Obligate cavity channel gob-side entry retaining wall filling method

A technology for filling walls and channels, which is applied in the direction of filling, earth drilling, safety devices, etc., can solve the problems of increased auxiliary transportation workload, ventilation, difficult pedestrians, complex multiple production systems, etc., to achieve labor intensity saving, Significant economic benefits and saving filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

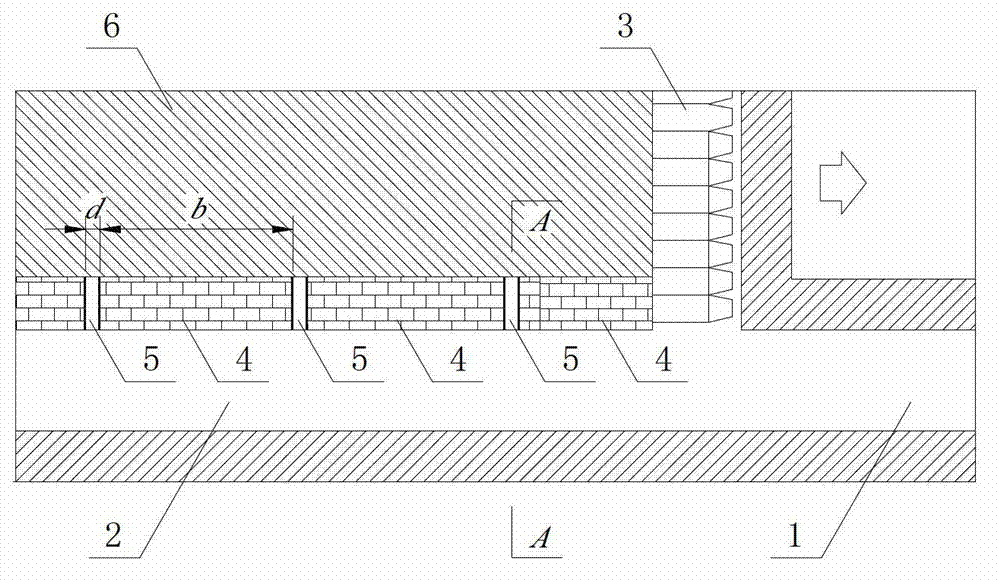

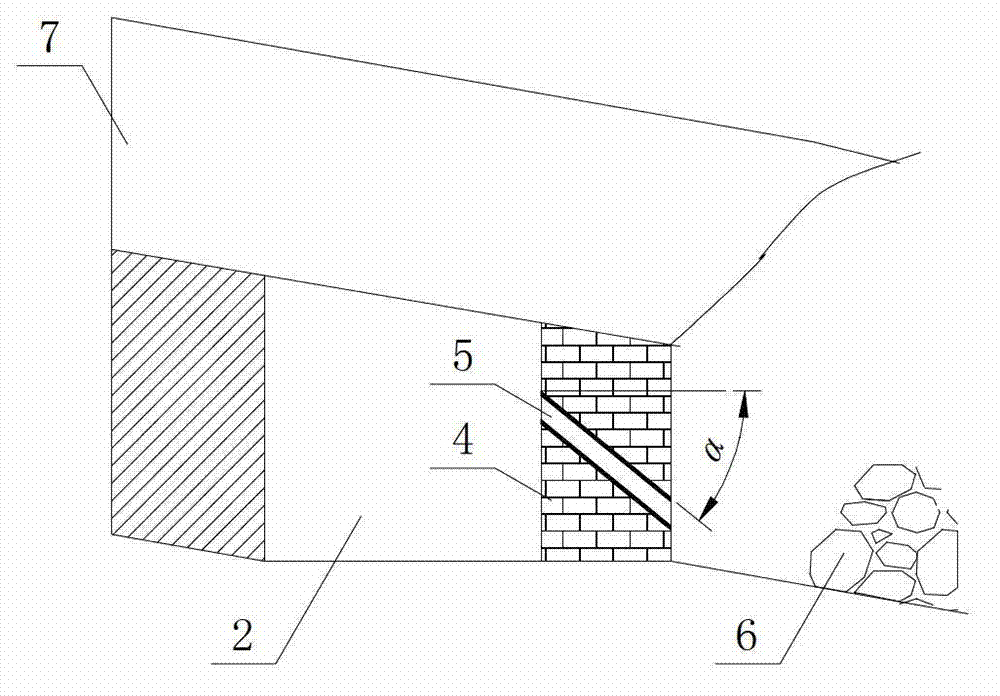

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0014] The method for filling the wall along the gob-side entry retaining of the reserved cavity channel of the present invention is as follows

[0015] a. Firstly, a pillar is erected behind the coal mining face 3, and under the effective support of the pillar, the coal mining face 3 is advanced to reach the filling step distance, that is, the length of one filling template, and the floating gangue on the floor of the gob-side retaining roadway 2 is thoroughly cleaned. and floating coal, the filling formwork is fixed on the goaf 6 side of the goaf retention 2, and plastic film or rubber woven bags are laid inside the filling formwork to avoid leakage of filling materials. For the thin-walled steel cylinder 5 with α ranging from 0 to 45°, when the inclination angle of the coal seam is greater than 8°, the channel inclination angle α of the thin-walled stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com