Positioning method of ink jet printing equipment and ink-jet printing head

A technology of inkjet printing and positioning method, which is applied in the direction of printing and printing devices, and can solve the problems of scratching the substrate 108, tailing of inkjet droplets, and inability of inkjet droplets 110 to fall on a predetermined position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

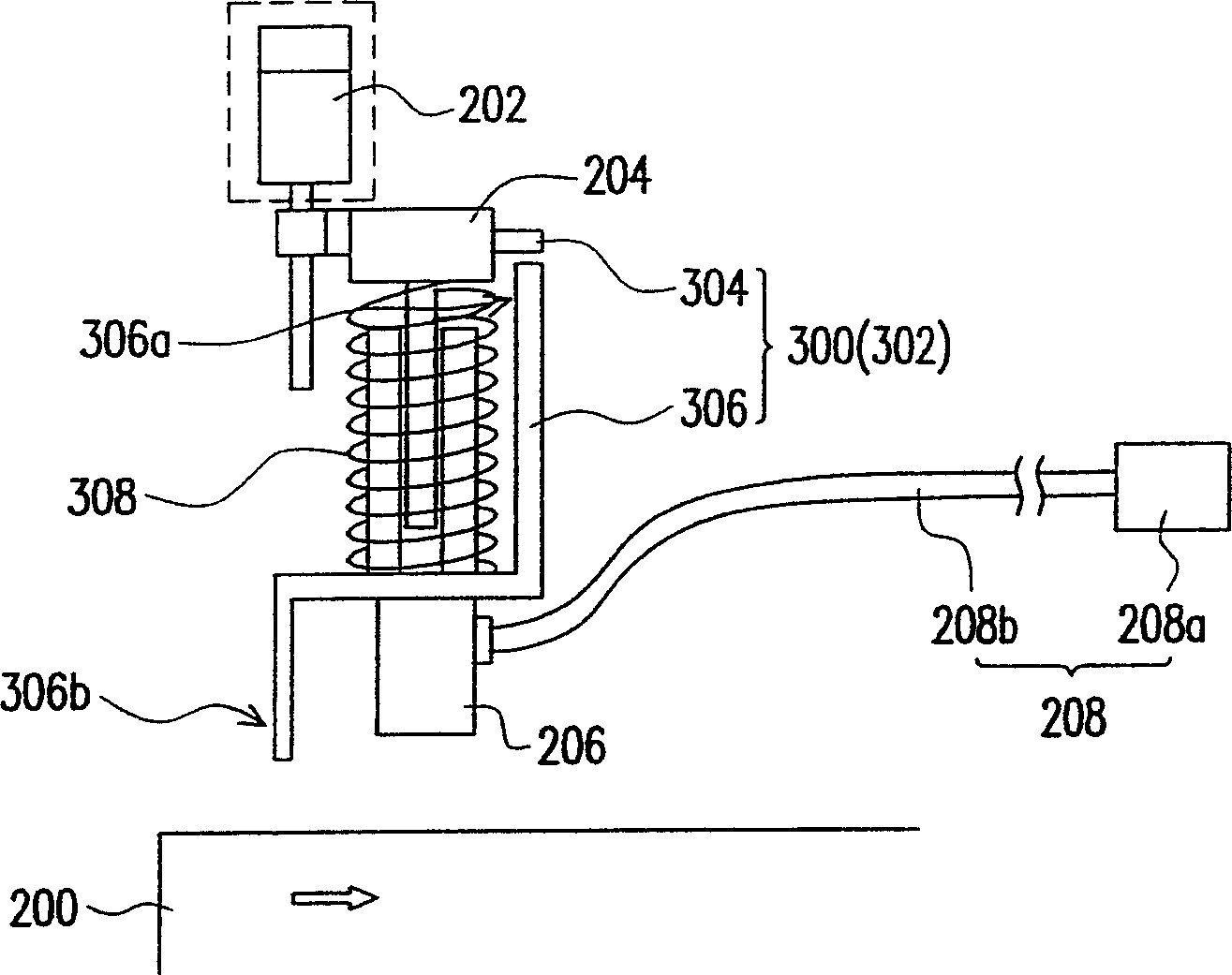

[0061] image 3 is a schematic diagram of an inkjet printing device according to a first embodiment of the present invention. Please refer to image 3 , the inkjet printing device of this embodiment is mainly composed of a carrier platform 200 , a servo motor 202 , a carrier 204 , a height sensing device 300 , an inkjet head 206 and a feeding device 208 . Wherein, the carrier platform 200 is suitable for carrying a substrate (not shown); the carrier 202 is disposed above the carrier platform 200; the servo motor 202 is connected to the carrier 204, and the servo motor 202 can control the movement of the carrier 204, thereby adjusting The distance from the carrier 204 to the carrying platform 200; the height sensing device 300 is configured on the carrier 204; the inkjet head 206 is configured on the carrier 204; and the feeding device 208 is connected with the inkjet head 206 to provide inkjet The ink solution is fed into the inkjet head 206 .

[0062] The height sensing de...

no. 2 example

[0070] Figure 7 It is a schematic diagram of an inkjet printing device according to a second embodiment of the present invention. Please refer to Figure 7 , the inkjet printing equipment of this embodiment is similar to the first embodiment, but the difference is that the height sensing device 400 of this embodiment is a non-contact height sensing device 402, and this contact height sensing device 402 is for example It is composed of a first fixed distance sensor 404 and a second fixed distance sensor 406 . Wherein, the first fixed distance sensor 404 is configured on the carrying platform 200 , for example, and the second fixed distance sensor 406 is configured on the carrier 204 , for example. In addition, the non-contact height sensing device 402 is, for example, a laser sensor or the like.

[0071] Figure 7 to Figure 10 It is a schematic flow chart of positioning the inkjet head according to the second embodiment of the present invention. Please also refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com