Patents

Literature

250 results about "Geometric element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A geometric element is an element in space (plane, line, point, or a combination of these) about which a symmetry operation is performed. Geometric elements are classified on the basis of the dimensionality N of the space on which they act, the upper limit on the dimensionality of the symmetry element being N -1. In...

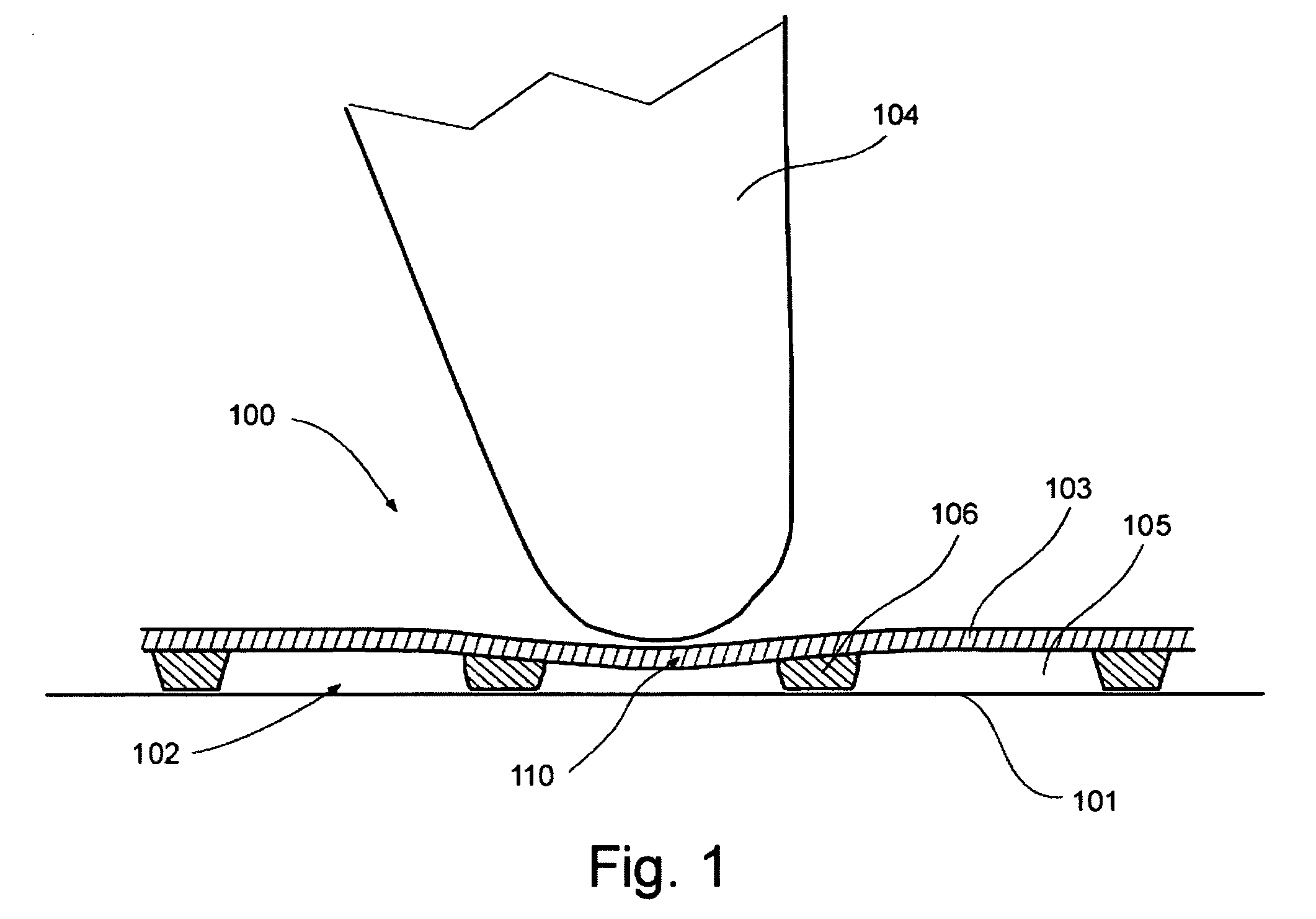

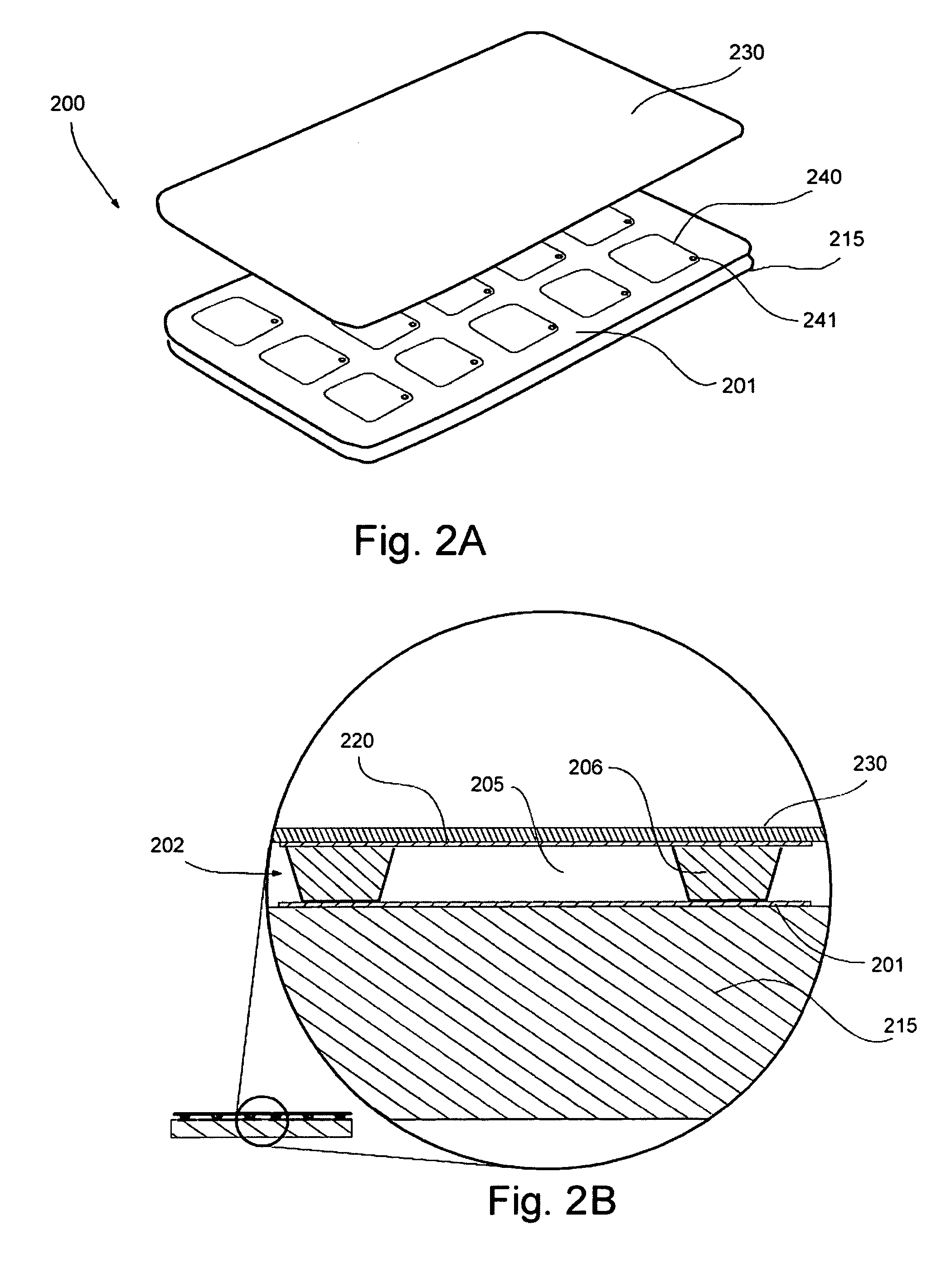

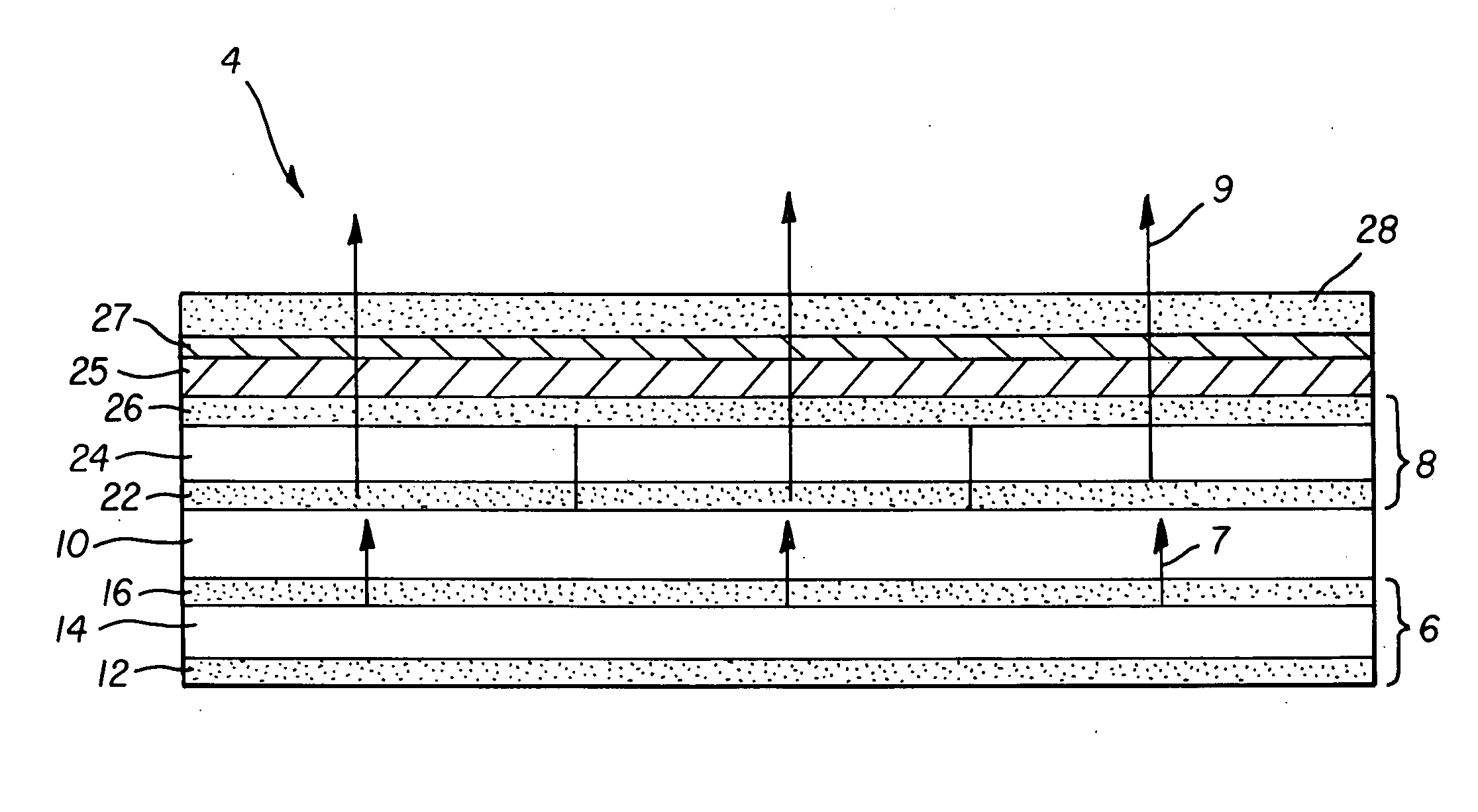

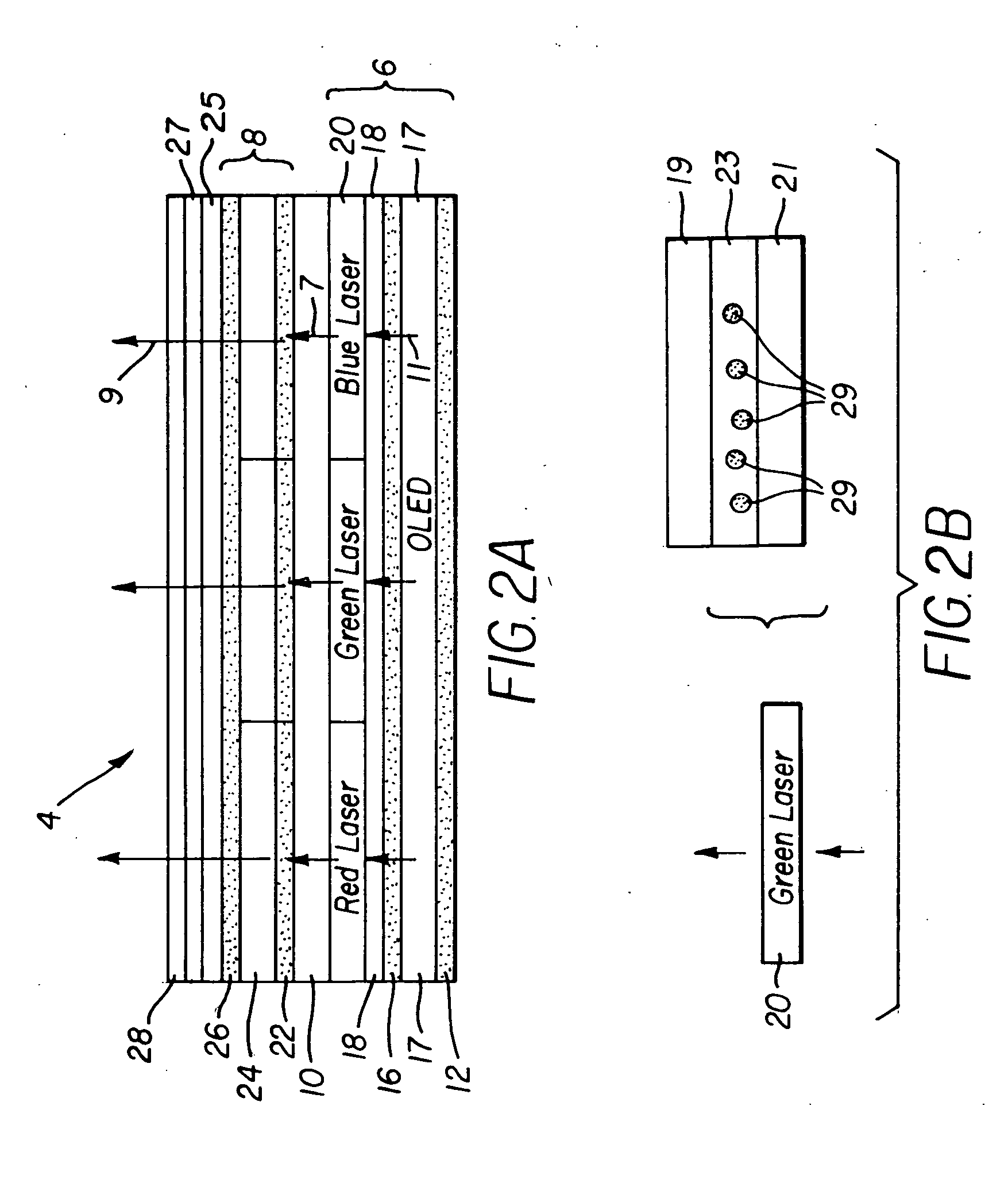

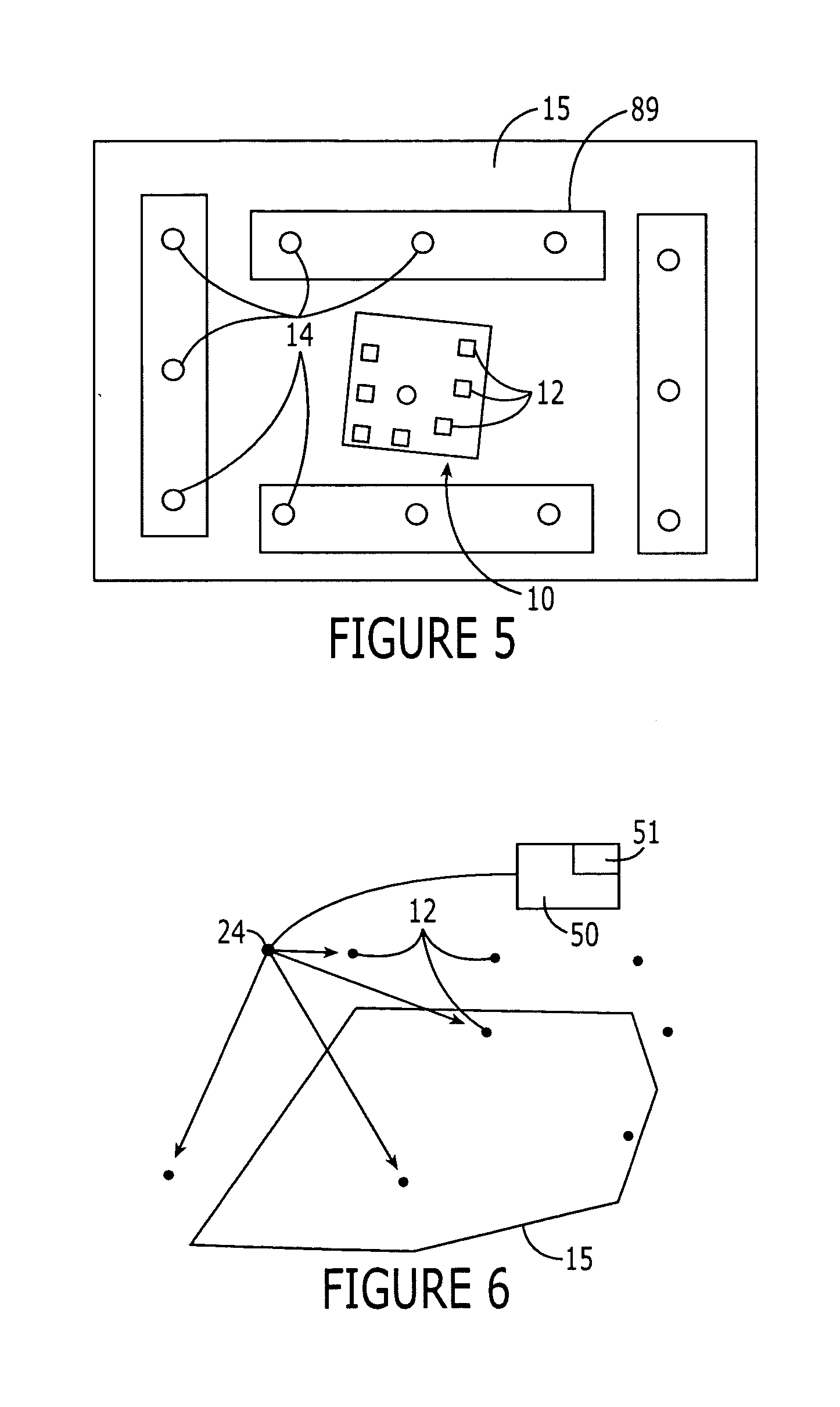

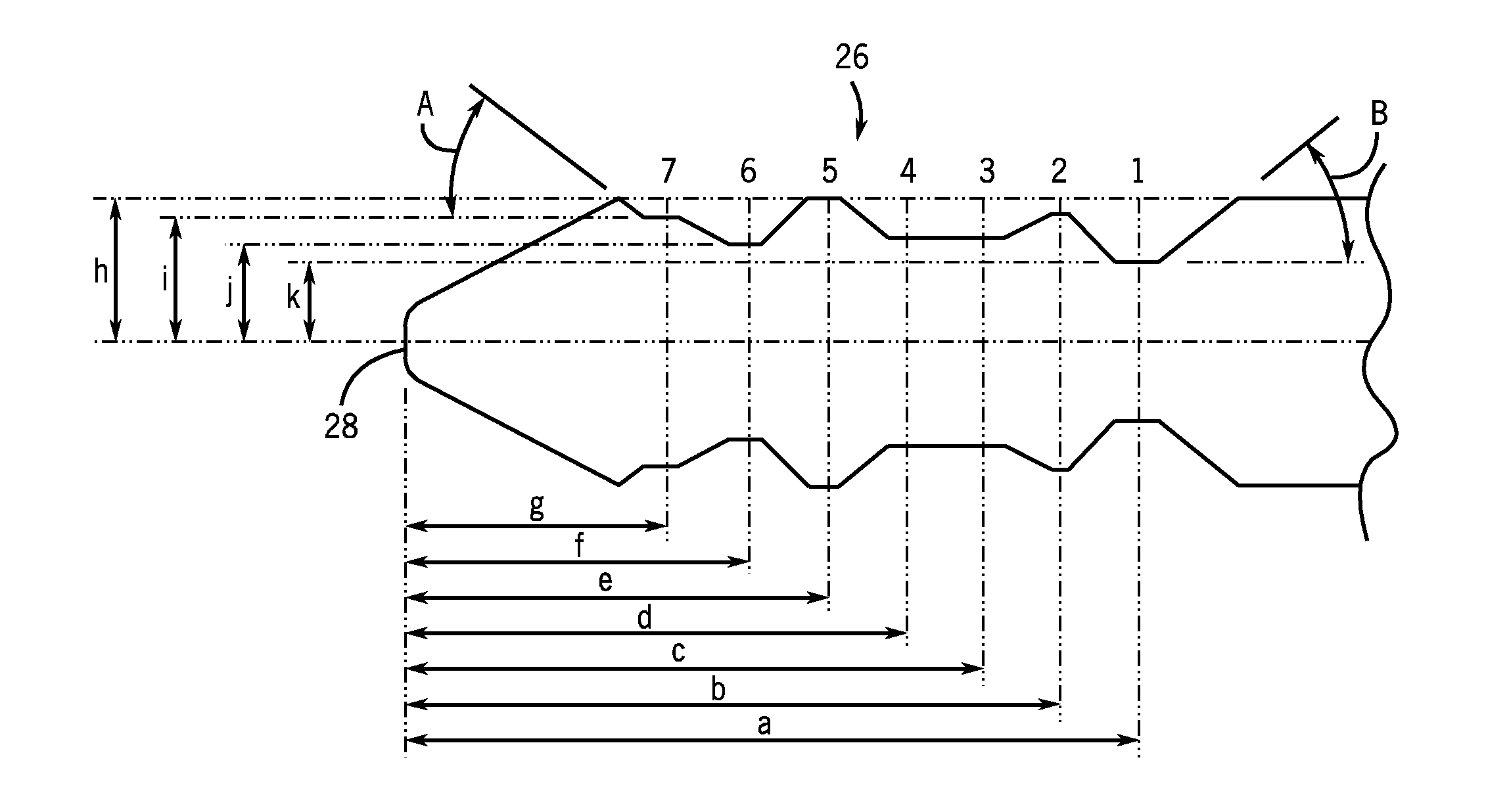

Reconfigurable tactile sensor input device

InactiveUS20070257821A1Low production costSmall sizeInput/output for user-computer interactionElectronic switchingCapacitanceDisplay device

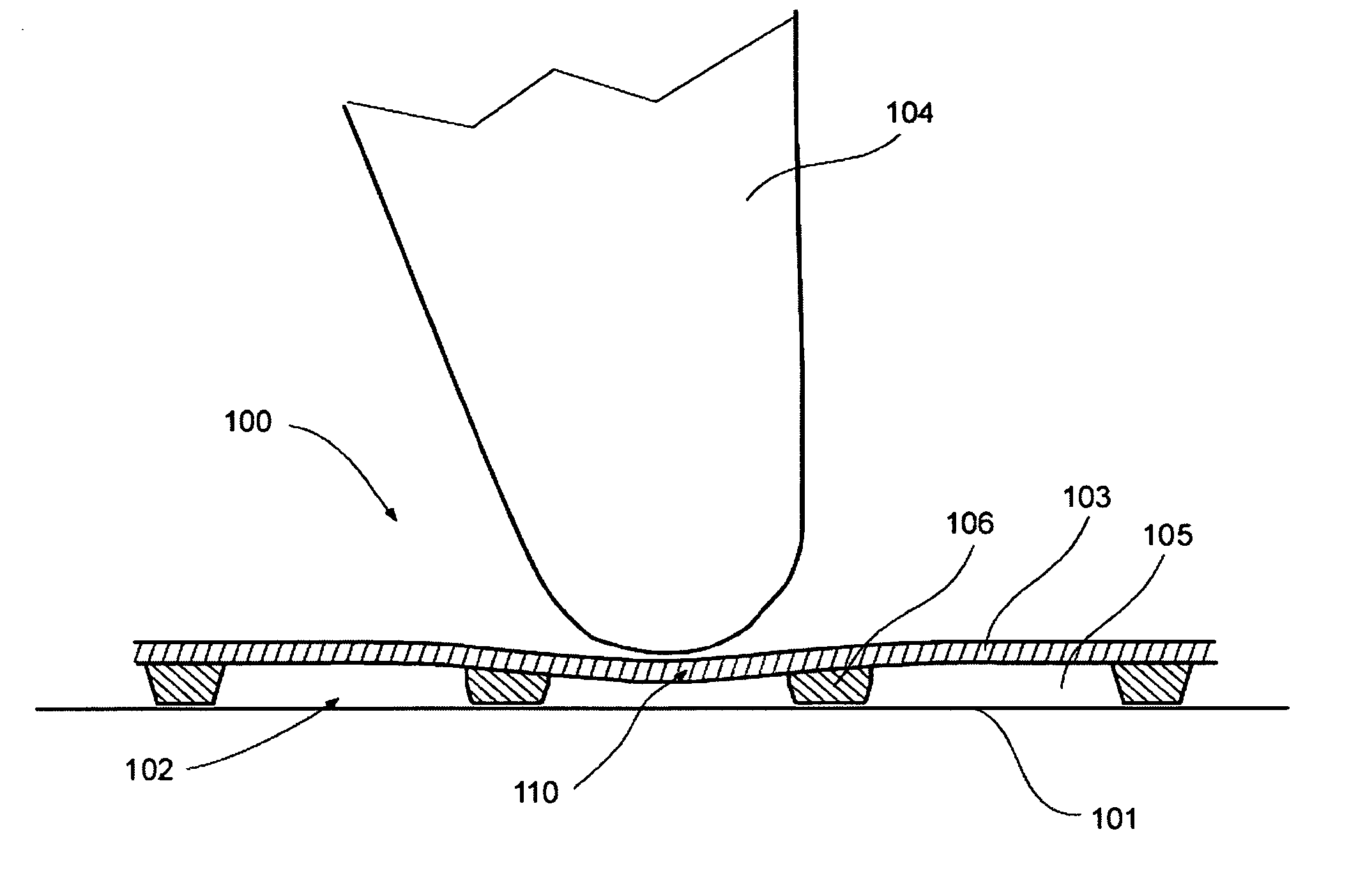

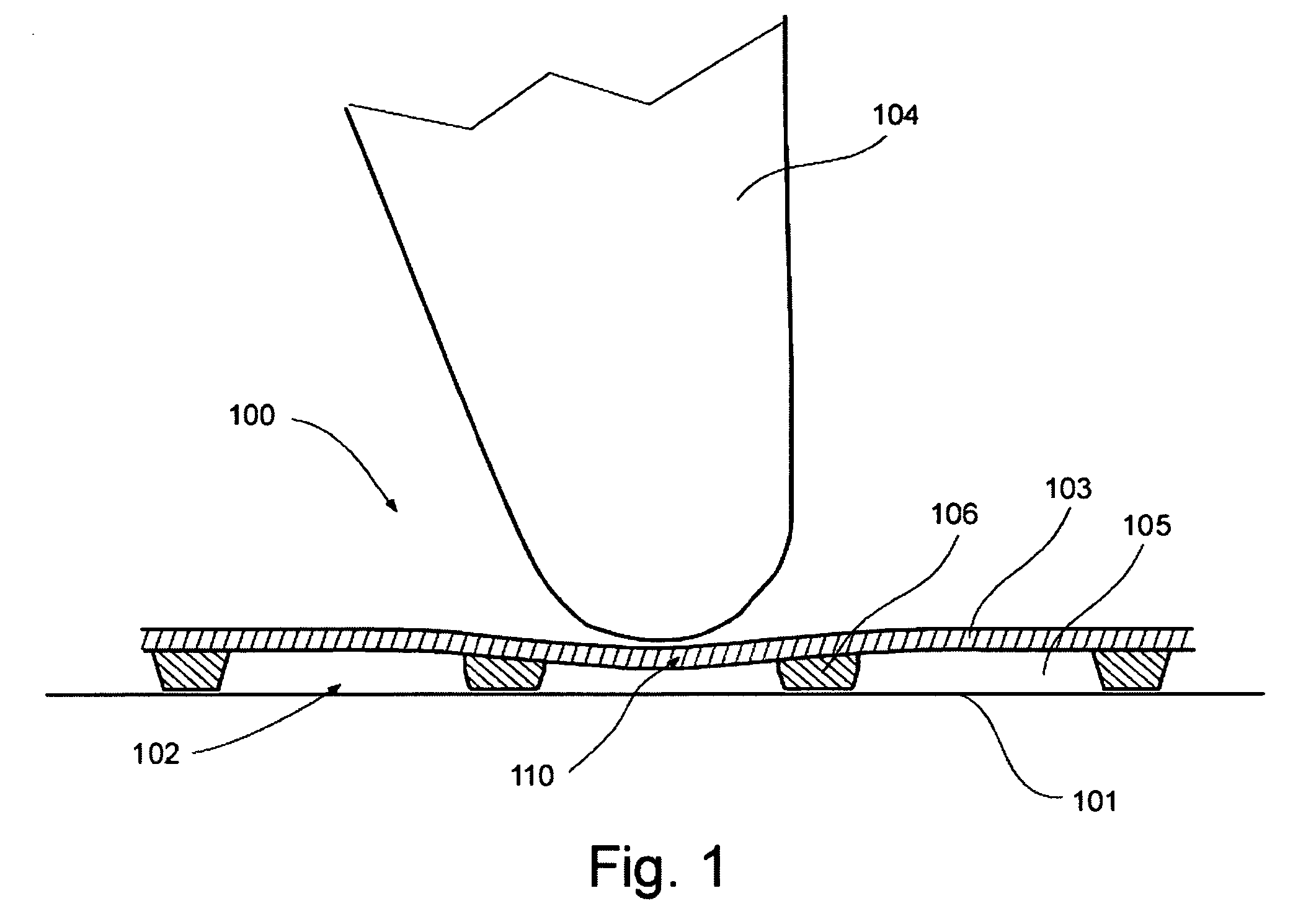

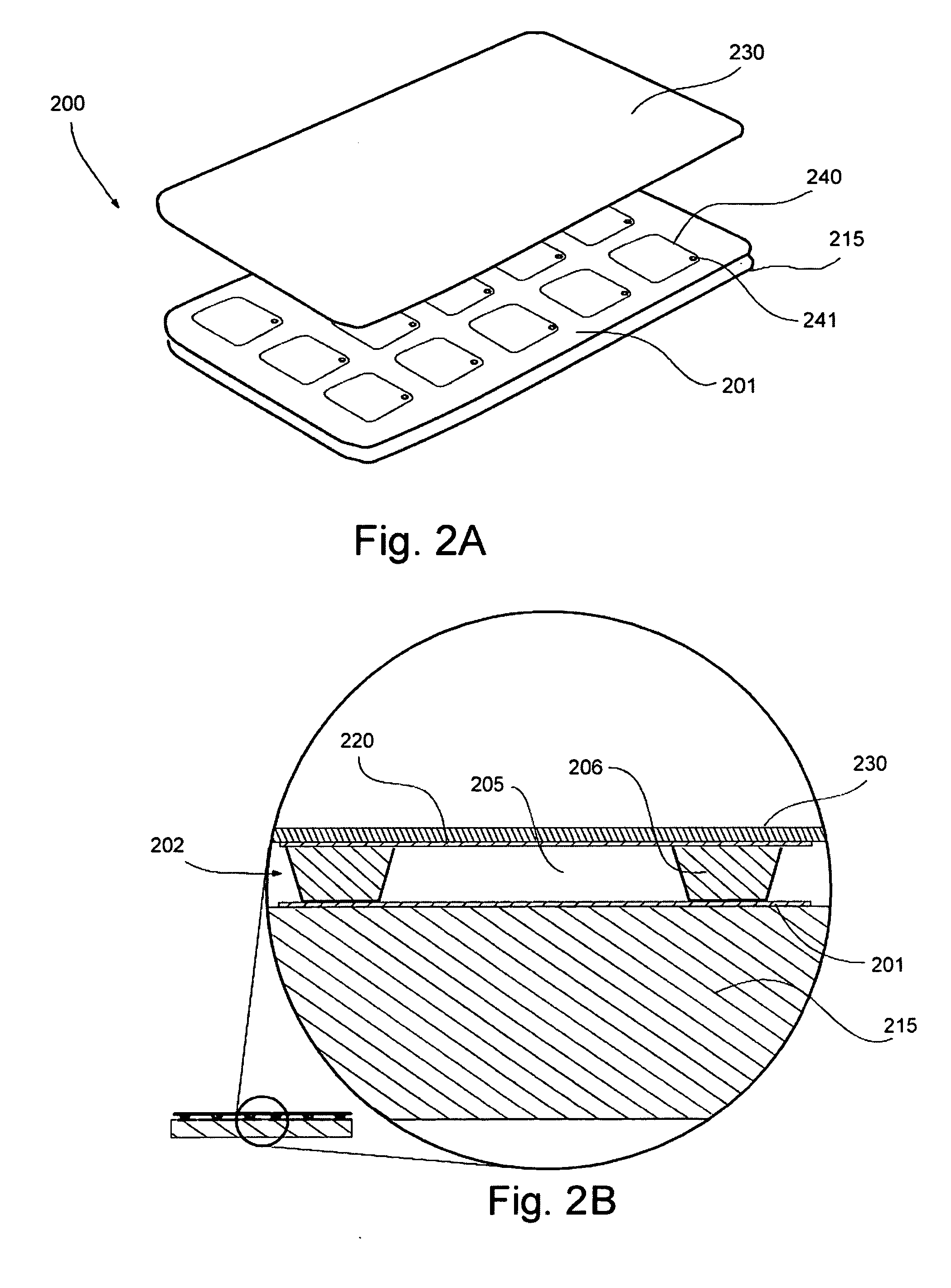

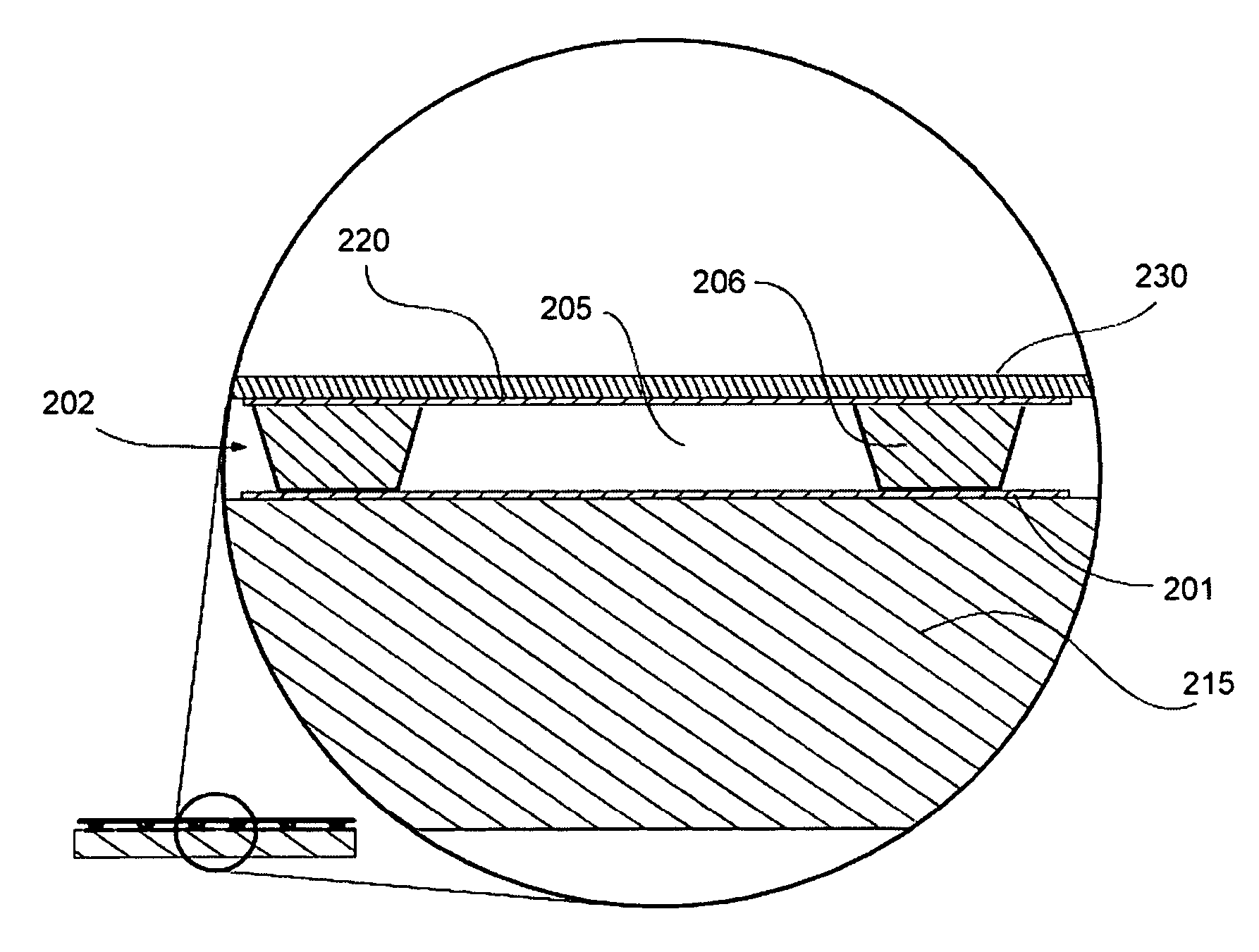

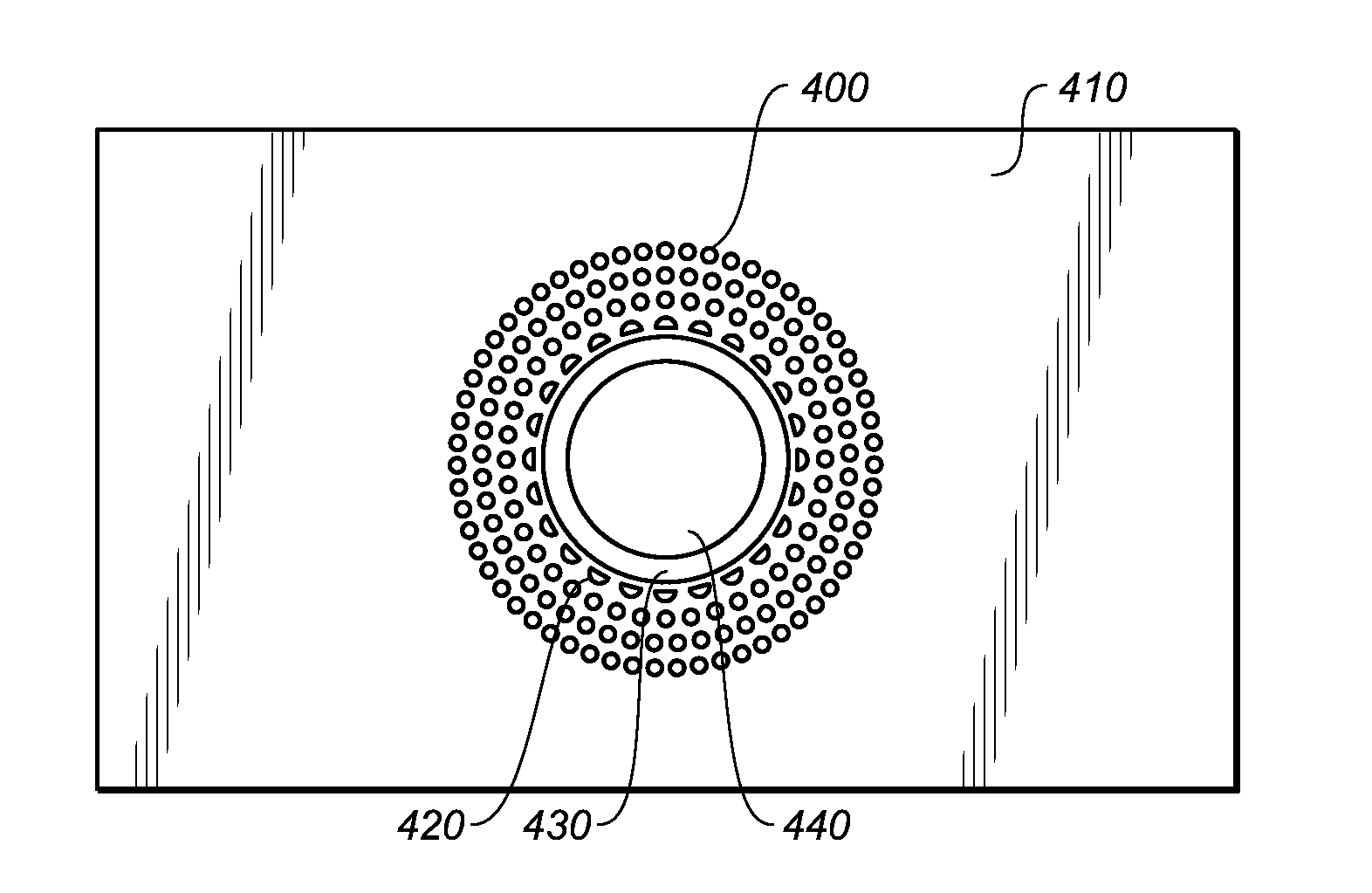

A reconfigurable tactile input device includes a first rigid electrode layer, a compressible dielectric structure, and a second flexible electrode layer forming together a tactile sensor with appropriate electrode connection means to a control means. The control means may include a mixed-signal IC mounted next to the input device in a compact package and capable of measuring capacitance in real time. The dielectric structure may include a matrix of compressible geometric elements with voids therebetween optionally vented to atmosphere, making the entire assembly thin and facilitating its use for mobile phones and other small, portable electronic devices. Some embodiments provide the user wit tactile feedback upon compression of the electrodes. An optional flexible display may be mounted over the input device to indicate the present configuration to the user.

Owner:WISETOUCH CO LTD

Reconfigurable tactile sensor input device

InactiveUS7609178B2Low production costSmall sizeInput/output for user-computer interactionElectronic switchingCapacitanceAtmospheric air

A reconfigurable tactile input device includes a first rigid electrode layer, a compressible dielectric structure, and a second flexible electrode layer forming together a tactile sensor with appropriate electrode connection means to a control means. The control means may include a mixed-signal IC mounted next to the input device in a compact package and capable of measuring capacitance in real time. The dielectric structure may include a matrix of compressible geometric elements with voids therebetween optionally vented to atmosphere, making the entire assembly thin and facilitating its use for mobile phones and other small, portable electronic devices. Some embodiments provide the user wit tactile feedback upon compression of the electrodes. An optional flexible display may be mounted over the input device to indicate the present configuration to the user.

Owner:WISETOUCH CO LTD

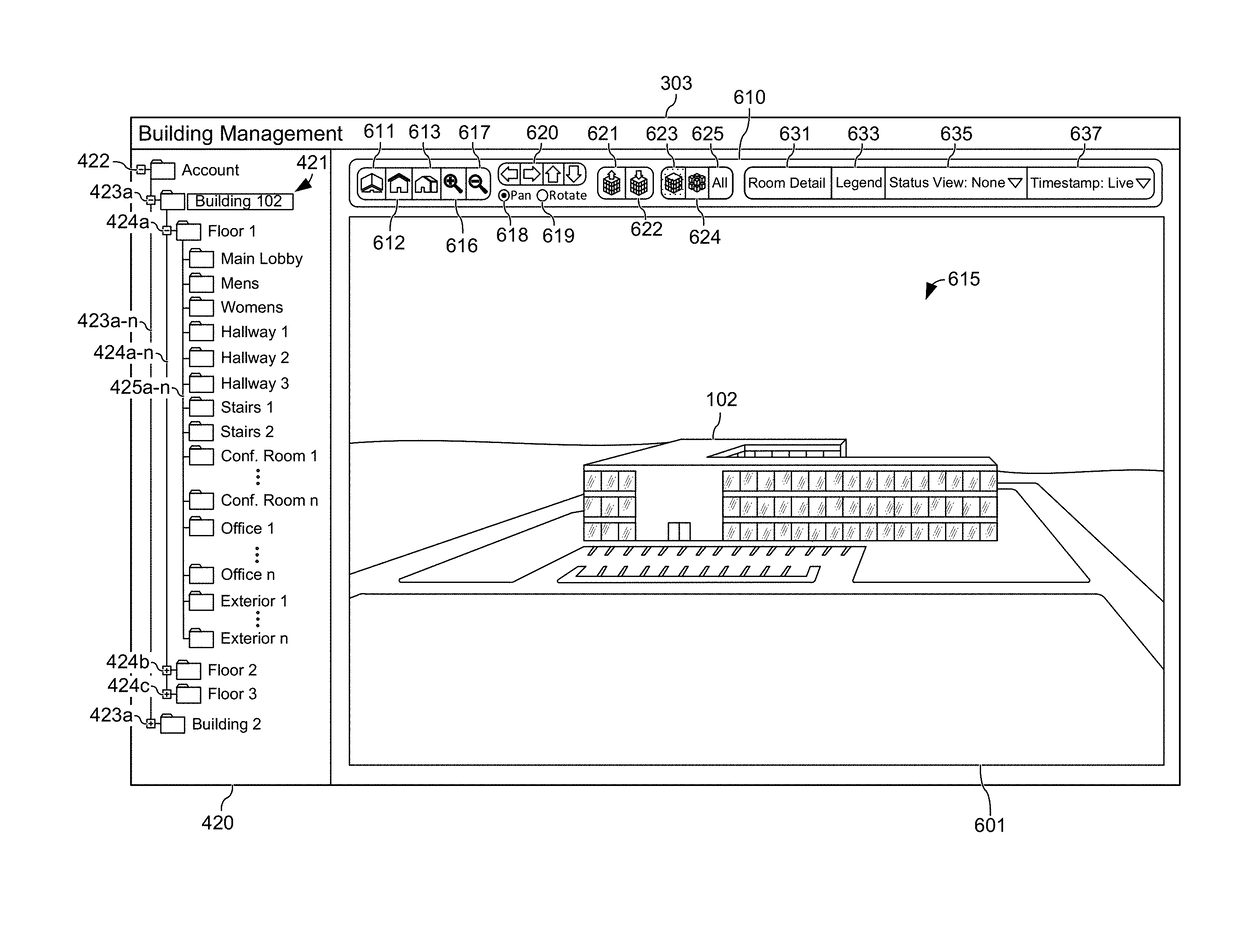

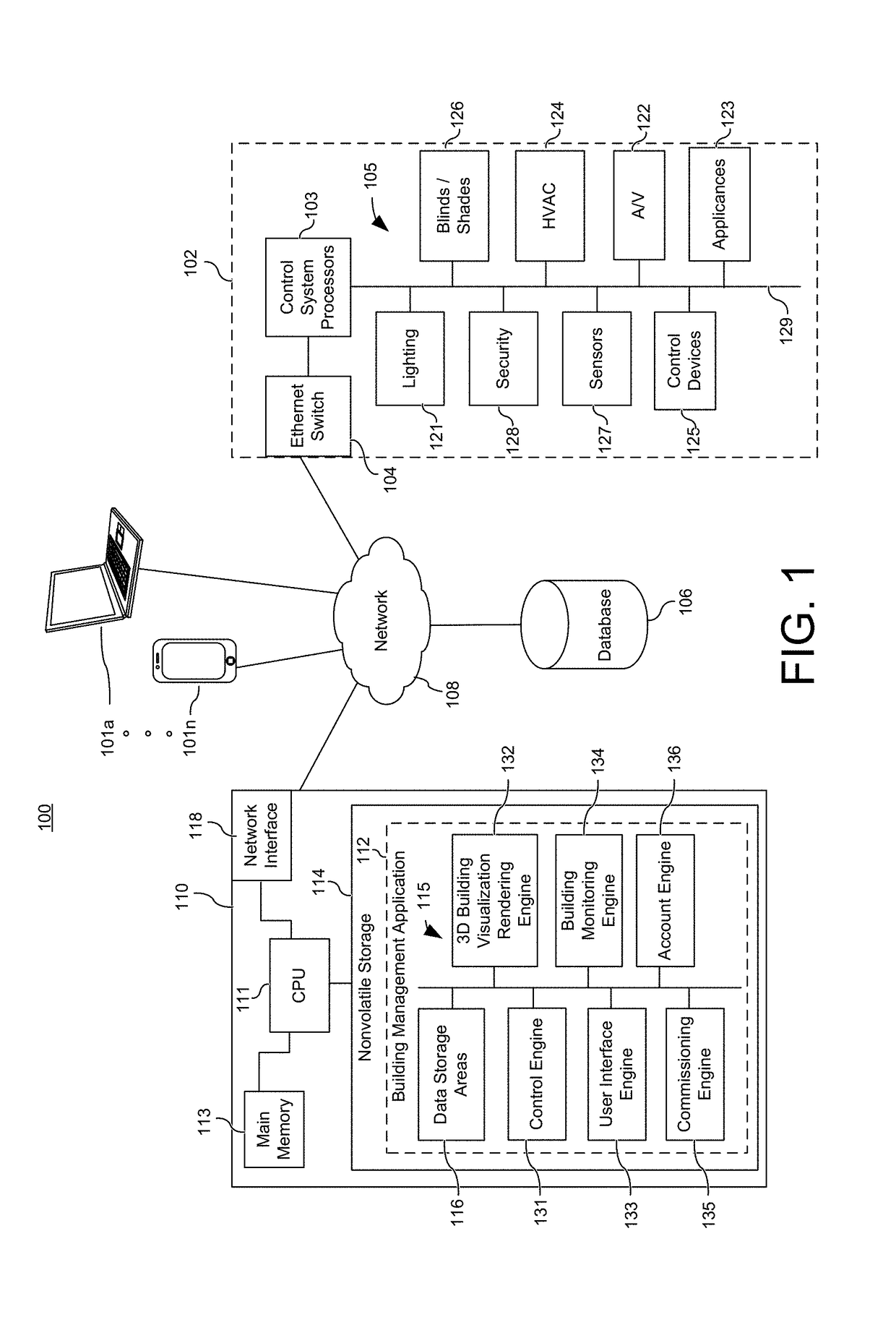

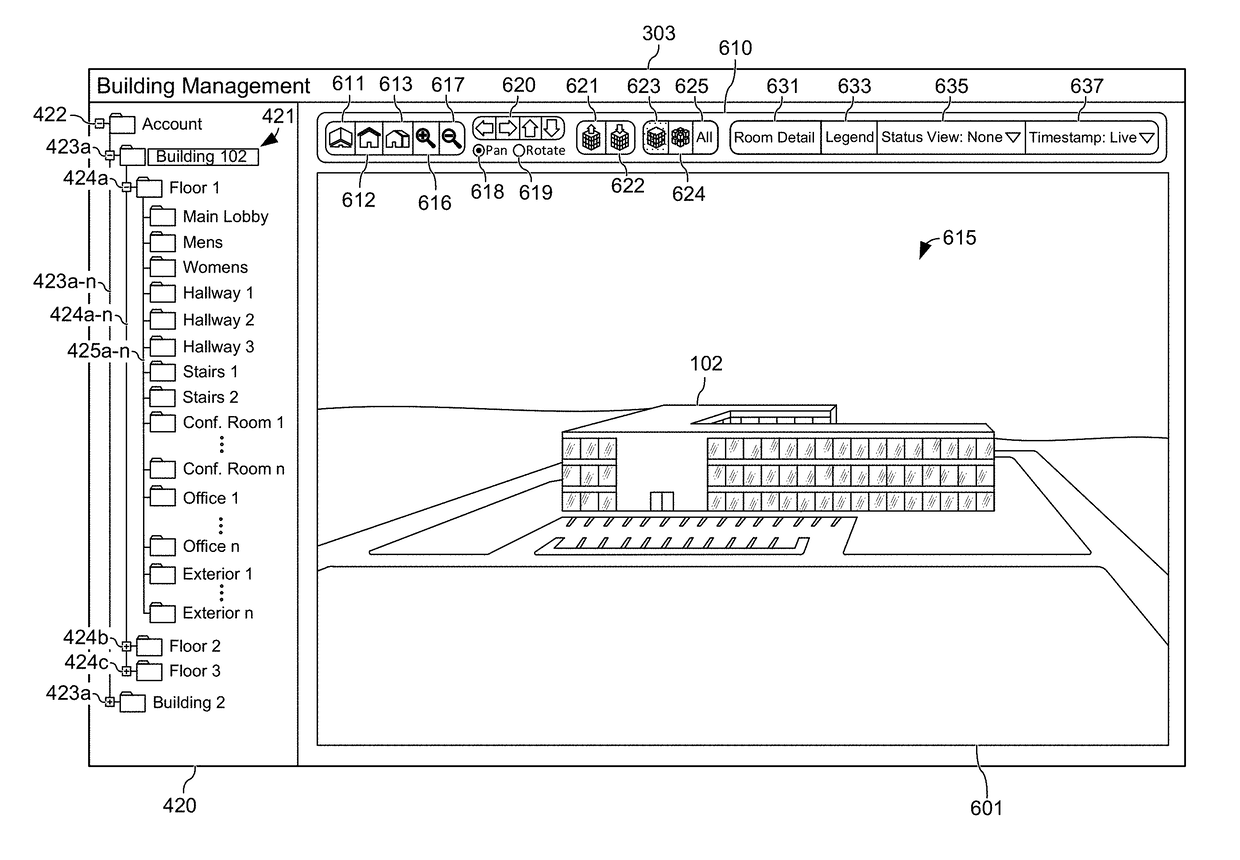

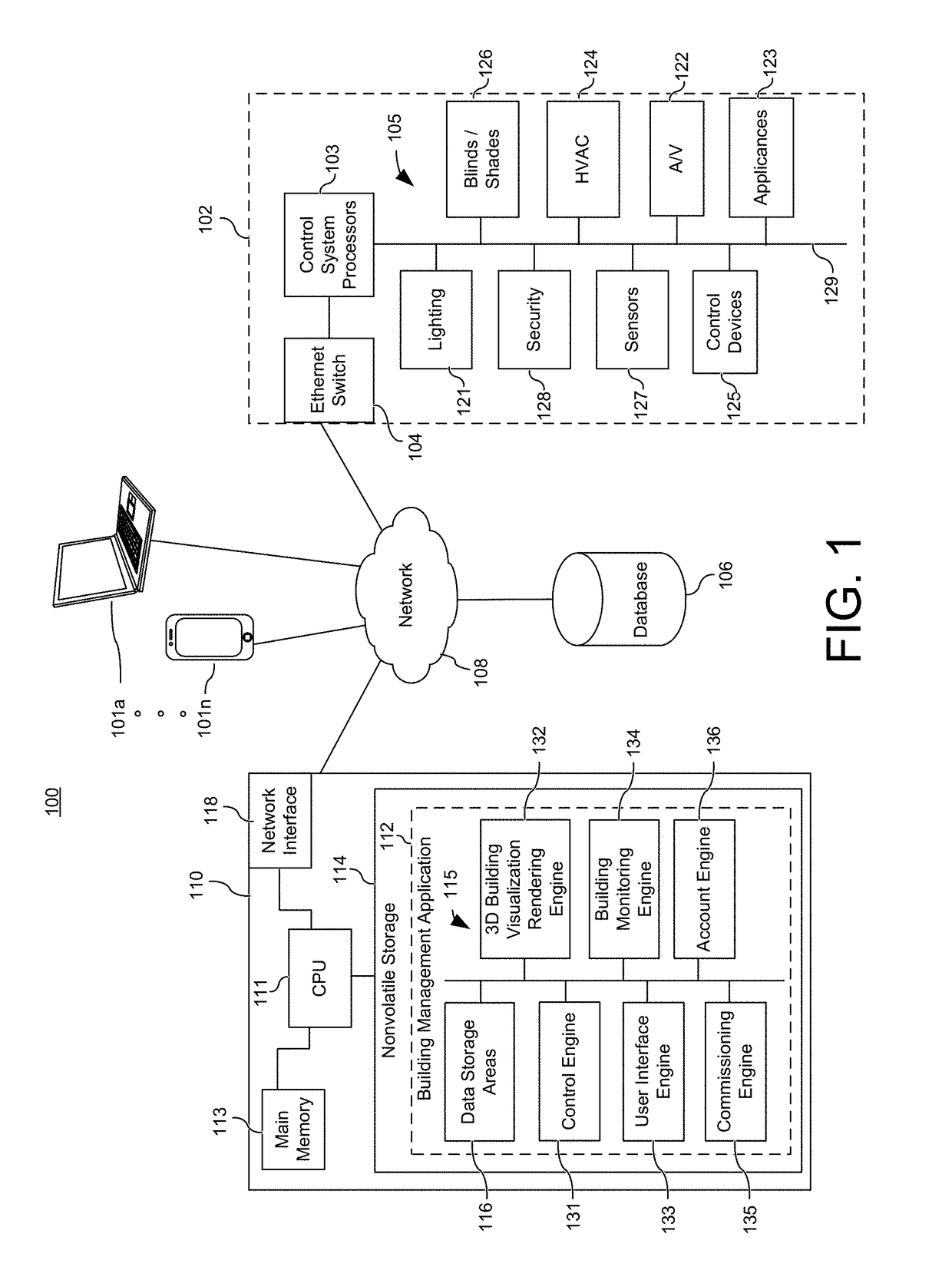

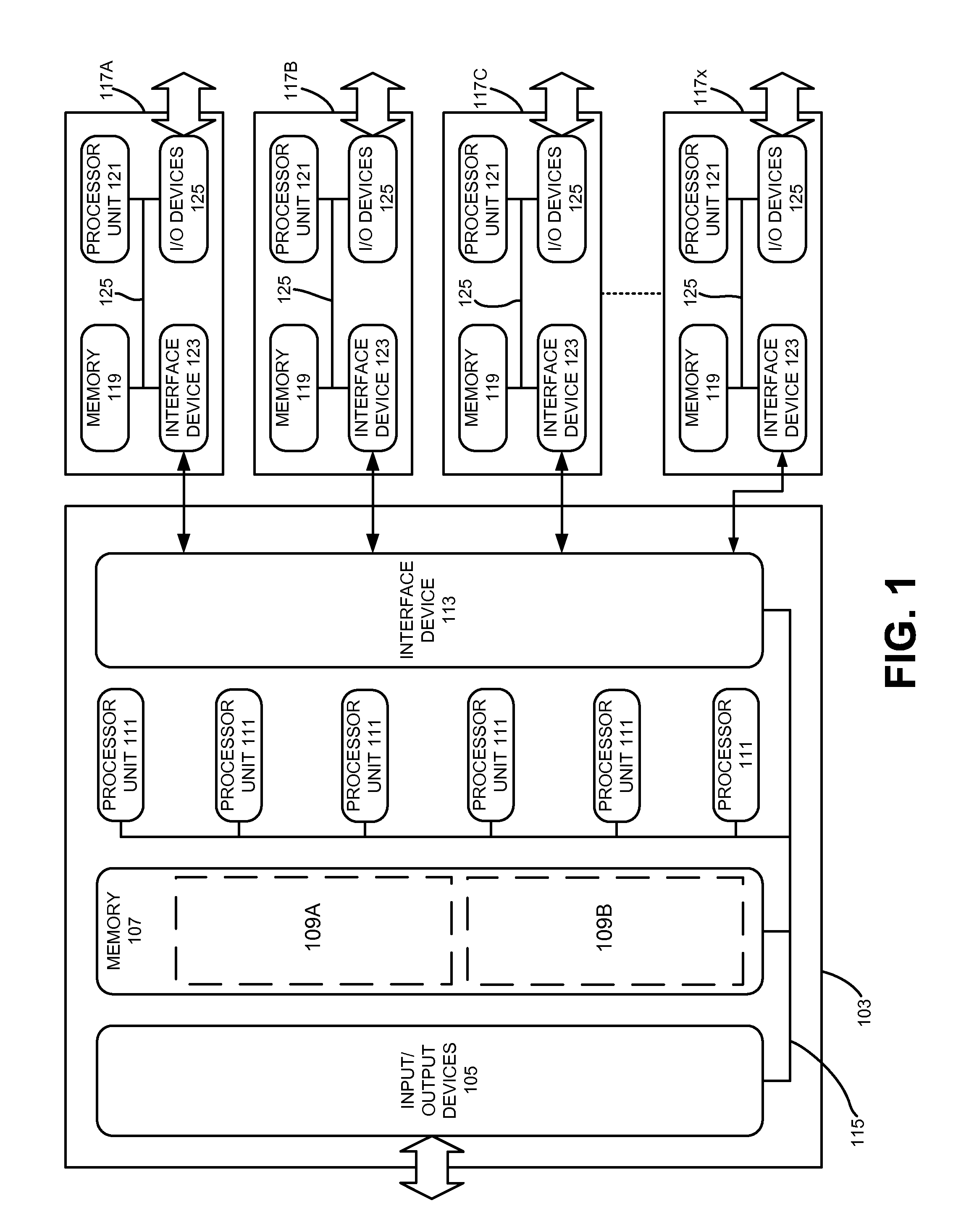

Three-dimensional building management system visualization

ActiveUS20170315697A1Effective for system testing and troubleshootingMany timesGeometric CADMechanical apparatusOperating energyInformation visualization

Systems, methods, and modes for on-demand rendering of a three-dimensional building management system visualization of a building. The system comprises a database configured for storing geometry elements and spatial elements. The geometry elements are mapped to spatial elements, wherein the geometry elements define three-dimensional geometrical representation of a building's structure, and the spatial elements define three-dimensional representation of spaces in the building. The spatial elements are associated with respective space nodes that identify the spaces located within the building, and the space nodes are associated with respective electronic devices installed within the spaces in the building. The system further comprises at least one processor configured for selectively recalling the geometry elements and spatial elements from the database, and rendering a three dimensional building visualization of the building via a user interface, wherein the three-dimensional building visualization comprises a status information visualization of at least one electronic device.

Owner:CRESTRON ELECTRONICS

CAD modeling system and method

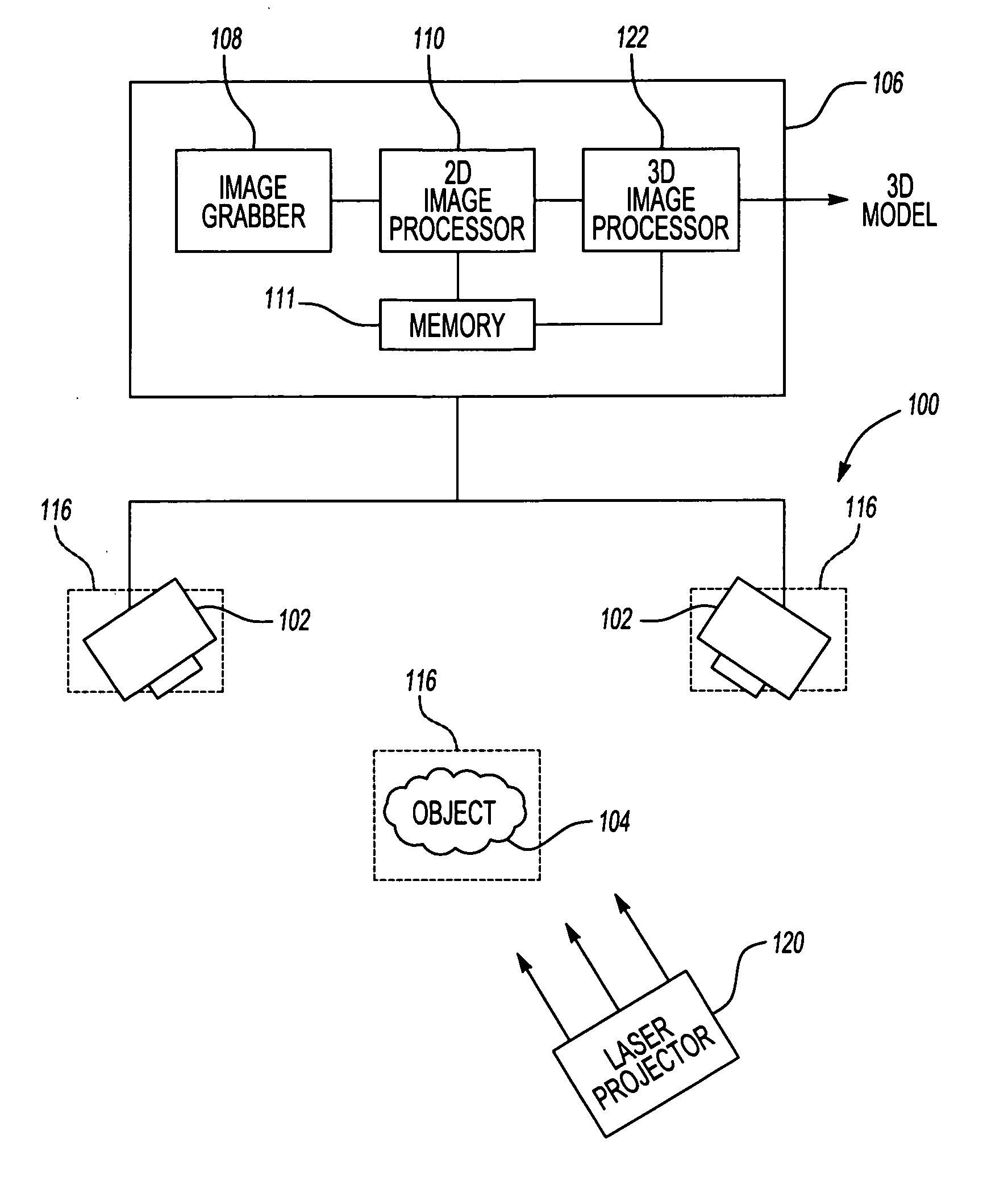

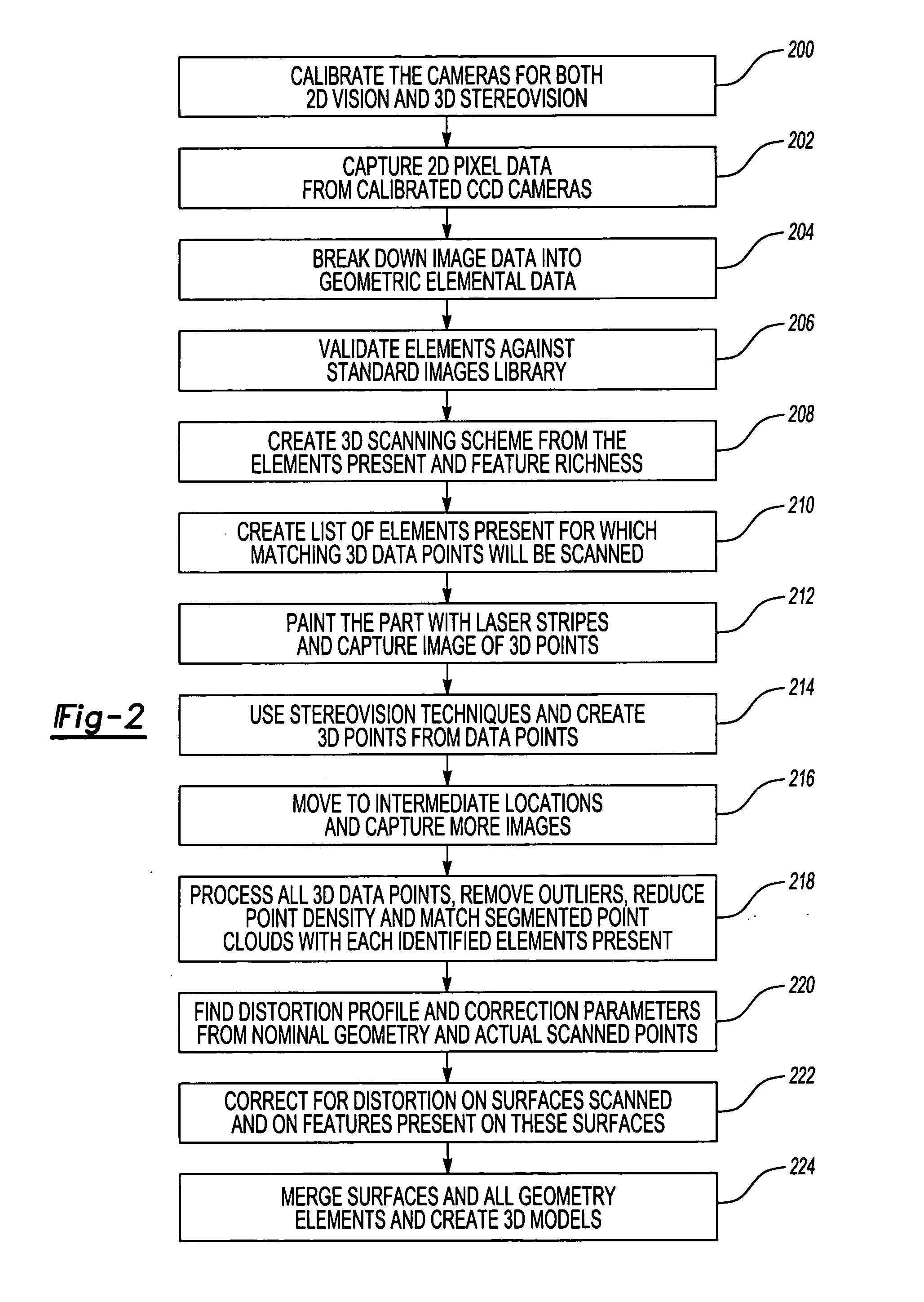

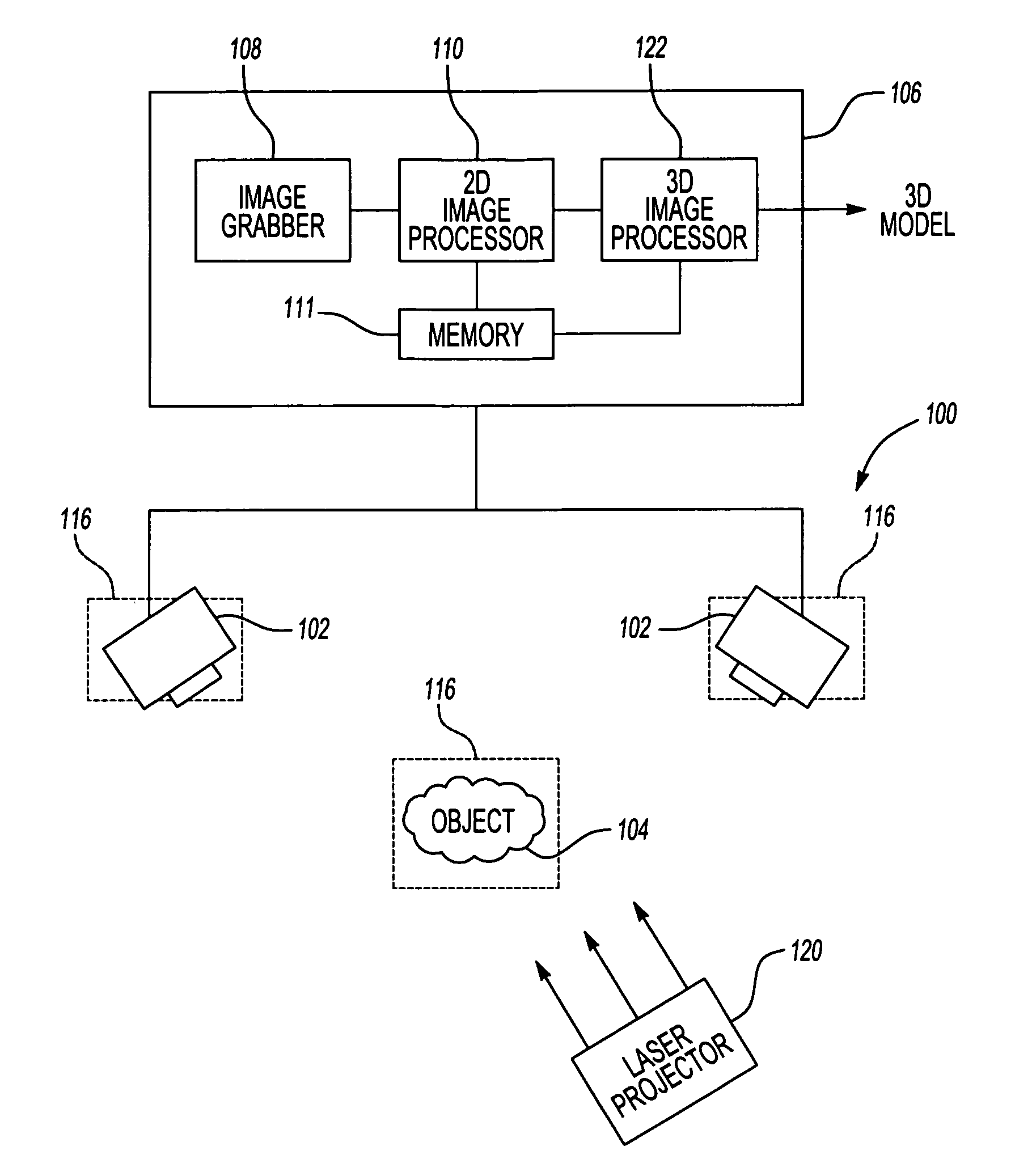

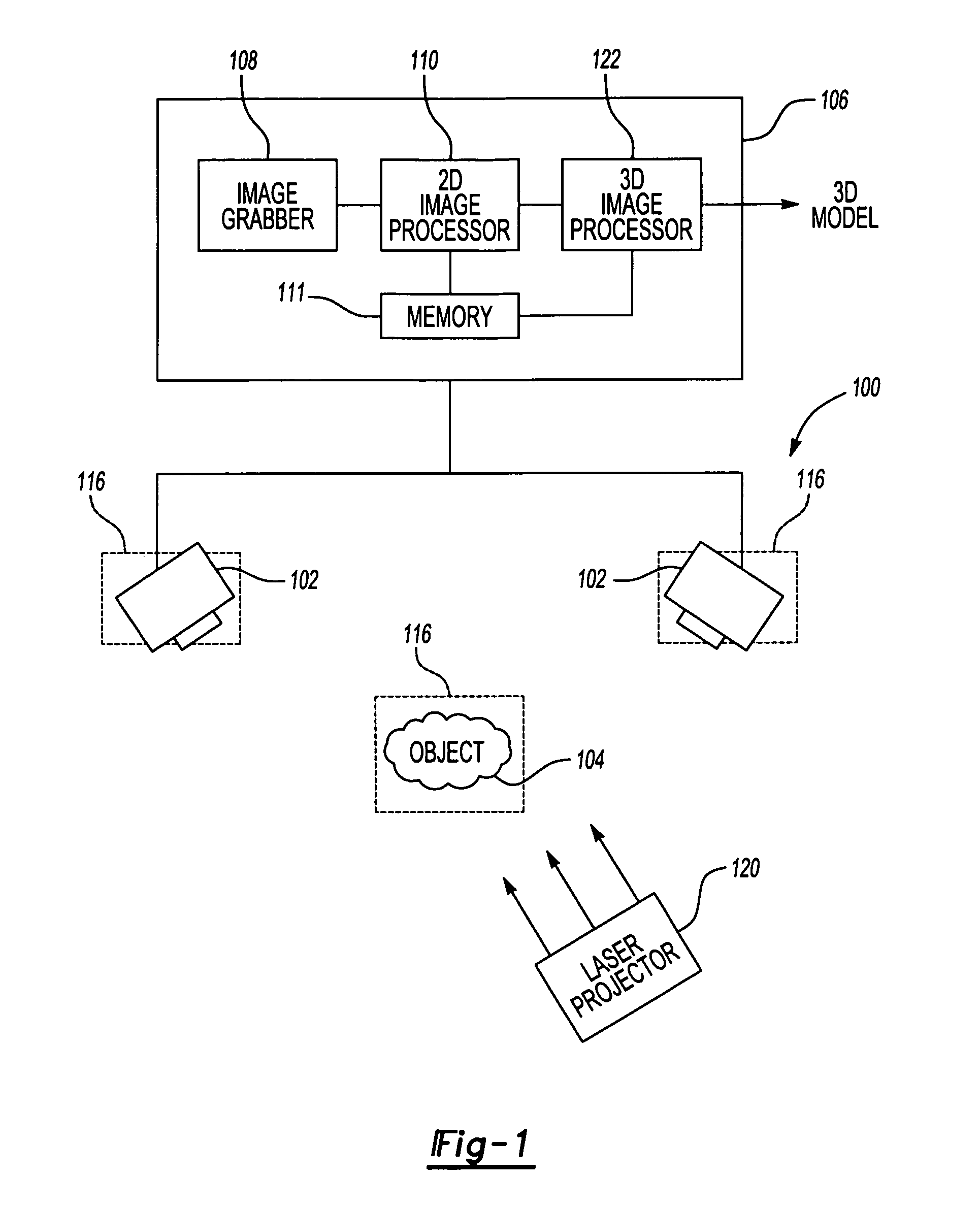

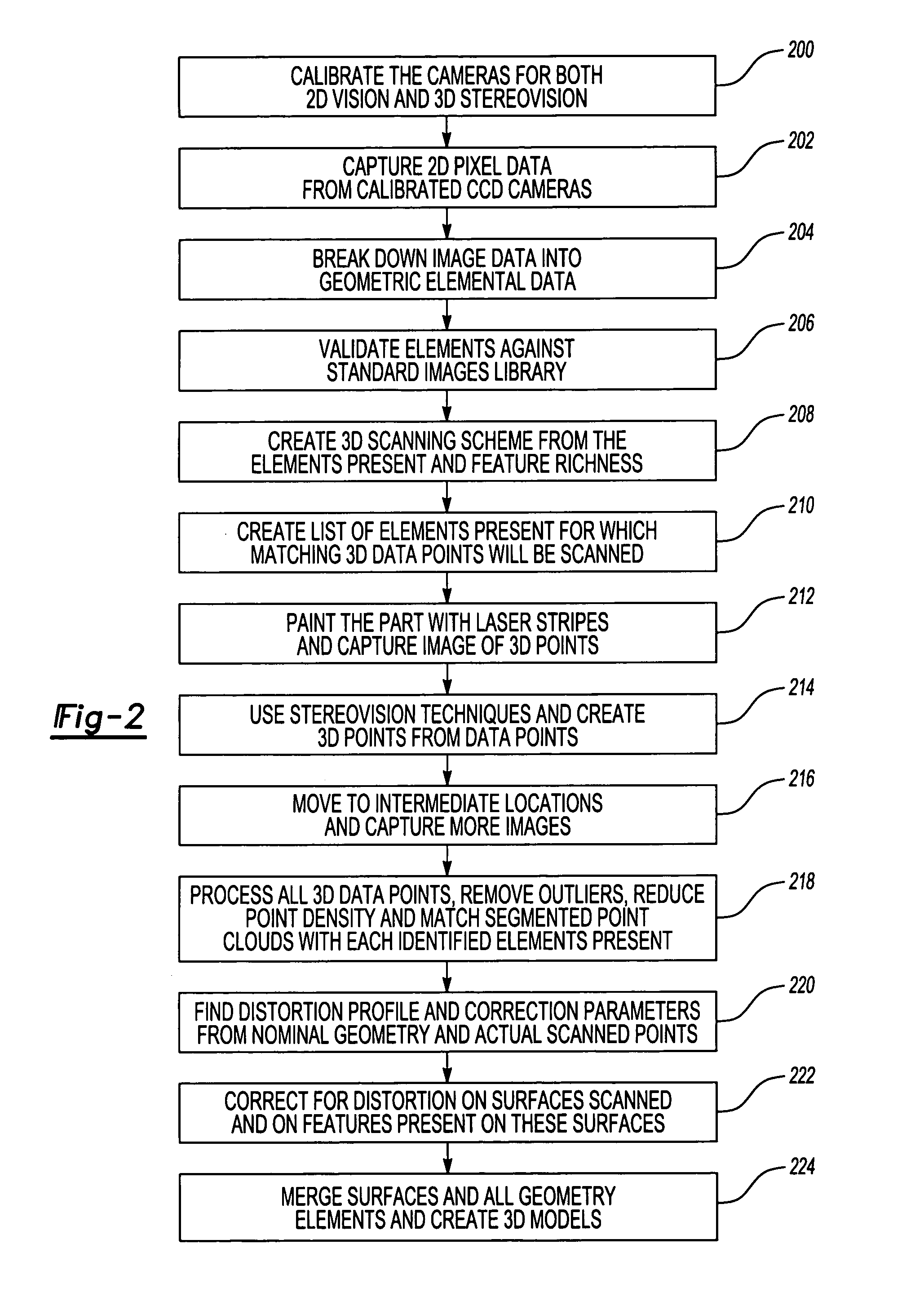

ActiveUS20050135670A1Scanning speed can not be increasedSolve the slow scanning speedDetails involving processing stepsImage analysisGeometric elementDistortion

A 3D object modeling system and method system and method captures a 2D representation of the object to be modeled and breaks the 2D image into its geometric elements. The 3D stereoscopic image is then fitted to the geometric elements generated from the 2D image to generate the final model. The 3D stereoscopic image may be compared with the geometric elements to detect distortions in the object, allowing the distortions to be corrected in the final model to ensure that the model accurately depicts the original object.

Owner:RAYTHEON TECH CORP

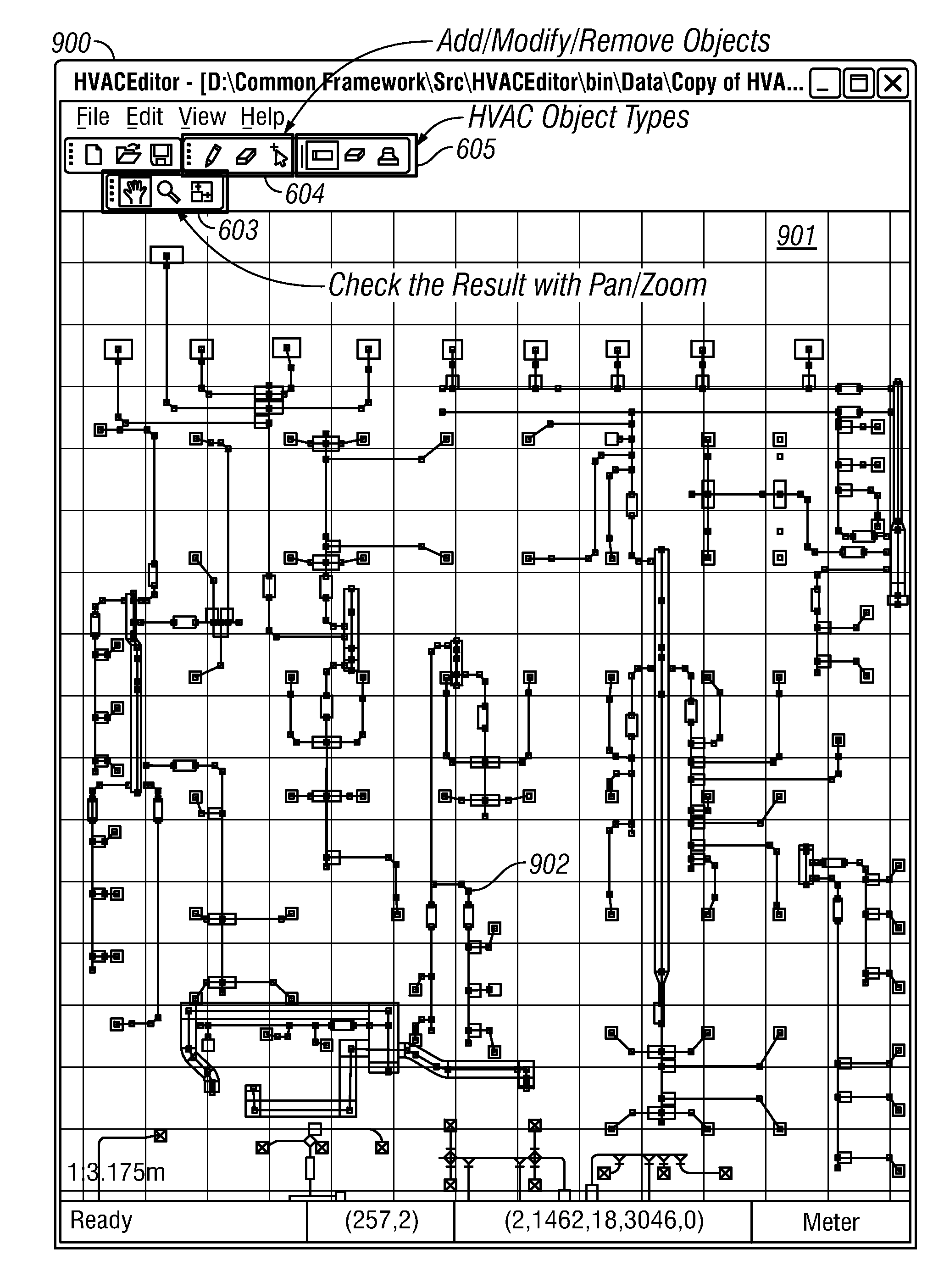

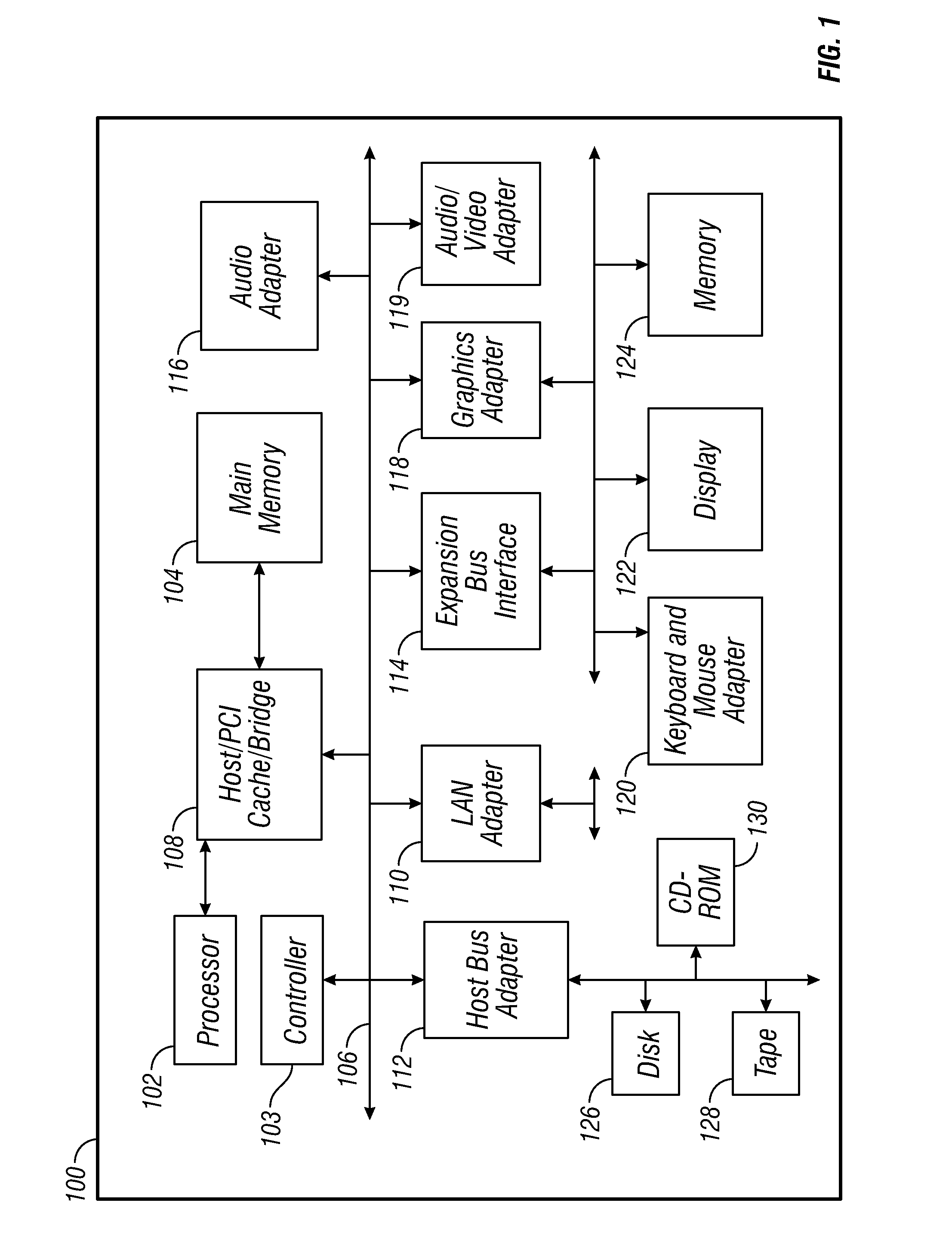

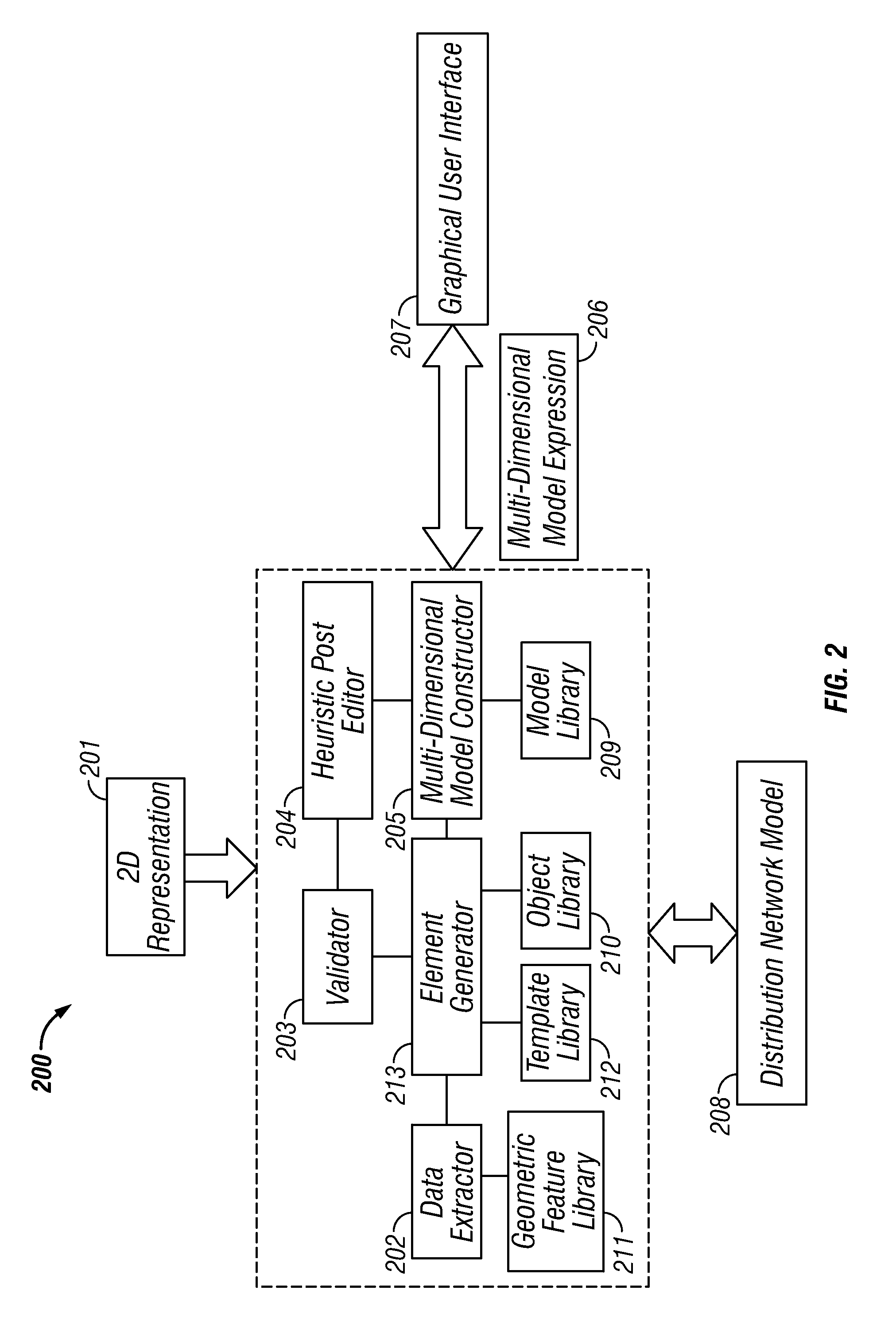

Methods and systems for constructing multi-dimensional data models for distribution networks

InactiveUS20110209081A1Easy to understandGeometric CADCharacter and pattern recognitionMultidimensional dataElectric distribution network

Methods, systems, and computer-readable medium are provided for constructing multi-dimensional data models for distribution networks. Geometric features are extricated from a 2D representation of a distribution network comprising a plurality of objects having a relationship to each other within a network. Distribution network elements are generated from the geometric elements according to a network distribution model. The distribution network elements comprise objects and components of the network and include semantic information on associated attributes and relationships thereof. The distribution network element(s) can be validated using rules to detect errors in the generation of the distribution network element(s). The distribution networks element(s) can be refined and a multi-dimensional digital model constructed from the distribution network elements according to the distribution network model.

Owner:HONEYWELL INT INC

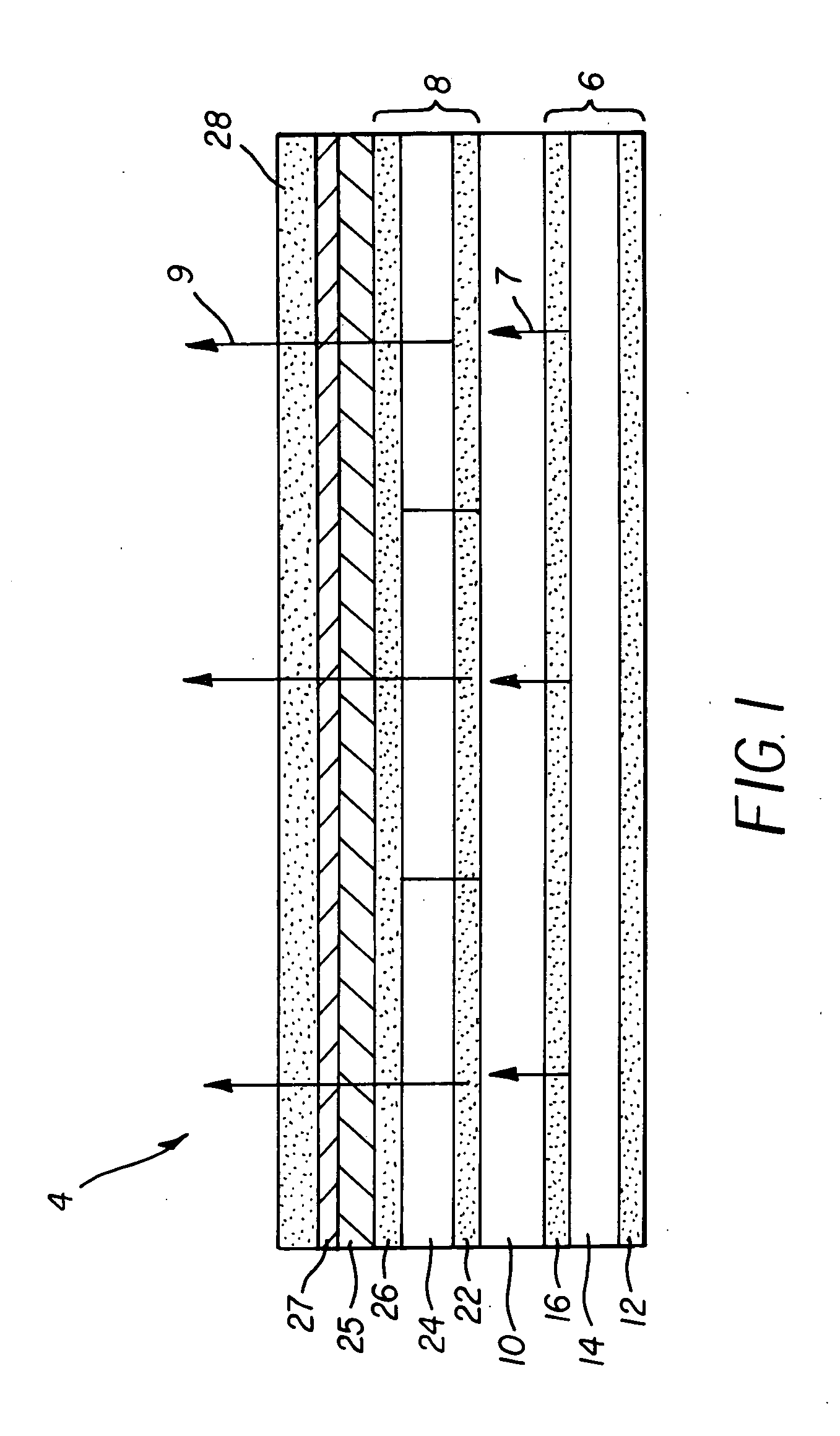

Organic laser and liquid crystal display

InactiveUS20050062903A1Improve efficiencySimple structureSemiconductor laser arrangementsLaser active region structureLiquid-crystal displayOrganic laser

An asymmetric light emitting structure for producing polarized light that includes a light emitting layer having a plurality of light emitting species, wherein orientation of the light emitting species is uncontrolled. Receipt of the emitted light from the light emitting layer is accomplished via an asymmetric geometric element that also produces polarized light. Additionally, the asymmetric light emitting structure includes a means for excitation of the light emitting layer.

Owner:EASTMAN KODAK CO

Photogrammetric measurement system and method

ActiveUS6990215B1Picture taking arrangementsCharacter and pattern recognitionGeometric elementPattern recognition

A method for characterizing a geometric element of an object includes positioning a calibrated target adjacent a calibration geometric element, the calibrated target having at least two differentially detectable features having a known geometric relationship to each other. Next a relationship of the calibrated target to the calibration geometric element is determined, and the calibrated target is moved adjacent a geometric feature of an object desired to be characterized. Then photogrammetry is applied to the calibrated target features and the desired geometric feature to spatially characterize the desired geometric feature. A system for characterizing a geometric element of an object includes the movable calibrated target and a photogrammetric analysis system for determining a relationship of the calibrated target to a calibration geometric element and for spatially characterizing the desired geometric feature using the calibrated target features.

Owner:GEODETIC SERVICES

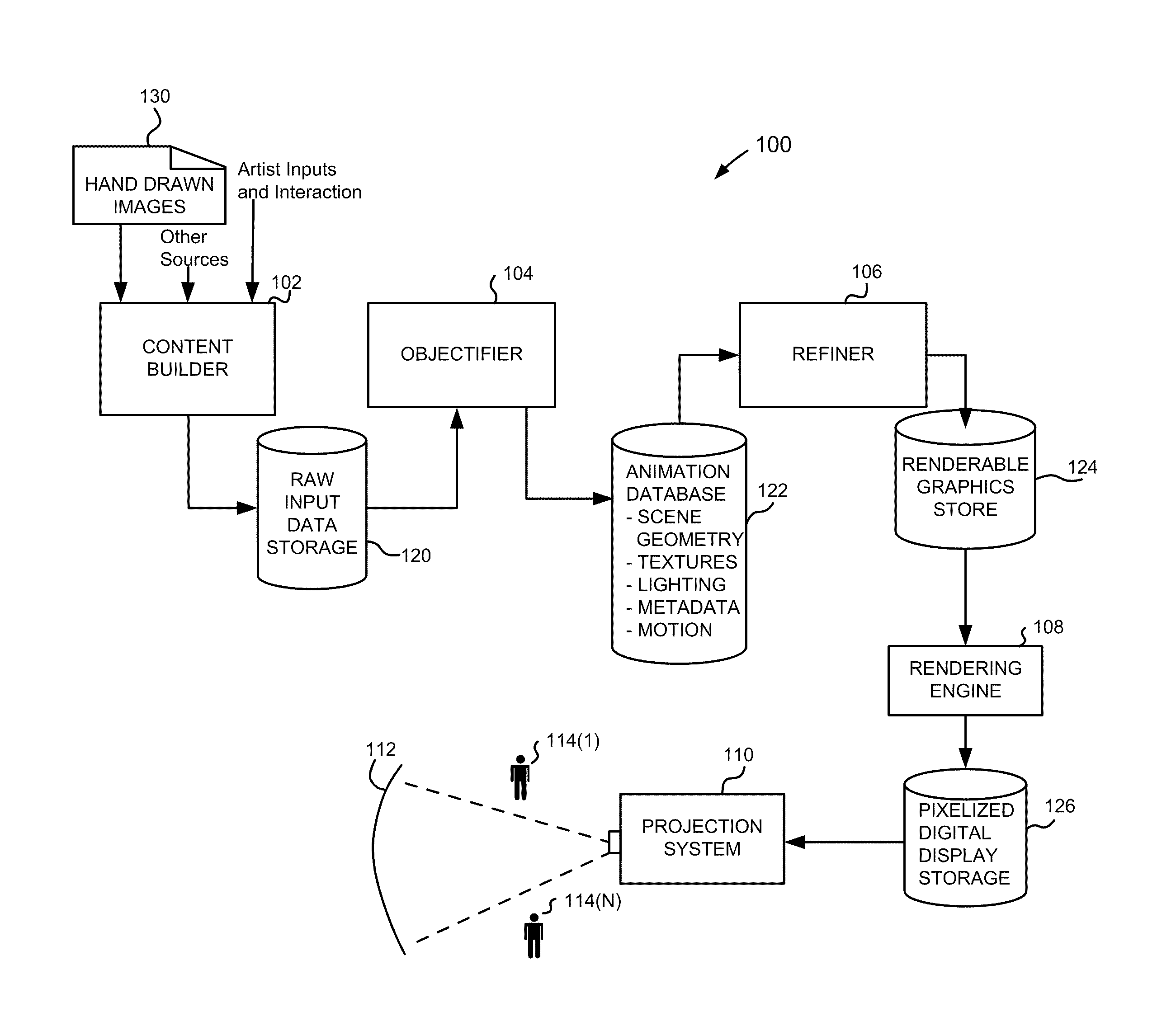

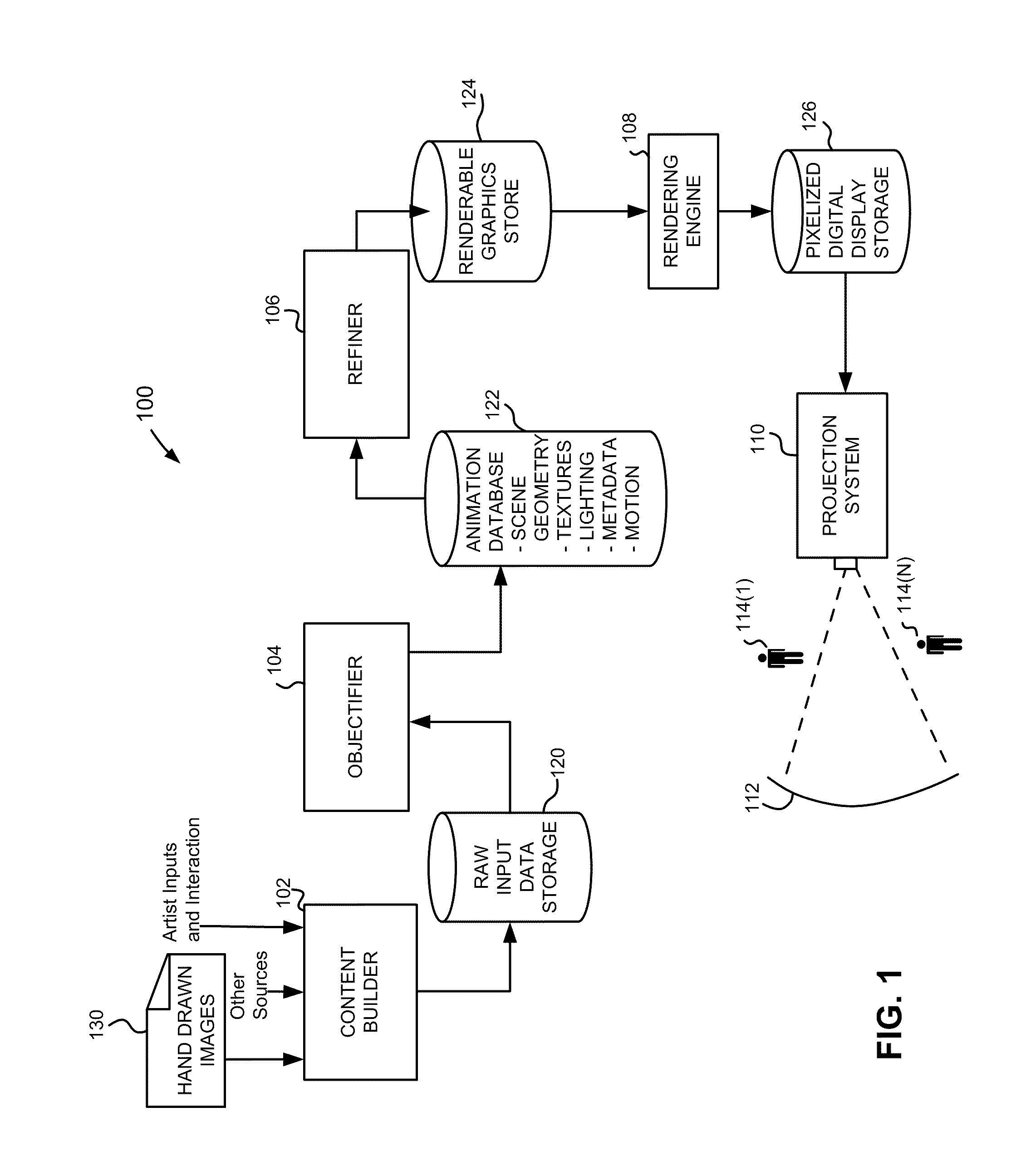

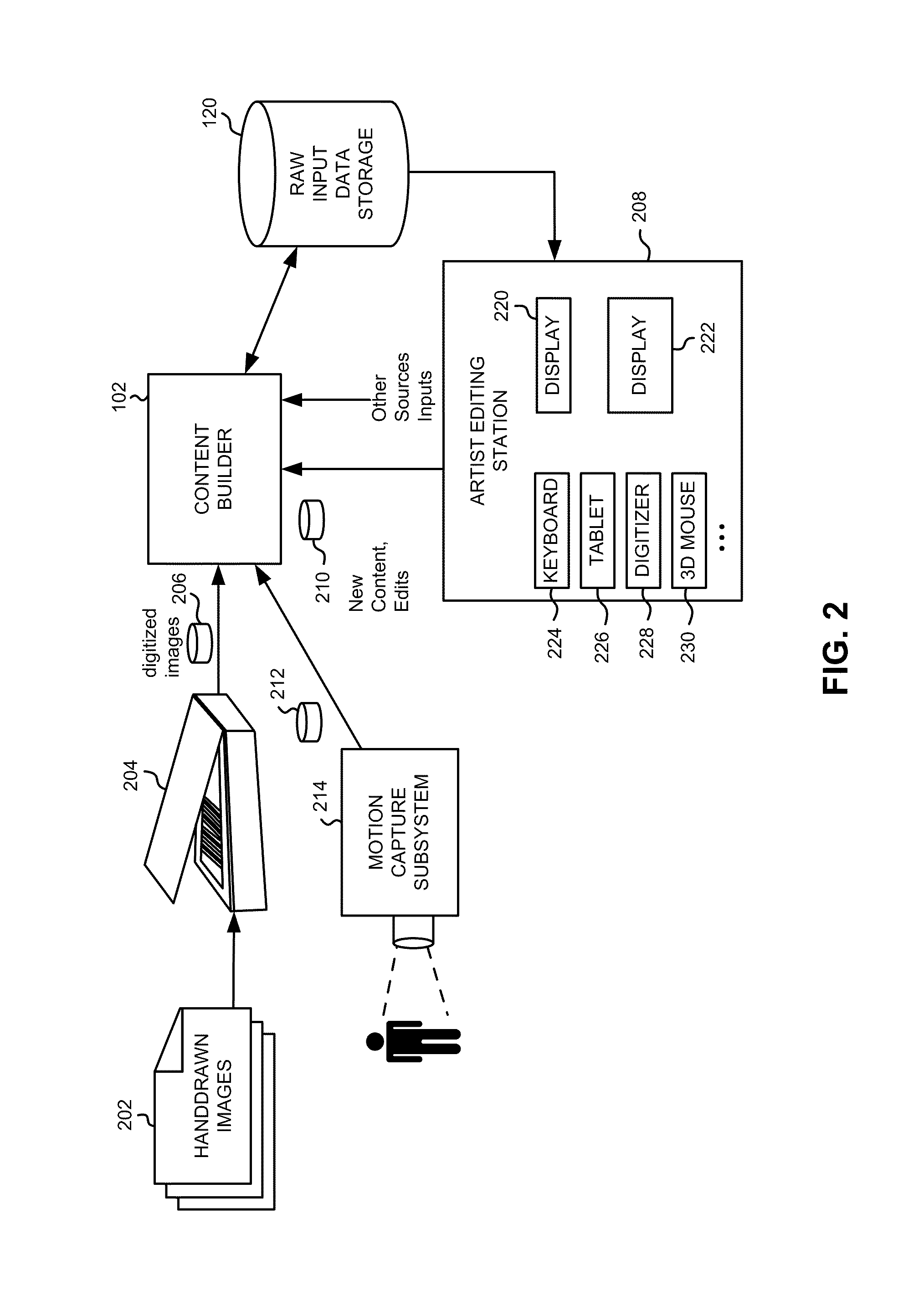

Automatic and semi-automatic generation of image features suggestive of motion for computer-generated images and video

In an animation processing system, generating images to be viewable on a display using a computer that are generated based on scene geometry obtained from computer readable storage and animation data representing changes over time of scene geometry elements, but also images can be modified to include shading that is a function of positions of objects at other than the current instantaneous time for a frame render such that the motion effect shading would suggest motion of at least one of the elements to a viewer of the generated images. Motion effects provide, based on depiction parameters and / or artist inputs, shading that varies for at least some received animation data, received motion depiction parameters, for at least one pixel, a pixel color is rendered based on motion effect program output and at least some received scene geometry, such that the output contributes to features that would suggest the motion.

Owner:DISNEY ENTERPRISES INC +1

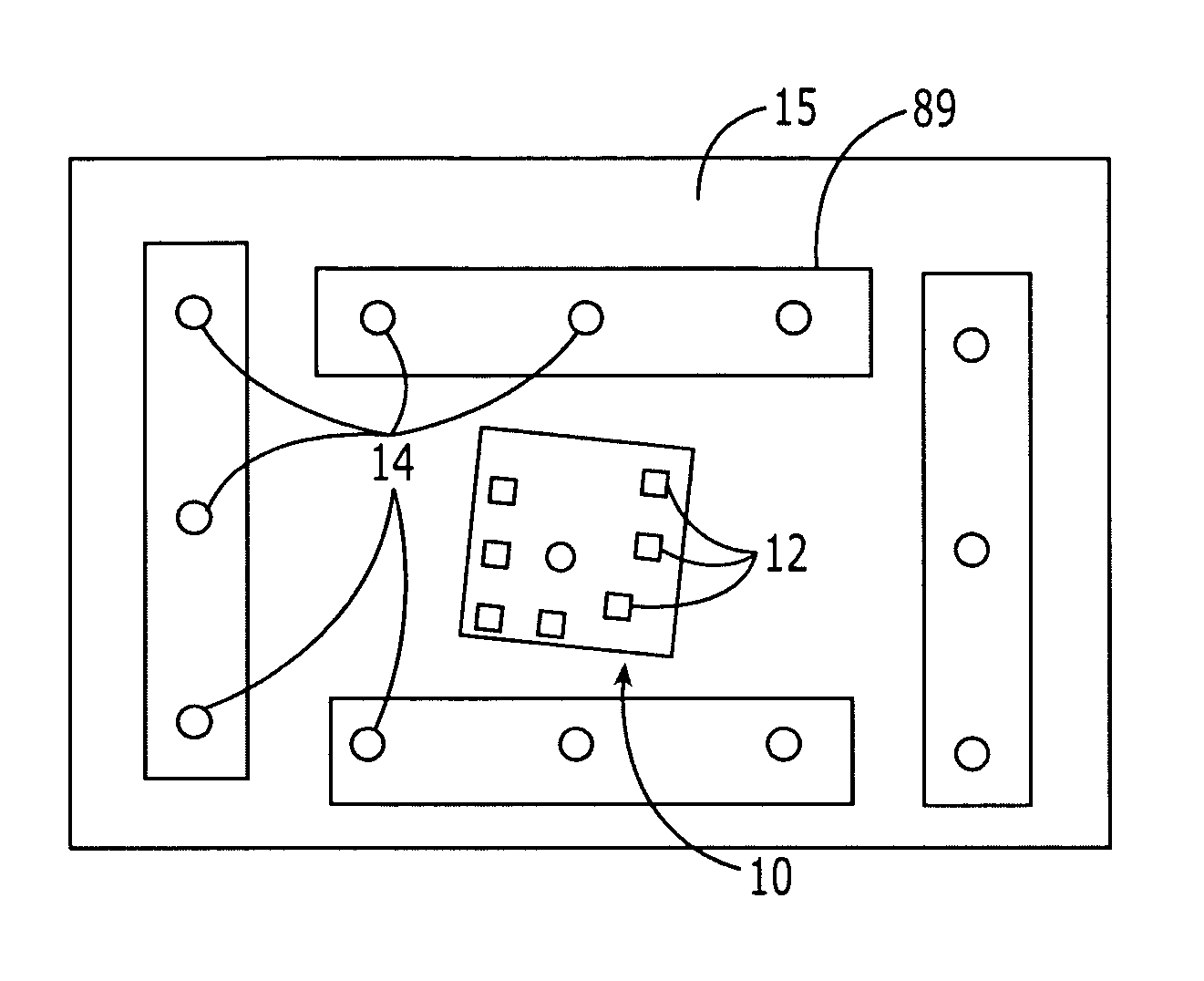

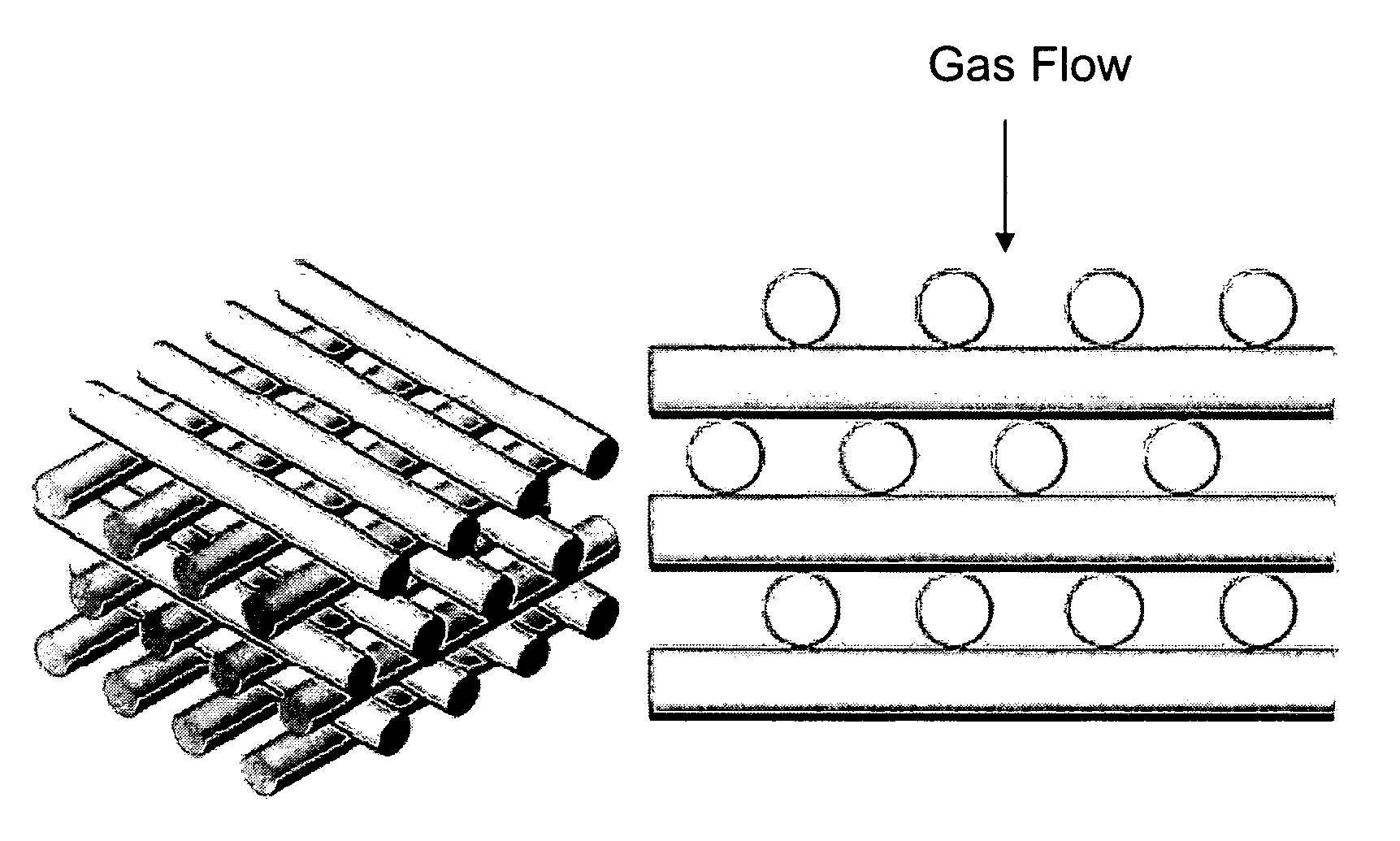

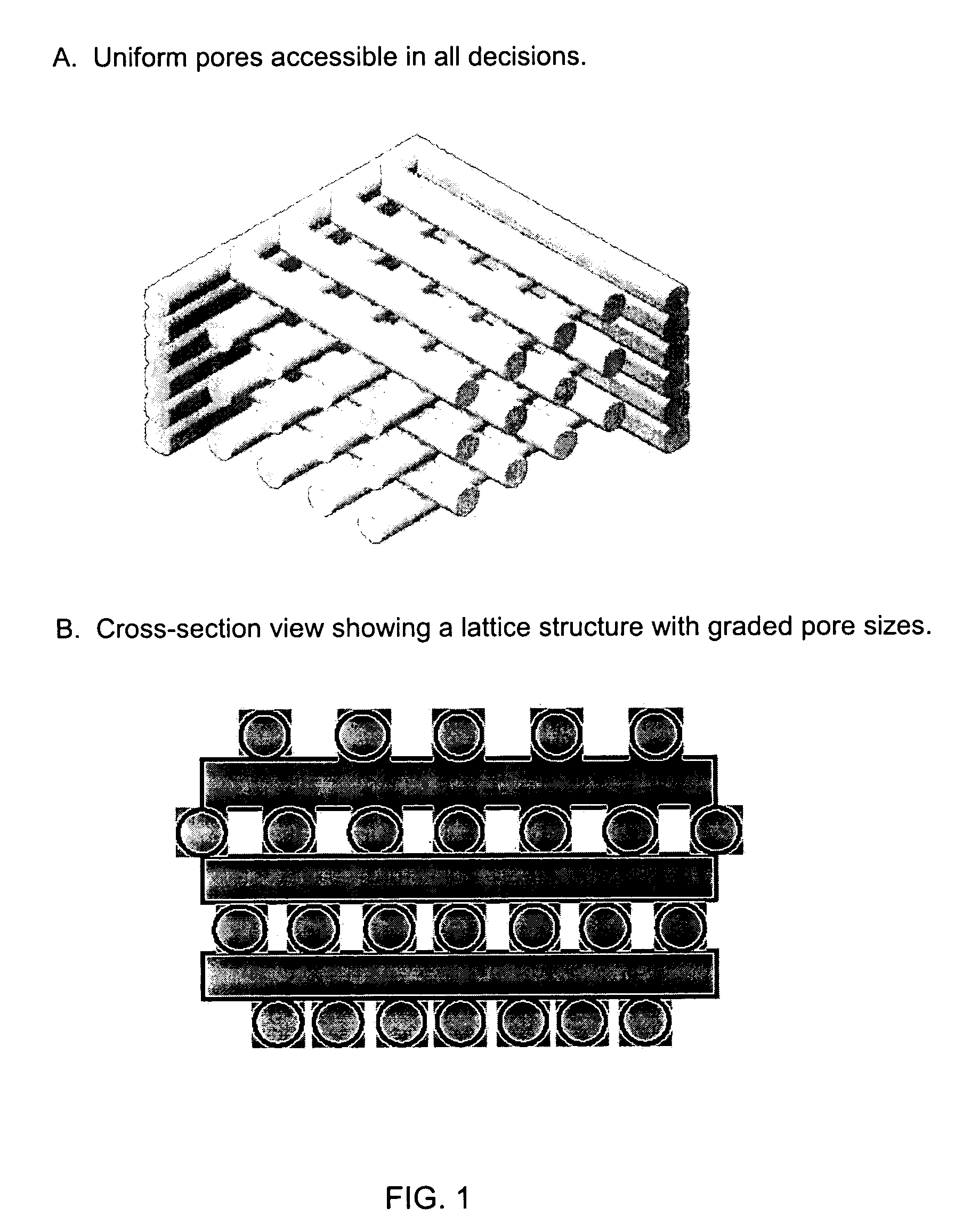

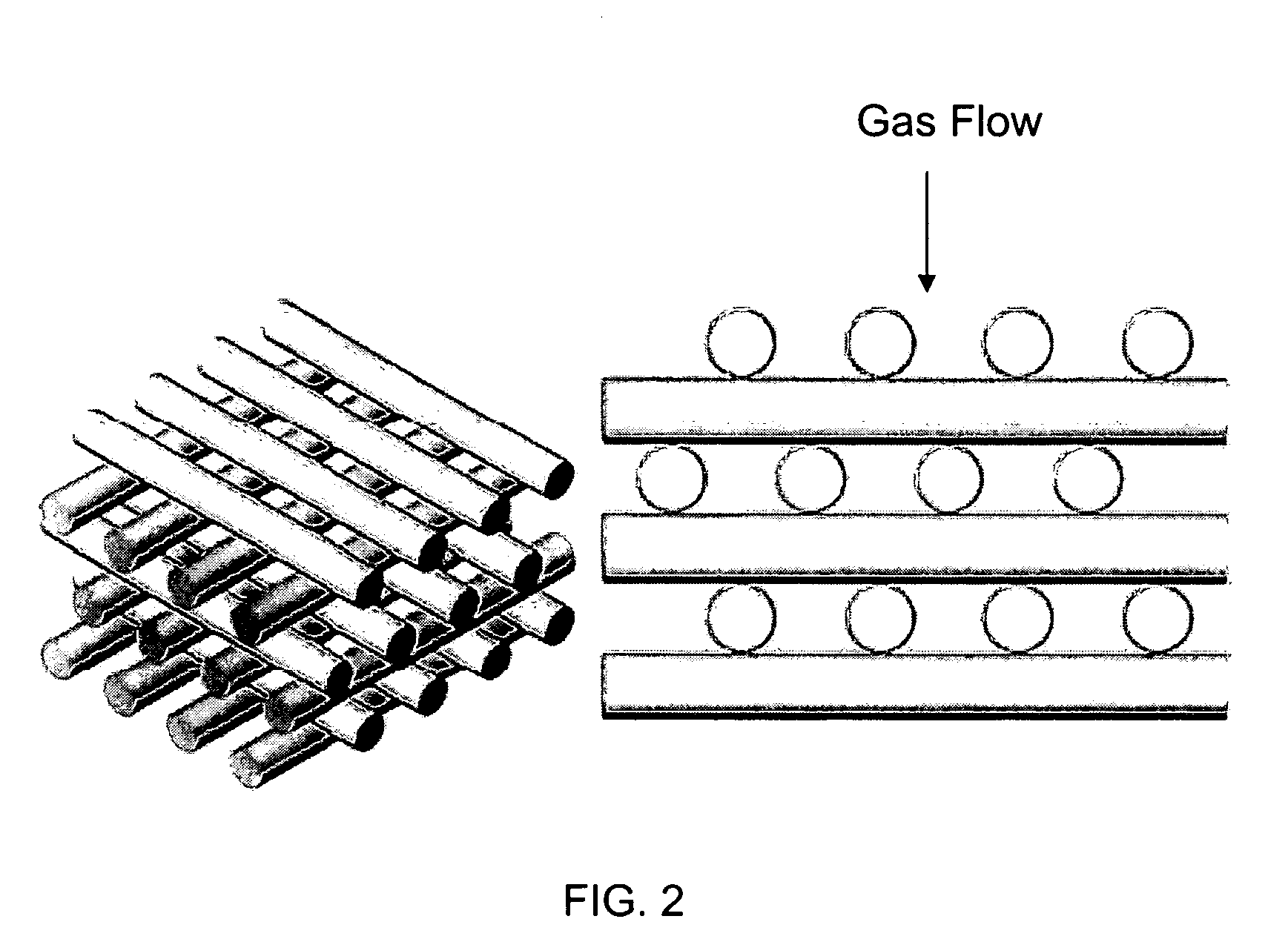

Regenerable particulate filter

ActiveUS7527671B1Other chemical processesDispersed particle filtrationParticulatesManufacturing technology

A method of making a three-dimensional lattice structure, such as a filter used to remove particulates from a gas stream, where the physical lattice structure is designed utilizing software simulation from pre-defined mass transfer and flow characteristics and the designed lattice structure is fabricated using a free-form fabrication manufacturing technique, where the periodic lattice structure is comprised of individual geometric elements.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

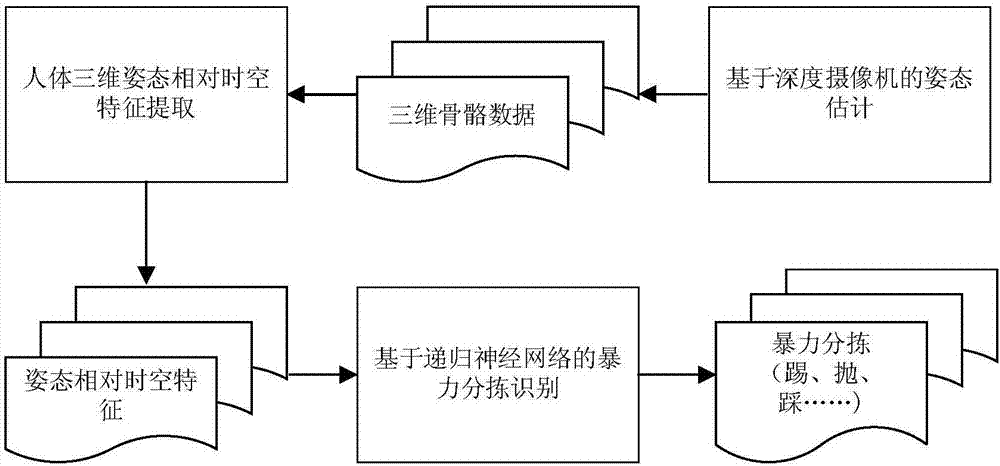

Computer vision-based express parcel violent sorting identification method

ActiveCN106897670ALow priceFacilitate large-scale deploymentCharacter and pattern recognitionHuman bodyFeature extraction

The present invention discloses a computer vision-based express parcel violent sorting identification method. The method comprises the following steps of: a depth camera-based pose estimation: a human pose estimation problem is converted into a problem of classifying depth image pixels captured by a depth camera, and human body pose estimation is realized by using a random forest method; human body three-dimensional pose relative spatial-temporal feature extraction: relative spatial-temporal positions of geometric elements of points, lines and surfaces formed by joints in three-dimensional poses and the measures of the change of the relative spatial-temporal positions are extracted and are adopted as the feature representations of the poses; and recurrent neural network-based violent sorting identification: modeling training is performed on the pose spatial-temporal relative features which are continuous in time and are extracted from the human body three-dimensional poses through a long and short memory model (LSTM), so that the identification of express parcel violent sorting behaviors can be realized.

Owner:NANJING UNIV OF POSTS & TELECOMM

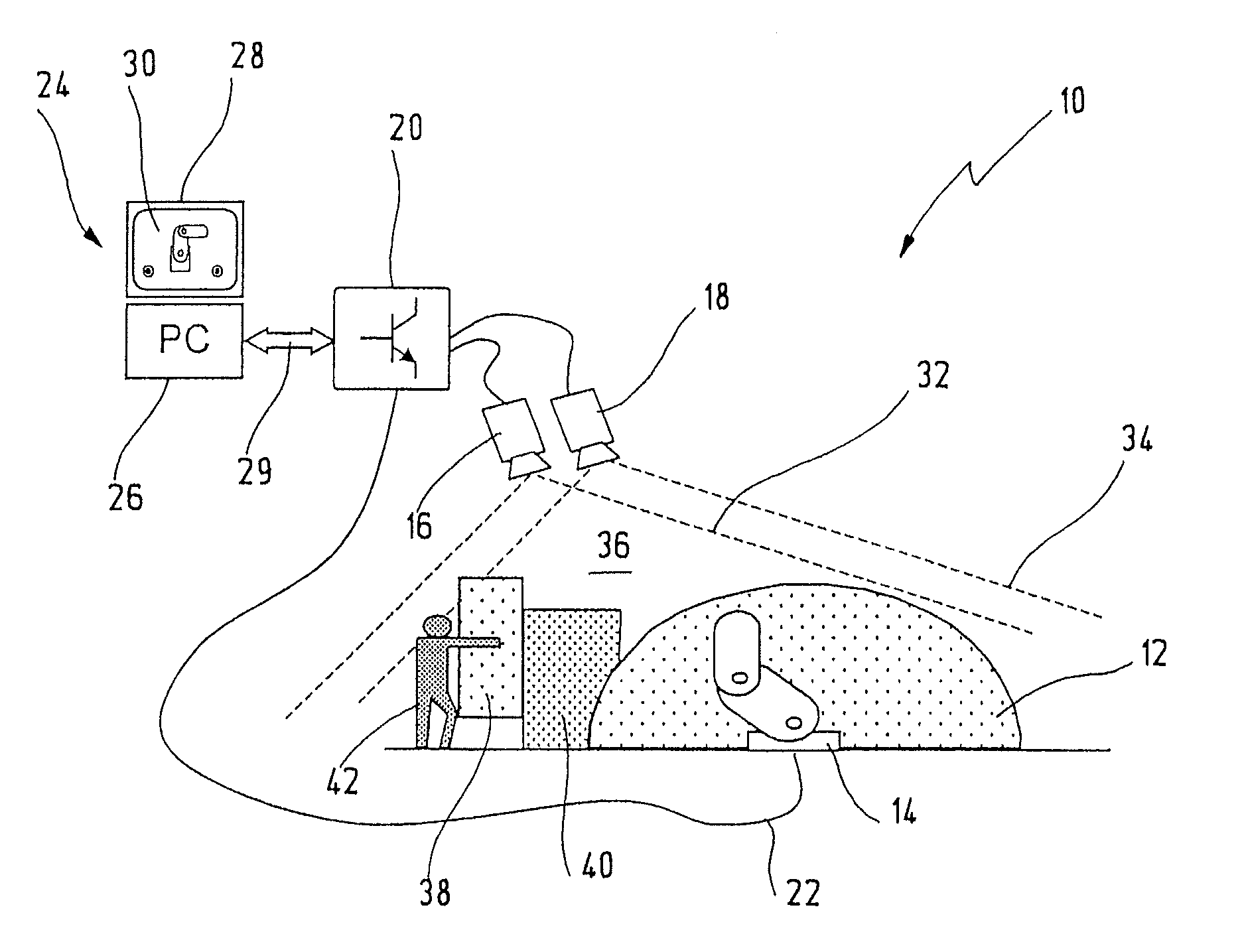

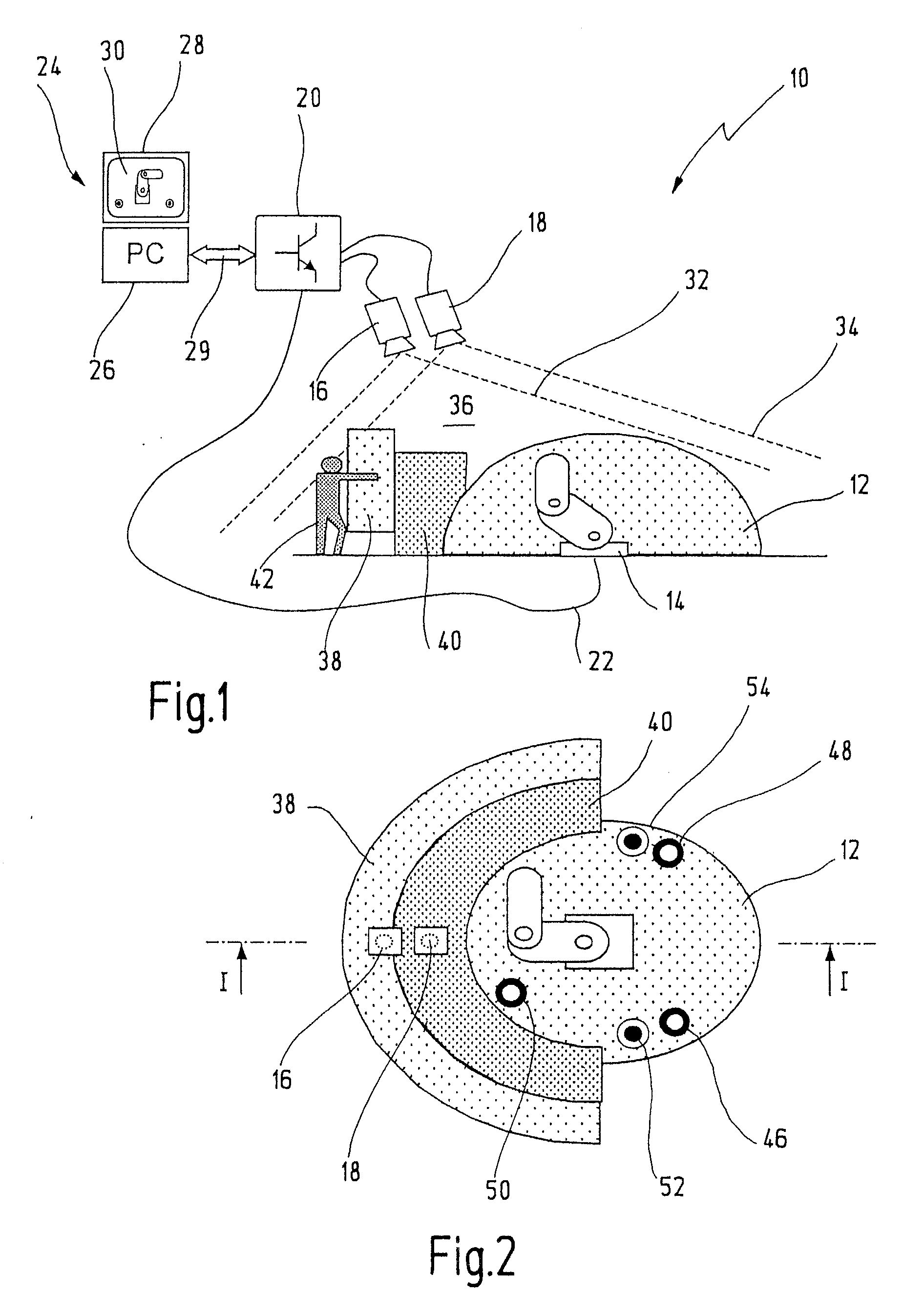

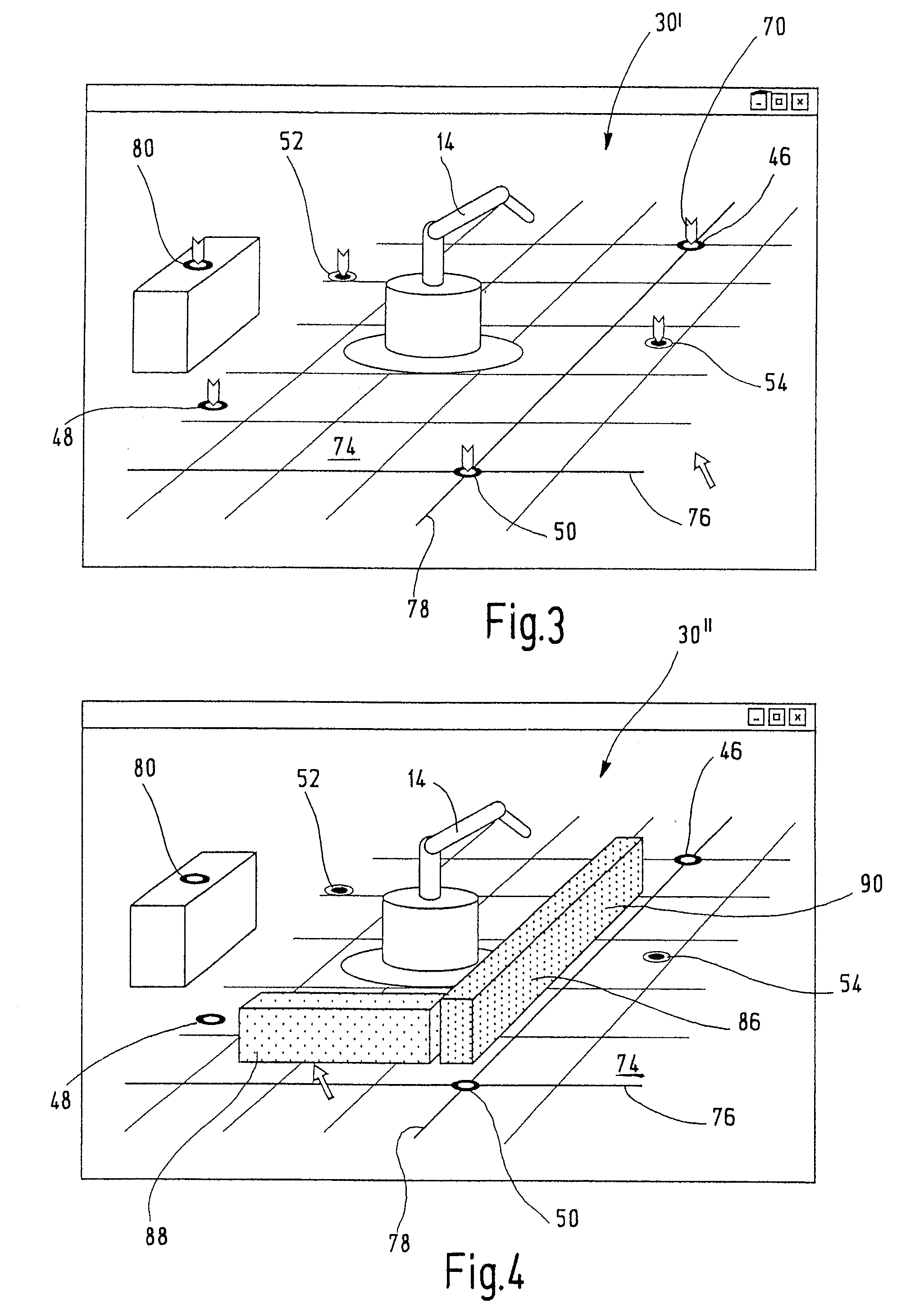

Method and system for configuring a monitoring device for monitoring a spatial area

ActiveUS20090015663A1Easy to optimizeImage analysisEngineering safety devicesImage recordingMonitor equipment

A monitoring device for monitoring a spatial area comprises at least one image recording unit. A three-dimensional image of the spatial area is recorded and displayed in order to configure. the monitoring device. A configuration plane is defined using a plurality of spatial points which have been determined within the three-dimensional image. Subsequently, at least one variable geometry element is defined relative to the configuration plane. A data record which represents a transformation of the geometry element into the spatial area is generated and transferred to the monitoring device.

Owner:PILZ (COMPANY)

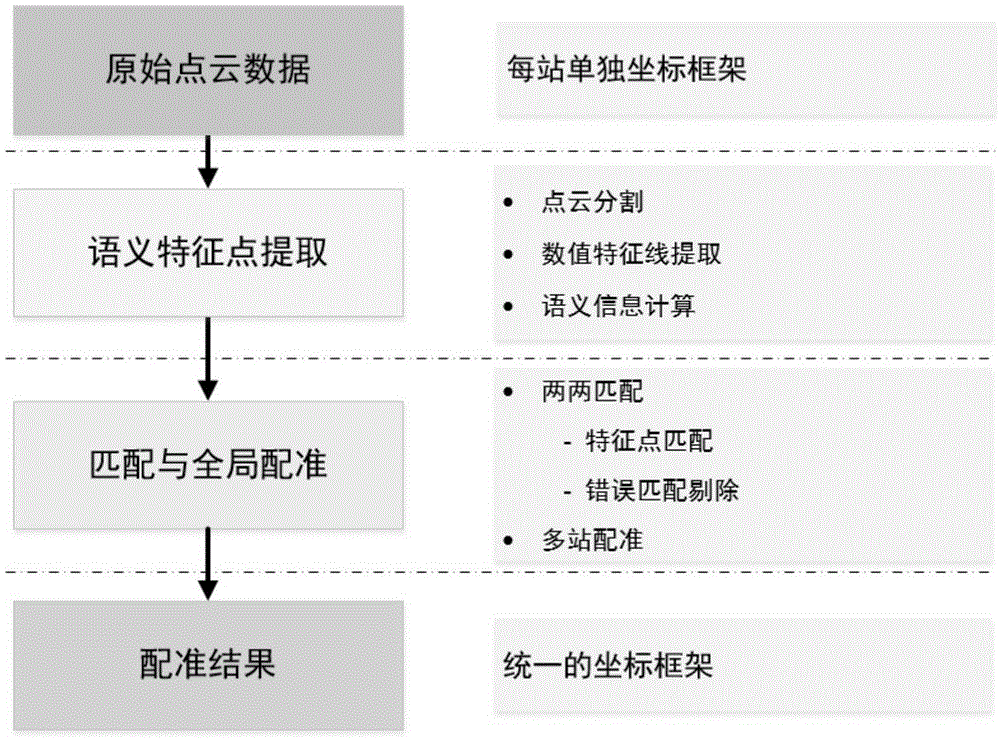

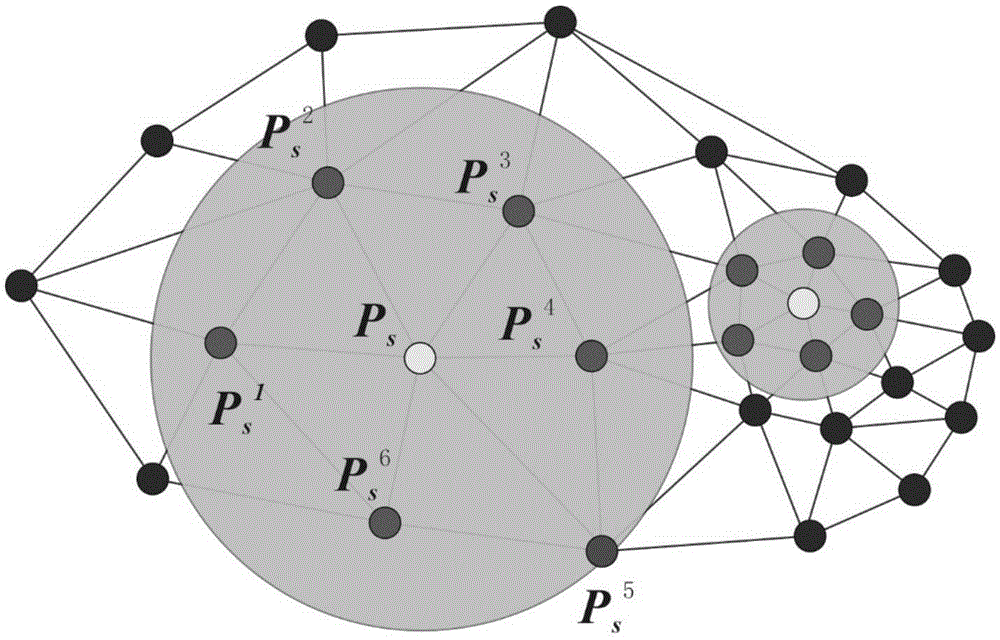

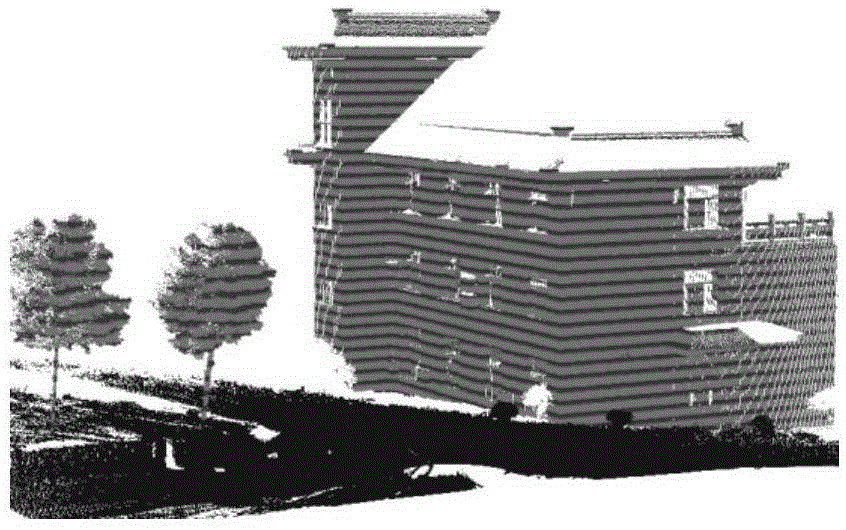

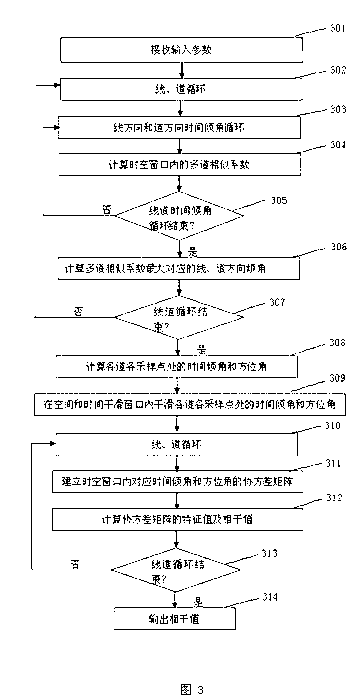

Method suitable for multi-view-angle automatic registration of ground laser point cloud data of multiple stations

InactiveCN105427317ASolve the difficulties in the registration process such as automatic selectionRealize global automatic registrationImage enhancementImage analysisGeometric consistencyPoint density

The invention relates to a method suitable for multi-view-angle automatic global registration of ground laser point cloud data. The method involves two key modules: a module for extracting semantic feature points and a module for feature matching. The method comprises: step 1, extracting the semantic feature points: obtaining the semantic feature points in a series of modes of data slicing, distance clustering, geometric element fitting and the like; step 2, matching the semantic feature points: matching the semantic feature points by constructing a triangular geometric constraint condition and a semantic constraint condition, and removing error matching in a geometric consistency clustering mode; and finally, constructing a weighted undirected graph by taking a reciprocal of a feature point number as a weight, and finally obtaining global registration parameters of all stations by taking a minimum spanning tree of the weighted undirected graph as a registration path, thereby realizing global optimal registration. According to the invention, the method suitable for multi-view-angle automatic global registration of the ground laser point cloud data is constructed; the method can effectively resist influences of noise, point density and coverage; and the method improves the laser scanning operation efficiency, thereby having very high practical values.

Owner:WUHAN UNIV

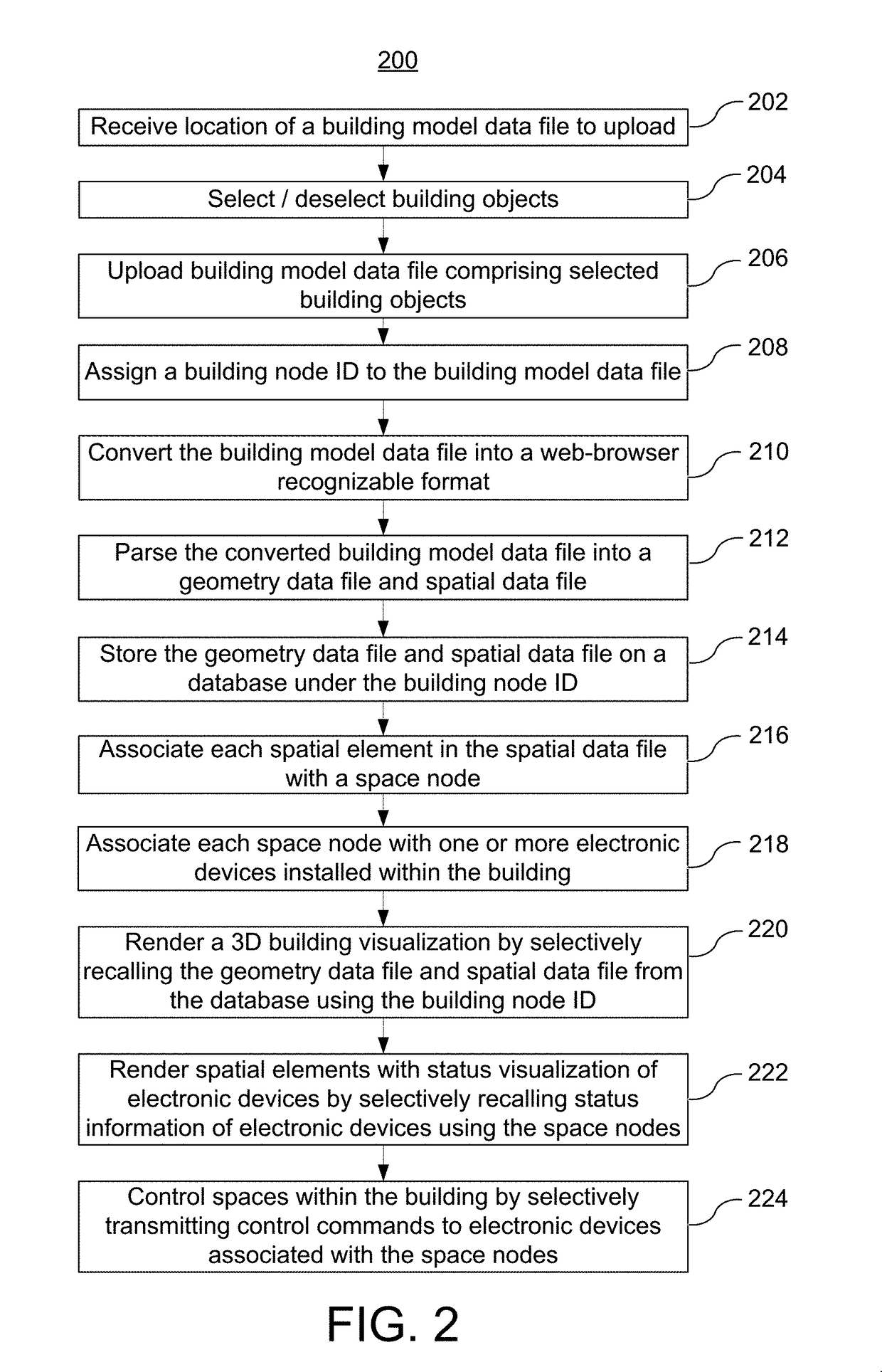

Three-dimensional building management system visualization

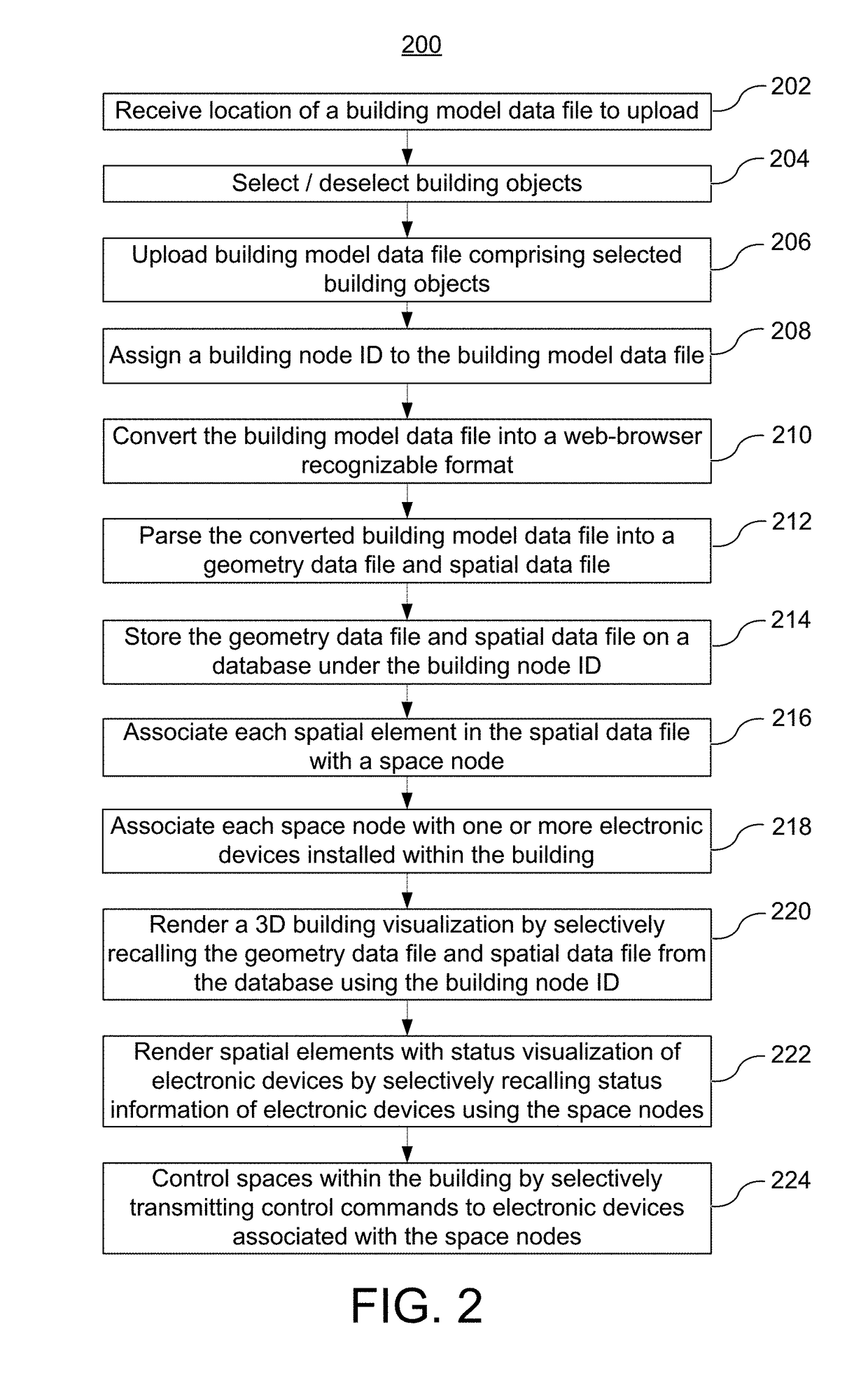

InactiveUS20170315696A1Effective for system testing and troubleshootingMany timesGeometric CADMechanical apparatusWeb browserData file

Systems, methods, and modes for on-demand rendering of a three-dimensional building management system visualization of a building via a web-browser. The system may comprise an uploader, a data extractor, a database, and at least one processor. The method and the system components are configured for uploading a building model data file to a building management server that comprises building objects combining geometry elements and spatial elements, parsing the uploaded building model data file into a geometry data file comprising the geometry elements and a separate spatial data file comprising the spatial elements, storing the geometry data file and the spatial data file on a database, associating the spatial elements in the spatial data file with respective space nodes identifying spaces located within the building, associating the space nodes with one or more electronic devices installed within respective spaces in the building, selectively recalling the geometry data file and spatial data file from the database, and rendering a three dimensional building visualization of the building via a user interface of a web-browser.

Owner:CRESTRON ELECTRONICS

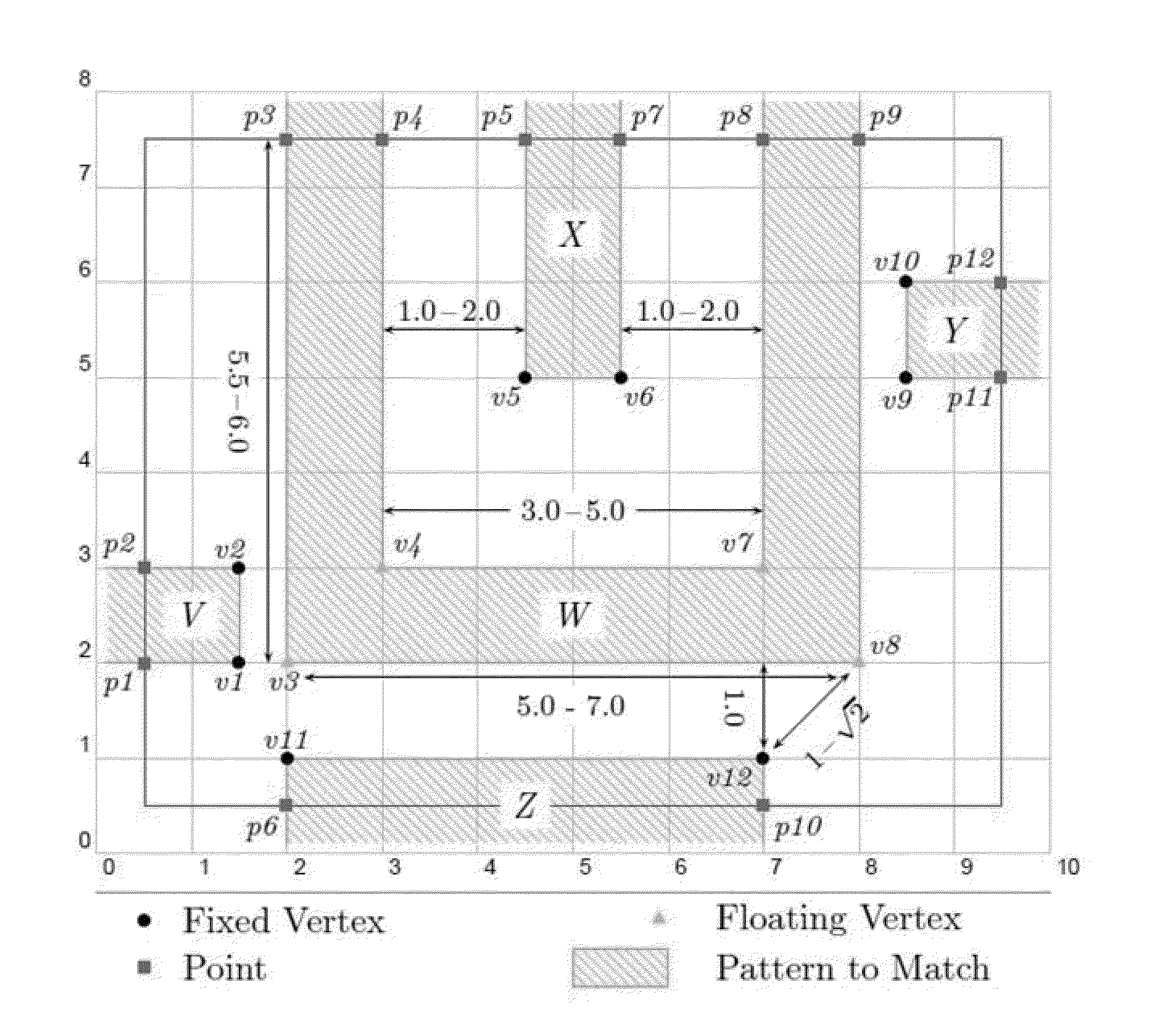

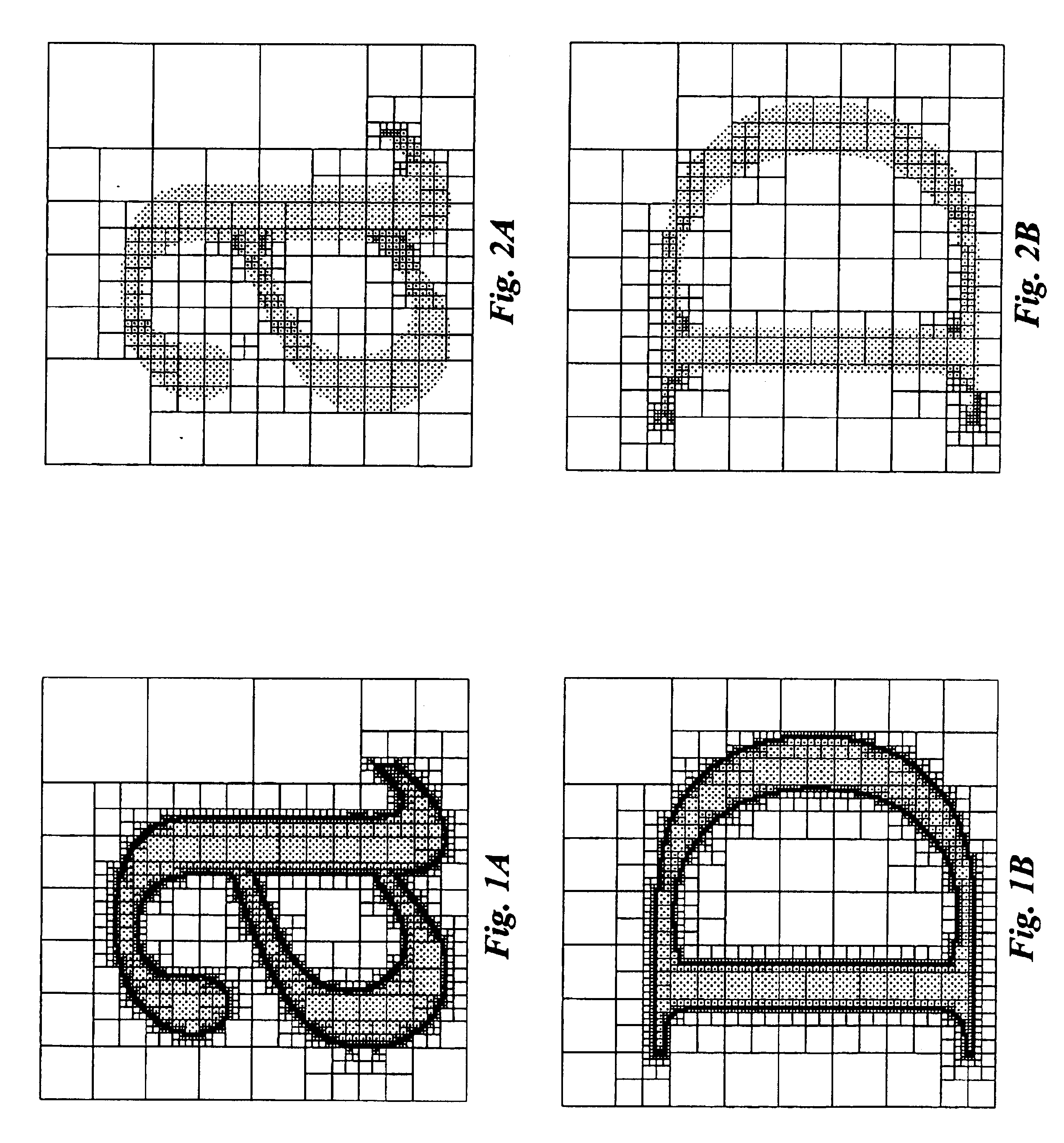

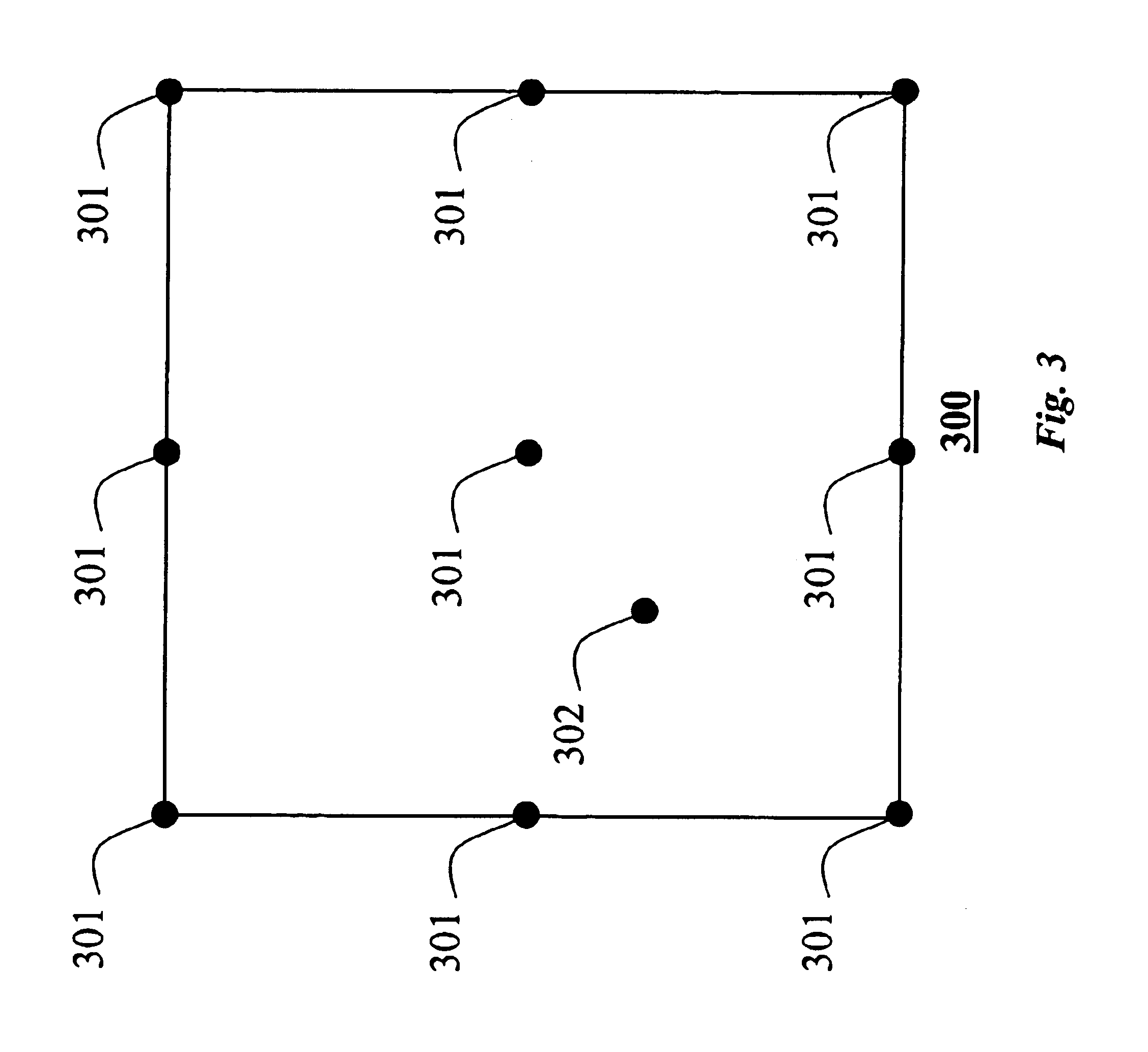

Topological Pattern Matching

InactiveUS20100185994A1Efficient identificationEfficient searchComputer aided designSpecial data processing applicationsPattern matchingSearch graph

Techniques for more efficiently identifying specific topological patterns in microdevice design data, such as layout design data. A user provides a topological pattern matching tool with a pattern template. In response, the topological pattern matching tool will analyze the pattern template to create a set of “design rule check” operations that can be performed to identify topological features of the layout design that will include the set of topological features specified for the template. The topological pattern matching tool also specifies properties that should be determined for each set of topological features identified by a design rule check operation. Once the design rule check operations have been created, the tool applies them to the layout design data being analyzed. The results produced by the design rule check operations will be a group of topological features in the layout design that encompass the topological features specified for the template. The results also will include a set of properties for each of the identified topological features. Next, the pattern matching tool creates a search graph based upon the results of the design rule check operations. Once the search graph is constructed, the pattern matching tool traverses the search graph to identify combinations of nodes connected by graph edges representing feature characteristics that match the constraints specified for the pattern template. For each such identified combination of nodes, the tool will output the arrangement of geometric elements corresponding to the nodes as a topological match to the original template.

Owner:PIKUS FEDOR G +1

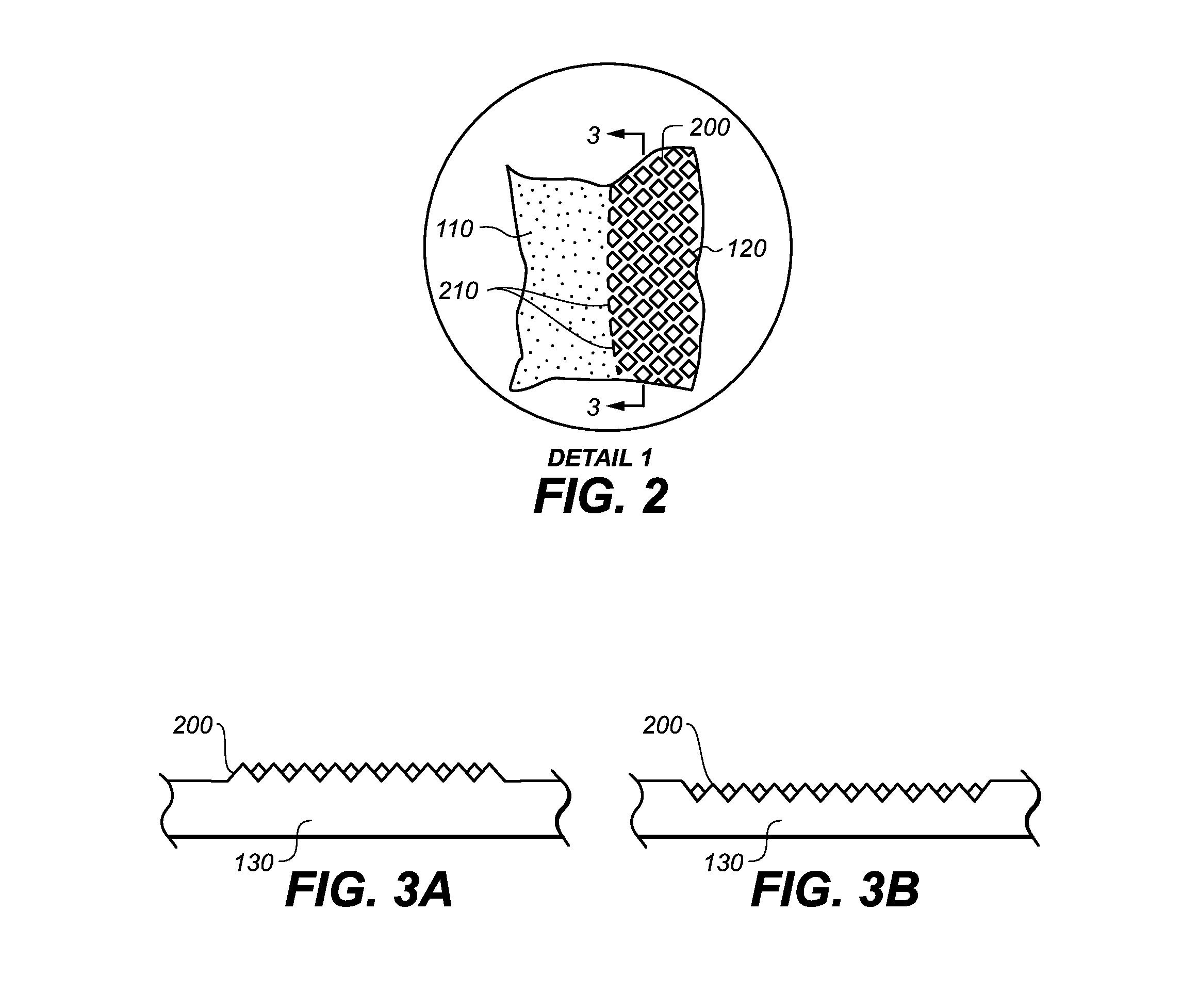

Laser-formed features

Embodiments are directed to laser-based processes for forming features on the surface of a part. The feature may include a geometric element, a color element, and / or a surface finish element. In some cases, the laser-formed features are formed as a pattern of textured features that produce an aesthetic and / or tactile effect on the surface of the part. In some cases, the texture features may be sufficiently small that they may not be discerned by the unaided human eye. Also, in some cases, a multiple laser-based processes are combined to form a single feature or a finished part having a specific aesthetic and / or tactile effect.

Owner:APPLE INC

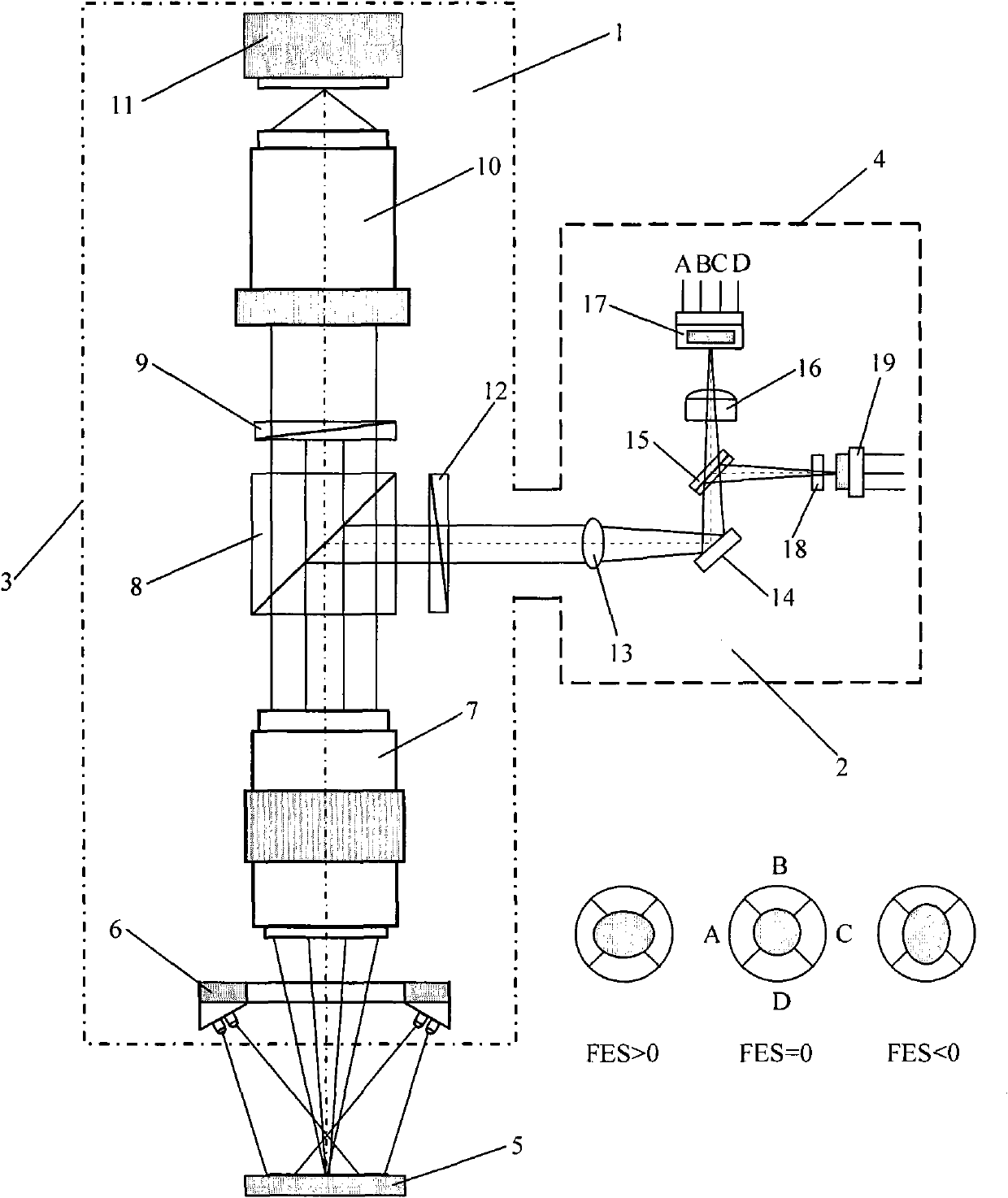

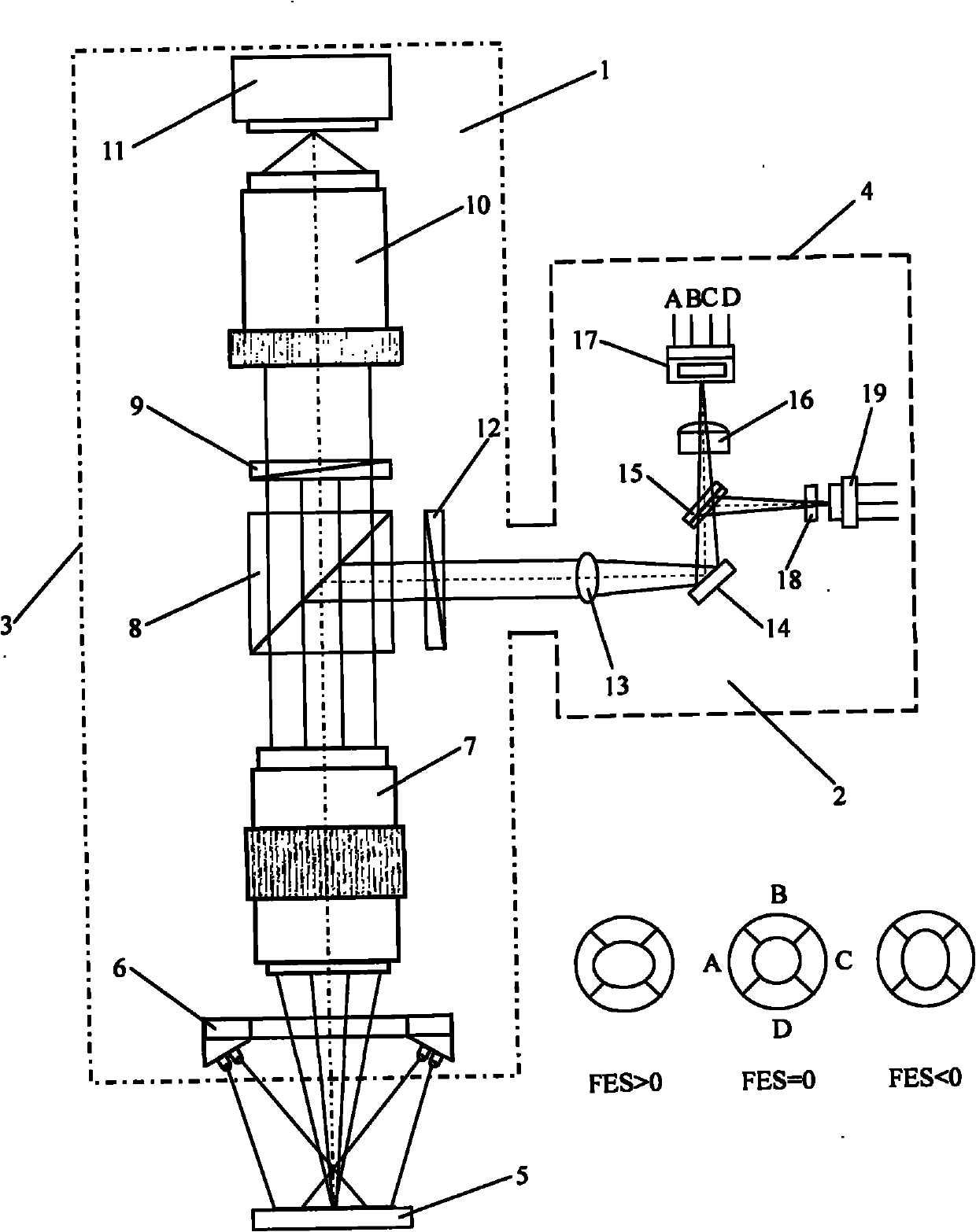

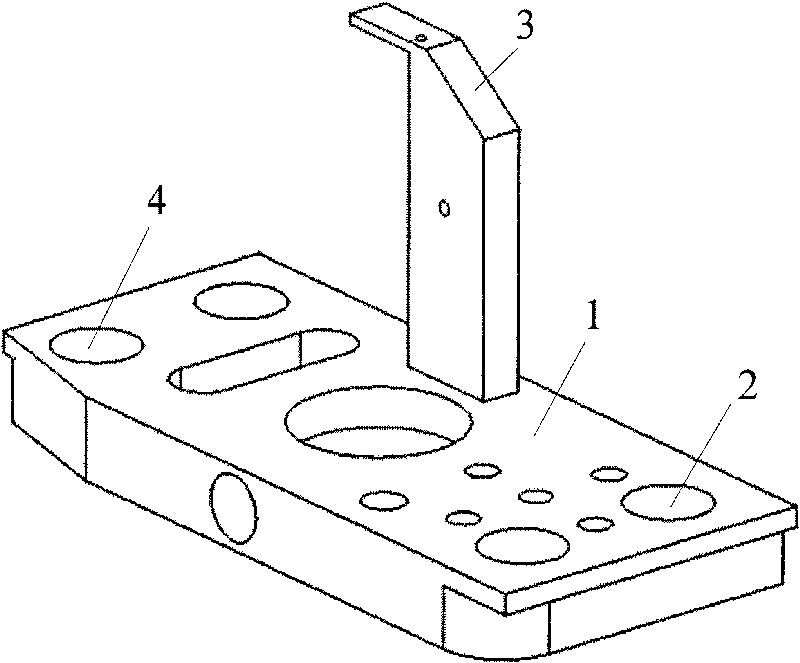

Non-contact three-dimensional optical measuring head and method for in-situ measurement of numerical control machine

InactiveCN101913105AHigh speedHigh precisionMeasurement/indication equipmentsNumerical controlThree-dimensional space

The invention discloses a non-contact three-dimensional optical measuring head and a non-contact three-dimensional optical measuring method for in-situ measurement of a numerical control machine, which are characterized in that: the non-contact three-dimensional optical measuring head consists of an image measuring system and a focus positioning system. The non-contact three-dimensional optical measuring method comprises the following steps of: firstly, making a focus judgment on the image measuring system by using an astigmatism method, determining a measuring plane, positioning the non-contact three-dimensional optical measuring head in a Z-axis direction at the same time and acquiring a Z-axis direction positioning value of a surface characteristic point of a workpiece; secondly, performing two-dimensional image measurement on basic geometric elements, of the workpiece, on the measuring plane by using a surface measuring method in image projection measurement to obtain two-dimensional plane coordinate values of the surface characteristic point of the workpiece; and finally, combining the two-dimensional plane coordinate values with the Z-axis direction positioning value to obtain the three-dimensional coordinate values of the surface characteristic point of the workpiece. The non-contact three-dimensional optical measuring head and the non-contact three-dimensional optical measuring method can effectively perform high-precision in-situ measurement of the geometric size of the workpiece processed by the numerical control machine, shorten the manufacturing period of products effectively and guarantee product quality.

Owner:HEFEI UNIV OF TECH

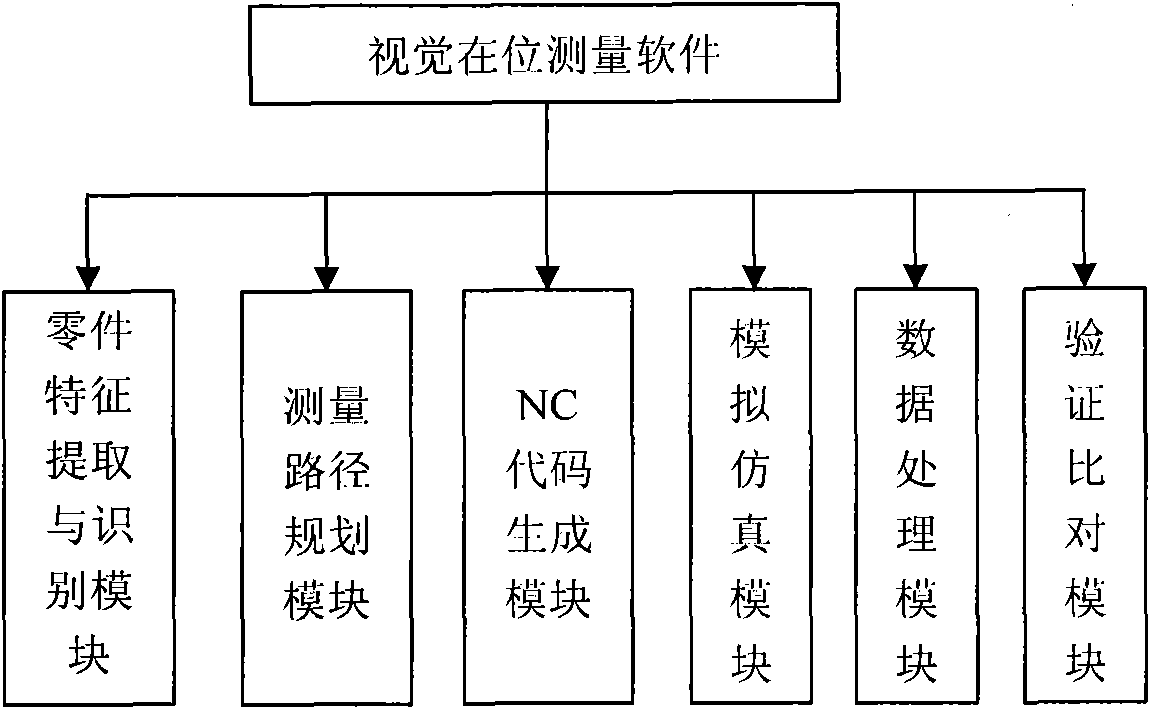

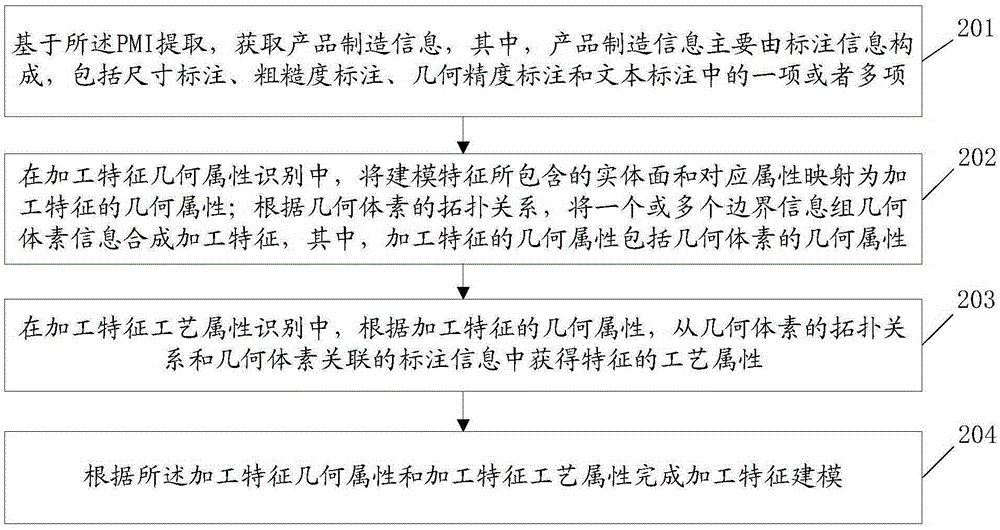

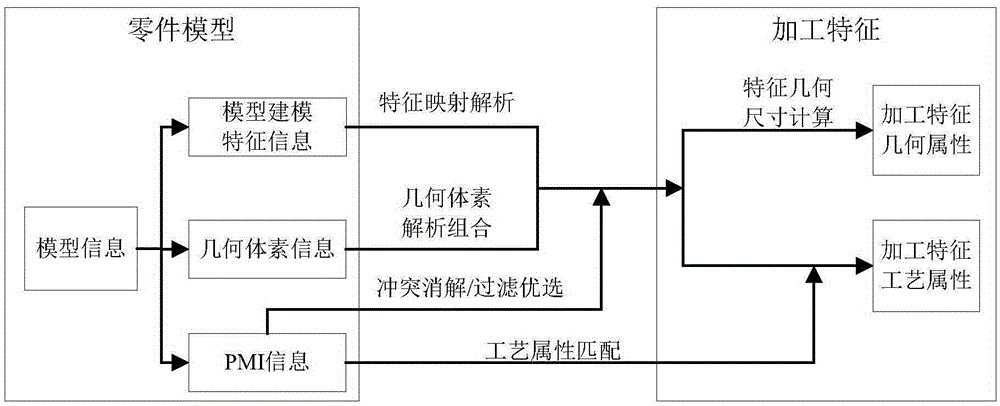

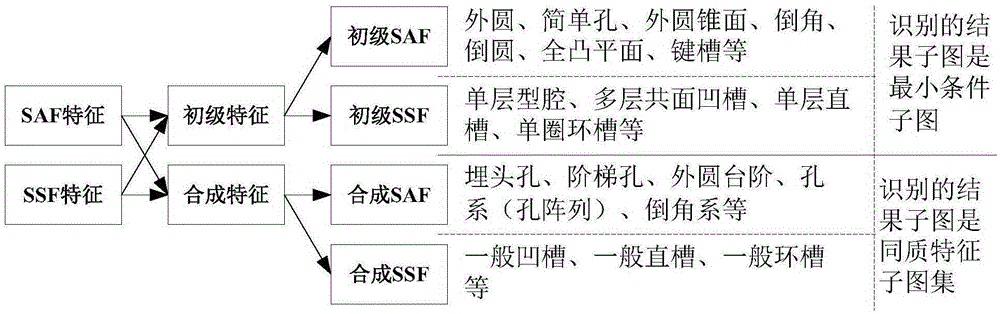

MBD model based processing feature identification and modeling method

The invention is suitable for the field of intelligent process design, and provides an MBD model based processing feature identification and modeling method. The method comprises: based on PMI extraction, obtaining product manufacturing information; during identification of a geometric attribute of a processing feature, synthesizing one or more pieces of geometric element information into the processing feature according to a topological relation of geometric elements, wherein the geometric attribute of the processing feature includes geometric attributes of the geometric elements; during identification of a process attribute of the processing feature, obtaining the process attribute of the feature from the topological relation of the geometric elements and labeled information associated with the geometric elements according to the geometric attribute of the processing feature; and finishing processing feature modeling according to the geometric attribute of the processing feature and the process attribute of the processing feature. According to an embodiment of the invention, a part model is analyzed from a process perspective, the processing feature is defined, and PMI information is converted into the process attribute of the processing feature. The method increases the utilization rate of a three-dimensional CAD model and has important significance for exciting the positivity of three-dimensional CAD application.

Owner:WUHAN KAIMU INFORMATION TECH

Automatic fault interpretation device for three-dimensional seismic data body

InactiveCN103135136AImprove interpretation efficiencyHigh precisionBiological modelsSeismic signal processingBody imagesComputer science

The invention provides an automatic fault interpretation device for a three-dimensional seismic data body. According to the automatic fault interpretation device for the three-dimensional seismic data body, a coherent body imaging module is used for detecting seismic faults, and outputting coherent bodies to depict the faults; an ant colony tracking module performs automatic three-dimensional fault tracking and judgment on the coherent bodies by using a directional ant colony algorithm, and outputs an automatic fault tracking result; an automatic fault separation module is used for judging and automatically separating each fault according to the automatic fault tracking result; and an automatic fault attribute calculation module measures and calculates geometric elements and dynamic attributes of the separated faults. The automatic fault interpretation device for the three-dimensional seismic data body can be used for automatically performing fault interpretation on various seismic data; the device has the advantages of high calculation efficiency, objectiveness and accuracy of fault interpretation results, and the like; and fault interpretation accuracy is effectively improved, and seismic interpretation efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

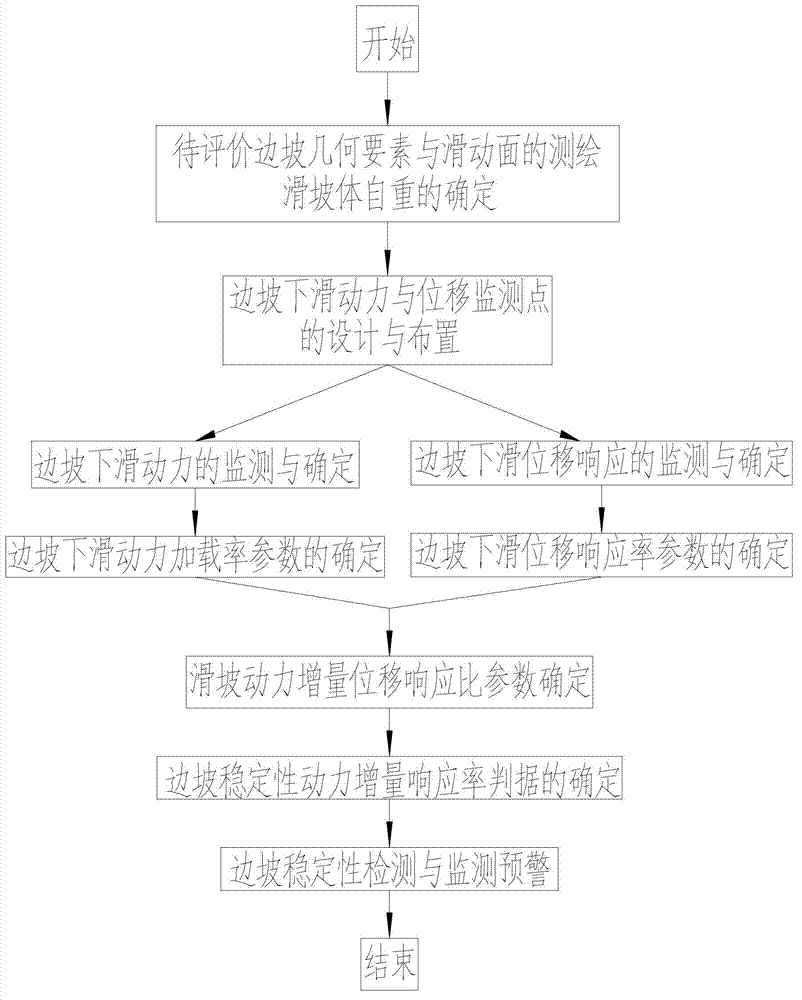

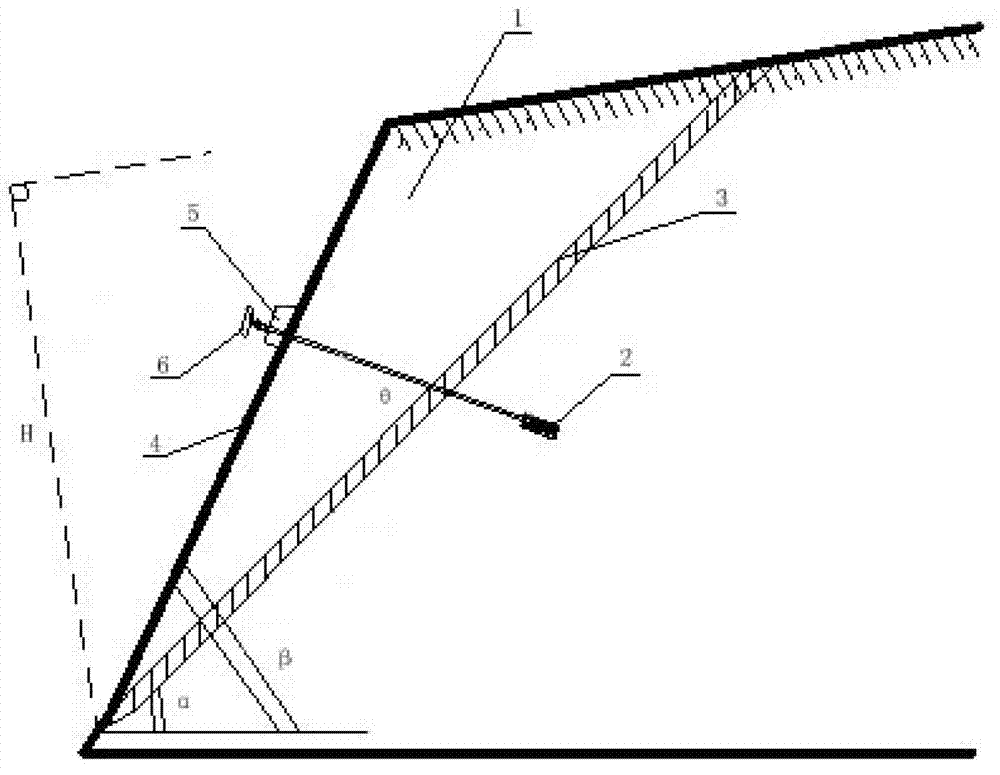

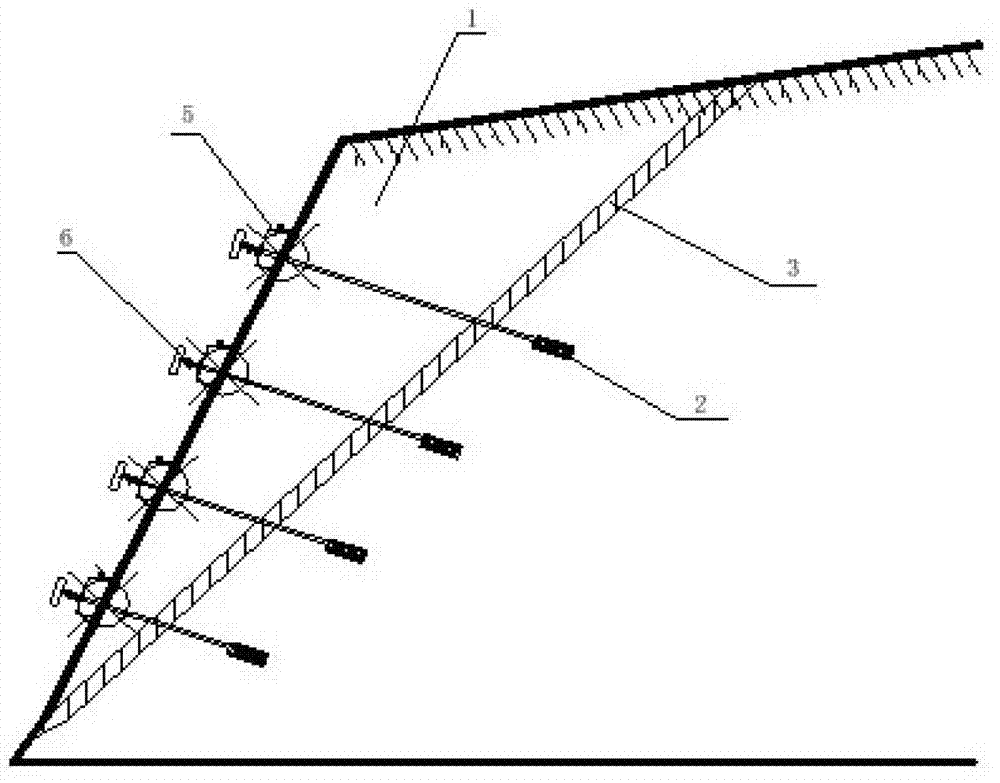

Motive power monitoring and warning method of rock mass landslide

InactiveCN103198619AAvoid complexityStability Unified Instability CriterionAlarmsIn situ soil foundationInstabilityLandslide

The invention relates to a method of detecting stability of a rock mass side slope and warning and forecasting instability of the side slope by adopting motive power increment displacement response ratio parameters. A motive power monitoring and warning method of rock mass landslide includes the following steps: (1) ensuring side slope geometric elements to be detected, mapping of a sliding surface and self weight of a landslide body, (2) designing and arranging side slope downward sliding motive power and displacement monitoring points, (3) monitoring and ensuring the side slope downward sliding motive power and downward sliding displacement response, (4) ensuring side slope downward sliding motive power loading rate parameters, (5) ensuring side slope downward sliding displacement response rate parameters, (6) ensuring landslide motive power increment displacement response rate parameters, (7) ensuring a landslide stability motive power increment displacement response rate criterion, and (8) monitoring side slope stability and monitoring and early warning. Stability coefficients of a limit equilibrium method are organically coupled with a displacement timing sequence analytic method and characteristics of displacement predictive parameters, and limitations of a traditional method are overcome.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for verifying three-dimensional tolerance marking correctness

ActiveCN103324794ARealize automatic verification of correctnessSupport for tolerance testingSpecial data processing applicationsValidation methodsDegrees of freedom

The invention discloses a method for verifying three-dimensional tolerance marking correctness. The method includes the steps: (1) building a three-dimensional solid model; (2) marking three-dimensional tolerances; (3) acquiring geometric elements marked with geometric tolerance information in the three-dimensional solid model; (4) building intrinsic directions of target elements; (5) determining natural degrees of freedom of target geometric elements; (6) acquiring the degree of freedom constraint level of datum elements for the target elements; (7) calculating the degree of freedom constraint capacity of a datum system; (8) checking the three-dimensional tolerance marking correctness. The tolerance marking correctness is checked by establishing relationships of various tolerance types and the degrees of freedom according to expression of the degrees of freedom of the geometric elements and a method for calculating the degrees of freedom constrained among the geometric elements, a three-dimensional tolerance domain is further quantitatively described by the aid of the concept of the degrees of freedom, the tolerances are more effectively inspected and measured, and the tolerance marking correctness is automatically verified.

Owner:HANGZHOU DIANZI UNIV

Method and apparatus for rendering cell-based distance fields using texture mapping

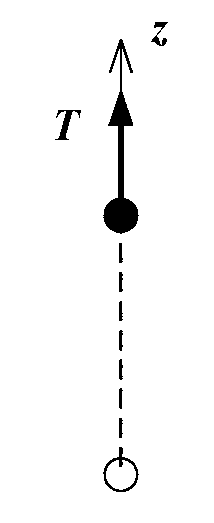

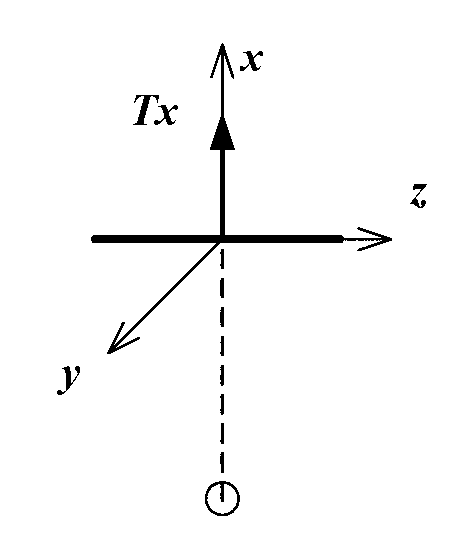

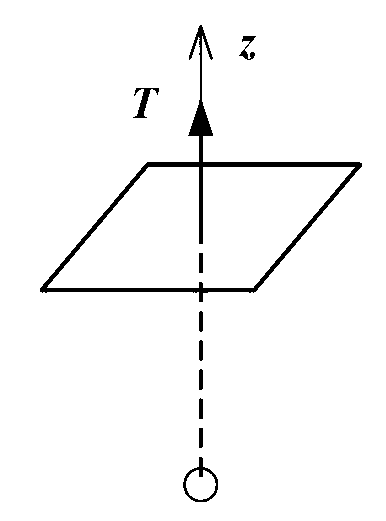

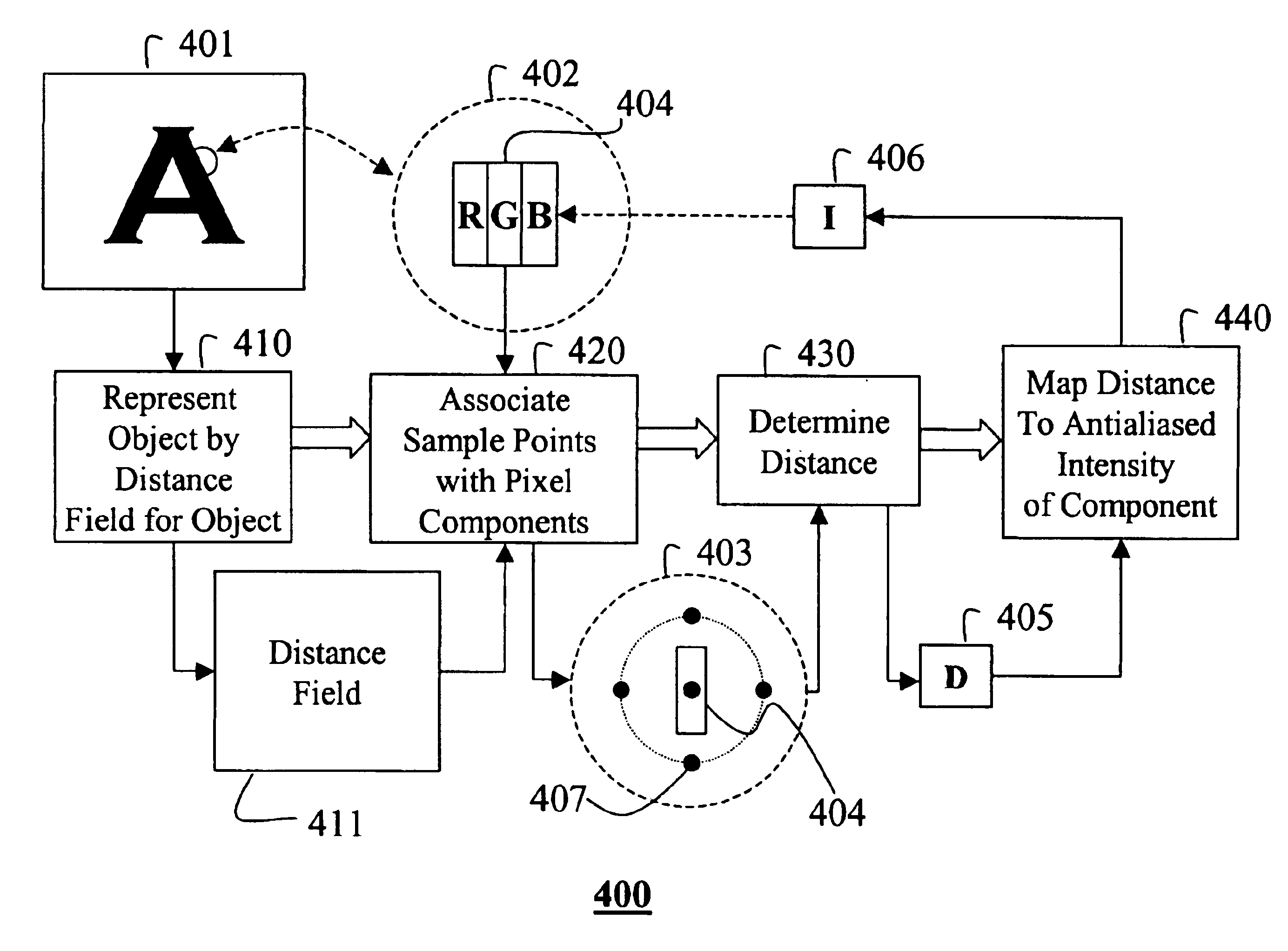

A method and apparatus render a region of a distance field representing an object. The distance field is partitioned into a set of cells, where each cell includes a set of distance samples and a method for reconstructing the distance field within the cell using the distance samples. A set of source cells is selected from the set of cells of the distance field to enable the rendering of the region. Each source cell is represented as a geometric element in a world coordinate system. Each geometric element is associated with a texture map, where the texture map includes distance samples of the corresponding source cell of the geometric element. Each geometric element is transformed from the world coordinate system to a pixel coordinate system and texture mapped, using the distance samples, to determine a distance for each component of each pixel associated with the geometric element. The distance of each component of each pixel is mapped to an antialiased intensity of the component of the pixel.

Owner:MITSUBISHI ELECTRIC RES LAB INC

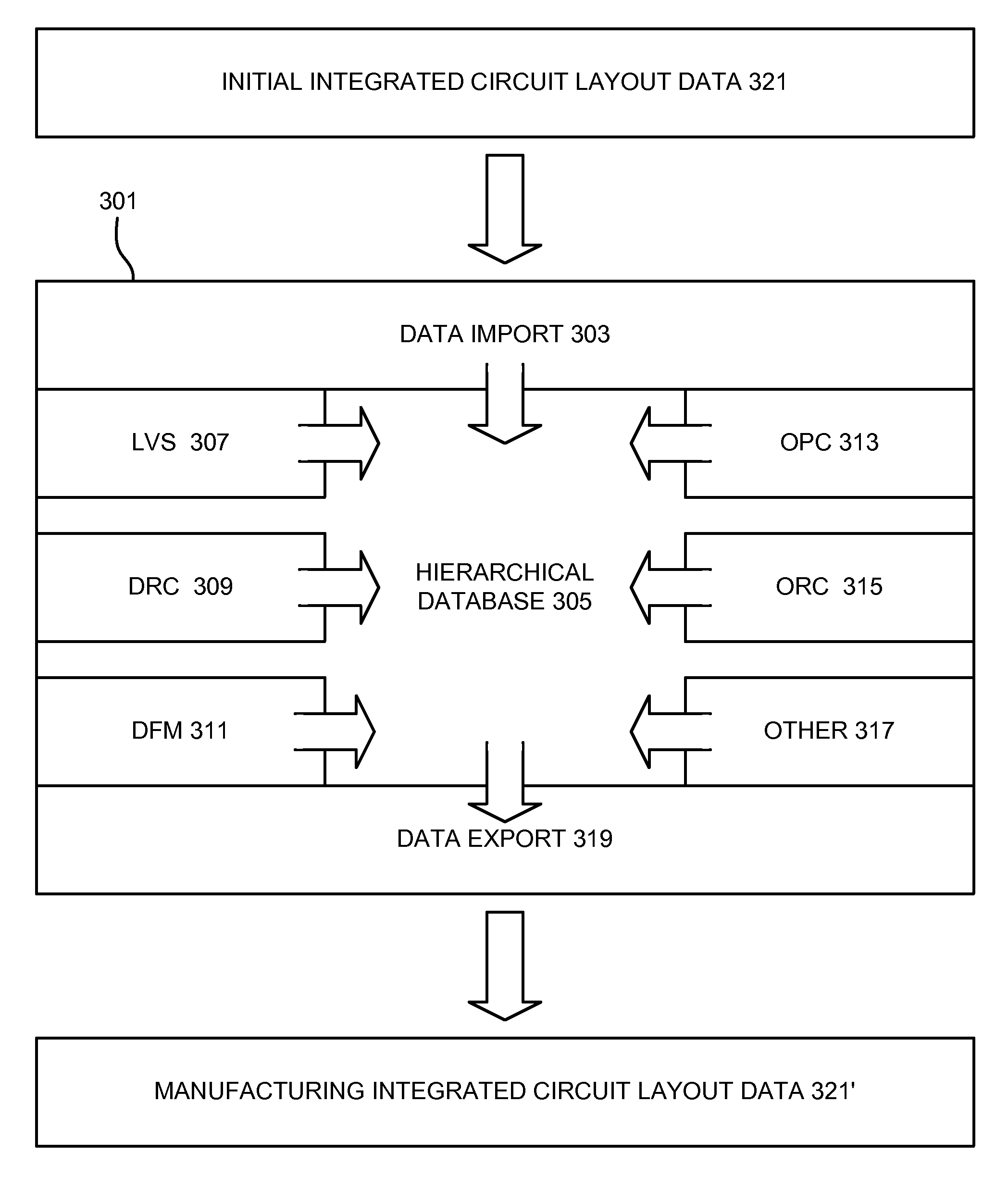

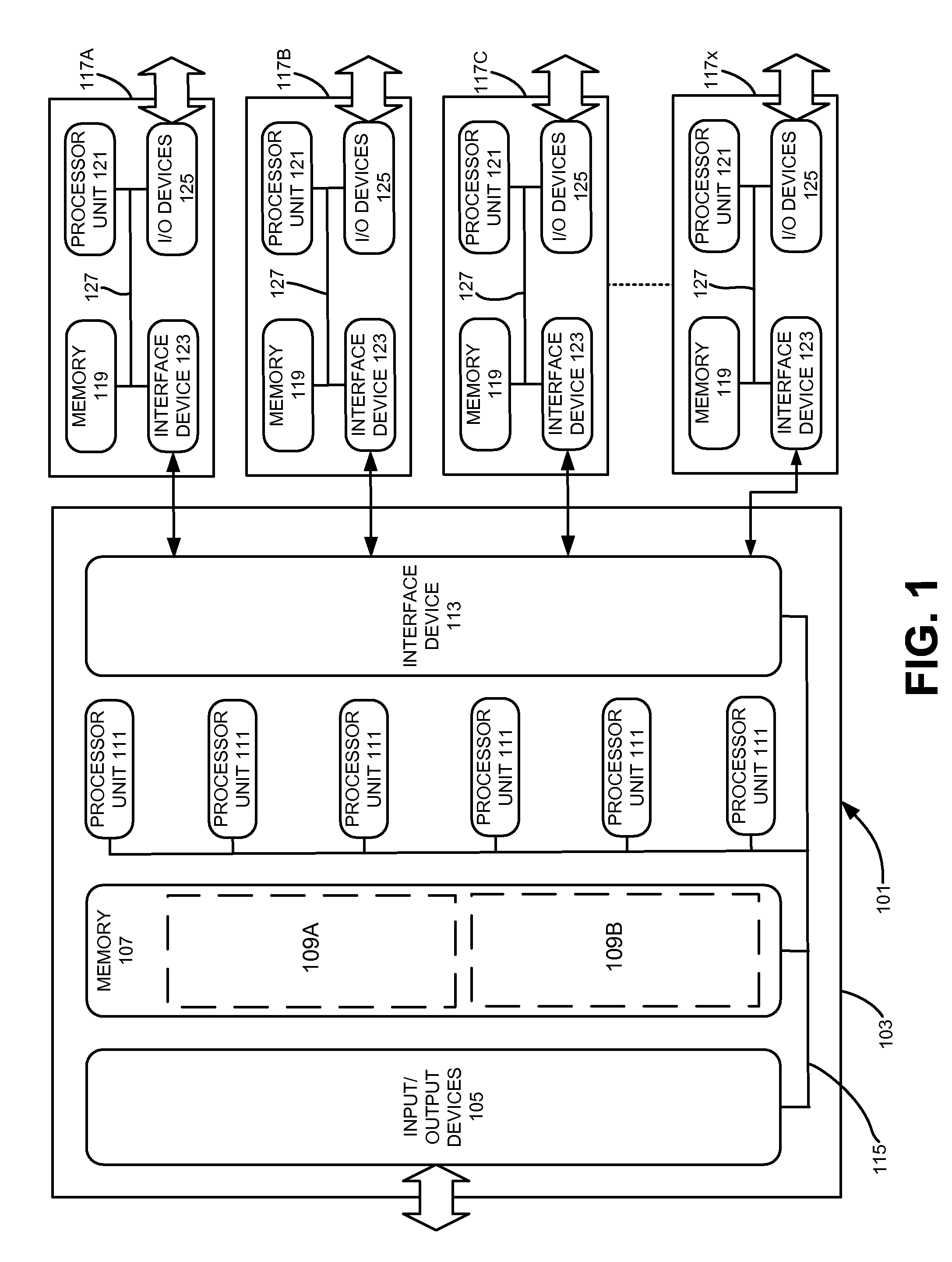

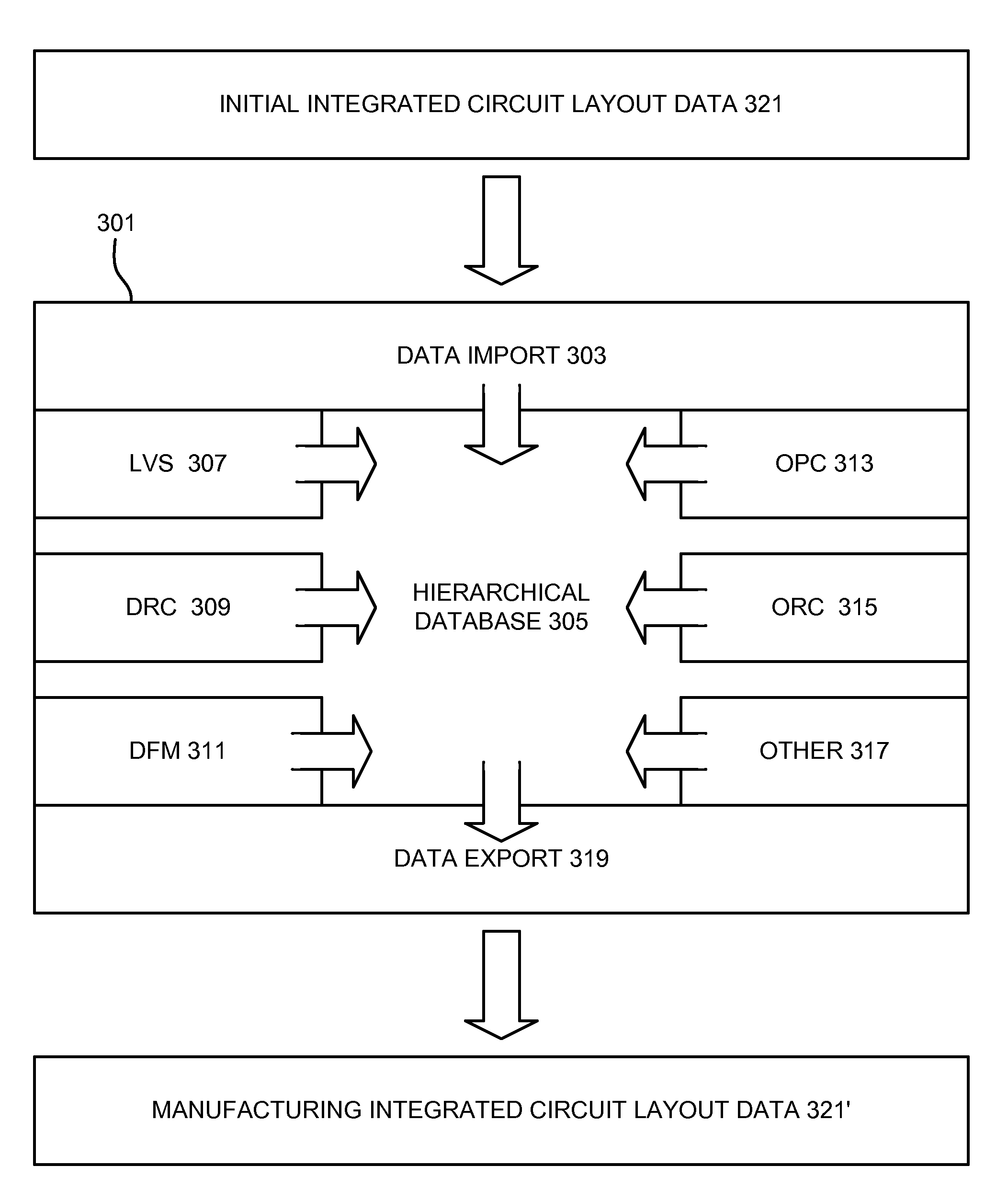

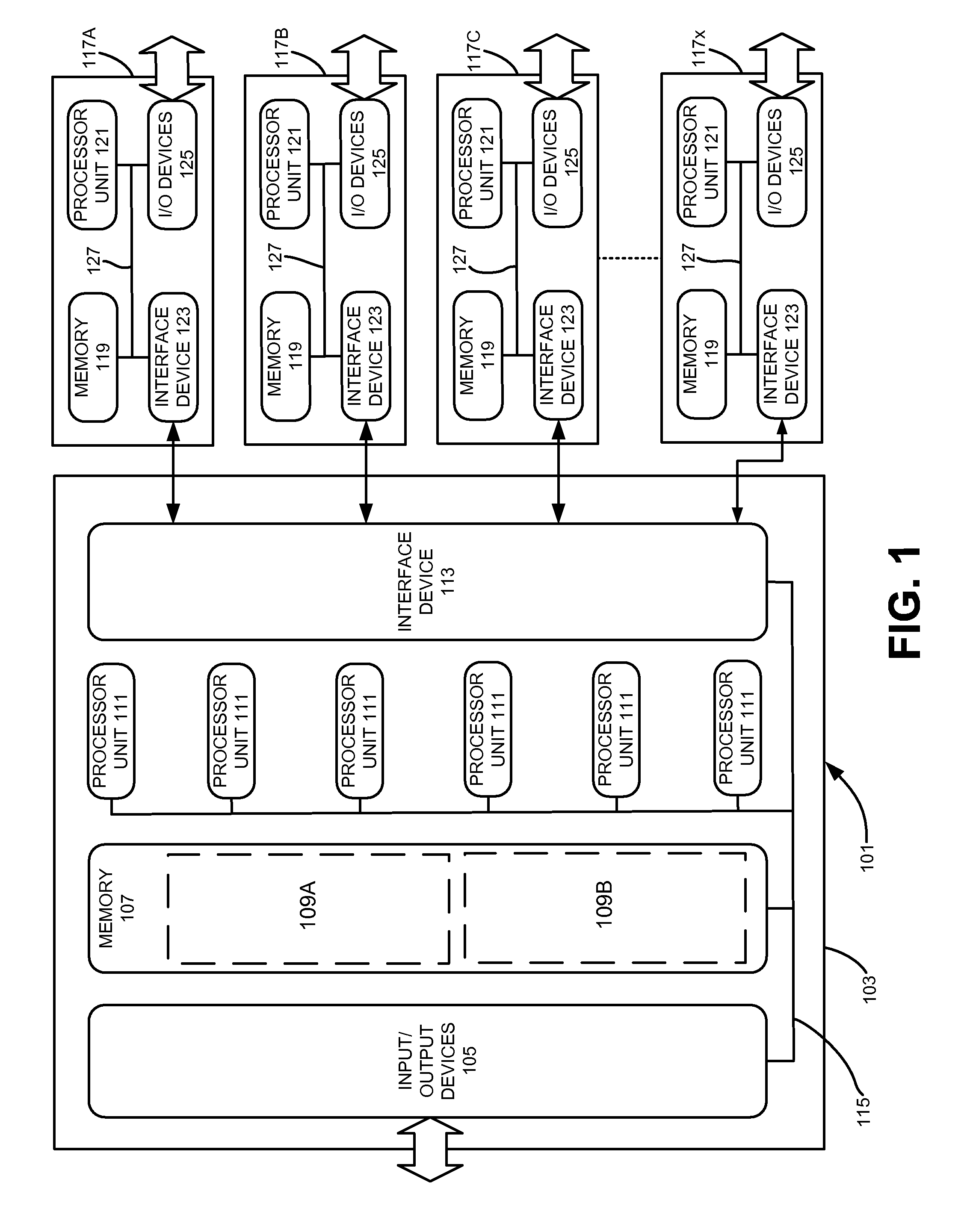

Properties In Electronic Design Automation

InactiveUS20080115096A1Easily calculateComputer aided designTotal factory controlComputer architectureLogic circuit design

One or more properties can be associated with a design object in a microdevice design. The design object may be an object in a physical layout design for a microdevice, such as a geometric element in a layout design. The design object also may be a collection of geometric elements in a layout design, such as a net, a cell in a hierarchical design, or even a collection of all of the geometric elements in a layer of a design. Still further, the design object may even be an item in a logical circuit design, such as a net in a logical circuit design for an integrated circuit. The values of one or more properties may be statically assigned for or dynamically generated during a design process performed by an electronic design automation tool. A property may be assigned a constant value or a value defined by an equation or other type of script that includes one or more variables. A property may be simple, where the definition of the property's value is not dependent upon the value of any other properties. Alternately, a property may be a compound property, where the definition of the property's value incorporates another, previously-determined property value. Still further, a property may be an alternative property, where the property is assigned one value definition under a first set of conditions and assigned another value definition under a second set of conditions. A first electronic design automation process may generate one or more property values. The generated property values then can be passed to another electronic design automation process in the design analysis flow for its use.

Owner:MENTOR GRAPHICS CORP

CAD modeling system and method

ActiveUS8050491B2Shorten speedSolve the slow scanning speedDetails involving processing stepsImage analysisGeometric elementDistortion

A 3D object modeling system and method system and method captures a 2D representation of the object to be modeled and breaks the 2D image into its geometric elements. The 3D stereoscopic image is then fitted to the geometric elements generated from the 2D image to generate the final model. The 3D stereoscopic image may be compared with the geometric elements to detect distortions in the object, allowing the distortions to be corrected in the final model to ensure that the model accurately depicts the original object.

Owner:RTX CORP

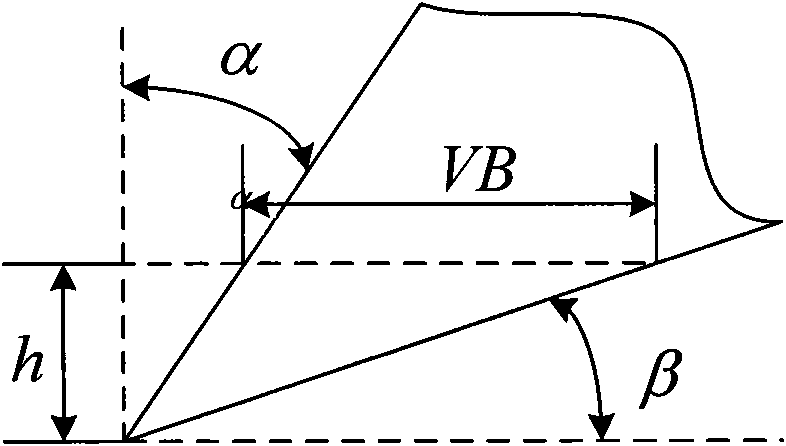

Wear measuring method based on profile duplication of grooving and milling cutter

InactiveCN101804583AEliminate the effects of wear measurementsEasy to set upMeasurement/indication equipmentsNumerical controlBatch processing

The invention relates to a cutter wear measuring method based on the grooving and milling profile duplication, belonging to the cutter wear measuring field. The method is characterized by comprising the following steps of: installing a workpiece material to be processed and a duplicate material on the same numerically-controlled machine workbench; firstly duplicating the initial profile of a cutter on the duplicate material before experiment, that is, feeding the cutter on the duplicate material in a grooving and milling mode for a preset distance, wherein the duplicate material is a tractable material of which the wear on the cutter can be ignored; processing the workpiece material according to the experimental scheme, and duplicating the profile of the worn cutter on the duplicate material after each processing is completed; processing the cutter wear geometric element shape on the duplicate material, extracting characteristic values, designing a measurement scheme based on the measurement requirements of the characteristic values, and measuring on three coordinates measuring machines after all experimental schemes are finished. The invention can obtain the cutter wear amount without closing down the tool, and has the advantages of simple setting for the cutter wear measurement, less measurement data, simple processing and batch processing and measurement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

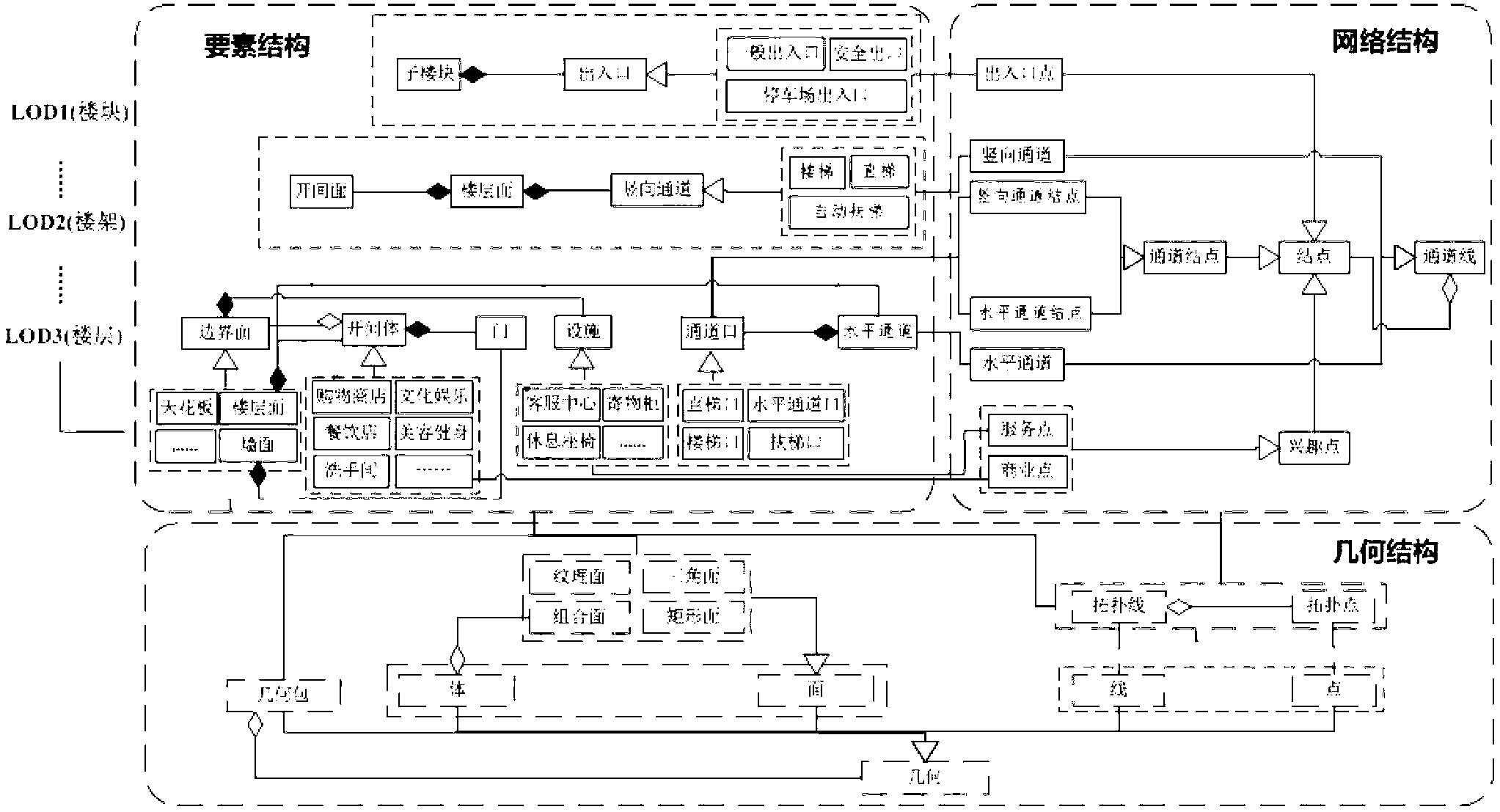

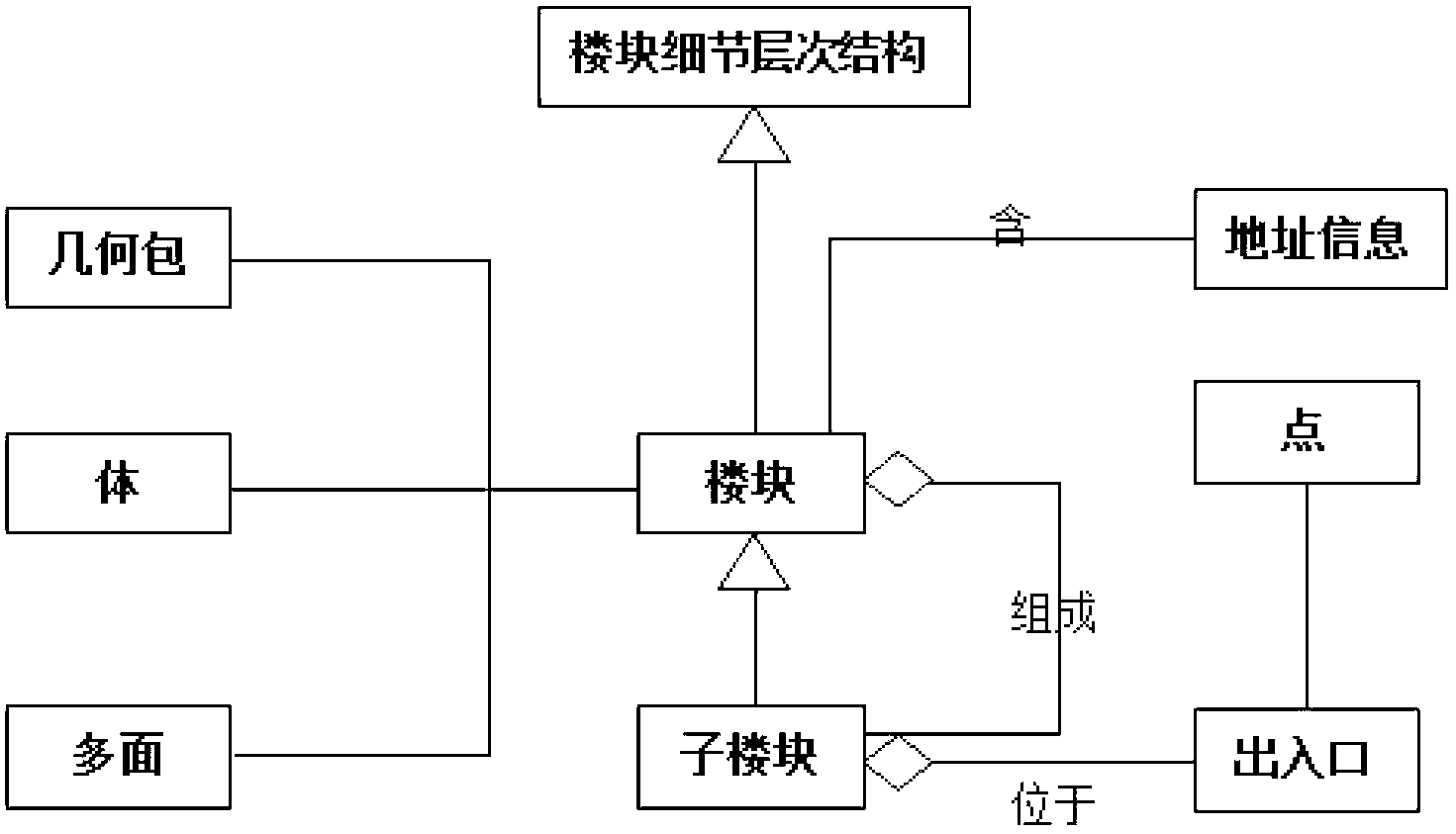

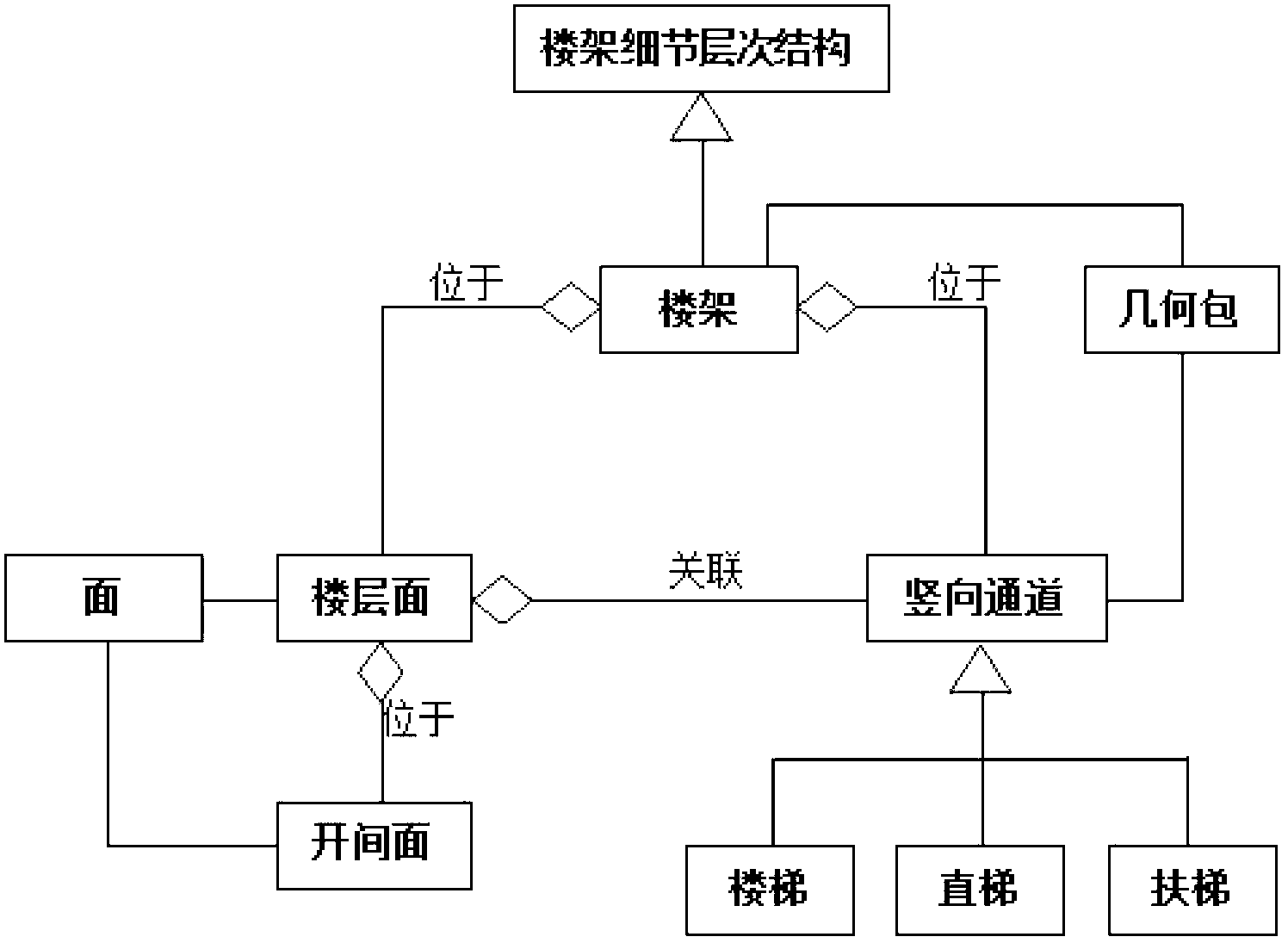

Three-dimensional visualized indoor navigation method oriented to large shopping center

ActiveCN103234539AImplement multiple levels of detail descriptionRealize multiple levels of detail expressionNavigation instrumentsLevel of detailNetwork structure

The invention relates to the field of GIS (Geographic Information System) three-dimensional visualization, and in particular relates to a three-dimensional visualized indoor navigation method oriented to a large shopping center. The method comprises the following steps of: carrying out extraction and classification on navigation elements, network structure elements and geometric elements of the shopping center from the perspective of function and visualization according to the characteristics of geographical elements in the existing large shopping centers, wherein similar elements are subjected to a same detail level grade description; and constructing a data model and a network structure according to the elements obtained through extraction and classification, and based on the data model and the network structure, carrying out indoor navigation based on three-dimensional visualization. According to the method, the achievements in the aspects of building the expression model of indoor three-dimensional navigation geographic elements, indoor three-dimensional navigation data logical models, indoor three-dimensional navigation models and the like not only create a novel LBS (Location Based Service) application mode, but also enrich the connotation of the indoor navigation technology, thereby providing a beneficial reference for the indoor three-dimensional navigation application of large shopping centers.

Owner:NANJING NORMAL UNIVERSITY

Programmable Design Rule Checking

InactiveUS20090106715A1Computer aided designSoftware simulation/interpretation/emulationEngineeringDesign rule checking

An analog design-rule-check tool analyzes a microdevice design, such as an integrated circuit design, to identify occurrences of geometric elements that share a specified relationship. When the tool identifies such an occurrence of these geometric elements, it will associate or “cluster” these geometric elements together into an identifiable unit. For specified “clusters” of geometric elements, the analog design-rule-check tool will then determine the value of a measurement or measurements required by a user. Once the analog design-rule-check tool has determined the necessary measurement values, it will use those values to evaluate the function describing a model.

Owner:MENTOR GRAPHICS CORP

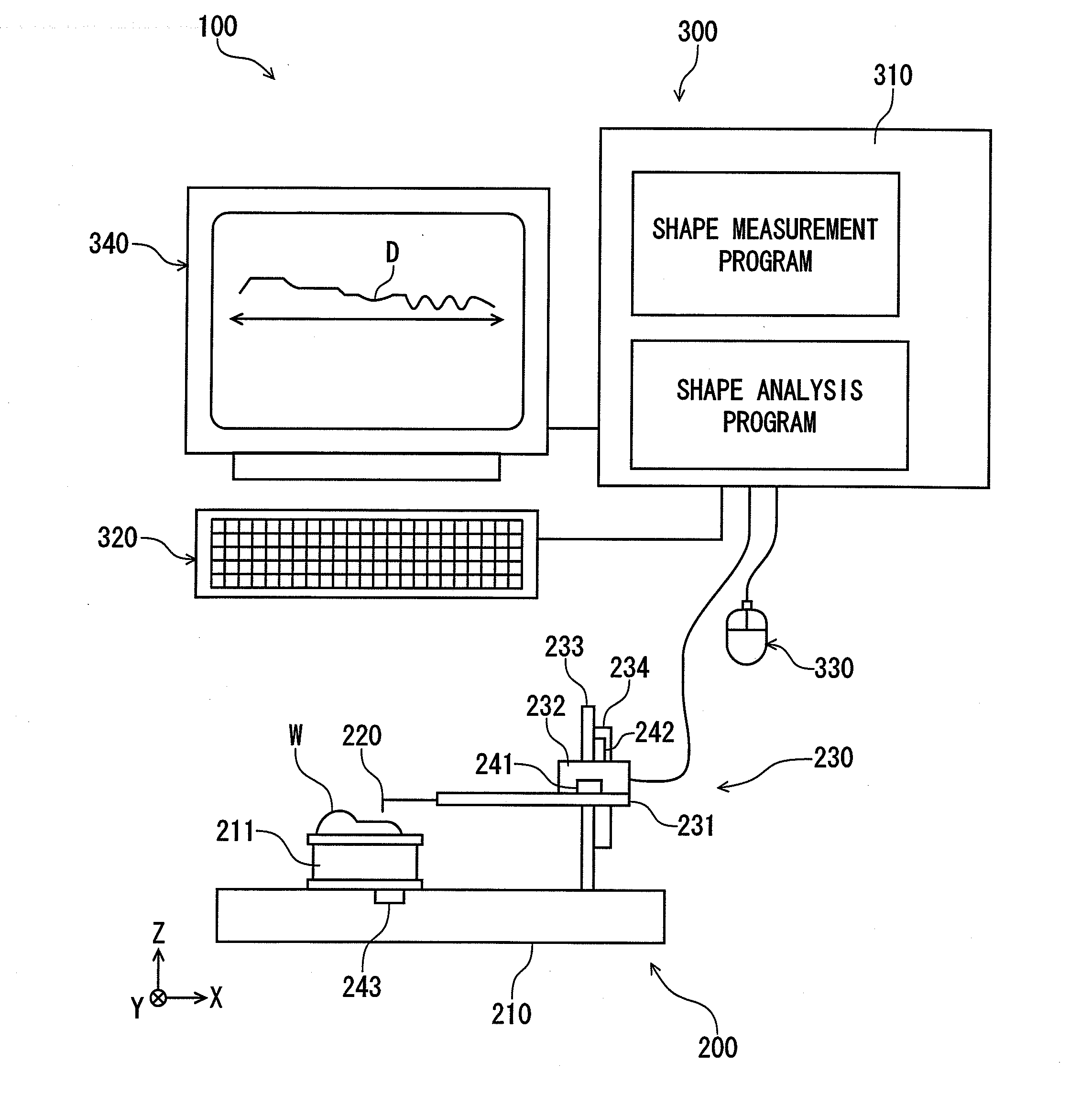

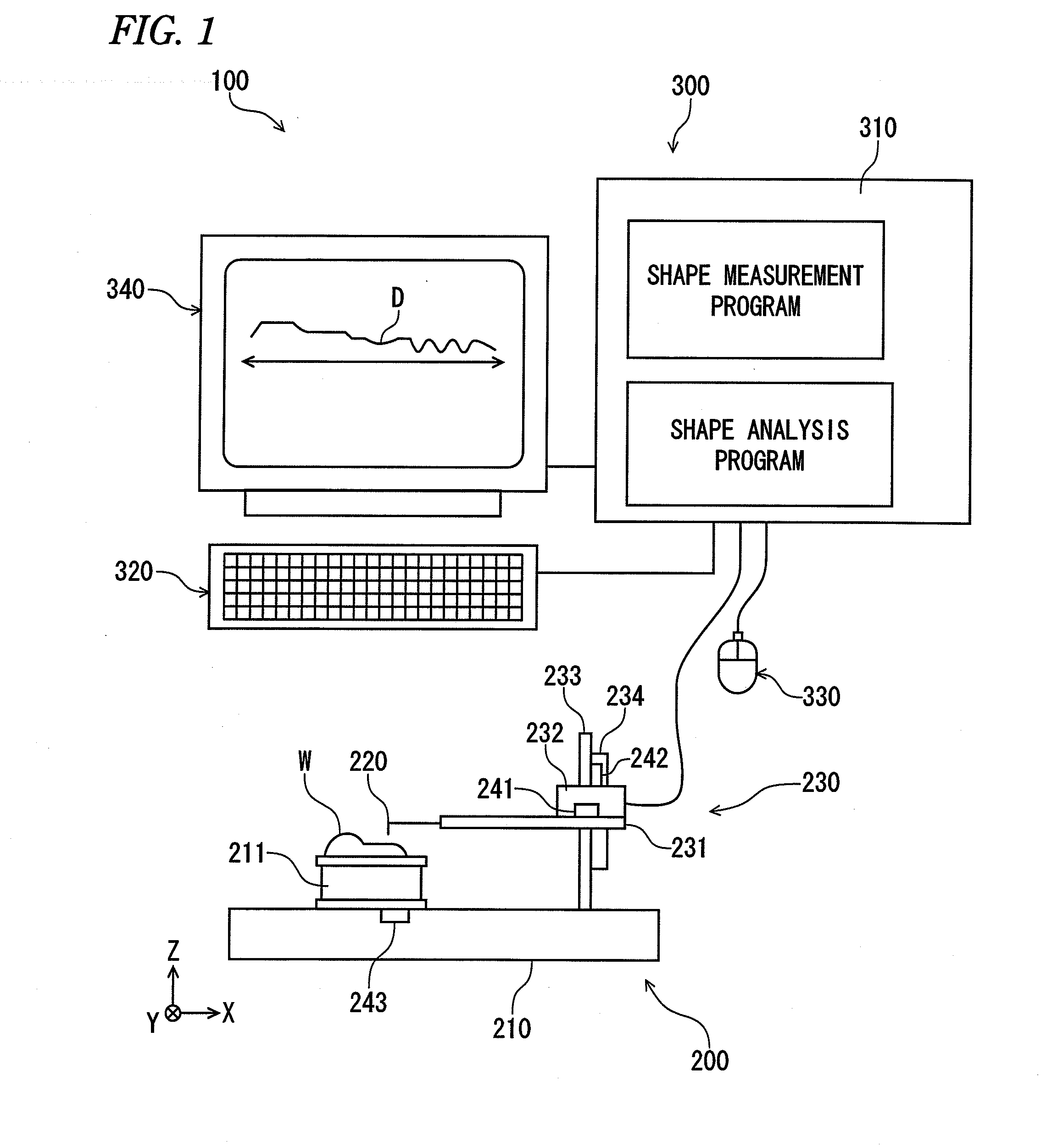

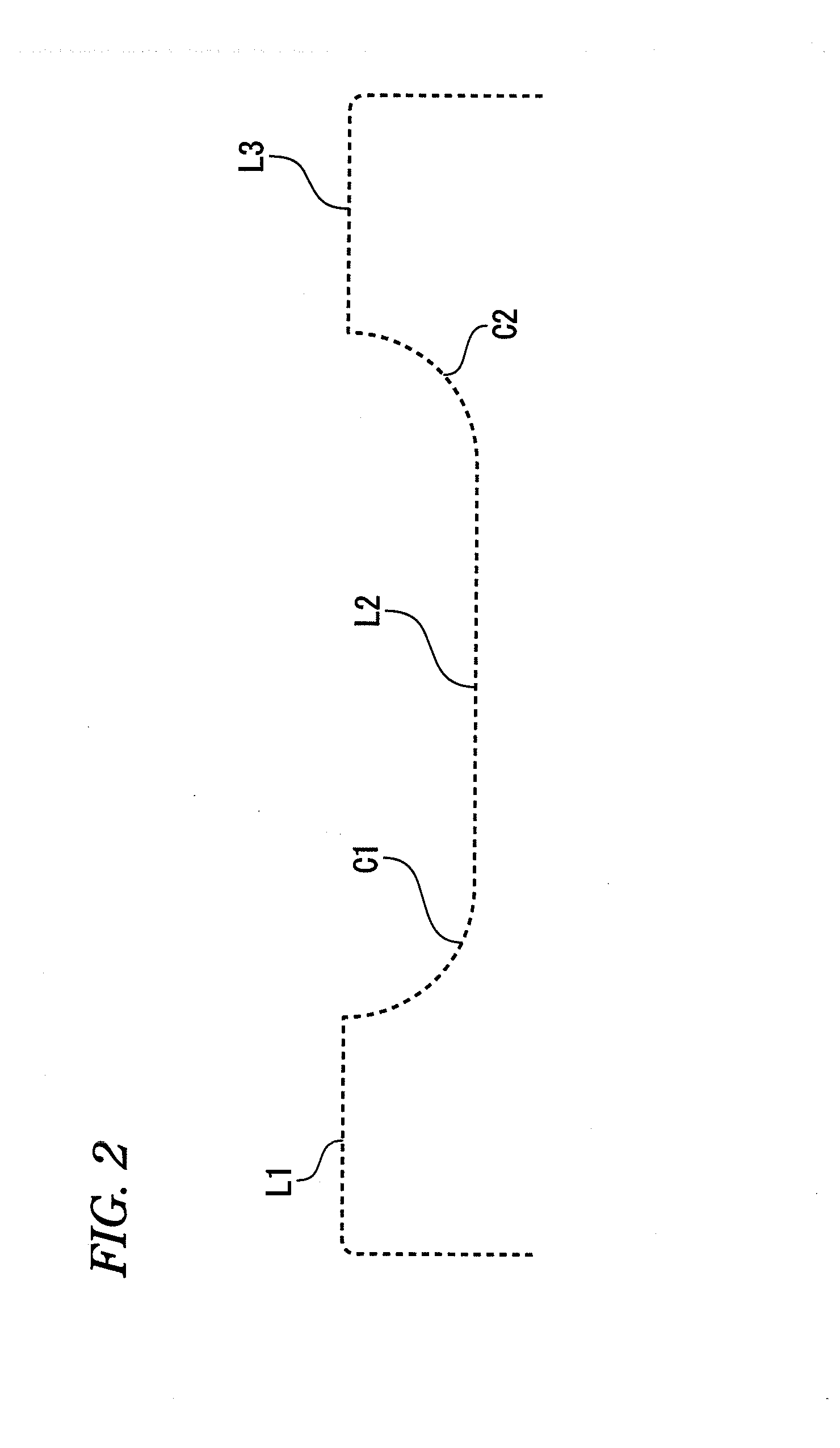

Shape analysis method and shape analysis program

ActiveUS20140005978A1Easy to operateImproving stabilizing evaluationAngles/taper measurementsFeeler-pin gaugesGeometric propertyData mining

A shape analysis method for analyzing shape data acquired by measuring a contour shape of a workpiece to be measured, includes: deciding a geometric element used in shape analysis; deciding one data point to be included in an evaluation range; applying the geometric element to an interval including the one data point; searching the widest interval for satisfying a threshold condition of a preset shape tolerance while changing a width of the interval; pinpointing two boundary points between which the interval found by the search is sandwiched; obtaining two edge points at which the two boundary points are respectively shifted by preset shift amounts; setting a range sandwiched between the edge points in the evaluation range; and targeting the shape data within the evaluation range for calculation of geometric properties.

Owner:MITUTOYO CORP

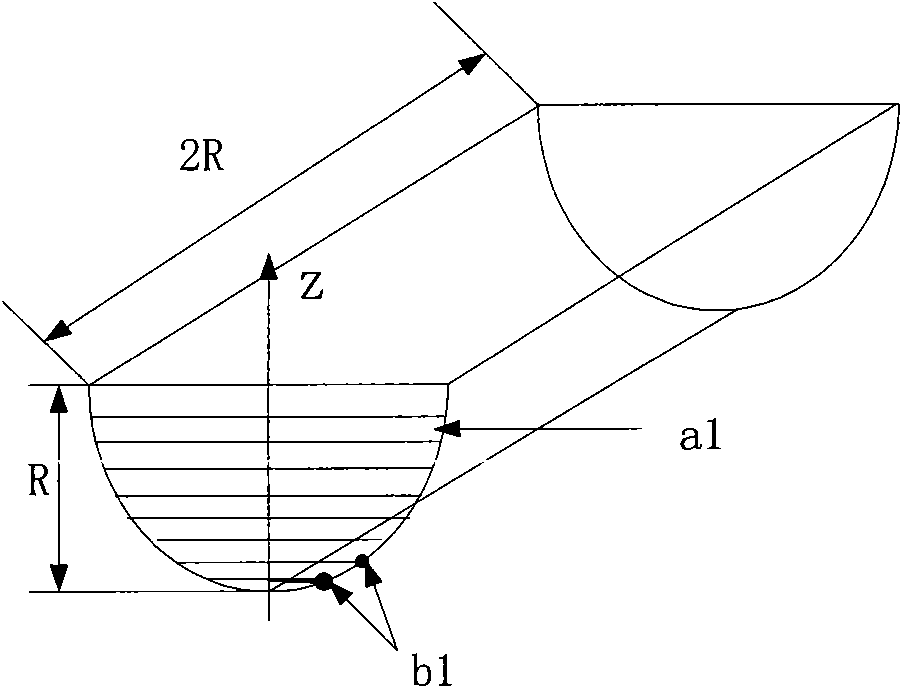

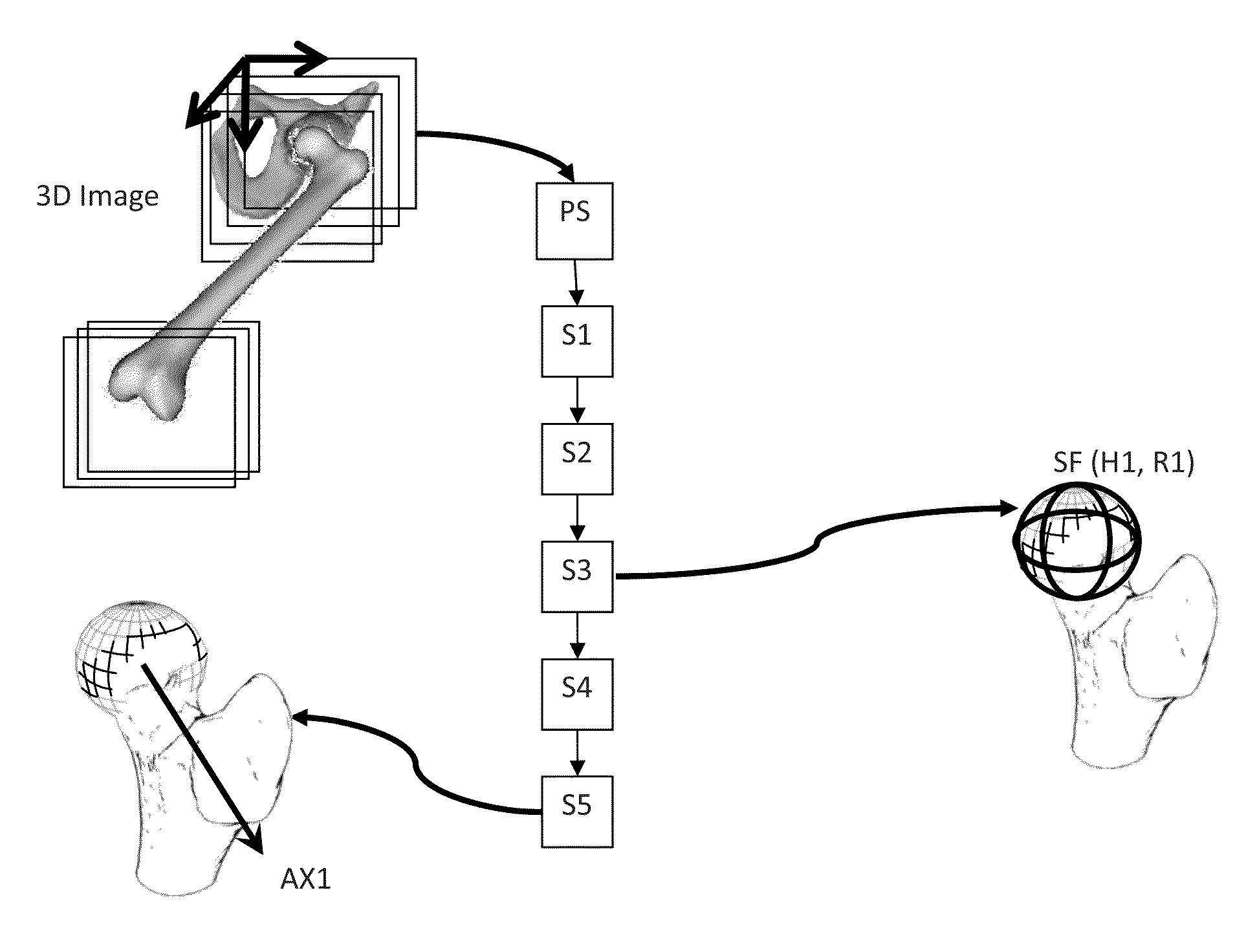

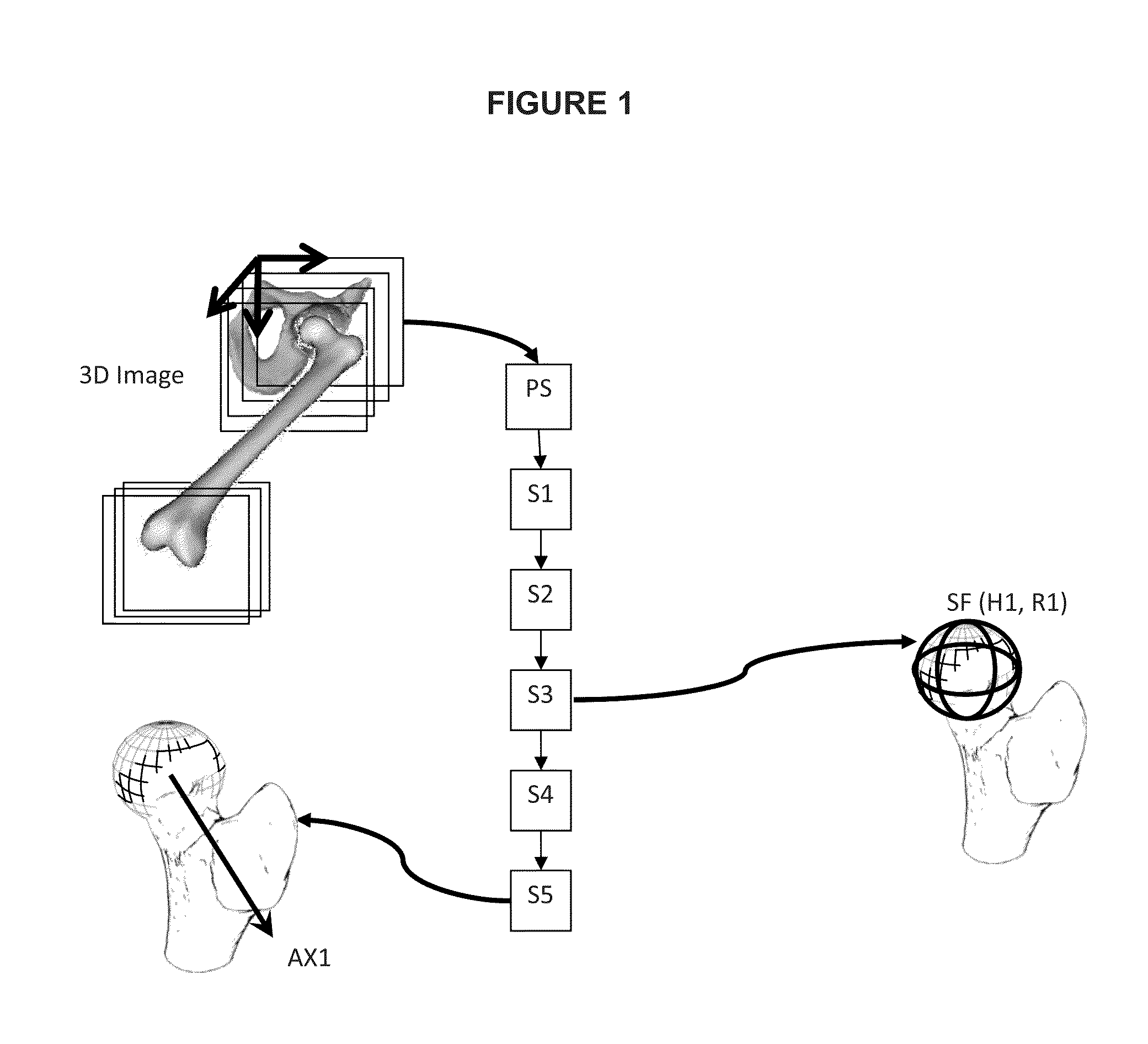

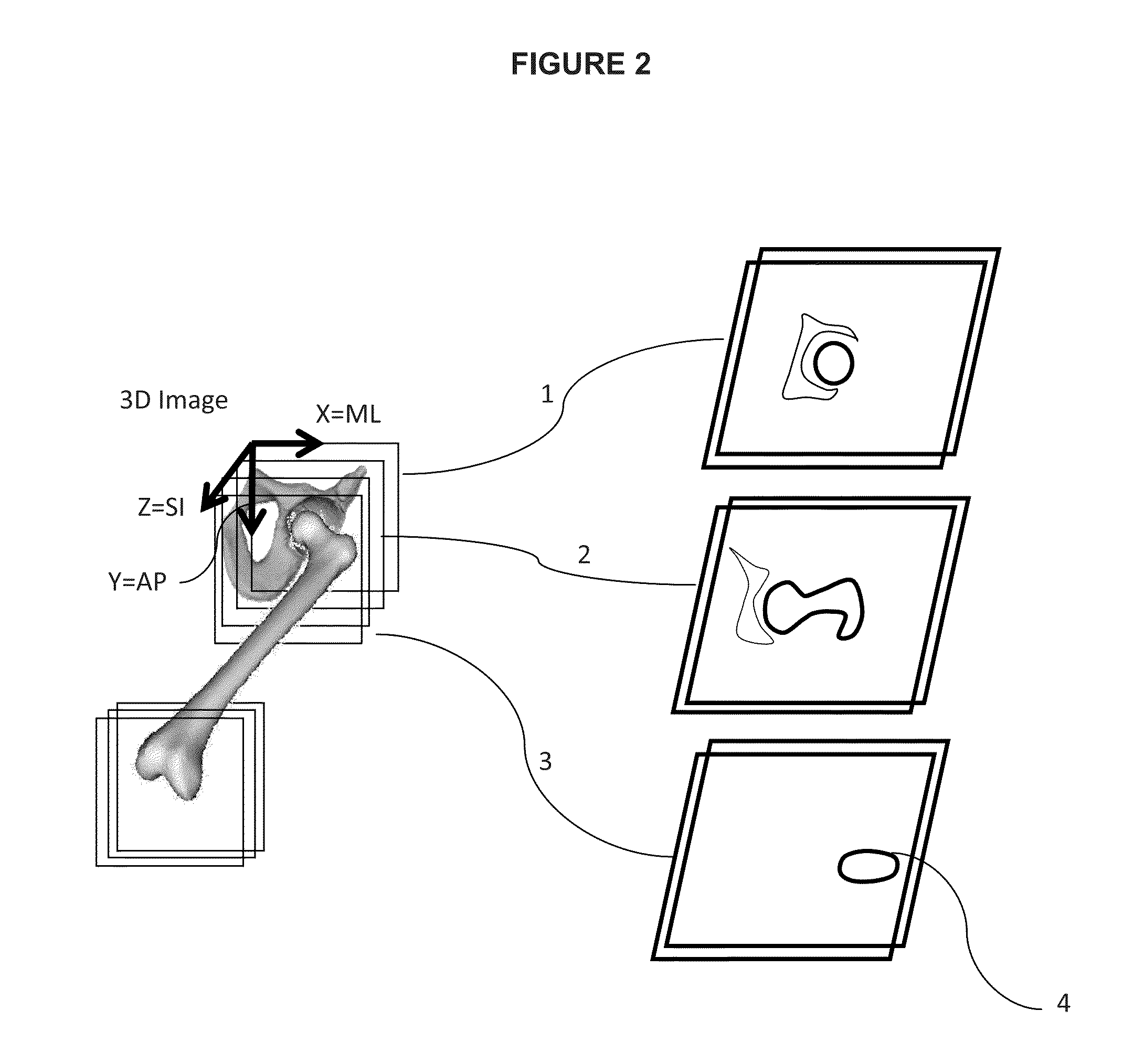

Method and system of automatic determination of geometric elements from a 3D medical image of a bone

The invention relates to an automated method for precise determination of the head center and radius and the neck axis of an articulated bone from acquired 3D medical image of an articulation, comprising the following steps: i) determining, from a 3D image of the bone, an approximate sphere (SFO) of the head of the bone that substantially fits the spherical portion of the head of the bone; ii) constructing from the 3D image and the approximate sphere (SFO), a 3D surface model (S) of the bone; iii) determining, from the 3D surface model (S) and from the approximate sphere (SFO), an approximate neck axis (AXO) of the neck of the bone; iv) determining, from the 3D surface model (S) and the approximate sphere (SFO), a precise sphere (SF); v) determining, from the 3D surface model (S), the precise sphere (SF) and the approximate neck axis (AXO), a precise neck axis (AX1).

Owner:SMITH & NEPHEW ORTHOPAEDICS

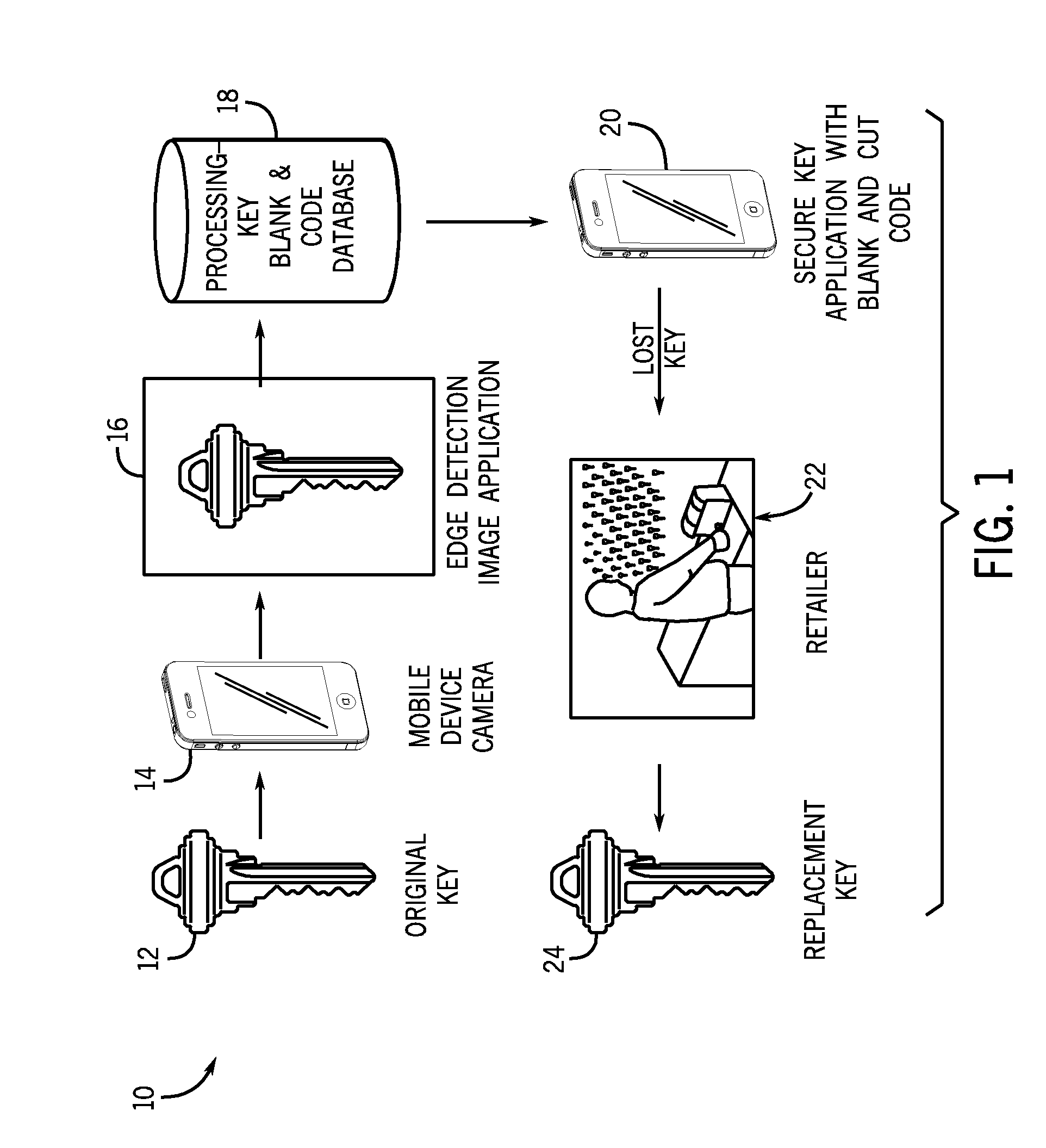

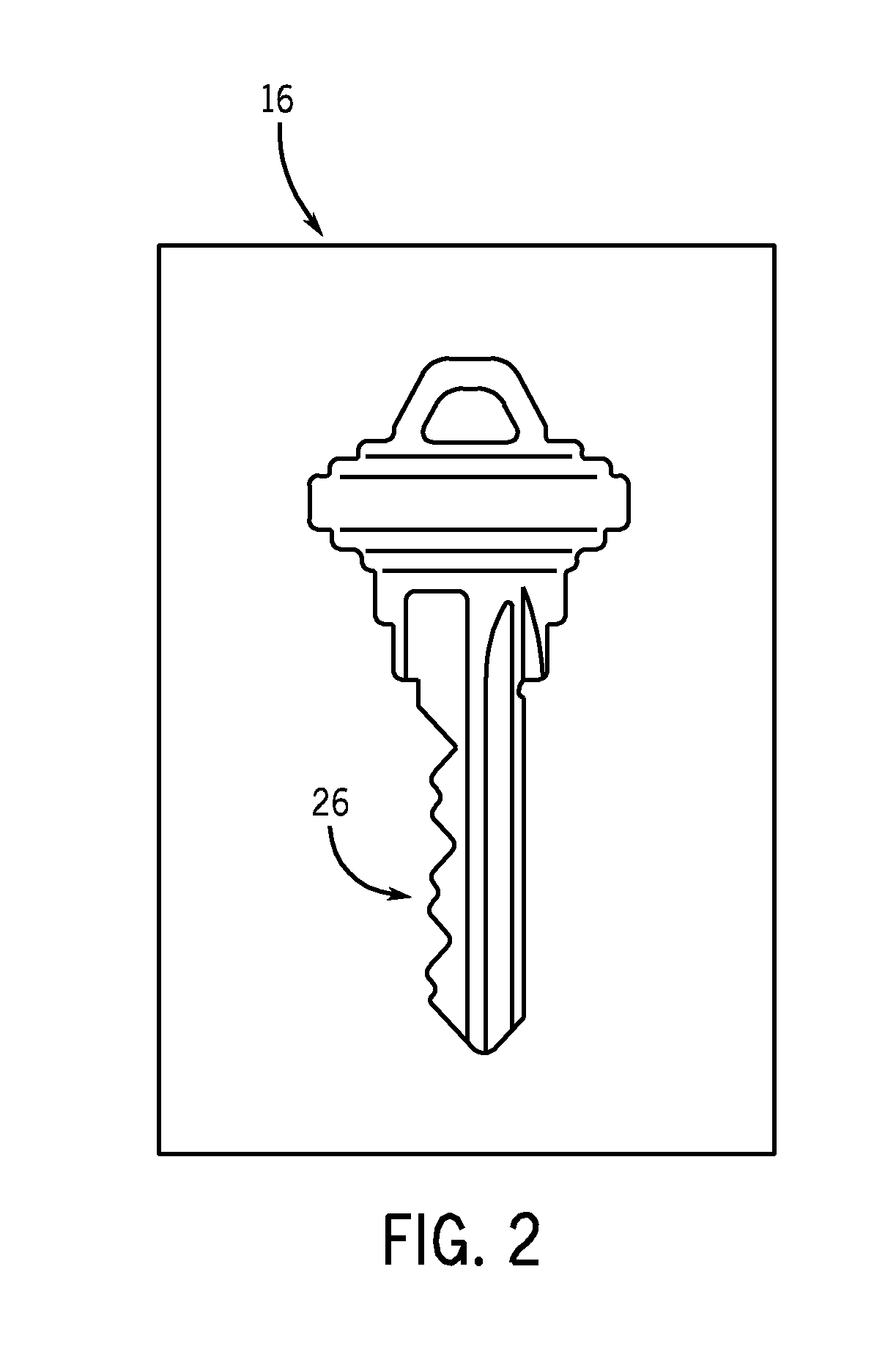

Mobile application for extracting geometric elements and mapping to a master key-code database

InactiveUS20140064597A1Character and pattern recognitionUsing optical meansComputer hardwareImaging processing

A method and application provide a universal key code for use when a key is lost. The code can be taken to a locksmith or retailer for duplication. The user can take a picture of their key and a software application can extract unique key geometries from the key, via, for example, edge detection technology and / or other mathematical methods, digital image processing methods and standard image processing methods. A key code can be determined from this extracted information and mapped to a known key code database. The software application can output, from a picture of an original key, the key blank and key cut code to allow a consumer to simply and conveniently obtain a duplicate key.

Owner:FAGAN ADAM PHILIP +1

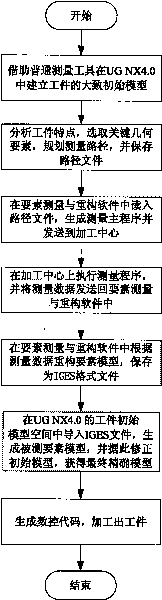

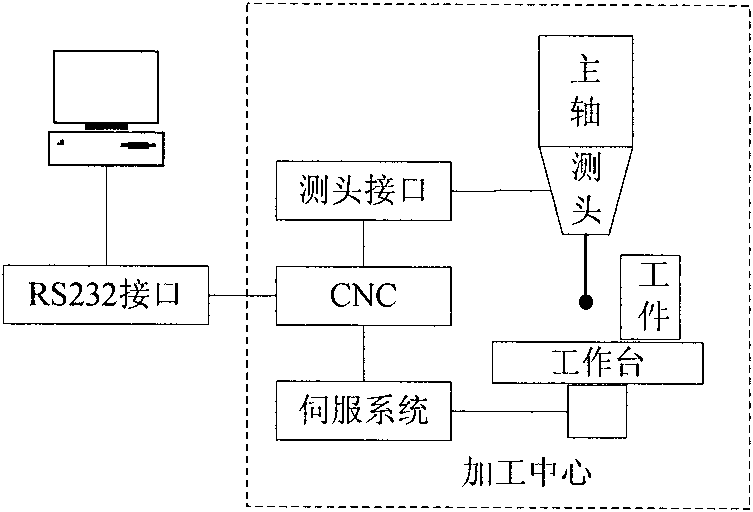

Reverse method based on CAD model modification and measurement path planning

InactiveCN101702087AGive full play to subjective initiativeSimplify the measurement processProgramme controlComputer controlEngineeringReconstruction algorithm

The invention relates to a reverse method based on CAD model modification and measurement path planning for designing and machining machine pieces, which belongs to the technical field of mechanical reverse engineering. The technical scheme comprises the following steps of: 1, establishing an approximate initial model of a workpiece in UG NX4.0 software; 2, selecting key geometric elements to plan a measurement path; 3, creating a primary measurement program according a path file; 4, executing the primary measurement program to measure the measured elements; 5, reconstructing the measured elements; 6, modifying the initial model; and 7,creating a numerically controlled code according to the final CAD model, and transferring the code to a numerically controlled process plant to realize piece machining and reverse process. The reverse method adopts a design of model modification, gives full play to the subjective capability of man, and only measures and reconstructs the key geometric elements that require high precision, thereby greatly simplifying the measurement process and reconstruction algorithm. The path planning based on UG NX4.0 model space and the automatic generation of the measurement program ensures the safety, the rapidity and the precision of the measurement.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com