Drying device for feed

A technology for drying equipment and feed, which is applied in the direction of drying, feed, and static material dryers. It can solve the problems of measurement accuracy, poor crushing effect, and no drying device, etc. The effect of small wind force, improving the utilization rate of hot air and shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

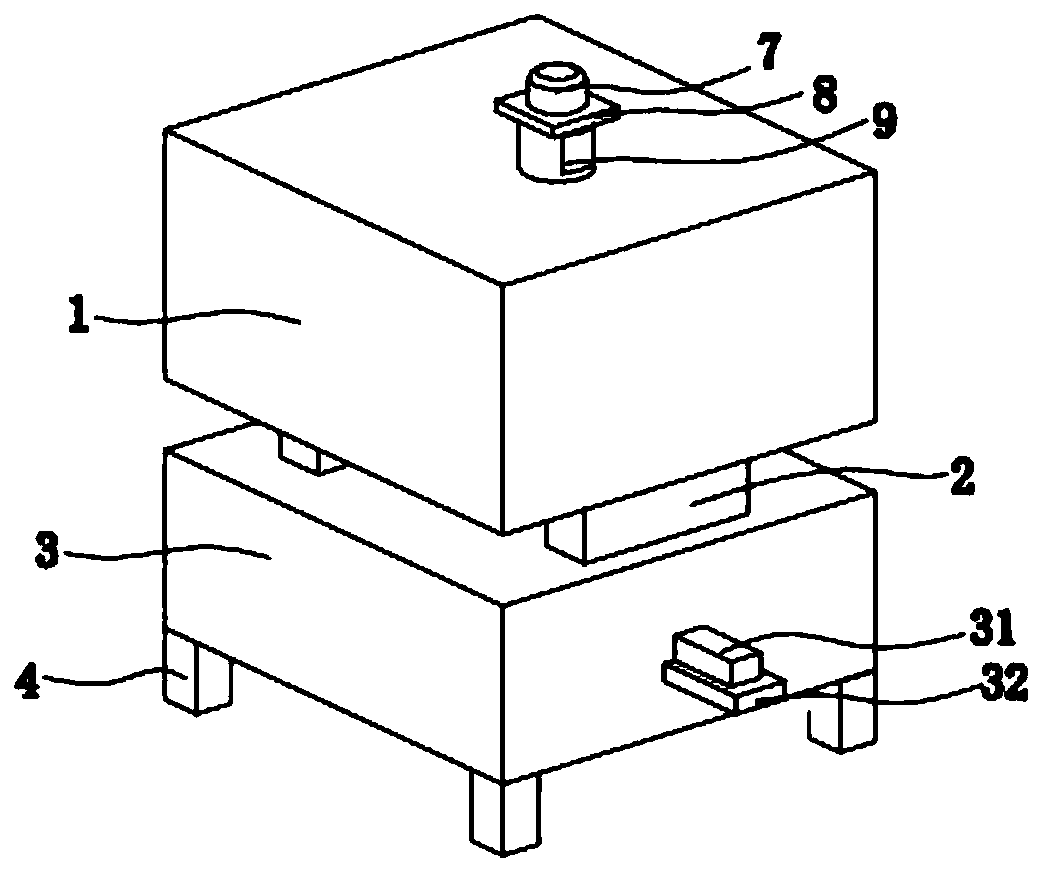

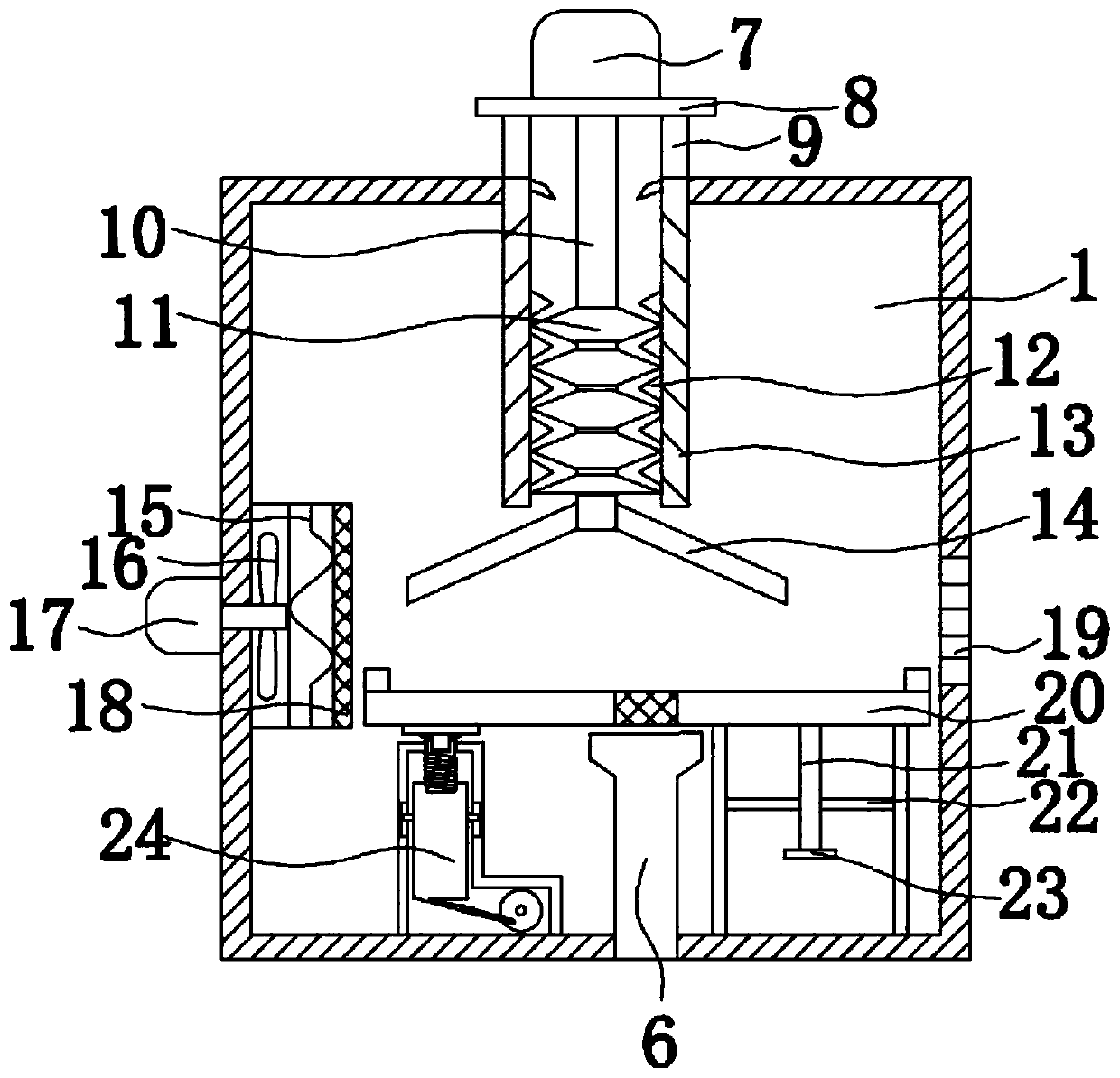

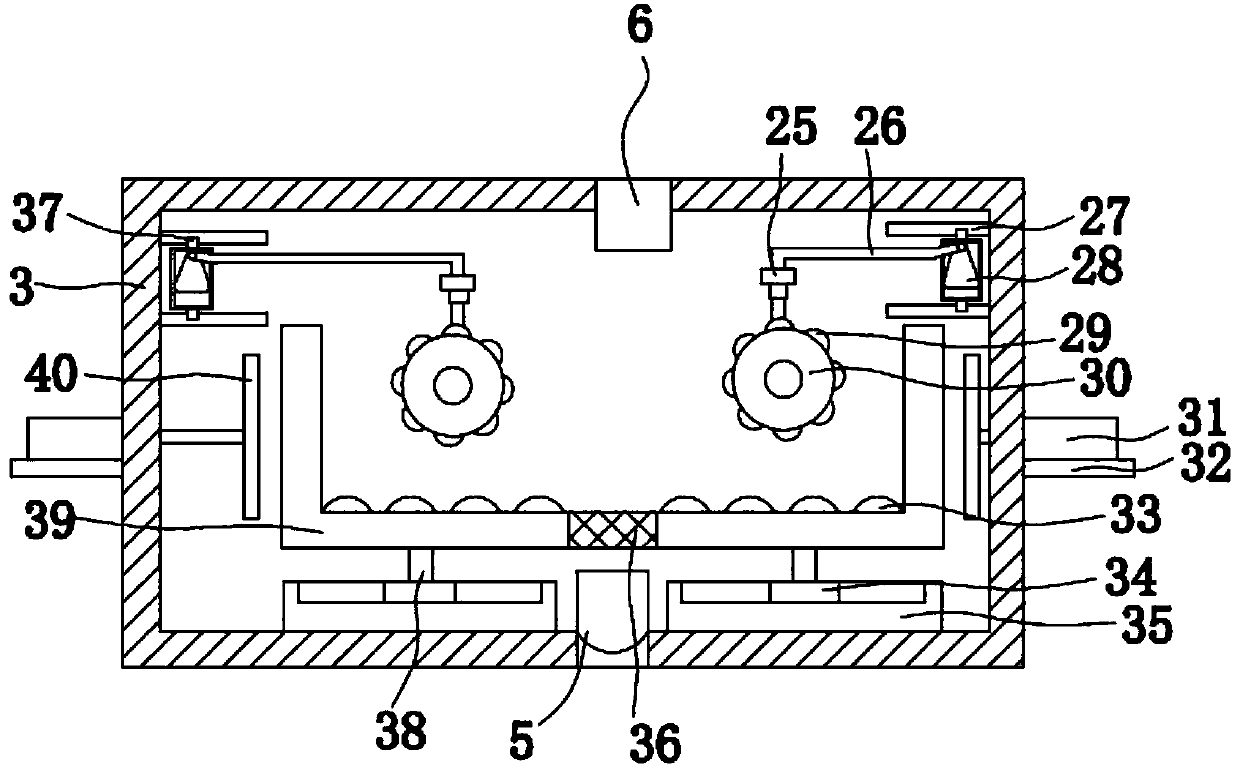

[0022] Such as Figure 1-4 As shown, the drying equipment for feed includes a drying box 1 and a crushing box 2, and the support column 2 is supported between the drying box 1 and the crushing box 2, and the bottom of the drying box 1 and the top of the crushing box 2 are formed by a transition The pipe 6 is connected, and the inside of the drying box 1 is provided with a filter screen 20, and a casing 13 is provided above the filter screen 20. Tapered teeth 12 are arranged on the inner wall of the casing 13, and a vibrating assembly 24 and a pull rod 21 are respectively provided below the filter screen 20. , The top of the drying box 1 is provided with a casing 13 . This device first cuts and extrudes the feed with high humidity and agglomeration. When the feed is extruded from the sleeve, it is poured into the filter through the deflector. The high-frequency vibration of the filter and the heating energy of the heating chamber The feed is quickly dried, and the drying time ...

Embodiment 2

[0032] When the drying equipment for feed of the present invention is actually used: first pour the feed with high humidity and agglomeration from the feed port 9 of the casing 13, and the agglomerated feed will pass through the rotation of the cutting blade 10 and the cone The cooperation of the shaped teeth 12 breaks up the agglomerated feed, so as to shorten the drying time of the feed, the broken feed will be slowly crushed and sent to the deflector 14, and the feed falling on the deflector 14 will be Slide along the slope of the deflector 14 to the surface of the filter screen 20, start the second motor 17, the second motor 17 provides corresponding kinetic energy for the fan blade 16, and the heating wire 15 will generate a large amount of heat after being energized, and the generated heat will be Dispersed into the drying box 1 through the blowing of the fan blades 16, the wind force and wind speed can be effectively reduced through the partition of the mesh partition 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com