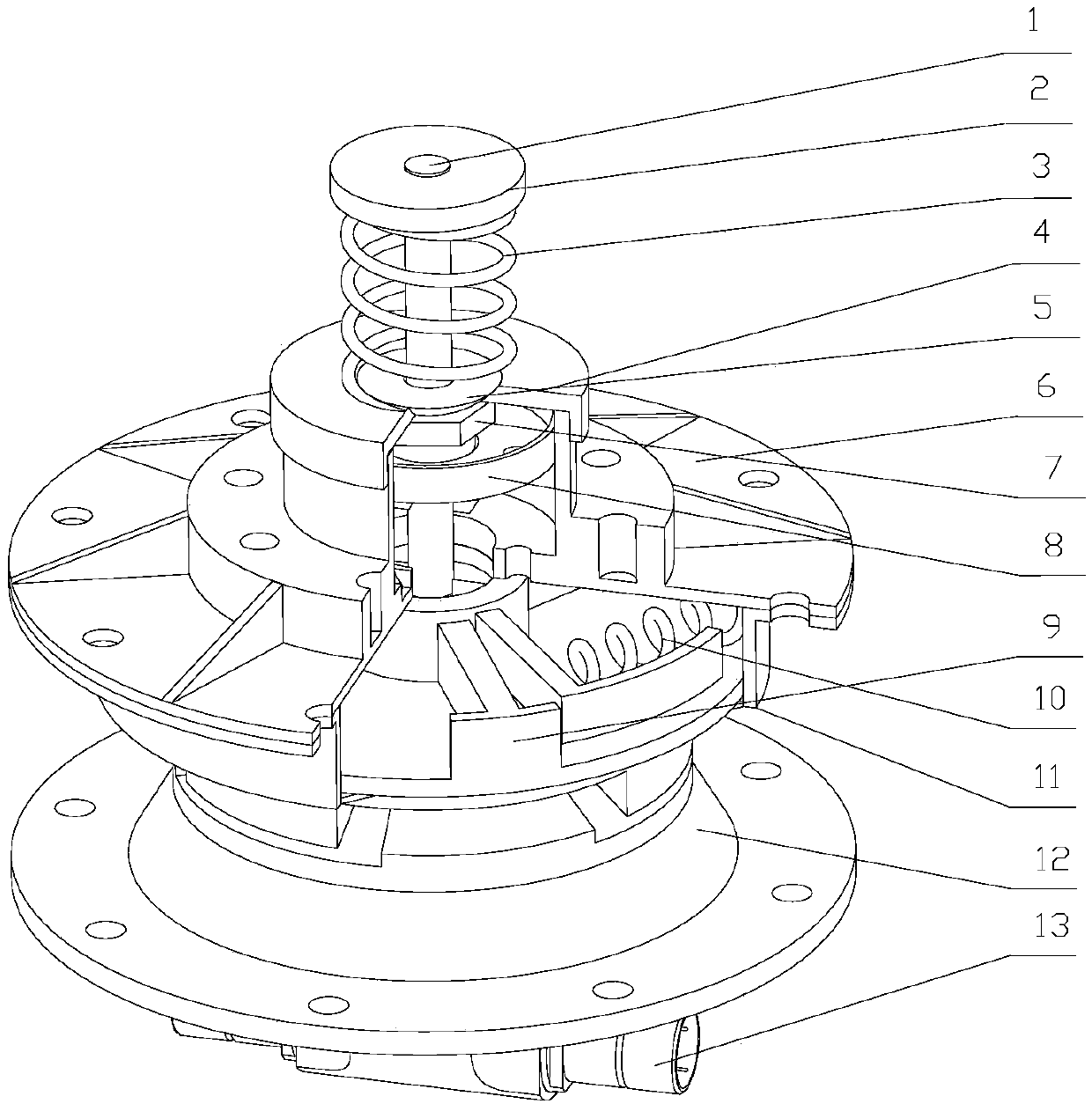

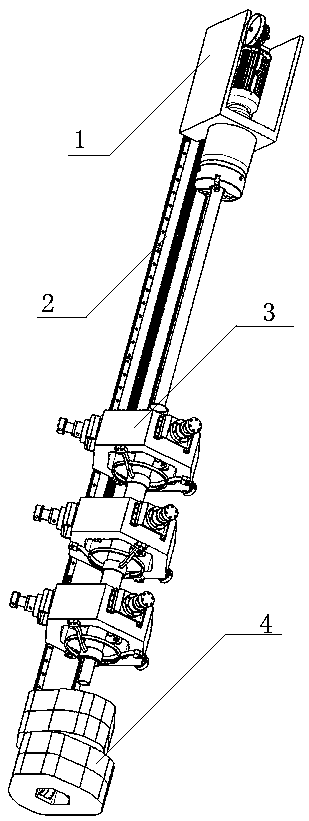

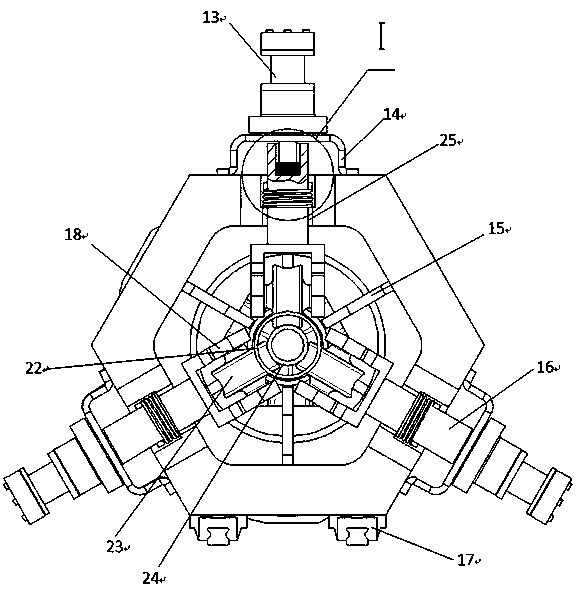

Rotary low-impact self-separation pressing and releasing device

ActiveCN107839906AAvoid damageImprove carrying capacityCosmonautic vehiclesCosmonautic component separationPetalEngineering

The invention discloses a rotary low-impact self-separation pressing and releasing device. The upper end of a compressing rod compresses a separation spring onto an upper end cover through a compressing cap, the compressing rod sequentially penetrates through the upper end cover, an upper base, a limiting block and a rotating lock petal, the lower end of the compressing rod is fixedly connected with a separation nut, and the separation nut is fixedly connected with a lower base; a compressing nut is fixed onto the compressing rod and used for limiting rotating motion of the locking petal through a limiting block; an unlocking spring is installed between a stop dog of the rotating lock petal and a stop dog of the upper base, when the device is locked, the separation spring and the unlockingspring are in a pre-compressed state, and tapered teeth at the bottom of the rotating lock petal is occlusive in an over against mode. By means of the rotary low-impact self-separation pressing and releasing device, connected objects at the two ends can be connected and separated and do not move relatively during separation.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

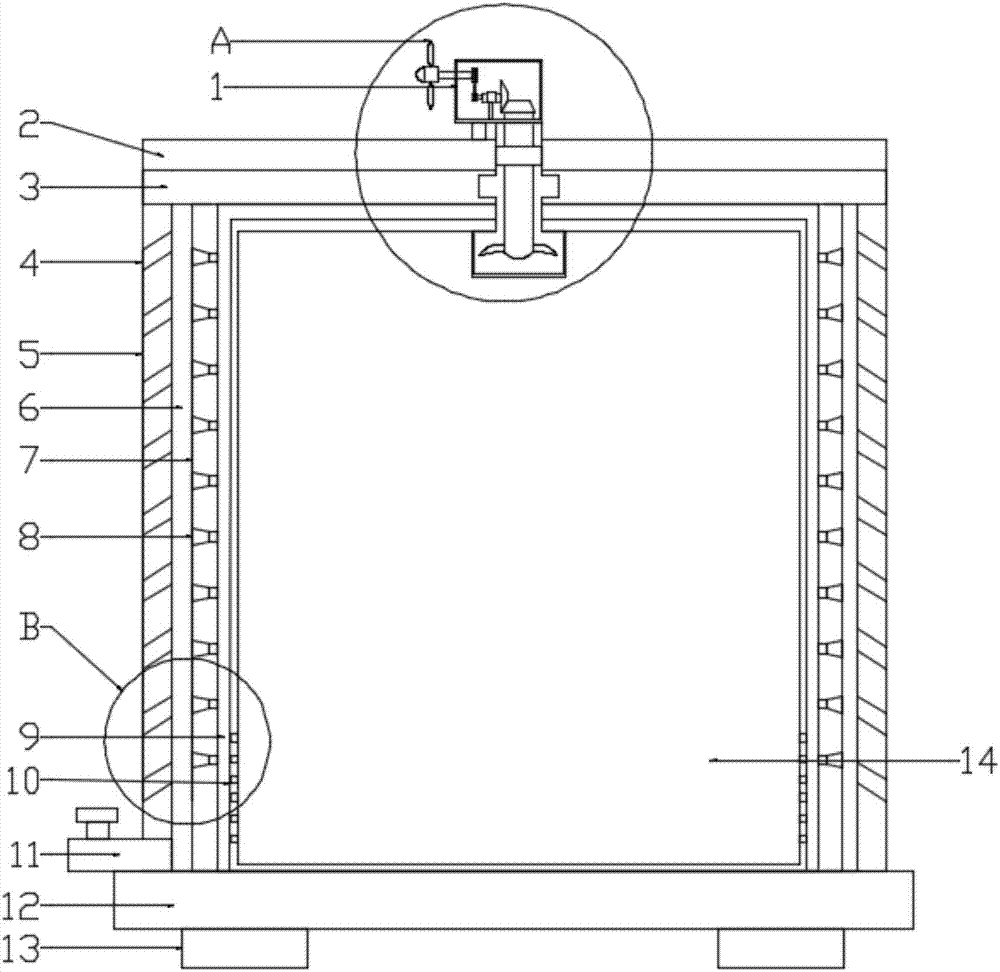

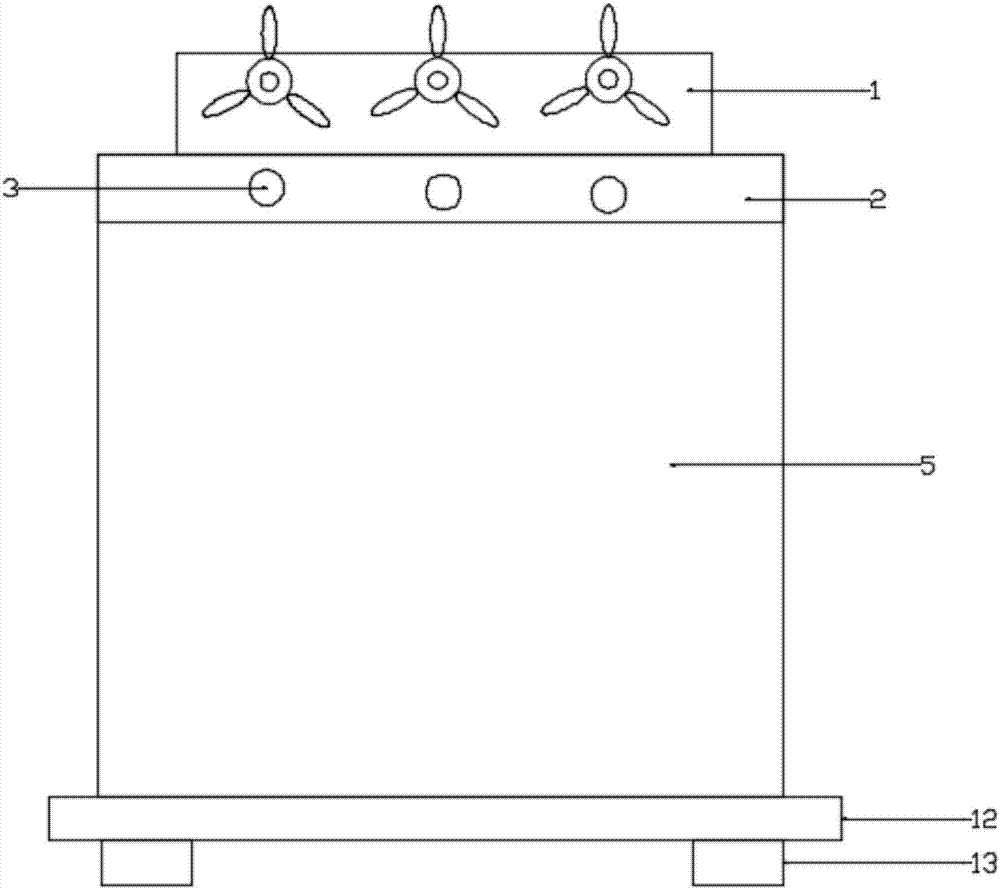

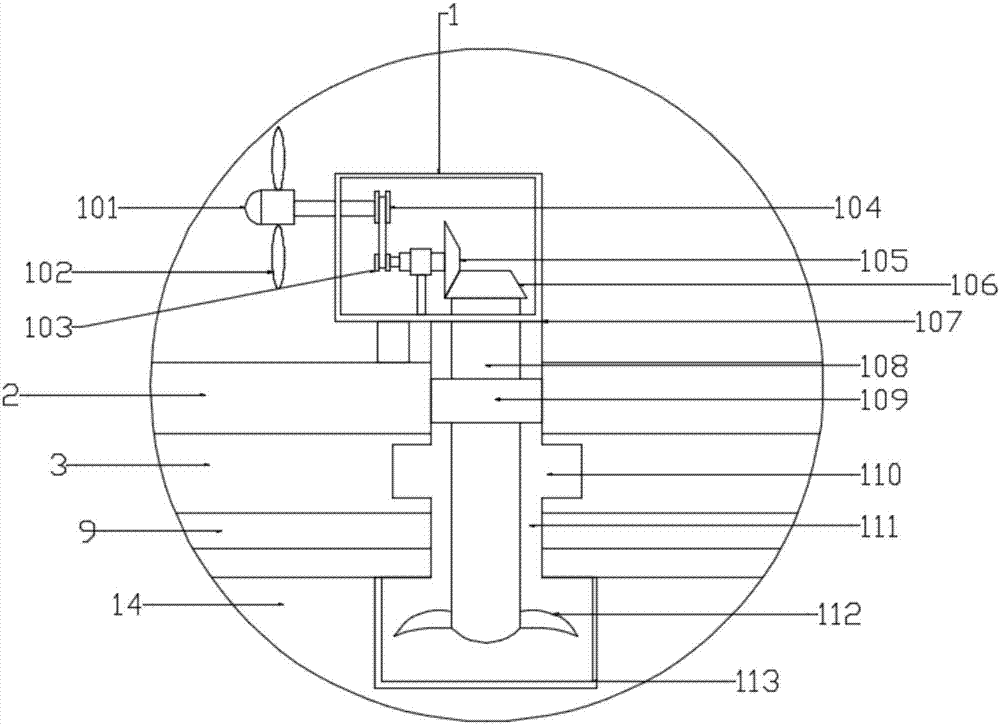

Dampproof high voltage distribution cabinet facilitating heat dissipation

PendingCN107546597AImprove cooling effectPrevent fallingSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsImpellerAgricultural engineering

The invention discloses a dampproof high voltage distribution cabinet facilitating heat dissipation. The dampproof high voltage distribution cabinet comprises an air draft device and a distribution box inner cabinet. A casing of the distribution box inner cabinet is provided with a second cavity layer, the outer side of the second cavity layer is provided with an inner layer box, the outer side ofthe inner layer box is provided with a first cavity layer, the outer side of the first cavity layer is provided with a casing, and the air draft device is provided with a gearbox. The left side of the gearbox is provided with a first rotating shaft, the first rotating shaft is provided with a first impeller, a large rotating wheel is fixed to the right side of the first rotating shaft through a connecting rotating shaft, the lower end of the first rotating shaft is connected with a small rotating wheel through a belt, the right side of the small rotating wheel is provided with first tapered teeth, the right sides of the first tapered teeth are meshed with second tapered teeth, the lower ends of the second tapered teeth are fixed to a second rotating shaft, the second rotating shaft penetrates and is inserted in a through pipe, the lower end of the through pipe is communicated with a net cover, and the second rotating shaft in the net cover is provided with a second impeller. The dampproof high voltage distribution cabinet facilitating heat dissipation is dampproof, power is provided by utilization of wind energy, and green and environment-friendly heat dissipation is achieved.

Owner:NANJING HK POWER SYST TECH CO LTD

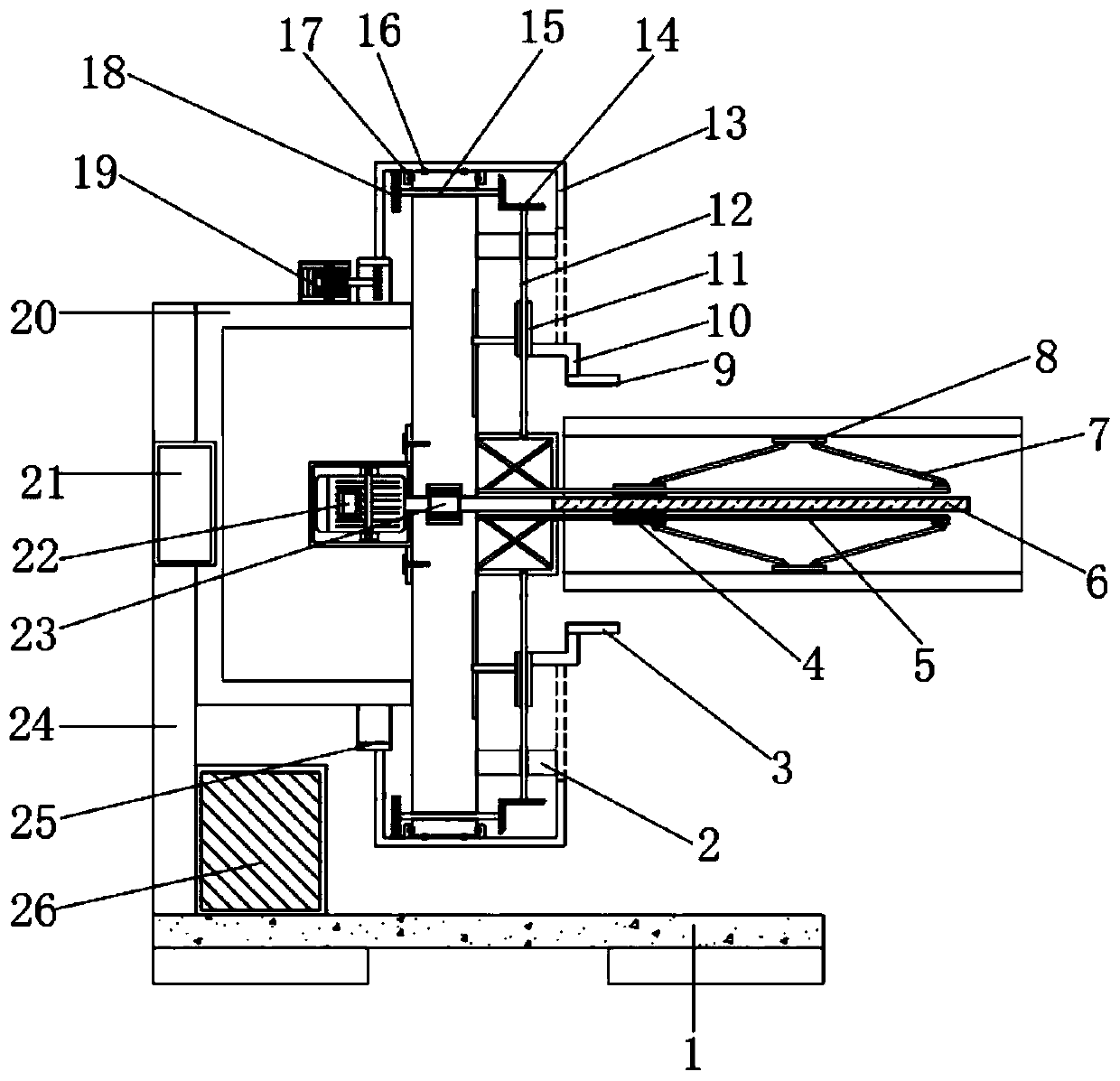

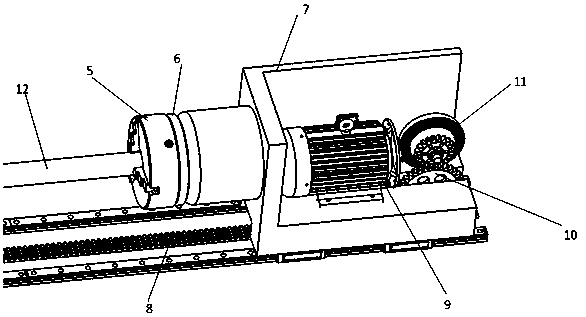

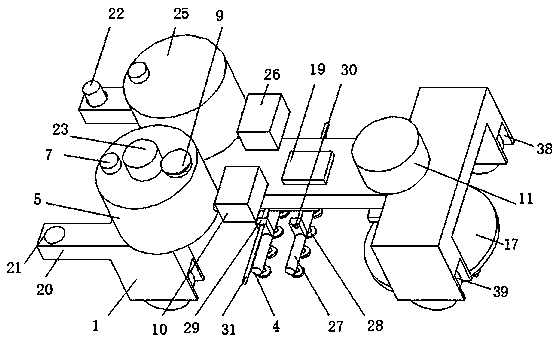

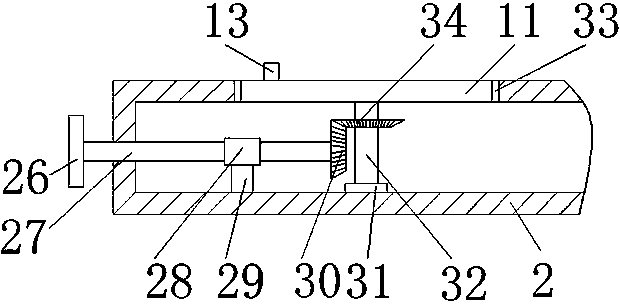

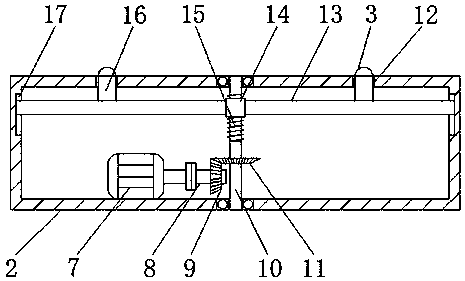

Pipe pushing rolling device for high-performance magnesium alloy seamless pipes

The invention provides a pipe pushing rolling device for high-performance magnesium alloy seamless pipes. The pipe pushing rolling device structurally comprises a floating supporting pressing roller device, a driven pressing roller set, a pushing device, an I-shaped guiding rail, a sliding key and a heating heat-insulation device. The floating supporting pressing roller device has the auxiliary supporting and centering effects; the driven pressing roller set rolls pipe blanks through pushing force on the pipe blanks; the pushing device is driven by a stepper motor, and after deceleration is conducted through a tapered tooth deceleration gear set, a gear rack transmission set drives a trolley to push the pipe blanks; the heating heat-insulation device conducts heat supplementing on the rolling process of the pipe blanks or preheating before rolling through joule heat generated by a heating coil; and the pushing device and the floating supporting pressing roller device are fixed to the I-shaped guiding rail through sliding blocks. The cracking and snapping phenomena in the rolling process of the pipe blanks can be significantly lowered, the structure performance of the rolled pipes is improved, the device is extremely larger in process flexibility, and the magnesium alloy pipes with different diameters and lengths can be rolled.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

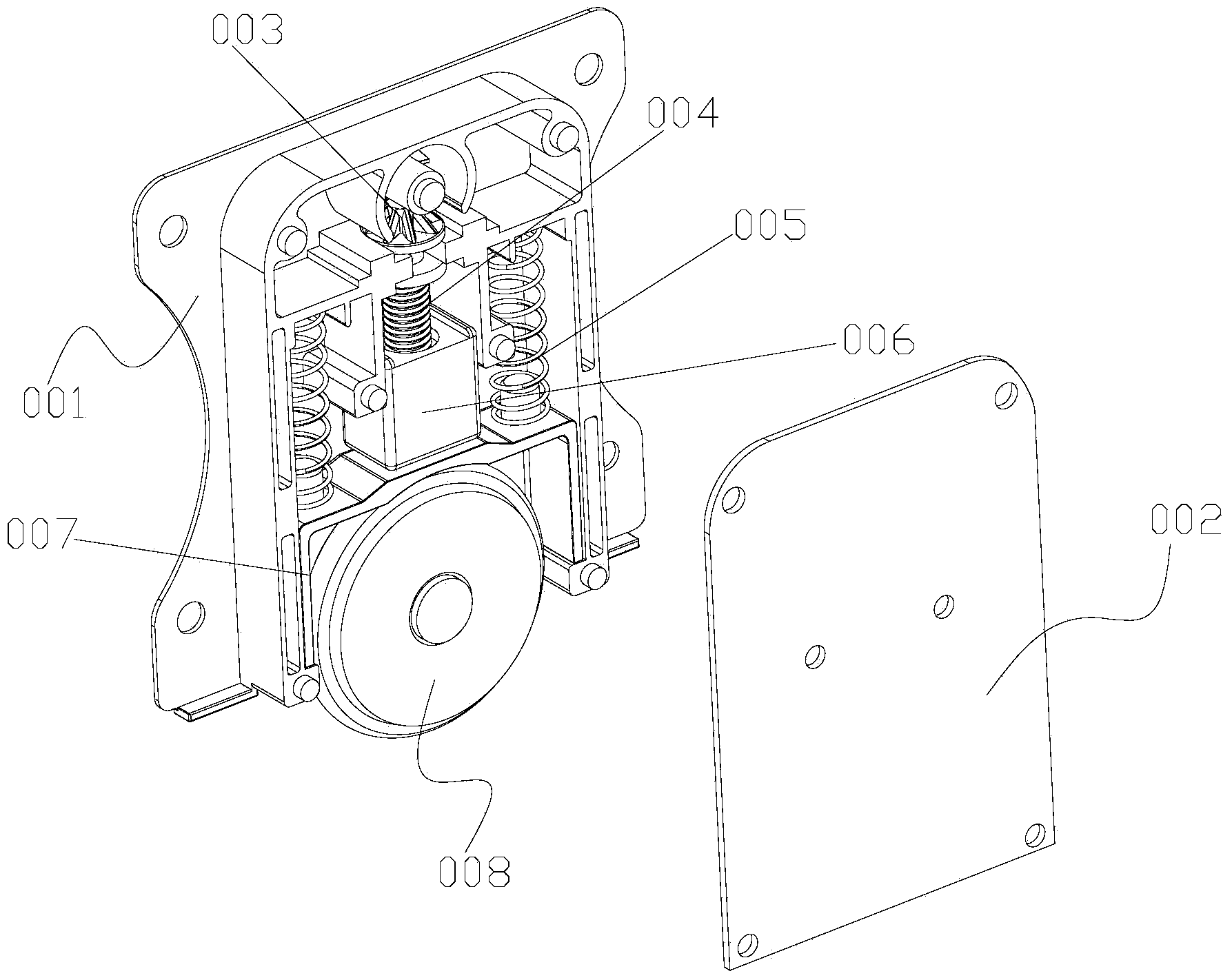

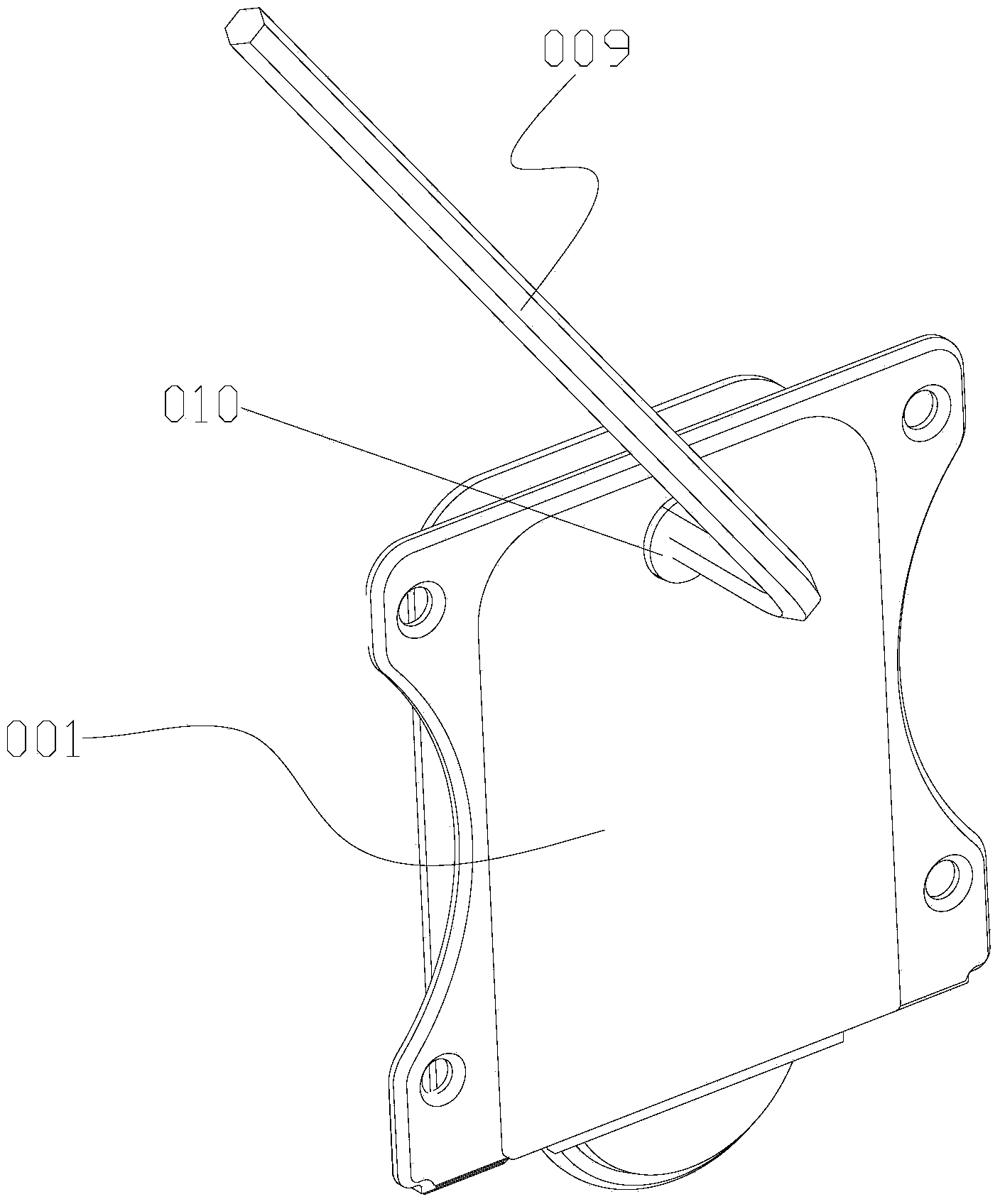

Pulley high-low position adjustment method based on sliding door application and sliding door adjusting device

InactiveCN103643849AReduce manufacturing costSimple structureWing suspension devicesEngineeringWrench

The invention discloses a pulley high-low position adjustment method based on sliding door application. A horizontal gear and a taper tooth screw are in close fit with each other; when the height of a gap between a door panel and a cabinet body needs to be adjusted, the horizontal gear is driven to rotate by a hexagon spanner and drives the taper tooth screw to rotate, and the taper tooth screw rotates left and right to drive a threaded slide block to lift up and down, so that a bearing slide block is pushed to lift up and down to realize up-and-down lifting of an adjusting wheel, and accordingly, the gap between the cabinet body and the door panel can be adjusted. The traditional vertical adjustment method is changed in the way that the horizontal gear is adjusted to realize height adjustment of the sliding door, and the adjustment is quick and convenient. The invention also discloses a sliding door adjusting device which has a simple structure, successfully converts vertical adjustment into horizontal adjustment, is low in manufacturing cost and convenient in use, can effectively prevent an adjusting wheel from jumping on a rail, and is safer in use.

Owner:东莞市荣翘泰五金有限公司

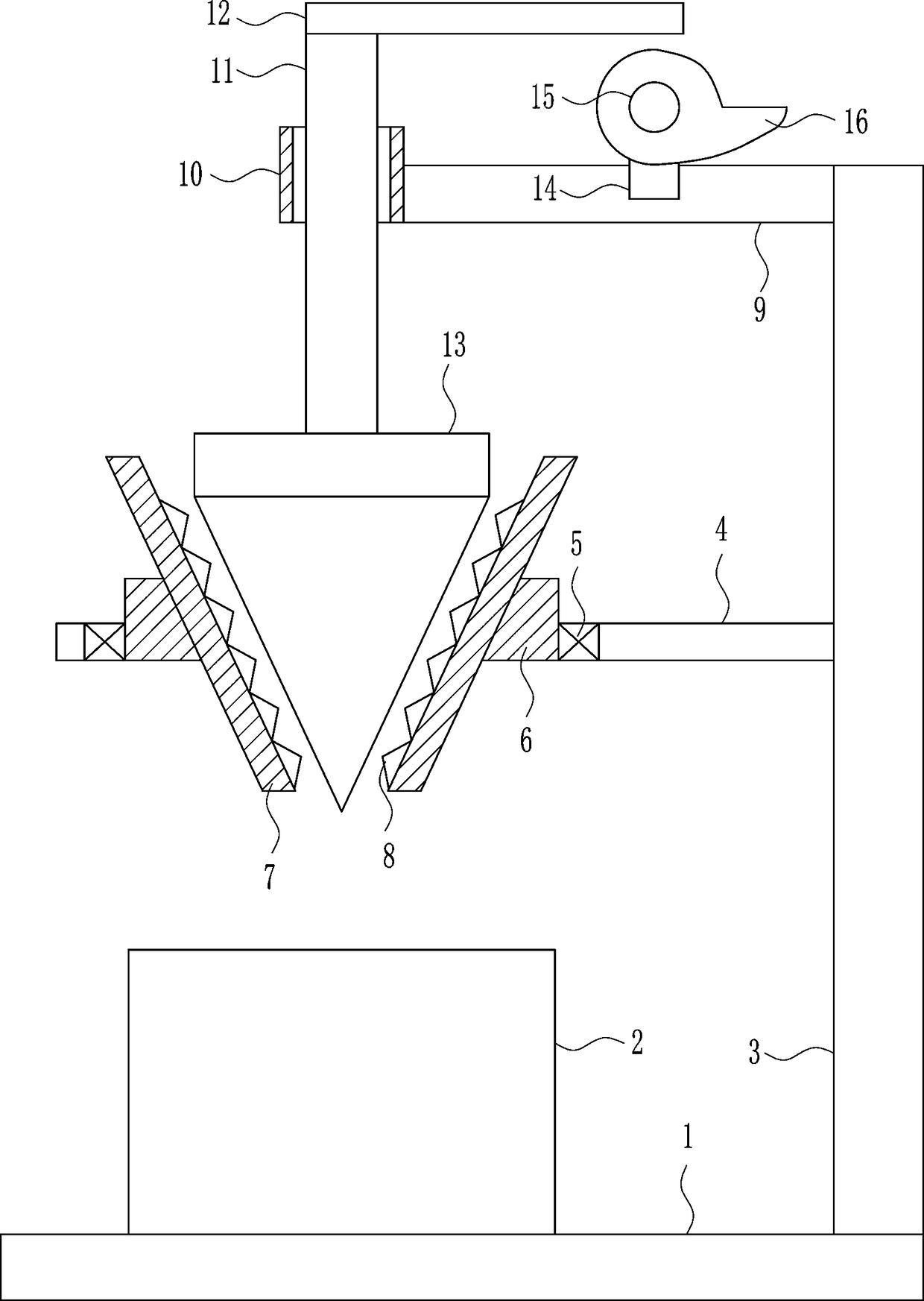

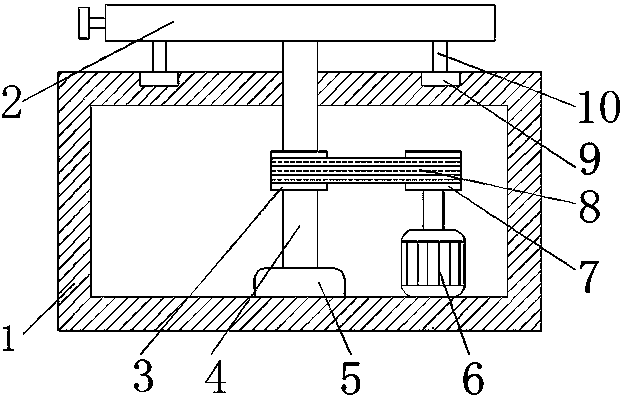

Pipe cutting machine capable of achieving quick clamping

InactiveCN107088676AQuick clampingImprove cutting efficiencyTube shearing machinesMaintainance and safety accessoriesCouplingDrive shaft

The invention discloses a pipe cutting machine capable of achieving quick clamping. The pipe cutting machine comprises a box body. The center of the bottom of an inner cavity of the box body is fixedly connected with a positive and negative rotation double-shaft motor. The outer sides of rotating shafts of the positive and negative rotation double-shaft motor are fixedly connected with driving shafts through couplings. The outer sides of the surfaces of the driving shafts are sleeved with first driving tapered teeth. The two sides of the bottom of the inner cavity of the box body are both movably connected with transmission shafts. According to the pipe cutting machine capable of achieving quick clamping, first driven tapered teeth, the transmission shafts, the positive and negative rotation double-shaft motor, the driving shafts, the first driving tapered teeth, second driving tapered teeth, the rotating shafts, second driven tapered teeth, threads, clamping plates, supporting rods, thread bushings and electric telescopic rods are matched for use, pipes can be clamped quickly, and therefore the cutting efficiency of the pipes is made higher, the problem that the cutting machine cannot clamp the pipes quickly in the pipe cutting process, and thus the cutting efficiency of the cutting machine is low is solved, and the production efficiency of the cutting machine is greatly improved.

Owner:湖州瀚丹诺家具有限公司

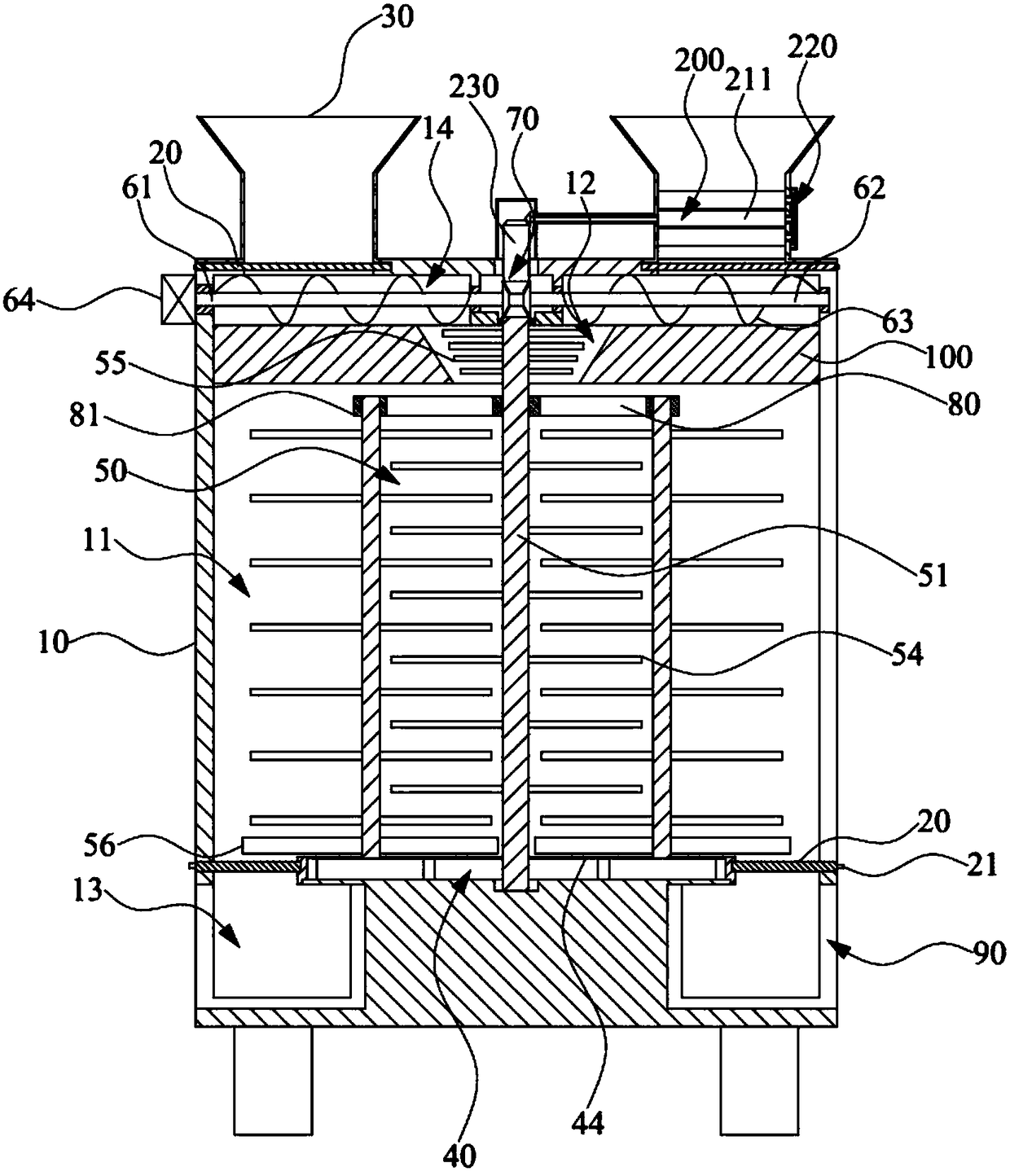

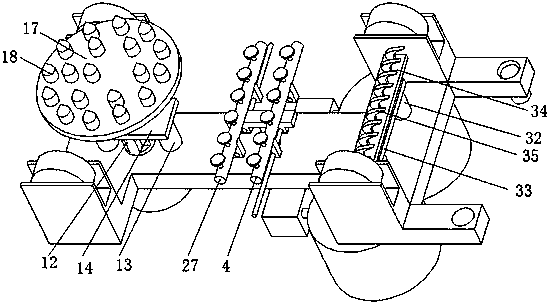

Graphene and plastic particle energy-saving stirring device

The invention discloses a graphene and plastic particle energy-saving stirring device. The graphene and plastic particle energy-saving stirring device comprises a shell body, two feeding funnels, a planetary gear assembly, a stirring assembly, a left rotary shaft and a right rotary shaft, spiral blades and a motor, wherein the shell body is provided with a main stirring cavity, an auxiliary stirring cavity, a discharging cavity and a feeding cavity; the two feeding funnels are arranged at the left and right sides of the feeding cavity; the planetary gear assembly is mounted at the bottom of the main stirring cavity; the stirring assembly penetrates through the planetary gear assembly; a stirring main shaft of the stirring assembly penetrates through the auxiliary stirring cavity to enter the feeding cavity from the main stirring cavity; the left rotary shaft and the right rotary shaft are arranged in the feeding cavity and are located at two sides of the stirring main shaft respectively; the spiral blades are arranged on the left rotary shaft and the right rotary shaft; the motor is mounted on the shell body and is used for driving the left rotary shaft; the left rotary shaft and the right rotary shaft are engaged with the stirring main shaft through tapered teeth. According to the graphene and plastic particle energy-saving stirring device disclosed by the invention, the rotary shafts are driven by the motor and graphene slurry is spirally conveyed into the stirring cavity; meanwhile, the rotary shafts drive the main shaft and the stirring assembly is further driven through the planetary gear assembly, so that the stirring of the graphene slurry is realized; finally, the discharging cavity is used for discharging; the graphene and plastic particle energy-saving stirring device has the advantages of energy saving, convenience and uniformity in stirring.

Owner:NINGBO FEICHAI ROBOT TECH CO LTD

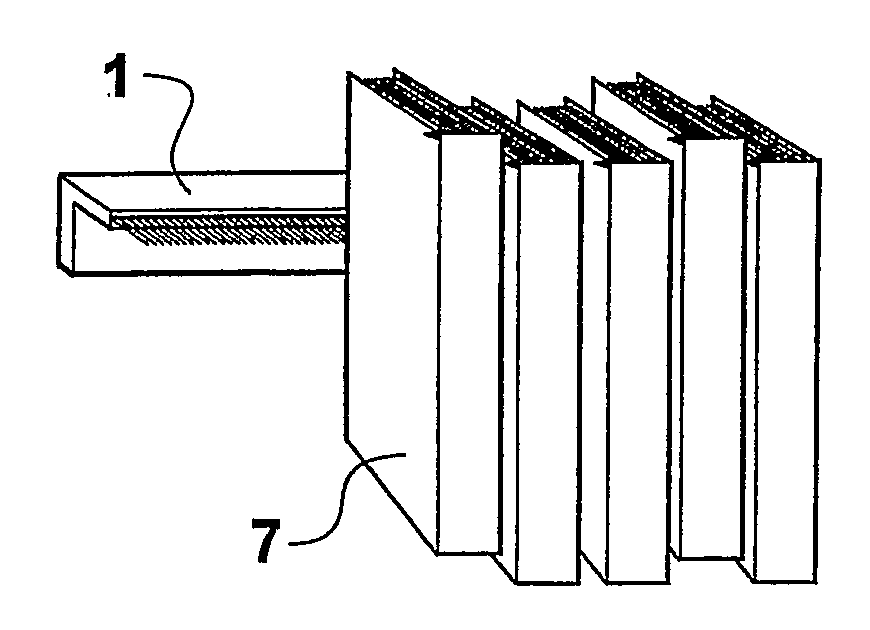

Shelving

A book or magazine shelving device (1), comprising a wall mountable bracket (2) having a comb-like book or magazine receiving member (5) with tapered teeth (6). The device holds books or magazines by gripping pages that are fed between the tapered teeth. The taper angle is in the range of 1.5 to 10.0 degrees.

Owner:NEIL ANTHONY BARRON GUSTO DESIGN

Additive chemical putting equipment for contaminated soil remediation

InactiveCN109940039APromote absorptionReduce evaporationContaminated soil reclamationChemical storagePollution soil

The invention discloses additive chemical putting equipment for contaminated soil remediation. The equipment comprises a mounting frame, a first electric telescopic rod is arranged in the middle of the bottom of the mounting frame, the bottom of the first electric telescopic rod is provided with a mounting plate, a connecting pipe is connected to the mounting plate, one side of the top of the mounting frame is provided with a chemical storage box, the top of the chemical storage box is provided with a liquid injection port and a feeding port, and a sealing cap is rotatably connected to the liquid injection port. The additive chemical putting equipment for contaminated soil remediation has the advantages that during remediation, firstly, soil is turned with soil turning teeth, large debrisin the soil is scraped out, then the work of a first water pump and a second water pump is controlled, and therefore a remediation solution and a nutrient solution are sprayed into the soil; the solutions can be fully mixed with the soil through rotating tapered teeth, the absorption by the soil is facilitated, and the evaporation of the solutions can be effectively reduced.

Owner:覃宁

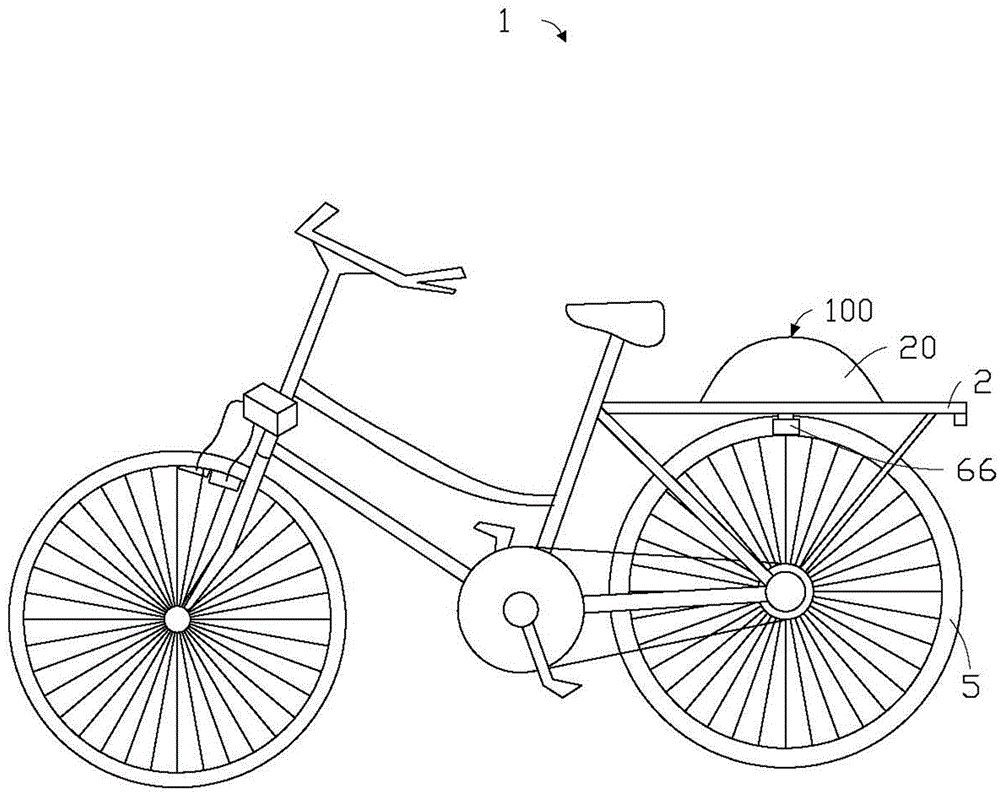

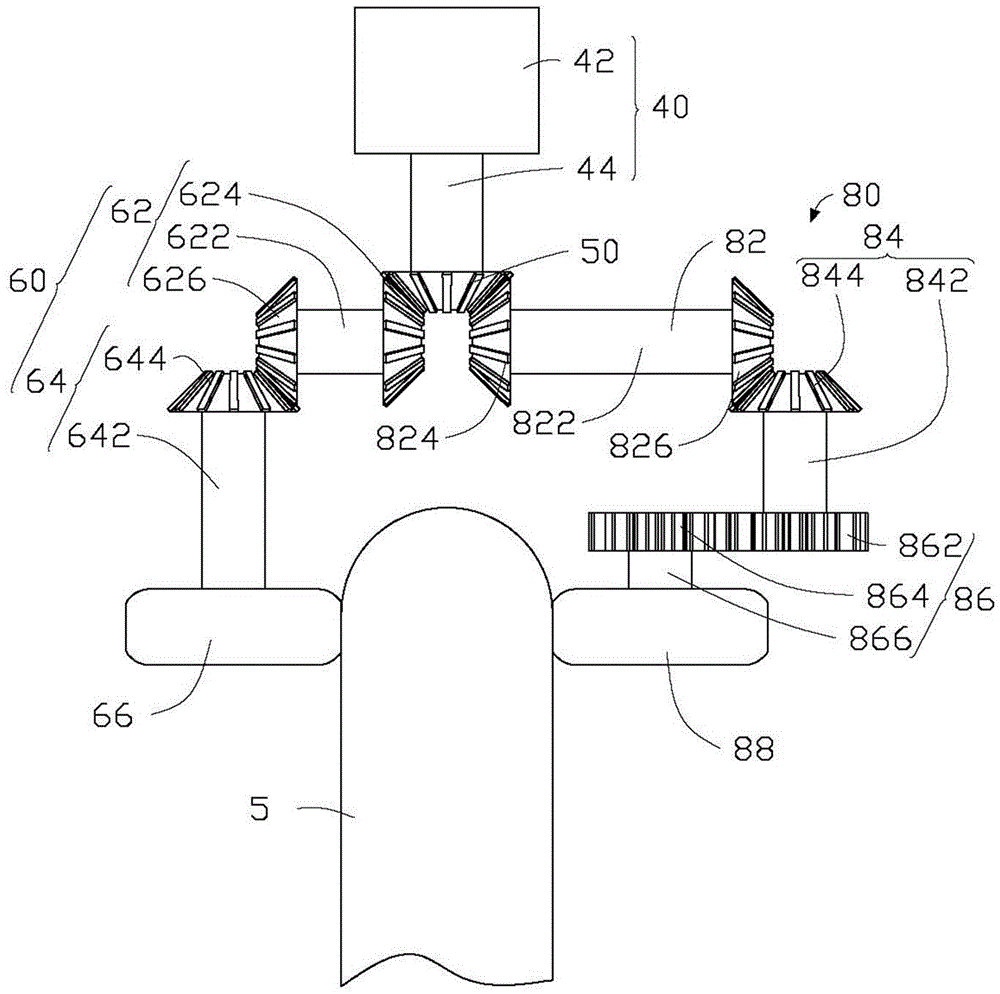

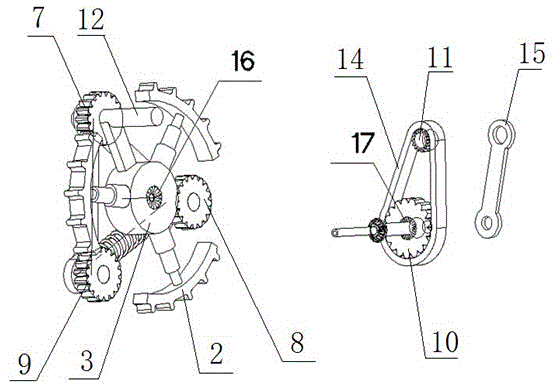

Bicycle and electric power assisting device thereof

An electric power assisting device comprises a drive piece, a main gear, transmission assemblies and friction wheels. The main gear is connected with the drive piece and can rotate in the first direction. The transmission assemblies comprise a first transmission gear and a second transmission gear. The first transmission gear comprises a transmission shaft, a first tapered tooth part and a second tapered tooth part, wherein the transmission shaft is sleeved with the first tapered tooth part and the second tapered tooth part in a spaced manner and extends in the second direction perpendicular to the first direction. The first tapered tooth part is engaged with the main gear. The second transmission gear comprises a rotary shaft and a third tapered tooth part arranged on the rotary shaft in a sleeving manner. The rotary shat extends in the first direction. The third tapered tooth part is engaged with the second tapered tooth part. The friction wheels are connected with the rotary shaft, spaced from the third tapered tooth part and used for abutting against a tire of a bicycle. The electric power assisting device is convenient to install.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Track wheel mechanism

InactiveCN104443088AIncrease the footprintImprove rigidityEndless track vehiclesWheelsHydraulic cylinderGear wheel

The invention discloses a track wheel mechanism comprising a track, a hydraulic support and three support wheels. The track comprises a rubber track body, reinforcing bars, iron teeth and limiting block. The second support wheel is connected with the third support wheel through a telescopic bar. A spring is fixed between the second support wheel and the third support wheel and sleeves the telescopic bar. A conversion shaft sleeves a hydraulic oil hollow shaft and is provided with tapered teeth. The first support wheel, as a corner gear, is connected with a first gear through a transmission shaft. The track wheel mechanism has the advantage that the hydraulic support is in the shape of a ring composed of a supporting hydraulic cylinder and three hydraulic bars, the running speed of the mechanism is high, the mechanism is suitable for running on dry roads, the travelling wheels form a triangle after the hydraulic support is contracted and after the distance between the second support and the third support wheel is enlarged due to resetting of the spring, and the track of the mechanism has ground area so that the mechanism is suitable for muddy places.

Owner:HUNAN NONGGUANG AGRI EQUIP CO LTD

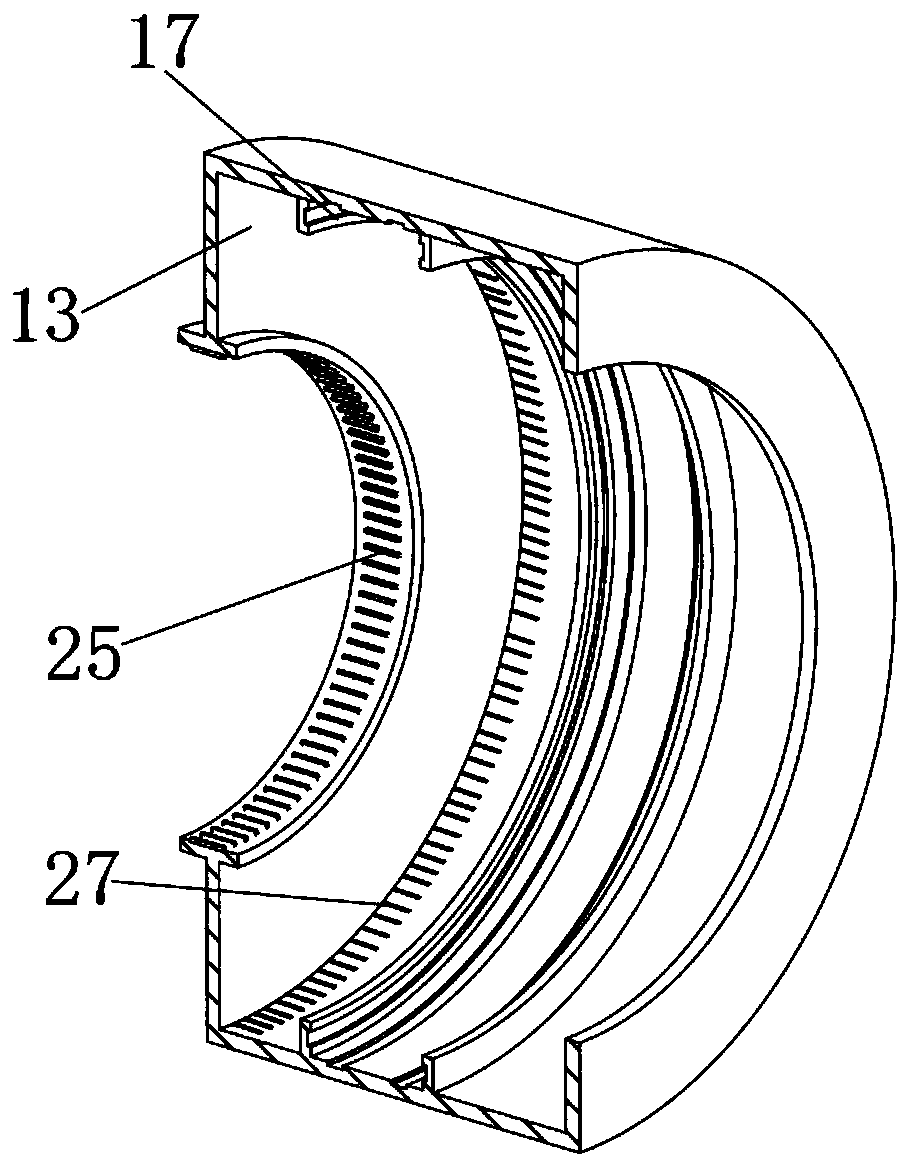

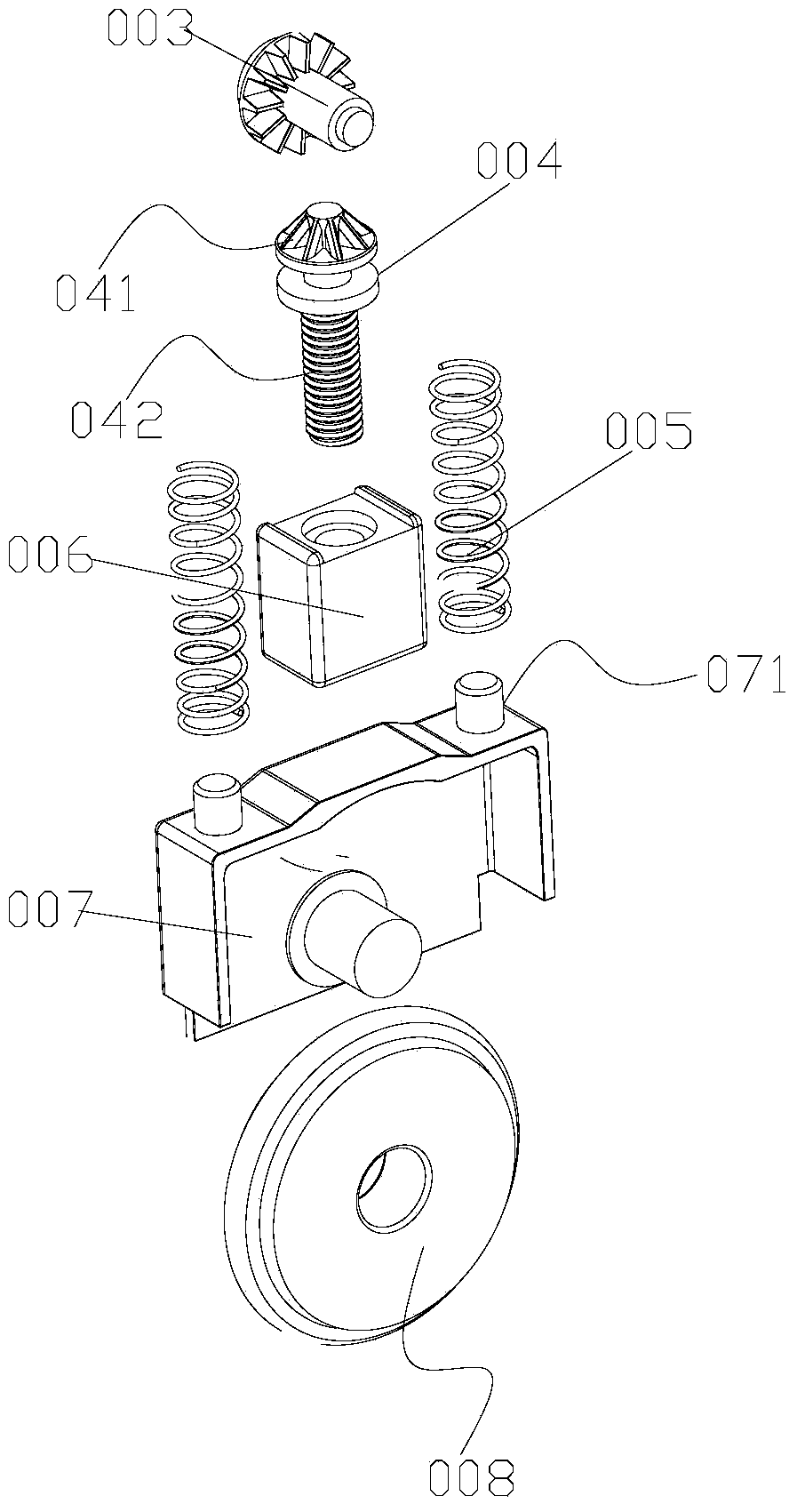

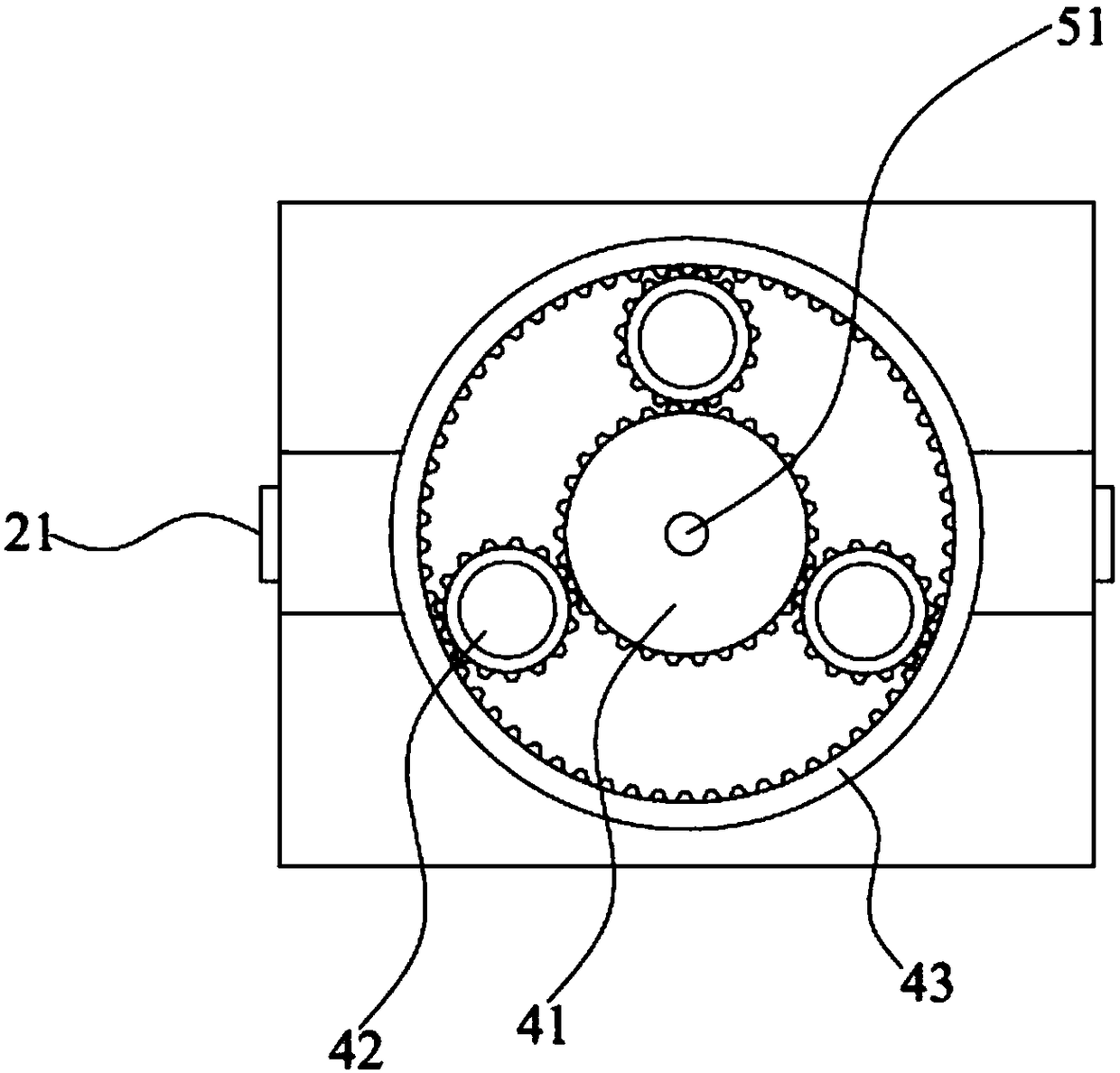

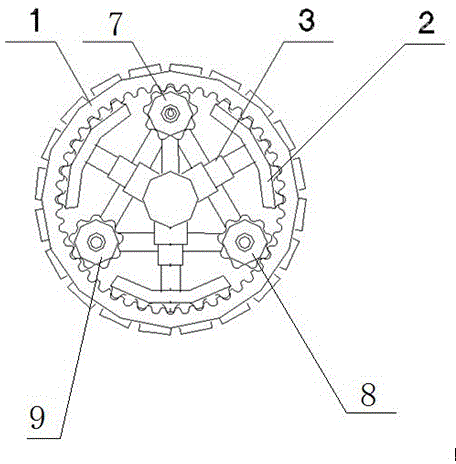

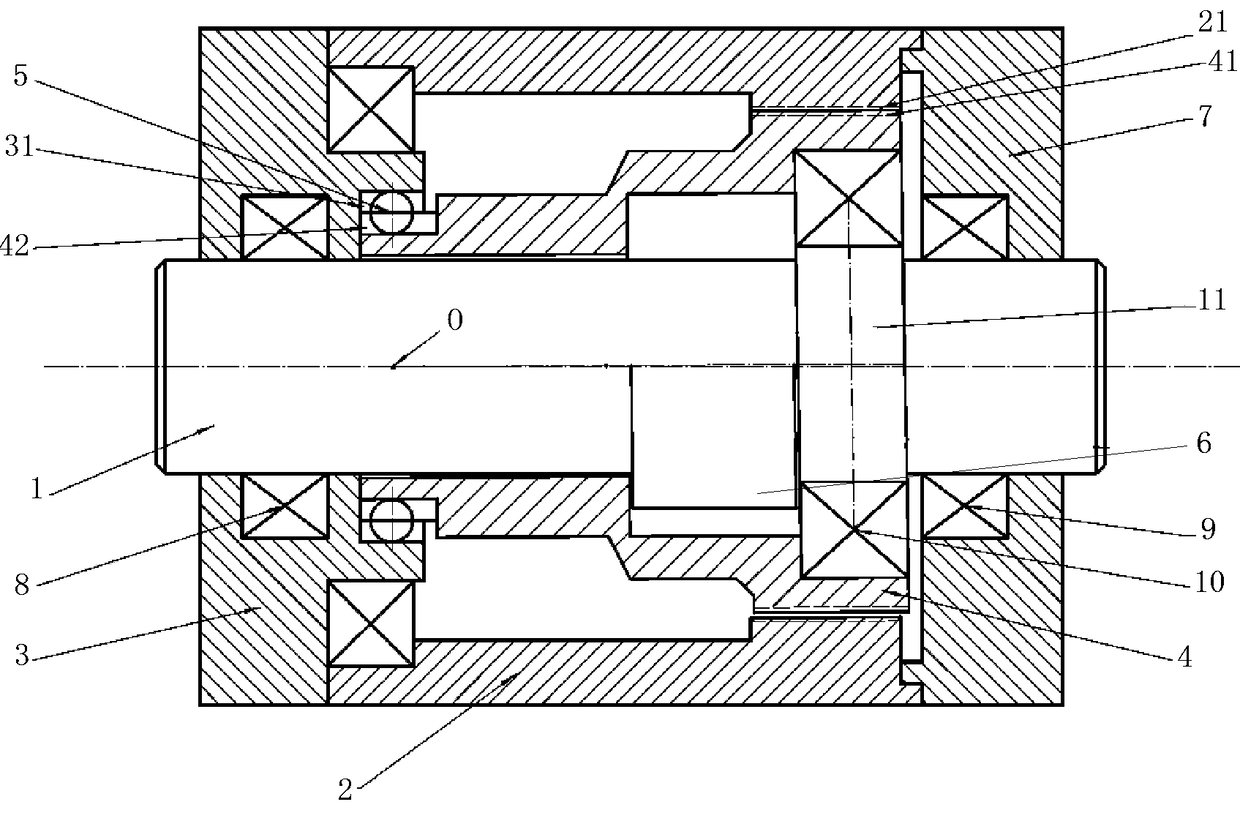

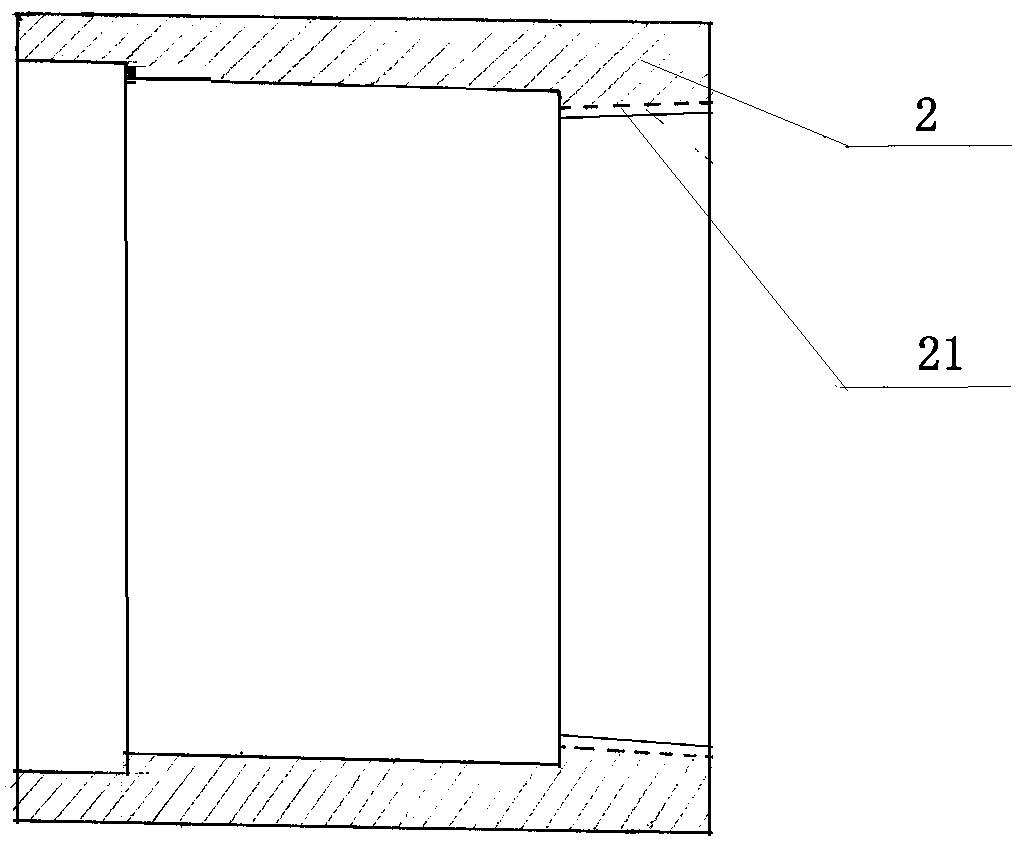

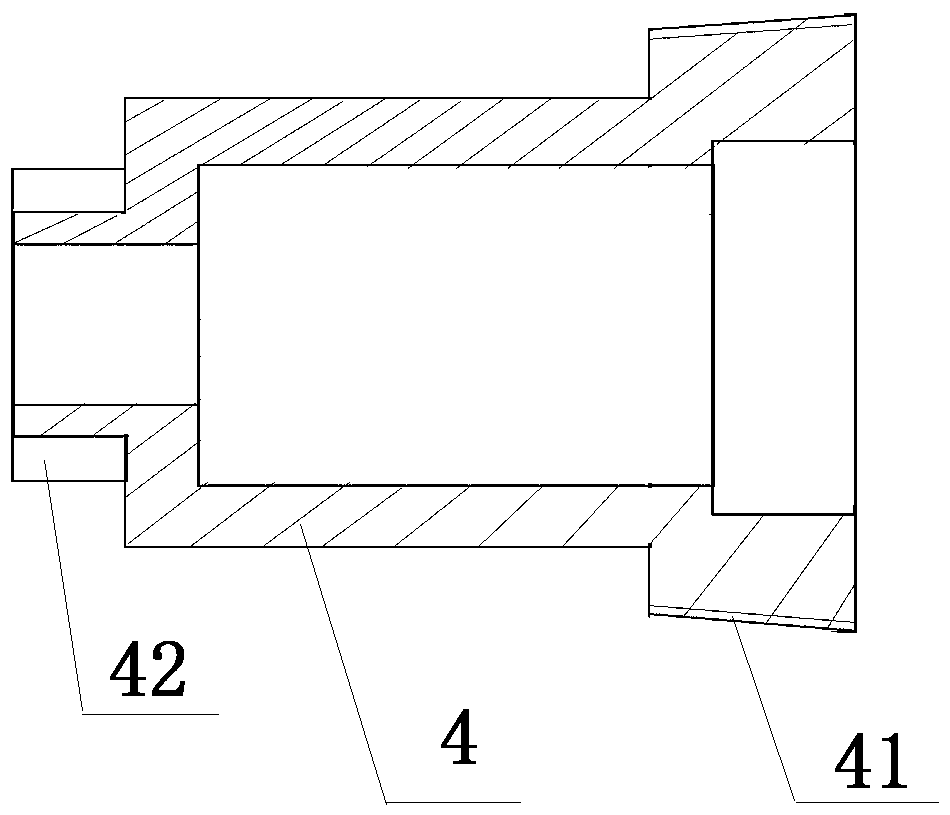

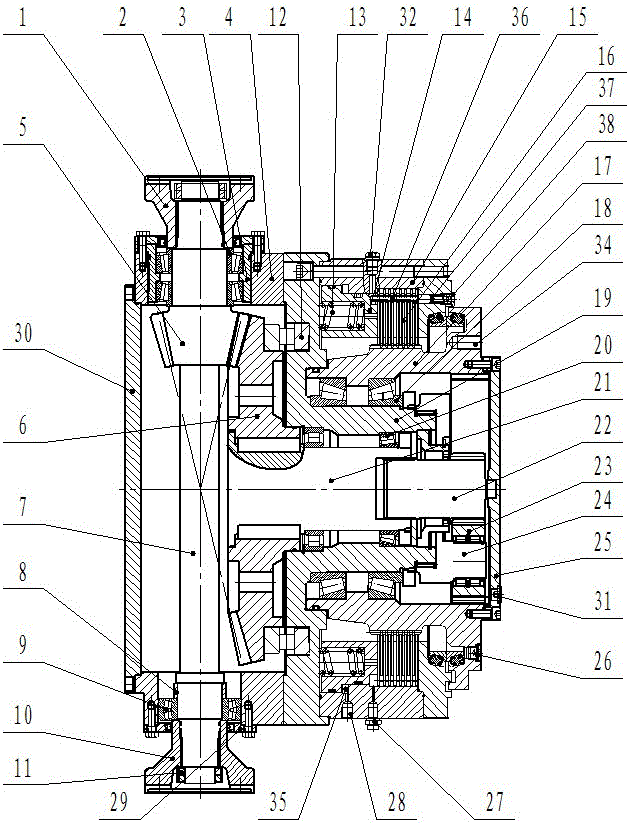

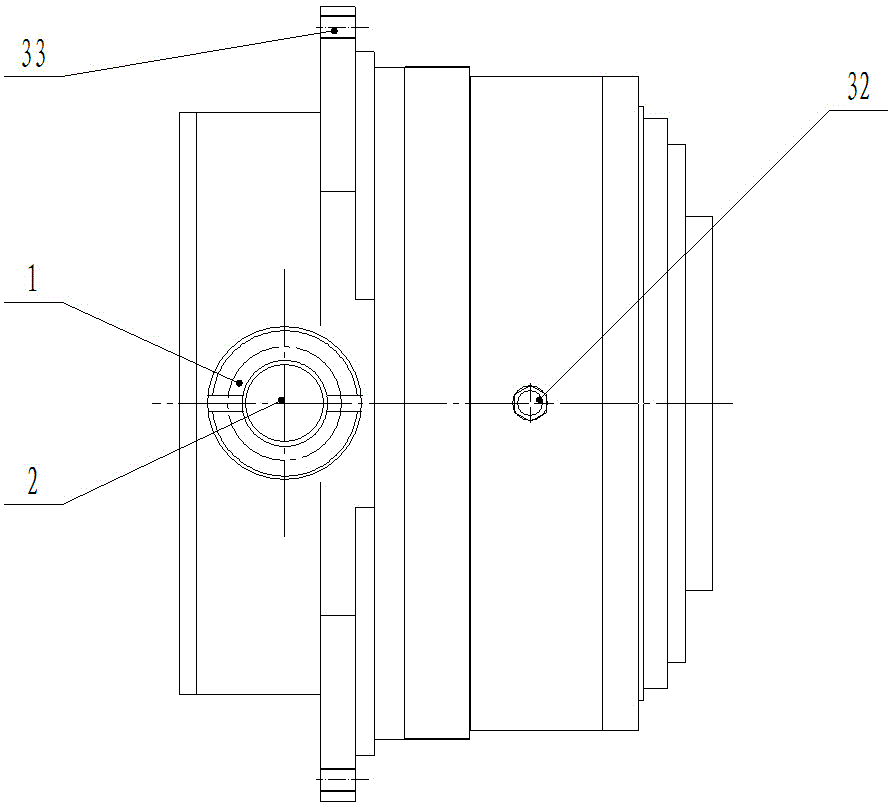

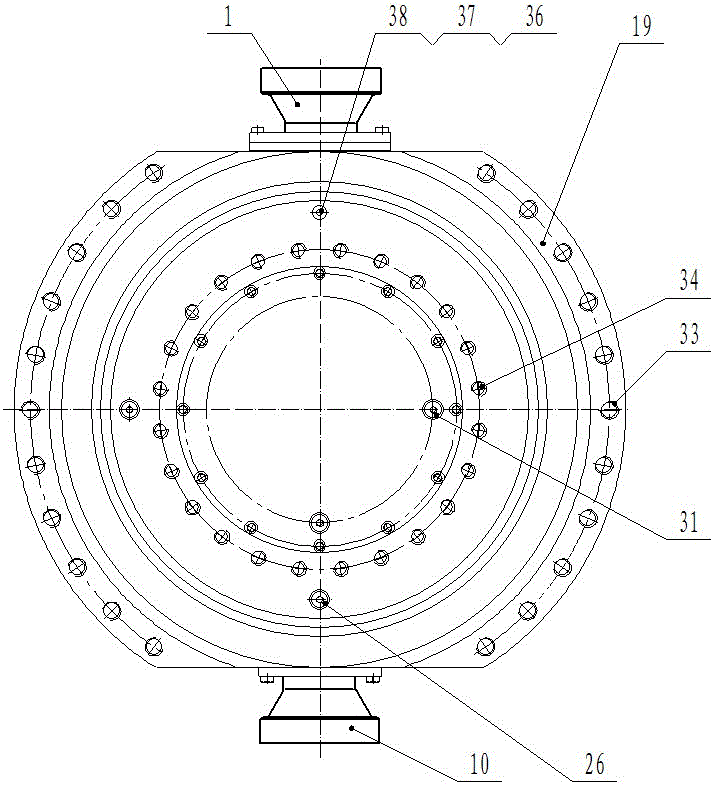

Tapered rolling cycloid planetary transmission mechanism

InactiveCN108087500ALoose spaceIncrease output torqueToothed gearingsPortable liftingCircular coneTapered teeth

A tapered rolling cycloid planetary transmission mechanism comprises an input component, an output component and a fixed inner toothed ring; first tapered teeth are evenly distributed on the inner circumference of the inner toothed ring; the input shaft is provided with an eccentric shaft which is connected with one end of a cycloid wheel through a bearing; the other end of the cycloid wheel is connected with the output component at the dead center position, and an eccentric angle is formed between the connecting line of the midpoint of the axis of the eccentric shaft and the dead center position and the axis of the input shaft; second tapered teeth capable of being engaged with the first tapered teeth are evenly distributed on the periphery of the cycloid wheel supported on the eccentricshaft, and the number of the first tapered teeth is larger than that of the second tapered teeth; the included angle formed by the engagement center line of the first and second tapered teeth and theaxis of the input shaft is equal to the eccentric angle; the cycloid wheel and the output component are provided with opposite semicircular slots, and the two semicircular slots form a complete circular hole; and connecting balls are disposed in the circular hole so that the output component and the cycloid wheel can be universally rotated and synchronously rotated, and the circle centers of the sphere center distribution circumferences of the connecting balls coincide with the dead center position.

Owner:SHENZHEN XINCHUANG TECH RES CO LTD

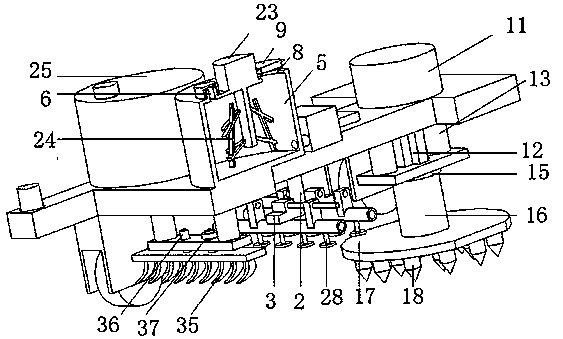

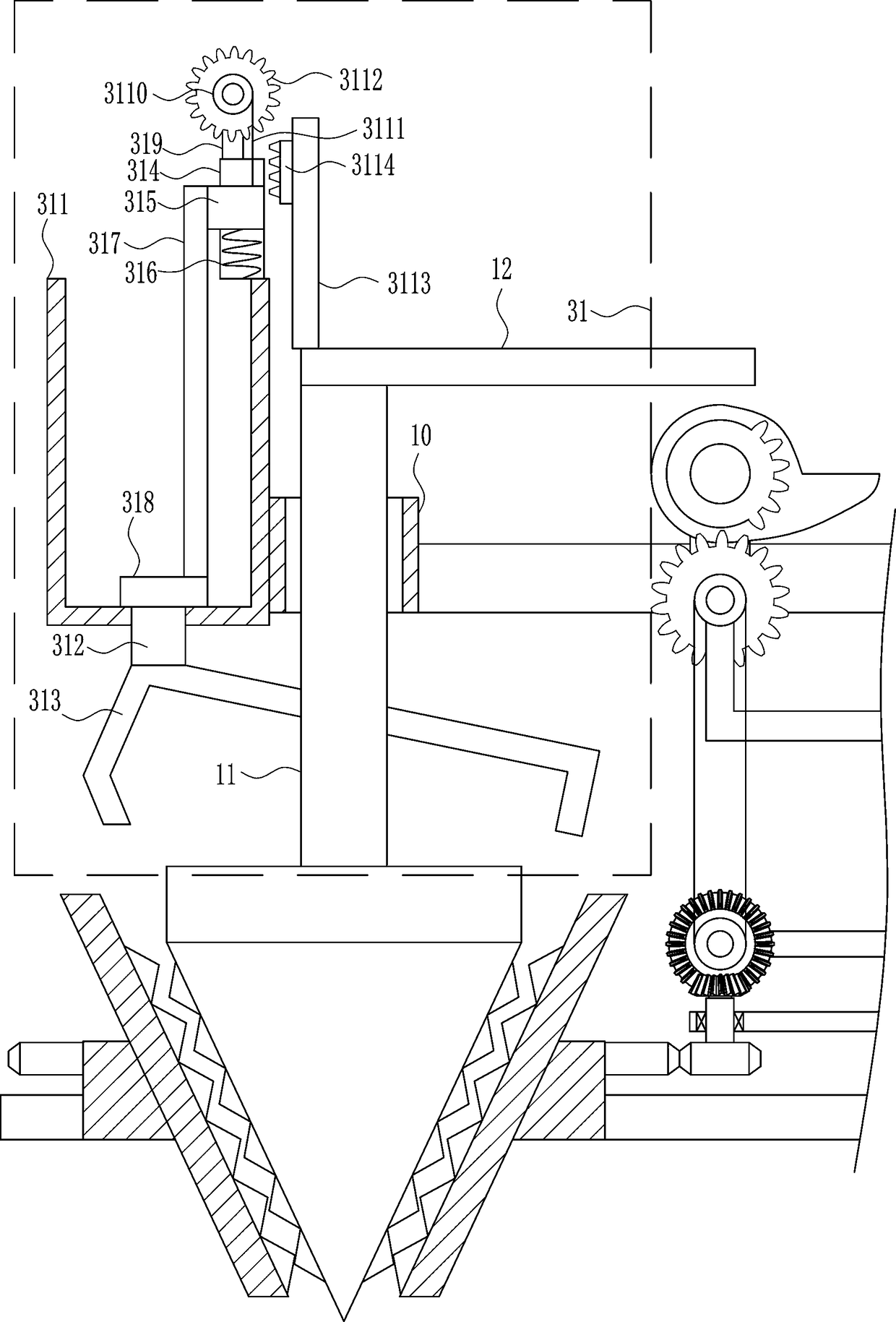

Feed pulverization grinding equipment for animal husbandry

InactiveCN108295935AWon't hurtAvoid inefficiencyFeeding-stuffGrain treatmentsAdditive ingredientEngineering

The invention relates to animal husbandry feed processing equipment, in particular to feed pulverization grinding equipment for animal husbandry, and aims to solve technical problems in the prior art.In order to solve the above technical problems, the feed pulverization grinding equipment which is applicable to animal husbandry and has the effects that both the time and the effort are saved through the automated grinding operation, feed ingredients need not be manually and frequently added to the feed pulverization grinding equipment in the grinding course, and the degree of automation is high is provided. The feed pulverization grinding equipment for animal husbandry comprises a baseplate, a collecting tank, a supporting plate, a fixing plate, a first bearing seat, a tapered ring, a tapered grinding hopper, tapered teeth, a mounting plate, a guide sleeve, a guide rail, a contact plate, a tapered block and the like, wherein the collecting tank is placed on the upper left side of the baseplate; and the supporting plate is mounted on the upper right side of the baseplate in a welding manner. The feed pulverization grinding equipment provided by the invention achieves the effects that both the time and the effort are saved through the automated grinding operation, the feed ingredients need not be manually and frequently added to the feed pulverization grinding equipment in the grinding course, and the degree of automation is high.

Owner:钟凤娣

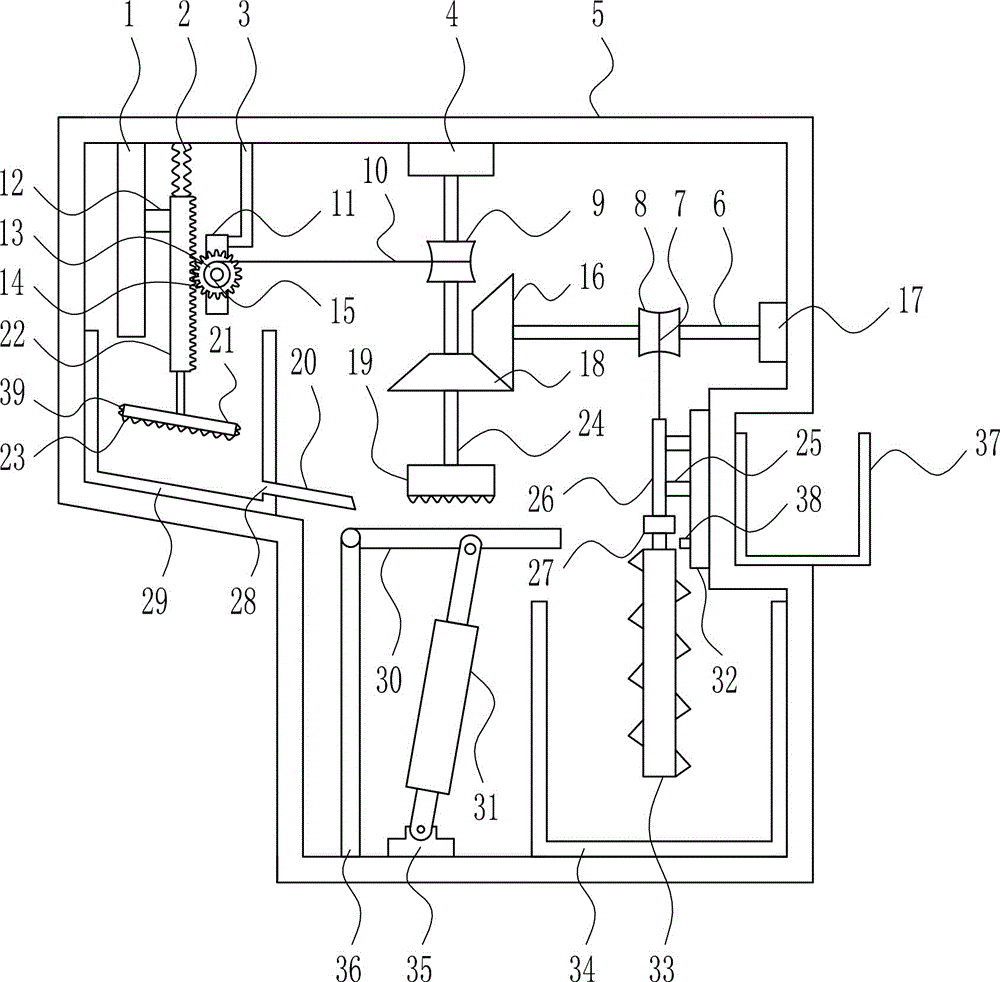

Multifunctional recycling apparatus for building waste

InactiveCN106431045AAvoid litteringIncrease stirring speedSolid waste managementCement mixing apparatusEngineeringConductor Coil

The invention relates to a recycling apparatus, in particular to a multifunctional recycling apparatus for building waste; the technical problem to be solved herein is to provide a multifunctional recycling apparatus for building waste having many functions. In order to solve the above technical problem, the invention provides such a multifunctional recycling apparatus for building waste, comprising a first slide rail, a spring, a first link, a first rotary motor, a support, a second rotary shaft, a second pull wire, a third winding wheel, a second winding wheel, a first pull wire and the like; the first slide rail is provided with a first slider, the right end of the first slider is provided with a rack, the upper end of the rack is connected to the lower end of the spring, the lower end of the rack is connected to breaking stone, and the bottom of the breaking stone is provided with first small tapered teeth. The multifunctional recycling apparatus for building waste has many functions; people may place belongings in a receiving basket provided herein such that littering of articles is prevented.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

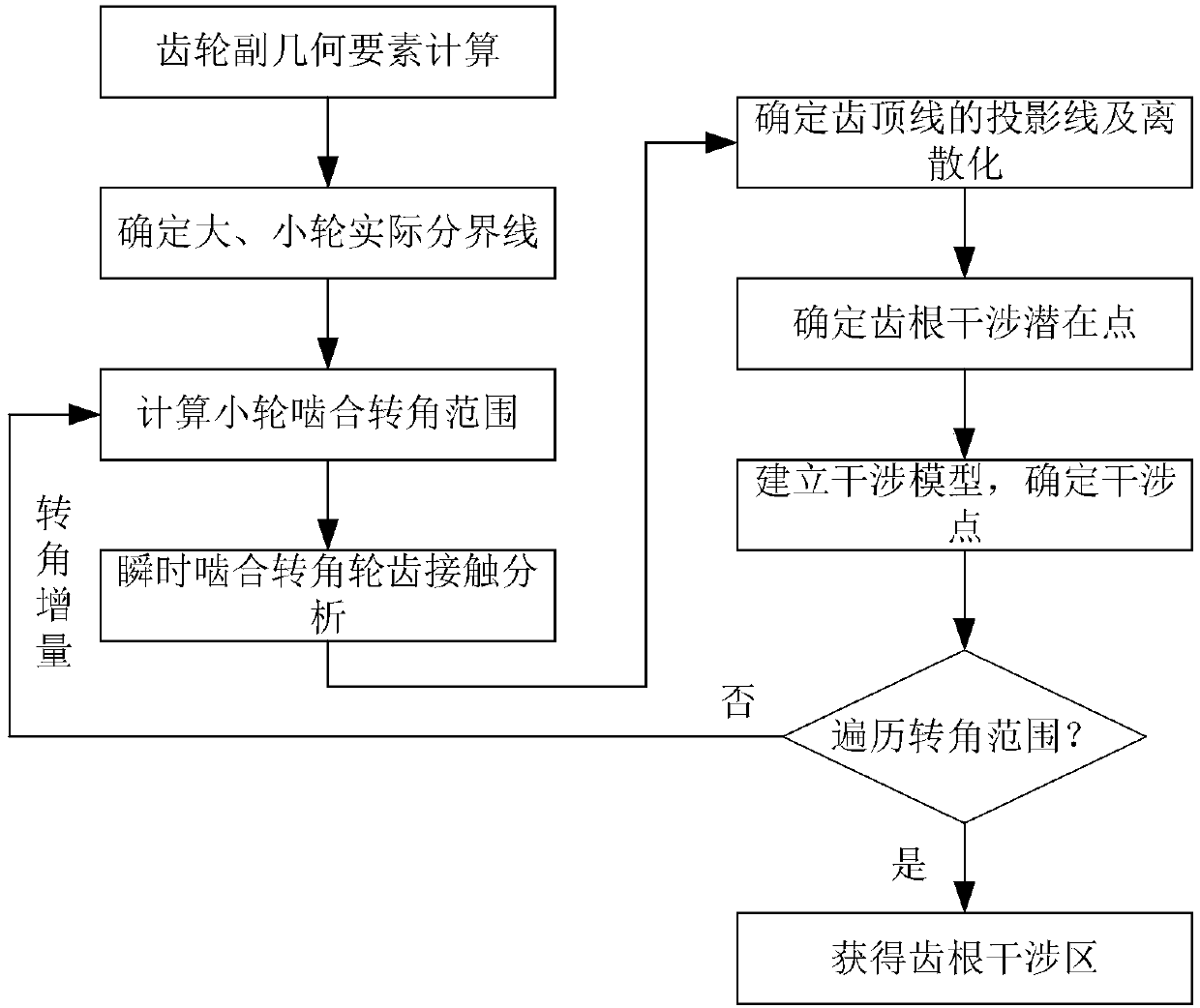

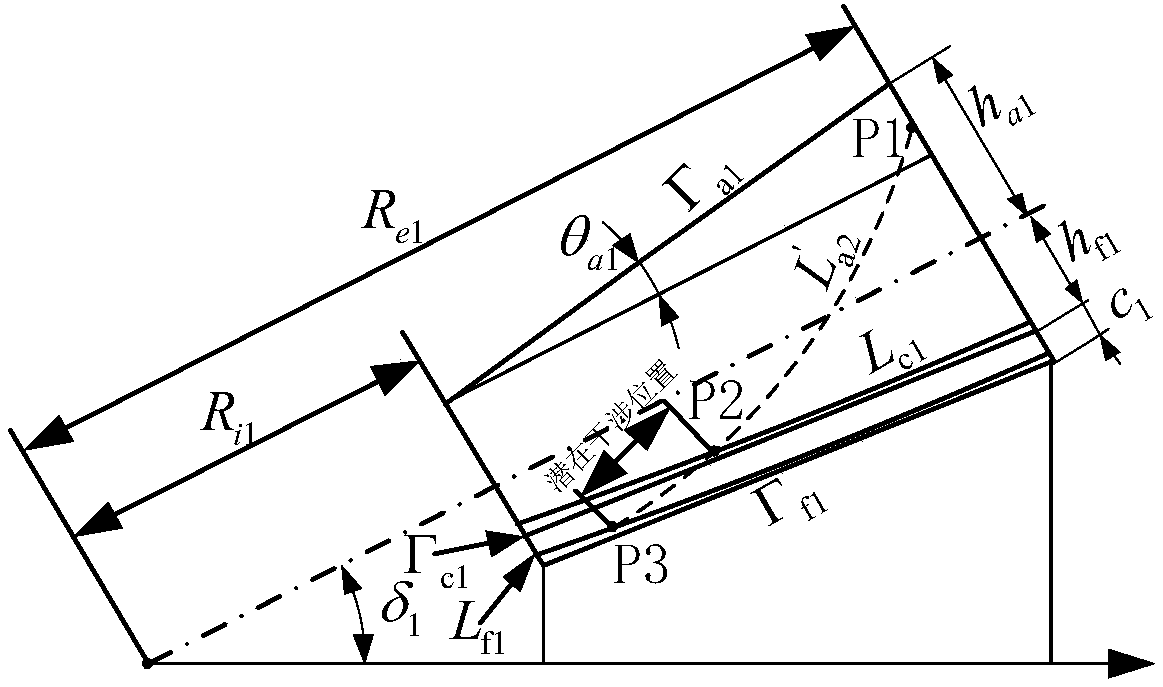

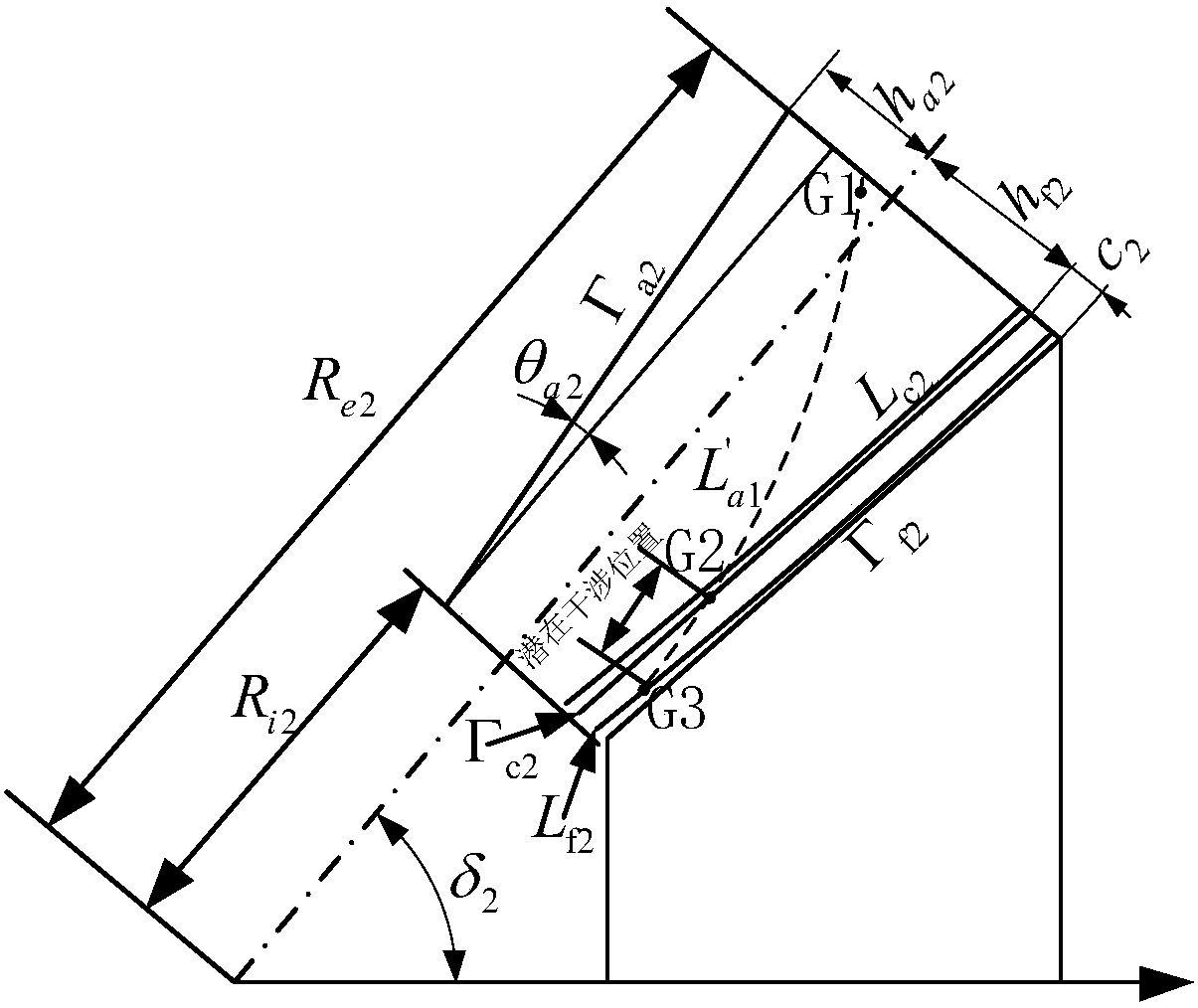

Method for checking tooth root interference of spiral bevel gears

InactiveCN108120596AImprove consistencyMachine gearing/transmission testingEngineeringProjection line

The invention discloses a method for checking tooth root interference of spiral bevel gears, which comprises the steps of calculating the inner tapered tooth crest height, the inner tapered tooth rootheight, a designed tooth root line and a designed boundary line of the gear according to geometric parameters, and determining a positional relation of the geometric elements; setting machine tool adjustment parameters and cutter parameters of the gear pair, and determining an actual tooth root line and an actual boundary line; solving small-gear rotation angles of an engaging-in point and an engaging-out point according to geometric conditions of the gear pair for being engaged at the tooth crests of the big gear and the small gear, discretizing the whole engaging process, performing tooth surface contact analysis on all small-gear rotation angles, transforming a tooth top line of the current gear to a paired gear to obtain a tooth crest projection line, discretizing the tooth crest lineto obtain a potential point of tooth root interference, further building a tooth root interference model, judging whether interference occurs or not according to the normal distance, and repeating the process to obtain a tooth root interference area. According to the method, tooth root interference caused by excessively large round corners of the cutter or unreasonable parameter setting of the machine tool can be checked out, and the actual boundary line between a transitional curved surface and a working gear surface and the tooth root interference area are determined.

Owner:CHANGAN UNIV

Machining rotary table with good fixing effect

InactiveCN108526924AEasy to fixSmooth rotationLarge fixed membersPositioning apparatusDrive wheelEngineering

The invention discloses a machining rotary table with the good fixing effect. The machining rotary table with the good fixing effect comprises a device body. A motor is fixedly connected with the right side of the bottom of an inner chamber of the device body. A driving wheel disk is fixedly connected with an output end of the motor. The driving wheel disk is sleeved with a belt. The left side ofan inner chamber of the belt is sleeved with a driven wheel disk. An inner chamber of the driven wheel disk is sleeved with a first rotary rod. A first bearing is movably connected with the bottom ofthe first rotary rod. Because the machining rotary table with the good fixing effect is provided with a moving pin, a moving rod, a secondary arc-shaped clamping claw, a transverse rod, a main arc-shaped clamping claw, a fixed transverse rod, a rotary rod, a second rotary rod, driving tapered teeth, a third rotary rod, through holes and driven tapered teeth, the problem that because a machining rotary table in the existing market does not have the function of effectively fixing a workpiece, the workpiece on a rotating machine is prone to colliding with a machine tool, and the own quality of aproduct is influenced, and potential safety hazard is brought to the staff in work at the same time is solved.

Owner:闫会云

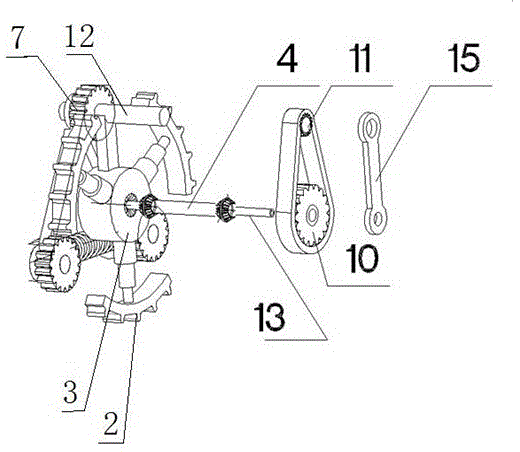

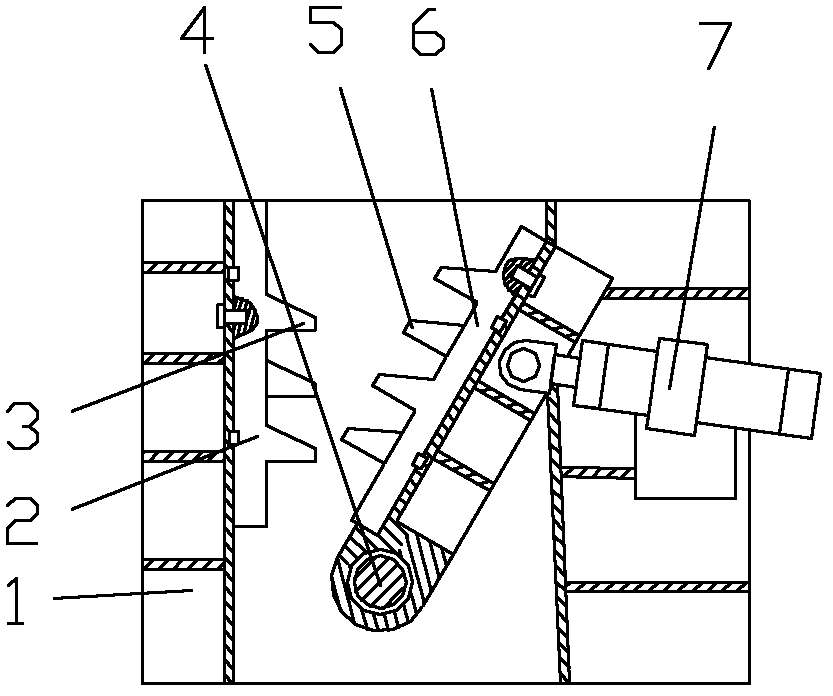

Through shaft tapered-tooth planet wheel side reducer with brake

PendingCN106704554AReduce width sizeReduce axial sizeBrake typesGearing detailsInjection portReduction drive

The invention belongs to the technical field of underground coal mine auxiliary conveying device spare parts and specifically relates to a through shaft tapered-tooth planet wheel side reducer with a brake. According to the shaft tapered-tooth planet wheel side reducer with the brake, the problem that the width of an overall support conveying vehicle is large due to the fact that the occupied space of a motor directly inserting wheel side reducer is large is solved. The shaft tapered-tooth planet wheel side reducer with the brake comprises an input fork frame I, a first rolling bearing, an inner supporting frame, an input shell, a small bevel gear, a large bevel gear, a through shaft, a shaft sleeve, a radial bearing, an output fork frame II, a locking nut, a brake spring, a brake block, a brake fixed sleeve, a friction plate set, an inner gear frame, a second rolling bearing, a bearing shaft sleeve, a third rolling bearing, a main transmission shaft, a sun wheel shaft, a planet wheel, a planet carrier, a right end cap, a vent plug, a high-pressure oil injection port, a small end cap, a left end cap, a rack installing hole, wheel installing screw holes and a high-pressure oil cavity. According to the shaft tapered-tooth planet wheel side reducer with the brake, the through shaft tapered-tooth planet combined reducer is adopted, power of an engine or a motor can be input through the transmission shaft, and the axial size of the reducer is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

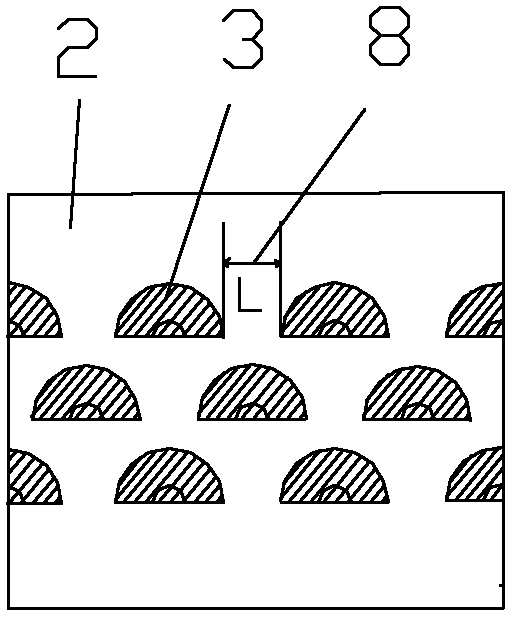

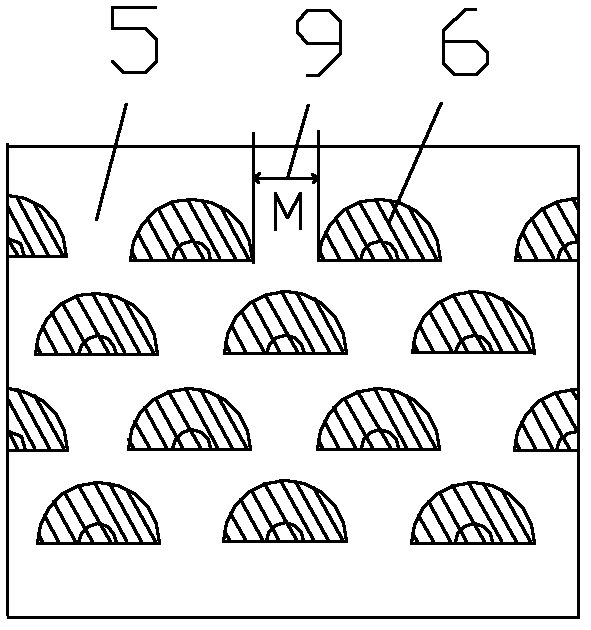

Special crusher for waste casting iron pieces

The invention discloses a special crusher for waste casting iron pieces, comprising a rack, a fixed jaw plate, a swinging shaft, a movable jaw plate, a hydraulic cylinder, semi-cylindrical conical teeth I and semi-cylindrical conical teeth II, wherein three rows of semi-cylindrical conical teeth I are arranged in parallel from top to bottom on the fixed jaw plate; and a gap L with same size is arranged between every two rows of semi-cylindrical conical teeth I. Four rows of same semi-cylindrical conical teeth II are arranged in parallel from top to bottom on the movable jaw plate; and a gap with same size is arranged between every two rows of semi-cylindrical conical teeth II. When the movable jaw plate and the fixed jaw plate of the crusher are meshed, the four rows of semi-cylindrical conical teeth II on the movable jaw plate and the three rows of semi-cylindrical conical teeth I on the fixed jaw plate are arranged horizontally at intervals. The invention provides the special crusher for the waste casting iron pieces, which has the functions of extrusion and shearing. According to the crusher, the branch-shaped waste casting iron pieces formed by casting heads and runners and the like can be quickly and effectively extruded and sheared into small casting iron blocks; and since the small casting iron blocks are arranged closely in an electric induction furnace, the occupied space is small, the melting can be quick and the power consumption is lower.

Owner:KEHUA HLDG

Vehicle placement plate for stereo parking garage

The invention discloses a vehicle placement plate for a stereo parking garage. The vehicle placement plate comprises a supporting column. The bottom of the right side of the supporting column is fixedly connected with a bearing plate. Through holes are formed in the two sides of the top of an inner cavity of the bearing plate correspondingly. The left side of the bottom of the inner cavity of thebearing plate is fixedly connected with a positive and negative rotating motor. The right side of the a rotating shaft of the positive and negative rotating motor is fixedly connected with a driving shaft through a coupling. The right side of the surface of the driving shaft is sleeved with driving tapered teeth. Through arrangement and cooperative use of protruding blocks, the positive and negative rotating motor, the driving shaft, the driving tapered teeth, a movable shaft, driven tapered teeth, through holes, a supporting plate, a threaded sleeve, screw teeth, connecting rods and a slidinggroove, a car on the surface of the bearing plate can be effectively limited, in this way, the car is effectively protected, and the problem that when the car is placed on the surface of the bearingplate, the bearing plate is not provided with a wheel limiting device, and consequently, the car falls off from the surface of the bearing plate is solved.

Owner:陈燕飞

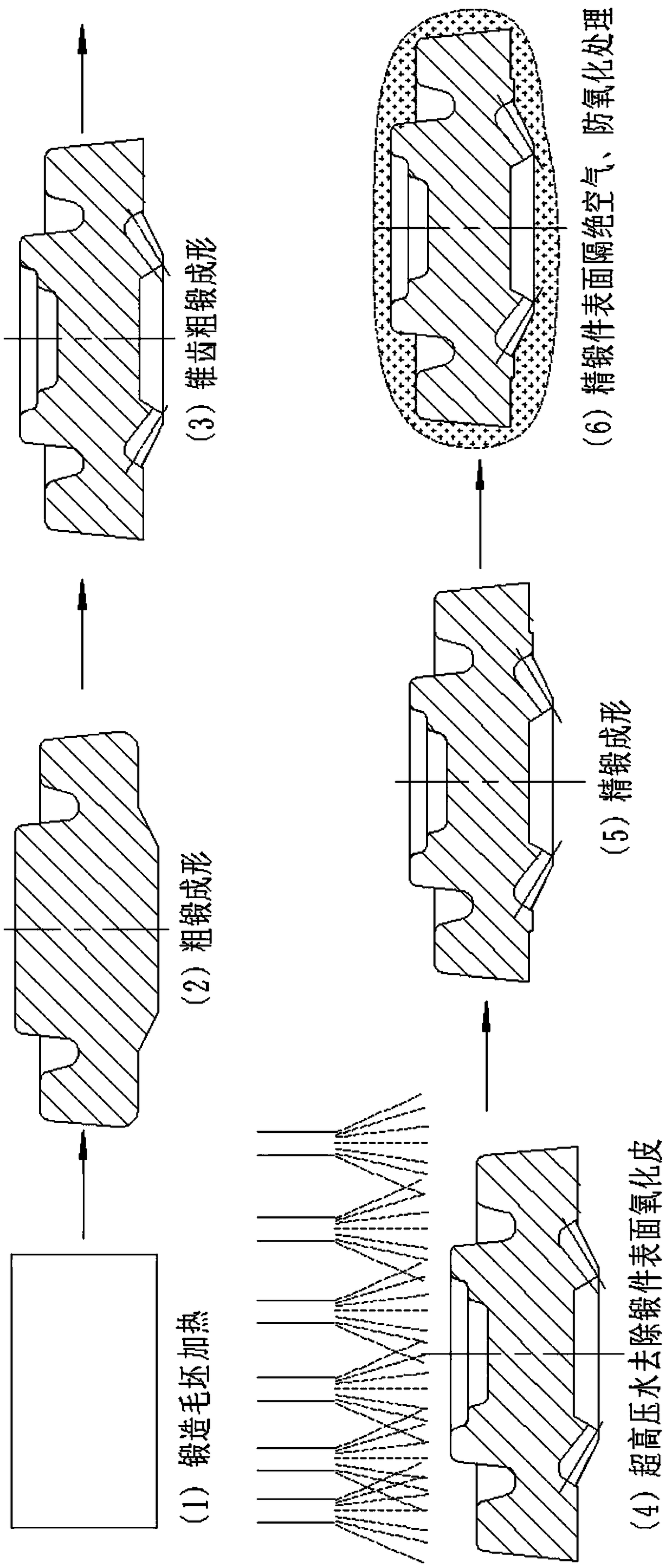

Triple-gear process of one-time heating continuous forging precision forming through bridge

InactiveCN109351897AShorten the timeEliminate surface defectsForging/hammering/pressing machinesCleaning using liquidsIntermediate frequencyWear resistance

The invention relates to a triple-gear process of a one-time heating continuous forging precision forming through bridge. The triple-gear process is characterized by comprising the following processing steps in sequence: (1) heating forging blanks: heating the forging blanks to the pre-forging temperature of 1040 DEG C to 1060 DEG C in an intermediate frequency furnace; (2) performing rough forging and forming; (3) performing rough forging and forming tapered teeth; (4) removing surface scale from forgings with superhigh-pressure water; (5) performing finish forging and forming: performing finish forging and forming the shapes of the tapered teeth so as to prepare finish forgings, wherein no machining is needed in the next step; and (6) isolating the surfaces of the finish forgings from air, and performing anti-oxidation treatment: covering the surfaces of the finish forgings with silver sand, and isolating the surfaces of the finish forgings from outside air, so that the finish forgings are prevented from being oxidized. The triple-gear process has the advantages of one-time heating, water recycling, water conservation, scale removal, good wear resistance, good finish forging andforming quality of the shapes of the tapered teeth, air oxidation resistance of forgings, good forging forming quality, high precision, high production efficiency, material saving, low production cost, energy conservation and long service life. The triple-gear process can be widely applied to wheeled vehicles.

Owner:QINGDAO THREE STAR PRECISION FORGING GEAR

Drying device for feed

InactiveCN110307696AShorten drying timeAddressing palatability issuesSievingDrying solid materials with heatEngineeringExchange time

The invention discloses a drying device for feed, and belongs to the technical field of drying devices. The drying device for the feed comprises a drying box and a smashing box, wherein support pillars are arranged between the drying box and the smashing box for supporting the drying box and the smashing box, the bottom of the drying box communicates with the top of the smashing box through a transition tube, a filter screen is arranged in the drying box, a sleeve is arranged above the filter screen, tapered teeth are arranged on the inner wall of the sleeve, a vibration assembly and a pull rod are respectively arranged below the filter screen, and the sleeve is arranged at the top of the drying box. The drying device for the feed dries the feed through vibration, shortens heat exchange time, and meanwhile avoids excess drying and blowing-away phenomena in production of small granule products, and guarantees quality of the feed.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com