Pulley high-low position adjustment method based on sliding door application and sliding door adjusting device

A technology of an adjusting device and an adjusting method, which is applied to the suspension device of the wing leaf, door/window fittings, wing leaf components, etc., can solve the problems of affecting the overall design of the sliding door, inconvenient adjustment, and difficulty in adjustment, etc., and achieves a simple structure. , The effect of low manufacturing cost and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

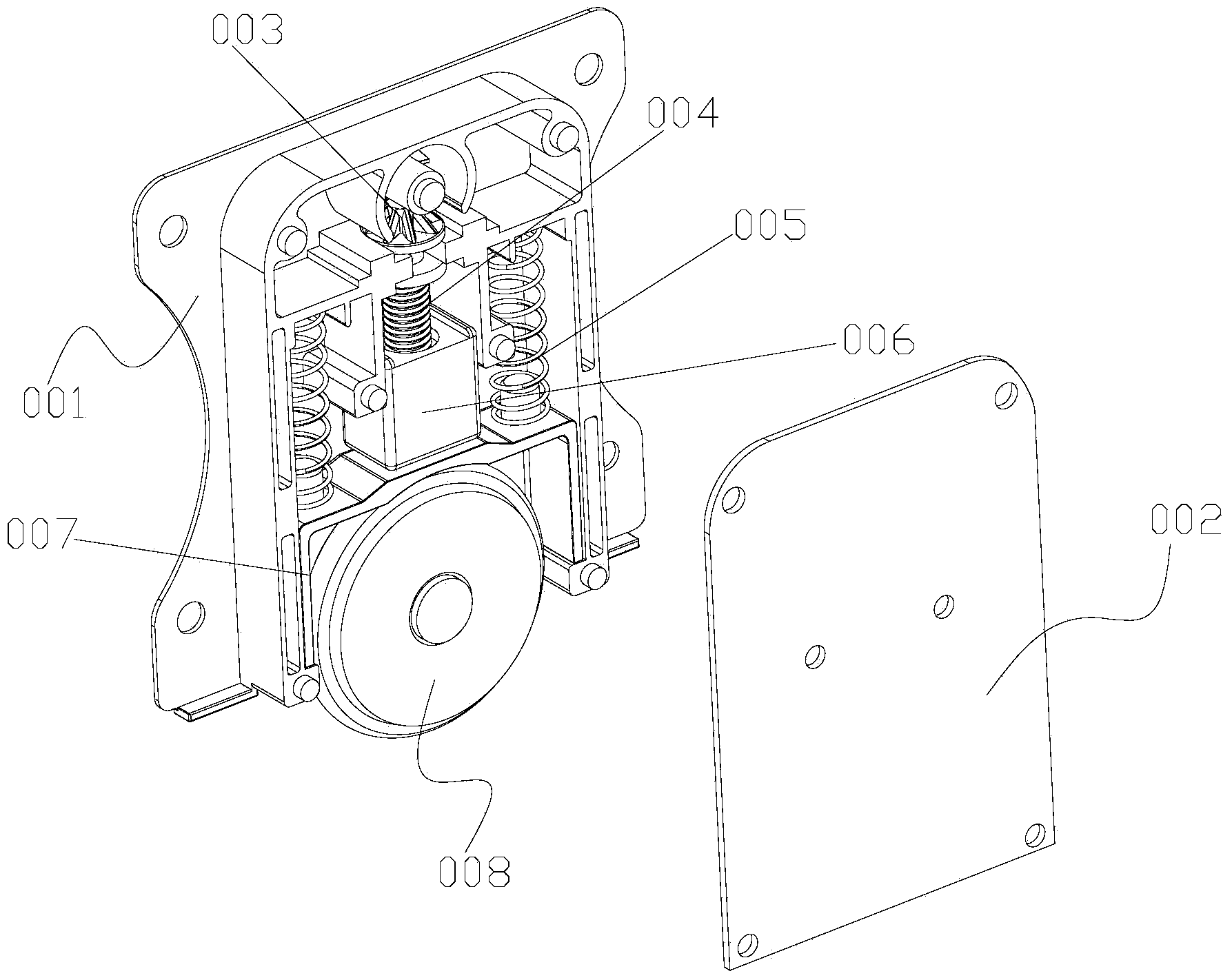

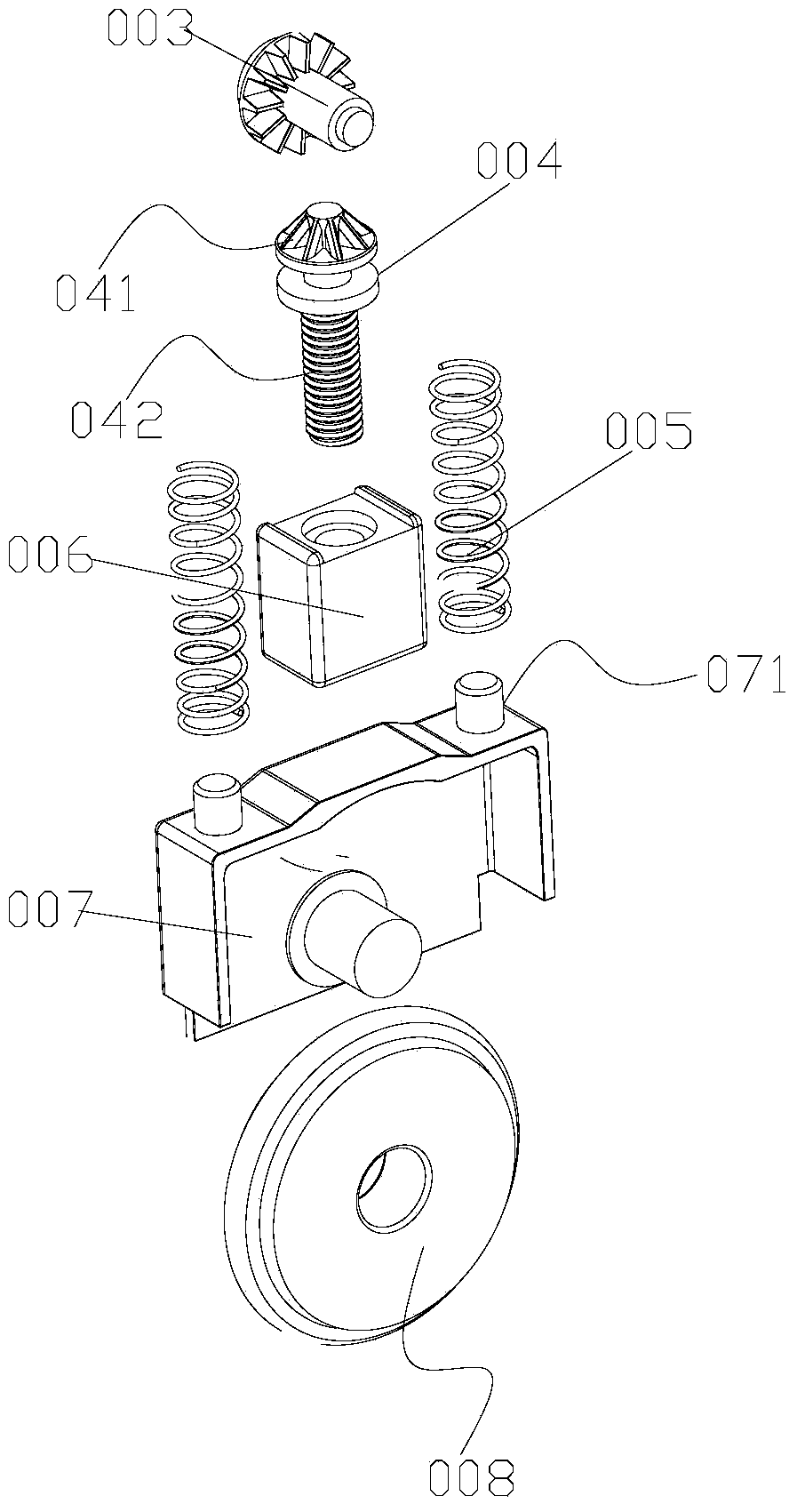

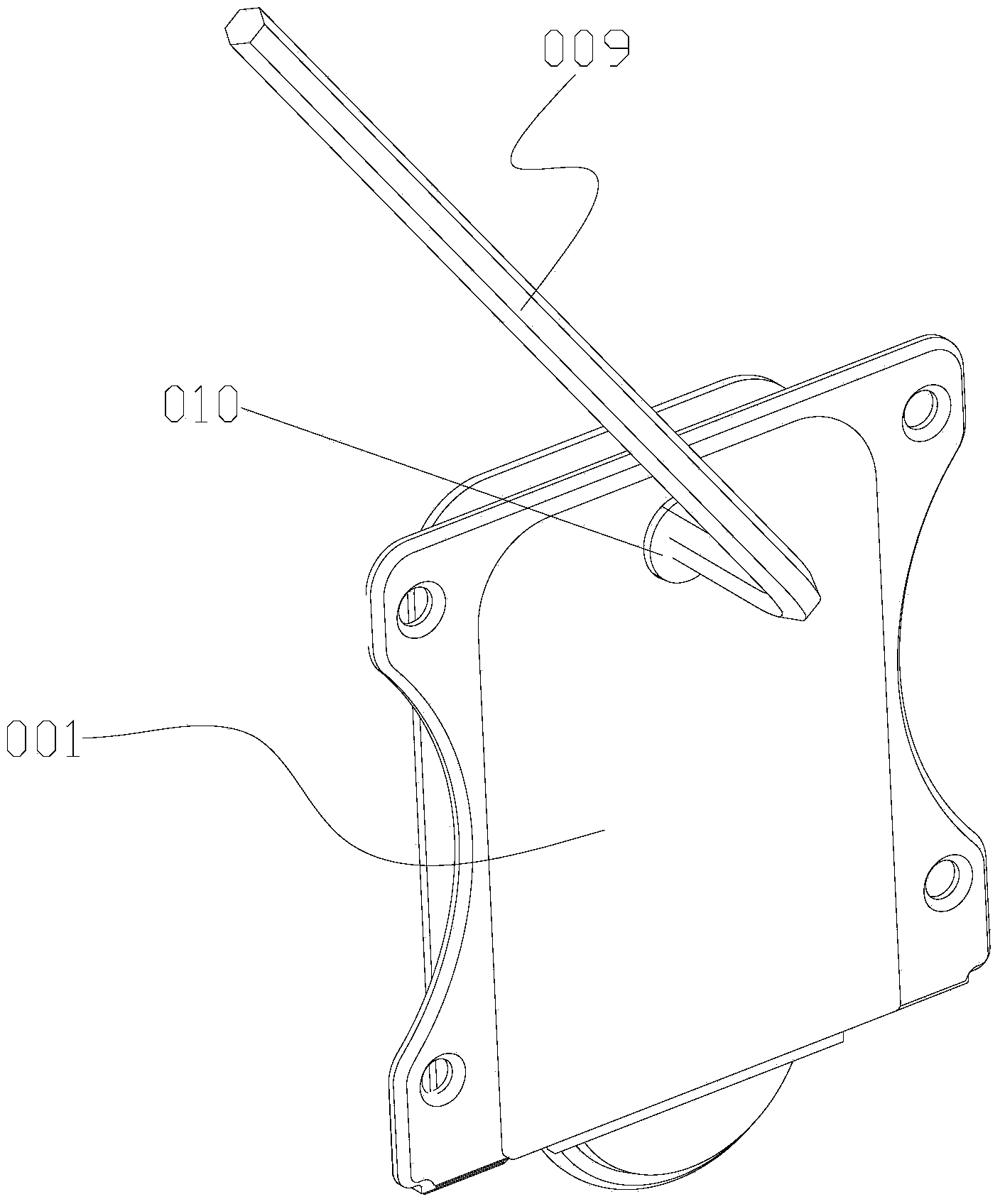

[0033] like figure 1 , figure 2 and image 3 As shown, a method for adjusting the height of the pulley based on the application of the sliding door in this embodiment includes the following steps:

[0034] (1) A sliding door adjustment device, an adjustment wheel 008 and a wrench 009 are provided, and a horizontal adjustment mechanism is arranged inside the sliding door adjustment device; the adjustment wheel 008 is arranged under the sliding door adjustment device, and the sliding door adjustment device also includes Externally fixed casing 001 and cover plate 002, the inner cavity of the casing 001 is a cavity for accommodating the lateral adjustment mechanism, and the wrench 009 is a hexagonal wrench.

[0035] (2) The horizontal adjustment mechanism is composed of interlocking horizontal gear 003, bevel tooth screw 004, thread slider 006, bearing slider 007 and spring 005; the horizontal gear 003 is set on the upper end of the bevel tooth screw 004, The bevel tooth scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com