Method for checking tooth root interference of spiral bevel gears

A technology of spiral bevel gear and inspection method, which is applied in the field of gear transmission and can solve problems such as interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

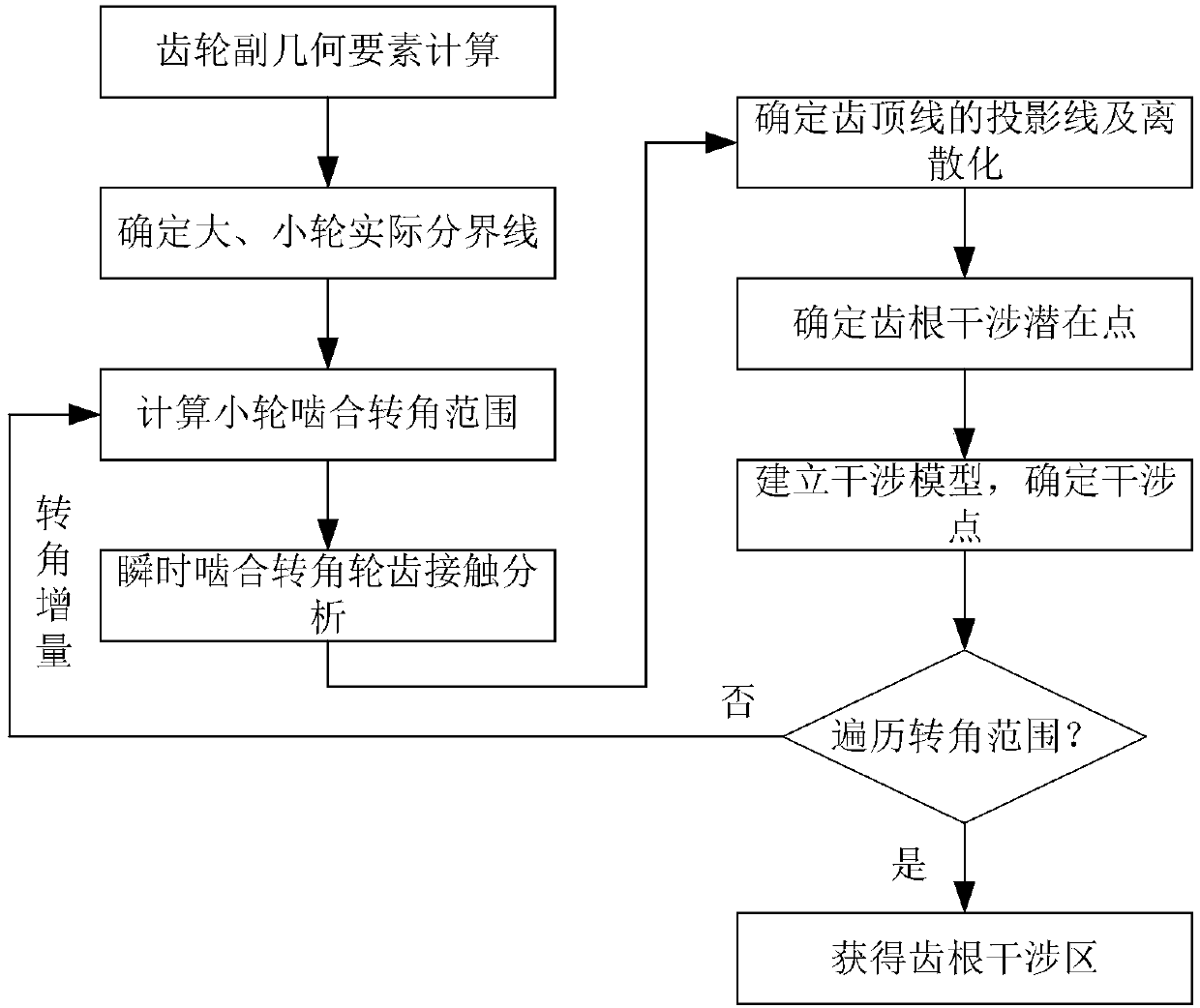

[0045] Such as figure 1 Shown, the inspection method of spiral bevel gear dedendum interference of the present invention, concrete steps:

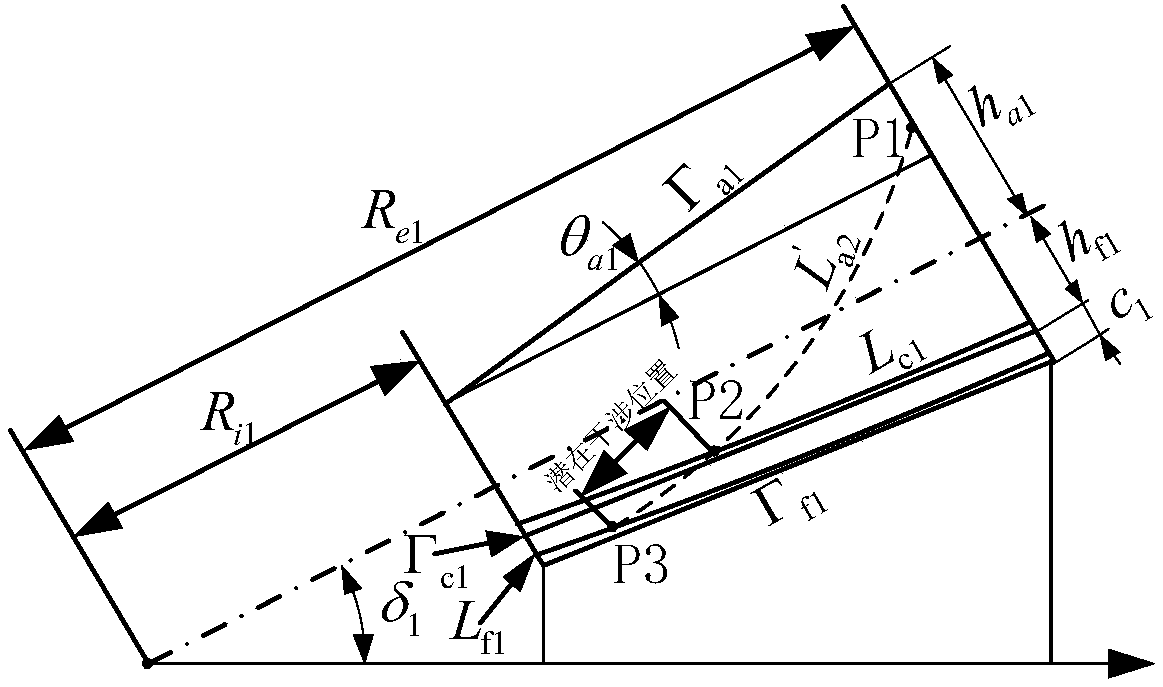

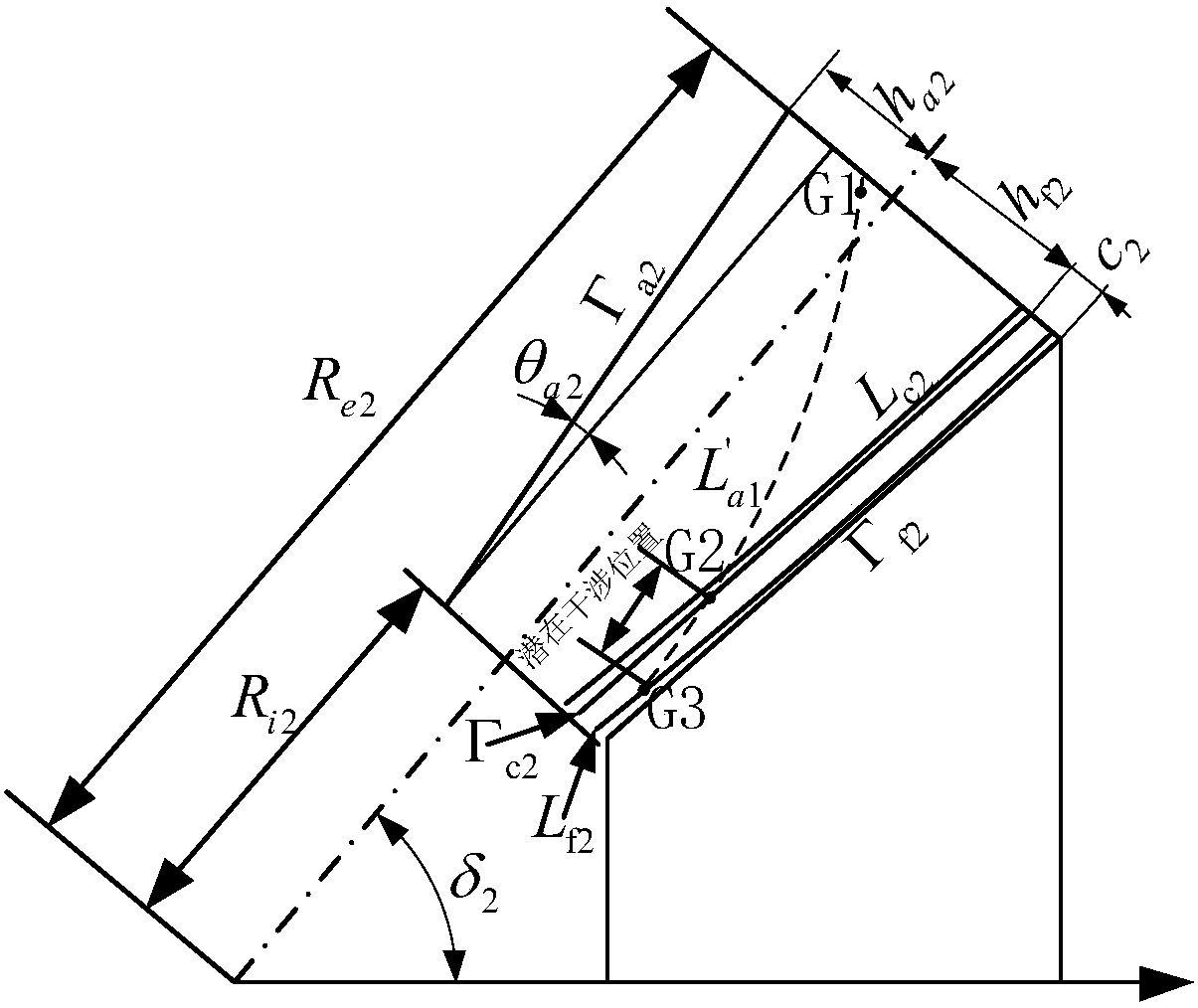

[0046] (1) The basic parameters of the spiral bevel gear pair include the height of the outer end addendum, the height of the outer end dedendum, the root cone angle, the pitch cone angle, the face cone angle, the top clearance, the tooth width, the outer cone distance and the inner cone distance, according to The above geometric parameters calculate the inner bevel addendum height, inner bevel dedendum height, design dedendum line Γ f and the design boundary Γ c , and express these contour elements on the rotation projection surface of the gear teeth, and determine the relative positional relationship of each geometric element.

[0047] (2) According to the machine tool adjustment parameters and tool parameters of the bevel gear pair, especially the tool fillet parameters, with the help of the gear space meshing principle and coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com