Central cylinder cyclone separation and sedimentation device

A sedimentation device and flow separation technology, which is applied in the direction of centrifugal separation water/sewage treatment, flocculation/sedimentation water/sewage treatment, grease/oily substance/floating matter removal device, etc. Large impact of fluctuations, unstable effluent water quality and other problems, to achieve the effect of increasing the effect of advection sedimentation, improving the effect of advection sedimentation, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

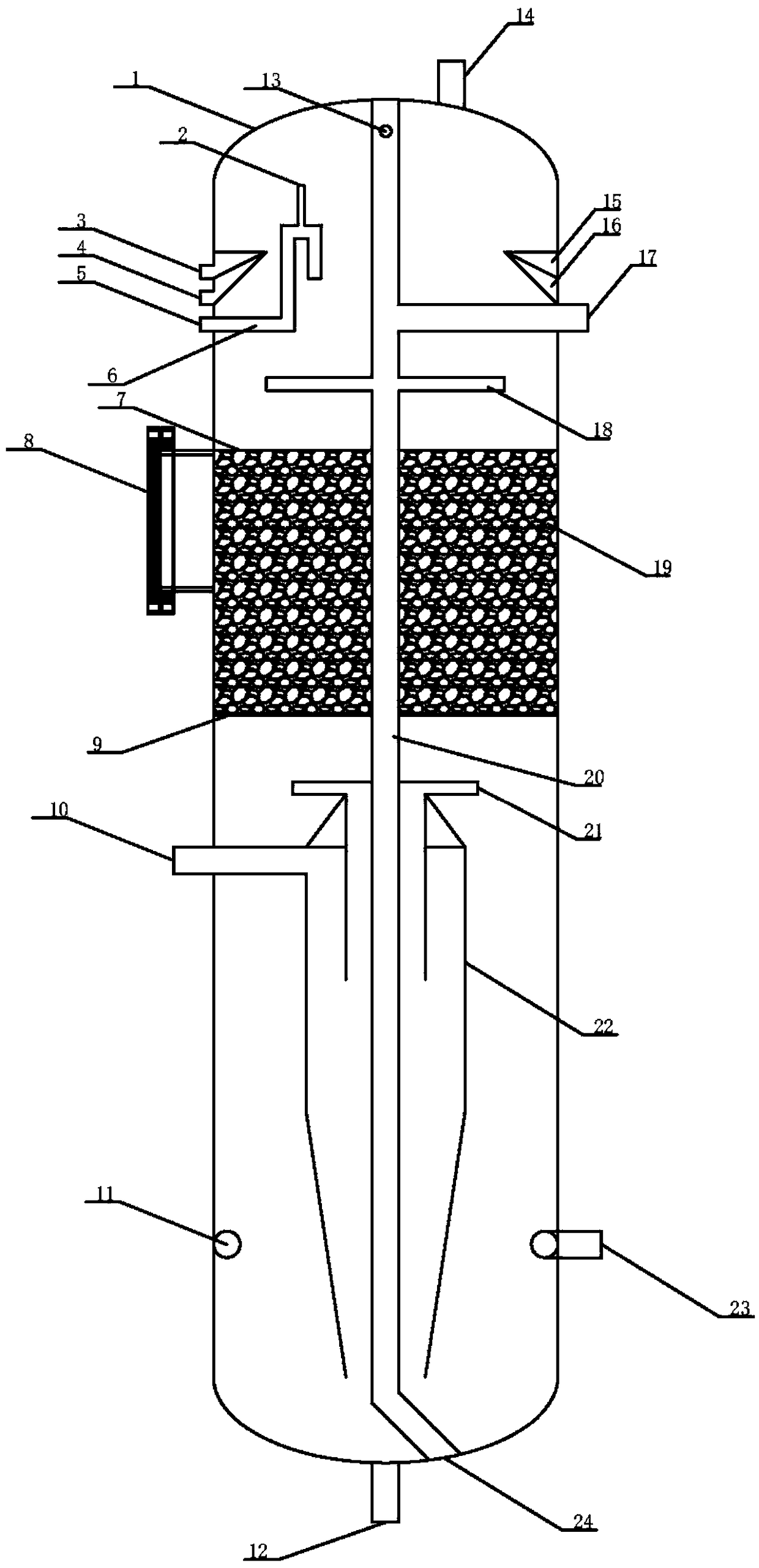

[0016] The technical solution is further described in conjunction with reference to the accompanying drawings, examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements or elements with the same or similar functions, but the description is only used It is used for explaining the present invention, but should not be construed as limiting the present invention.

[0017] please see figure 1 , a central cylinder cyclone separation and sedimentation device provided by the present invention includes a tank body 1, a broken siphon port 2, a slag discharge port 3, an oil discharge port 4, an overflow port 5, an inverted U-shaped overflow pipe 6, an upper filter Plate 7, manhole 8, lower filter plate 9, water inlet pipe 10, backwash water distribution pipe 11, sewage outlet 12, central pipe breathing hole 13, breathing port 14, slag collecting tank 15, oil collecting tank 16, water outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com