Drum type washing machine

A washing machine, drum technology, applied in the field of improved structure of the driving part, capable of solving problems such as damage, reduced productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

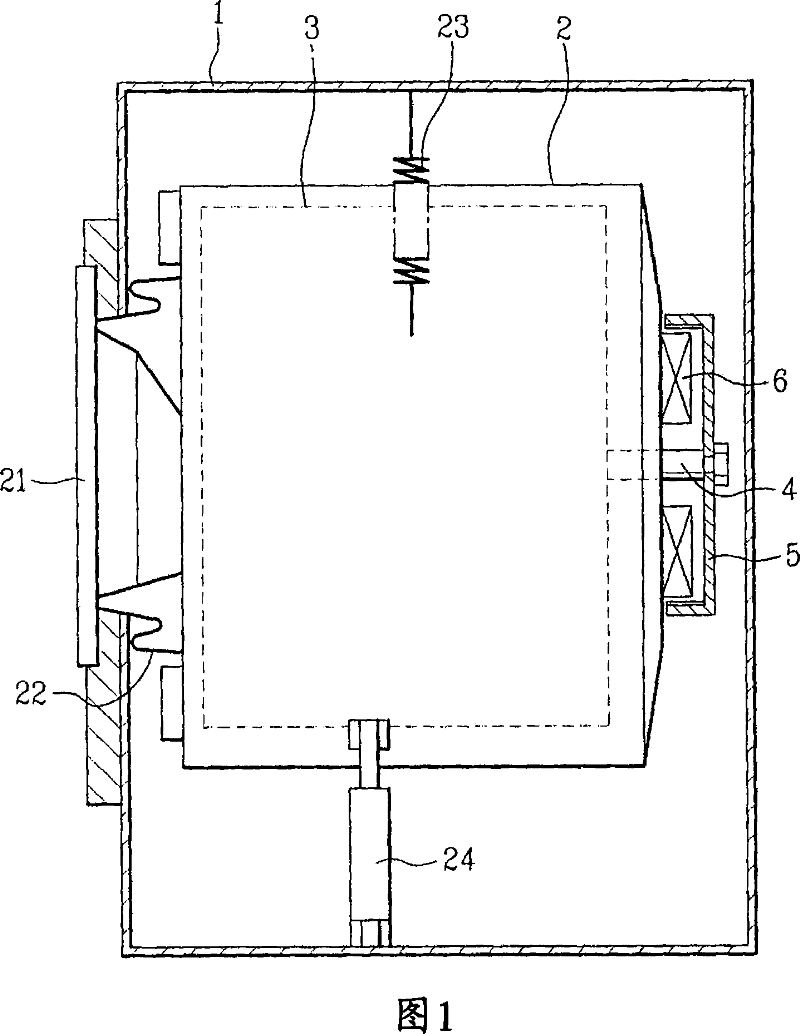

[0054] Reference will now be made in detail to preferred embodiments of the present invention, examples of which are schematically illustrated in FIGS. 4 to 14 .

[0055] 4 schematically shows a longitudinal sectional view of a direct-drive type drum type washing machine according to a preferred embodiment of the present invention, and FIG. 5 shows an enlarged longitudinal section of part 'A' in FIG. 4 of the drum type washing machine of the present invention. picture.

[0056] Fig. 6 shows a cutout perspective view of the rear wall of the barrel, Fig. 7 shows a perspective view of a single bracket and a bearing seat in Fig. 5, Fig. 8 shows a back perspective view of Fig. 7, and Fig. 9 shows a perspective view of Cross-sectional view of line I-I.

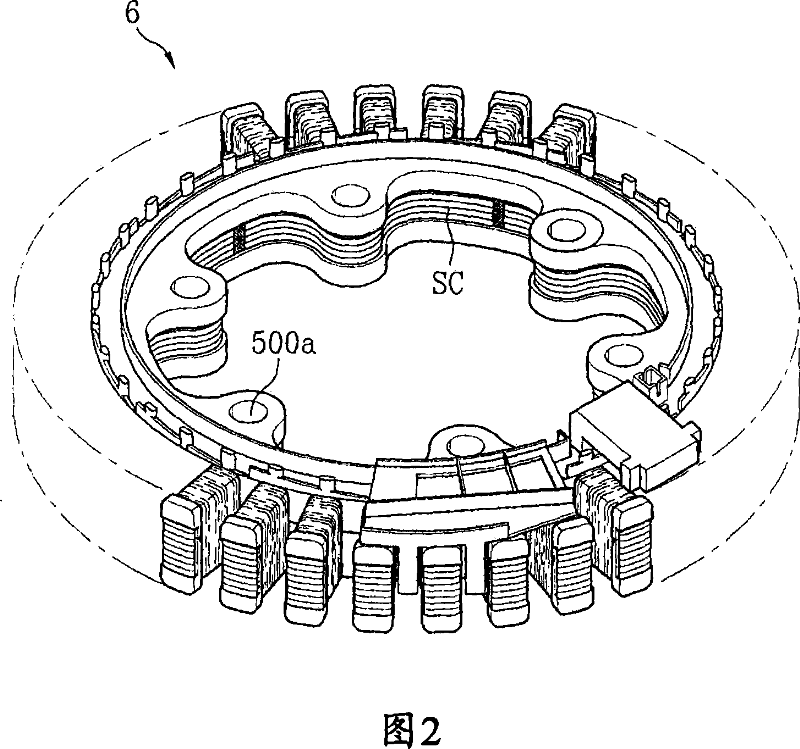

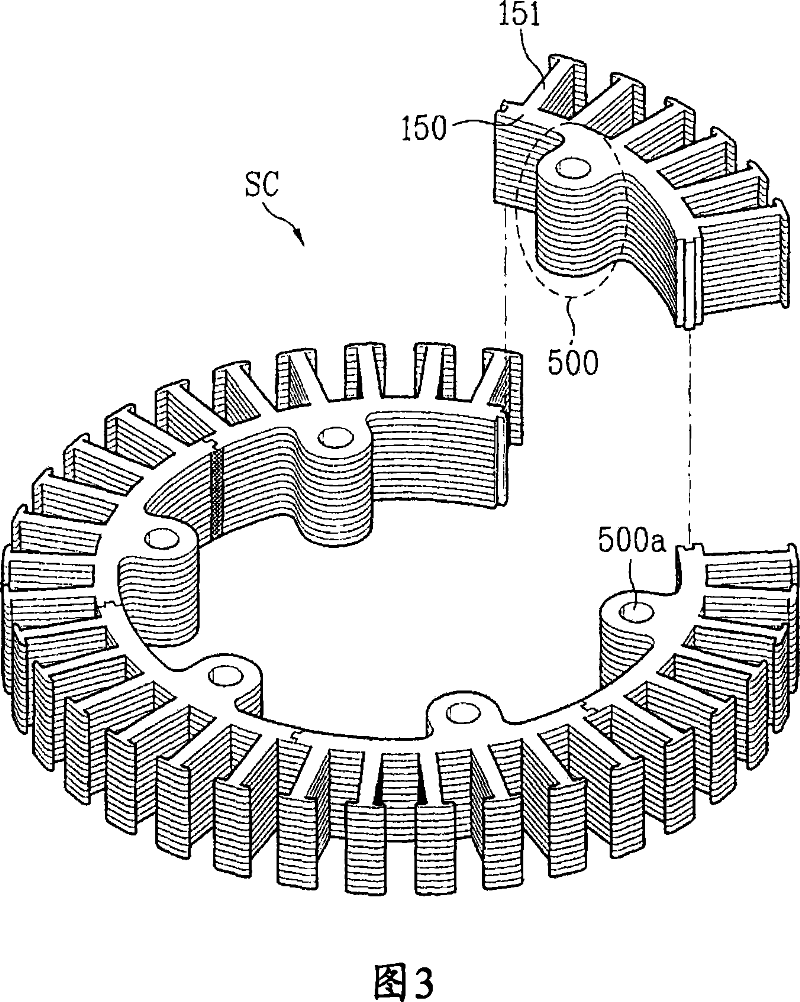

[0057] Figure 10 shows a perspective view of the stator in Figure 5, Figure 11 shows a perspective view of the spiral core in Figure 10, Figure 12A shows a plan view of the main part of the stator in Figure 10, Figure 12B shows a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com