Reverse method based on CAD model modification and measurement path planning

A technology of measurement path and model correction, applied in simulators, program control, comprehensive factory control, etc., can solve problems such as difficult fitting of complex surfaces, huge amount of data information processing, long measurement process, etc., to simplify the measurement process and repeat Constructing algorithms and ensuring the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, the present invention will be further described through embodiments in conjunction with the drawings.

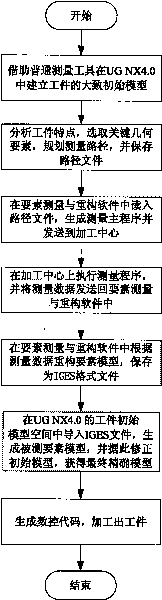

[0037] Reference attached figure 1 , Based on the reverse method of CAD model correction and measurement path planning, including the following steps:

[0038] (1) Use ordinary measuring tools (such as calipers, height gauges, etc.) to perform simple measurements on the workpiece, and use the measured data to establish a rough initial model of the workpiece in the model space of the UG NX4.0 software;

[0039] (2) Analyze the technical characteristics and accuracy requirements of the workpiece, select the key geometric elements that need to be accurately measured (such as: plane, cylindrical surface, round hole surface, etc.), and plan the measurement path; in the UG model space, the measurement path is determined by the operator on the workpiece Add a series of intermittent path points on or around the surface to describe; save the planned path point informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com