Graphene and plastic particle energy-saving stirring device

A technology of plastic particles and stirring devices, which is applied in the field of graphene production, can solve the problems of increasing solvent costs and drying energy consumption, and achieve the effects of improving stirring efficiency, saving energy consumption, and stirring evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

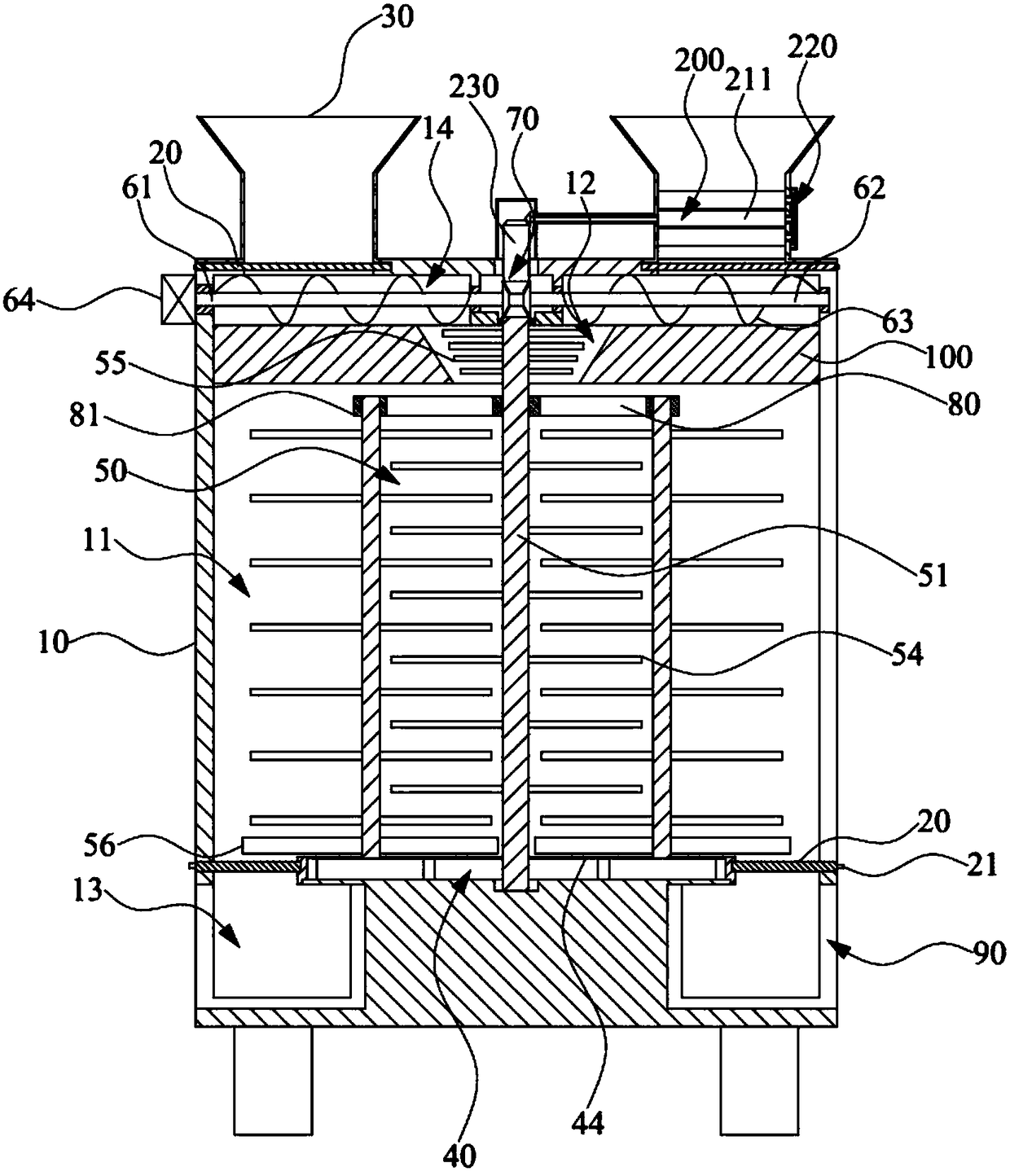

[0028] Please refer to figure 1 , figure 1 It is a schematic diagram of an energy-saving stirring device for graphene and plastic particles according to an embodiment of the present invention. As shown in the figure, a graphene and plastic particle energy-saving stirring device includes an outer shell 10, the outer shell 10 has a main stirring chamber 11, an auxiliary stirring chamber 12 located on the upper side of the main stirring chamber 11 and connected to the main stirring chamber 11, and an auxiliary stirring chamber 12 located on the main stirring chamber 11. The left and right sides of the stirring chamber 11 communicate or close the two discharge chambers 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com