Cone resistive friction sleeve large-deformation anchor rod

A friction sleeve, large deformation technology, applied in the installation of bolts, mining equipment, earth-moving drilling and other directions, can solve the problems of low elongation, unsatisfactory constant resistance effect of large deformation bolts, poor supporting effect, etc. To achieve the effect of ensuring the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

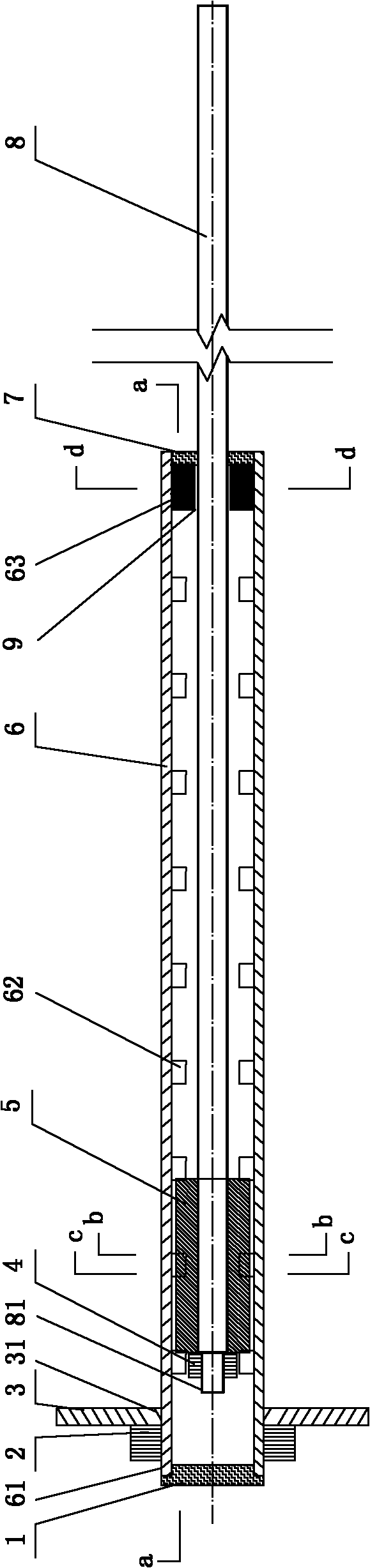

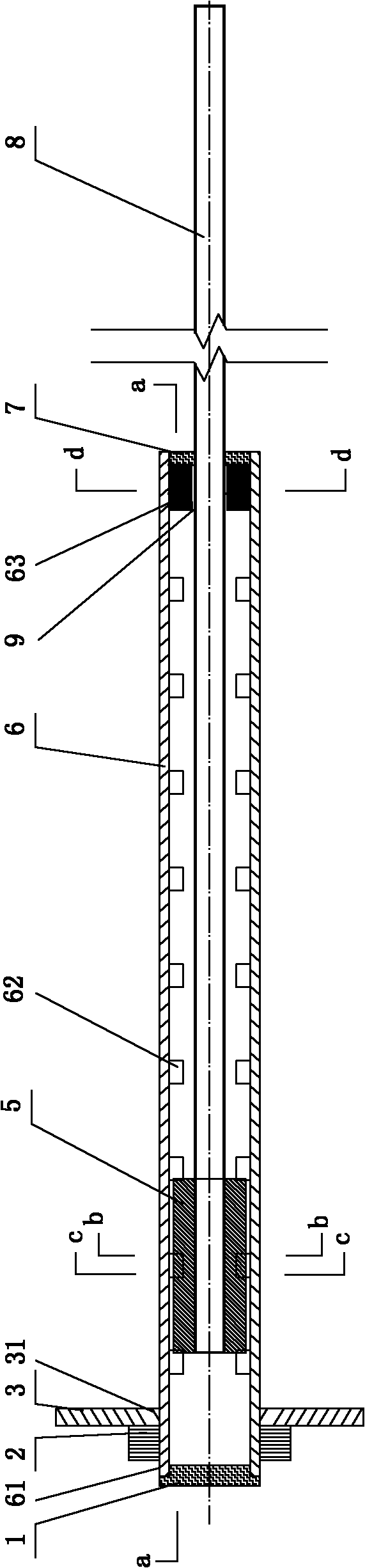

[0035] Such as figure 1 As shown, the present invention includes an outer nut 2, an inner nut 4, a backing plate 3, a bevel tooth friction body 5, a friction sleeve 6, a rod body 8, and the like. The backing plate 3 and the outer nut 2 are sequentially connected to the tail of the friction sleeve 6, wherein a reserved hole 31 is set in the middle part of the backing plate 3 for the friction sleeve 6 to pass through, and the outer nut 2 is connected to the friction sleeve through a thread 61 The barrel 6 and the friction sleeve 6 have a length ranging from 10cm to 150cm, which can be determined according to the allowable displacement of the surrounding rock.

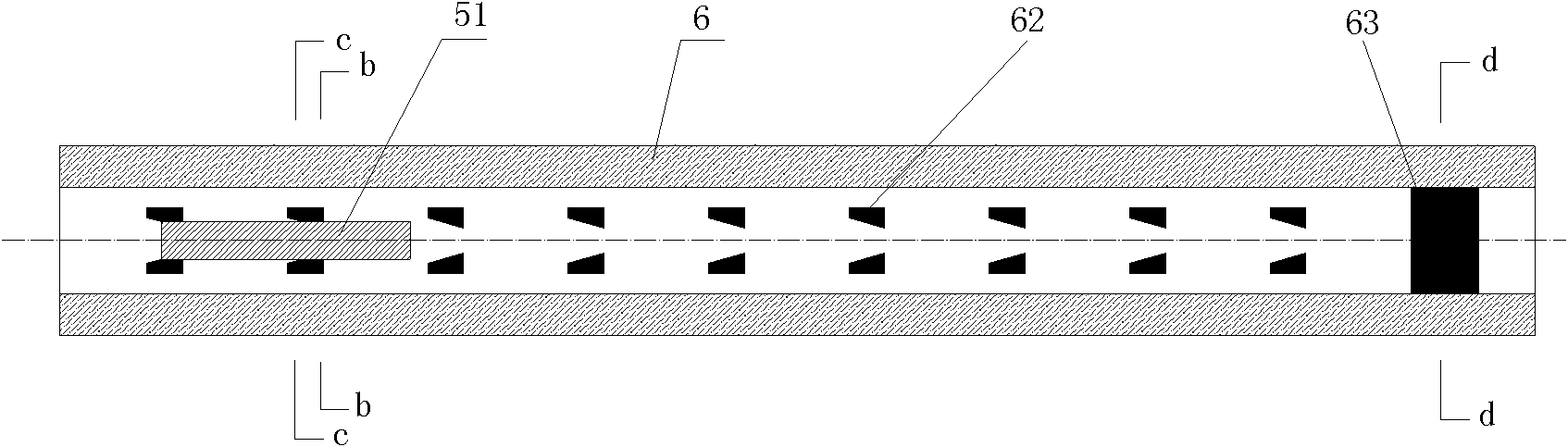

[0036] In order to realize the large deformation performance of the present invention, the inner surface of the friction sleeve 6 is provided with sleeve friction grooves 62, and the sleeve friction grooves 62 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com