Pipe pushing rolling device for high-performance magnesium alloy seamless pipes

A seamless pipe and magnesium alloy technology, applied in metal rolling, metal rolling, workpiece heating devices, etc., can solve the problems of pipe cracking, low forming efficiency, long time required, etc., and achieve good centering function and reliability The effect of high performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Based on the solutions in the present invention, all other solutions obtained by those of ordinary skill in the art without creative work are all Belong to the protection scope of the present invention.

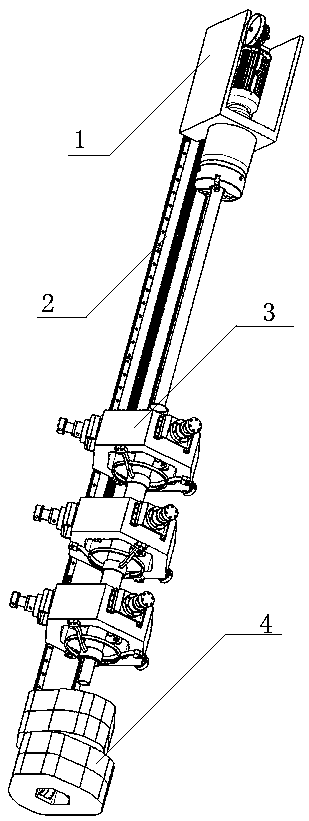

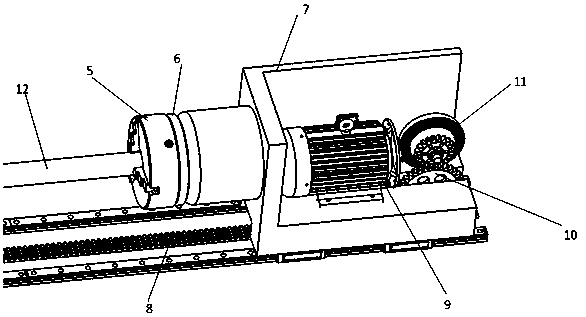

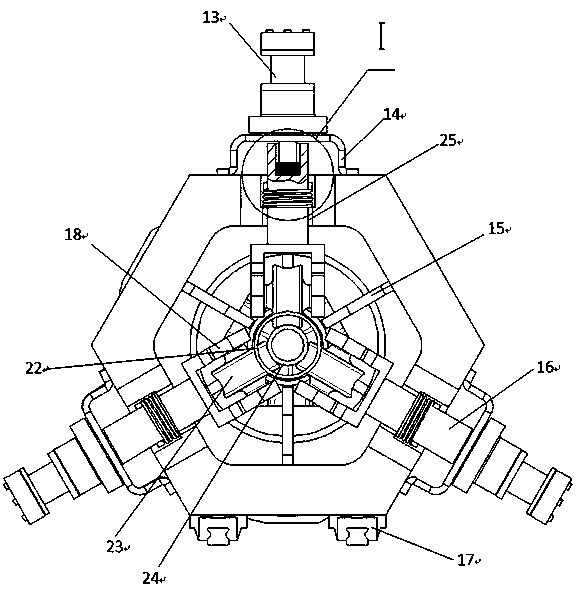

[0021] The present invention will be described below in conjunction with accompanying drawing, as Figure 1-8 As shown, the present invention provides a tube pushing and rolling device for high-performance magnesium alloy seamless pipes, which mainly includes a pushing device 1, an I-shaped guide rail 2, a floating support roller device 3, a driven rolling roll group 4, a slide Key 17 and heating and heat preservation device, wherein, the floating support roller device 3 and the push device 1 are fixed on the I-shaped guide rail 2 by the sliding key 17, and the distance between multiple groups of floatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com