Method for verifying three-dimensional tolerance marking correctness

A verification method and correctness technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the relationship between the number of tolerance types and the corresponding benchmarks, and achieve automatic correctness verification and support for tolerances The effect of inspection and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

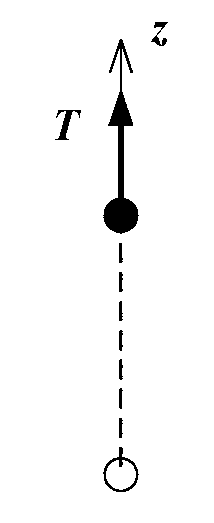

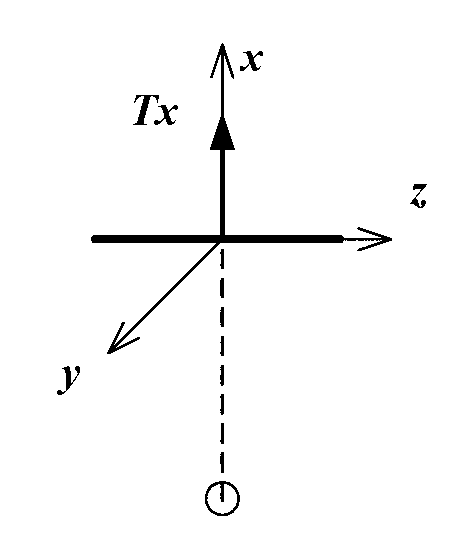

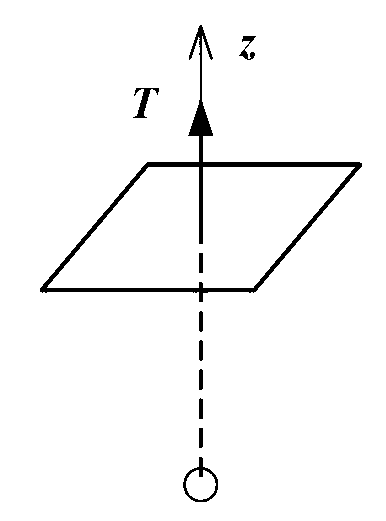

[0061] Example 1 is based on Figure 4a , 4b and Figure 5a , 5b The model in is implemented as an example. Figure 4a , 4b and Figure 5a , 5b The part models are the same, the difference is the geometric tolerance annotation, where, Figure 4a , 4b Dimension for the correct geometric tolerance, Figure 5a , 5b The datum order in the geometric tolerance frame of object C and object D is artificially changed in order to check whether the method of the present invention can detect this erroneous modification. It should be noted that the method described in the present invention is a general method applicable to other mechanical products and components.

[0062] image 3 It is the tolerance verification flow chart of the present invention. First, establish a three-dimensional solid model in three-dimensional software and mark it with three-dimensional tolerances, and then use the method of the present invention to carry out secondary development of the software to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com