Special crusher for waste casting iron pieces

A technology for crushers and iron castings, which is applied in the field of special crushers for scrap iron castings, and can solve problems such as poor crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

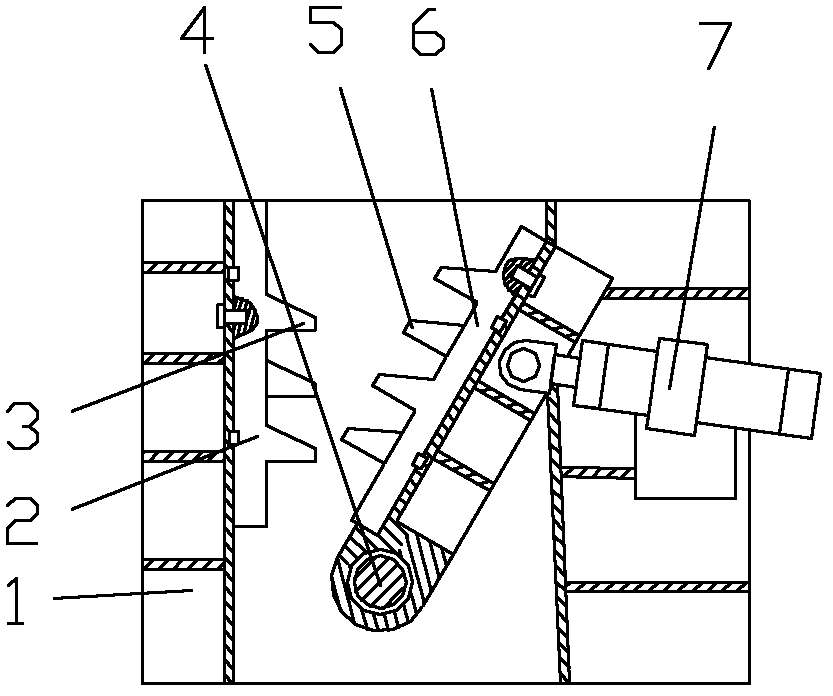

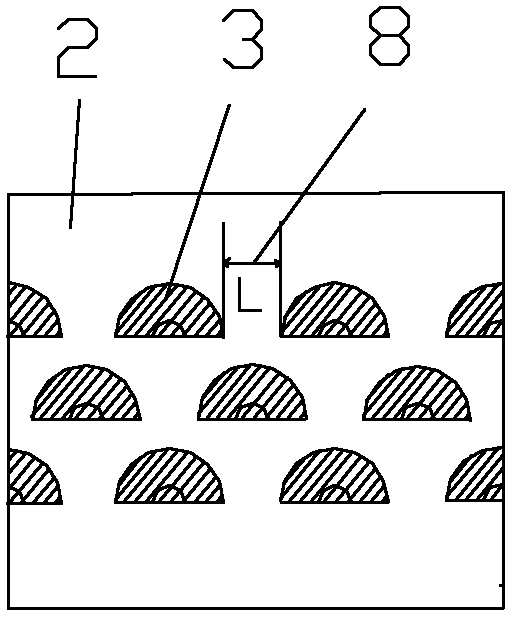

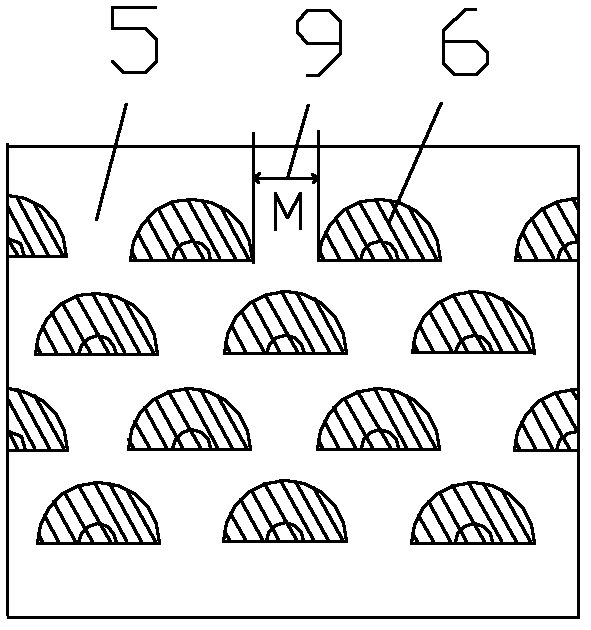

[0021] The embodiment shown in each figure is as follows: a special crusher for waste iron castings. The crusher has a fixed jaw plate 2 fixed on the frame 1 and a movable jaw plate 6 fixed on the frame 1 that can swing around the swing shaft 4 . The movable jaw plate 6 is movably connected with the hydraulic cylinder 7 . There are semi-cylindrical bevel teeth I3 and semi-cylindrical bevel teeth II5 on the fixed jaw plate 2 and the movable jaw plate 6 respectively. Its characteristics are:

[0022] On the fixed jaw plate 2, three rows of semi-cylindrical bevel teeth I3 are arranged in parallel from top to bottom. There is a gap L8 of the same size between the semi-cylindrical bevel teeth I3 in each row. Both the first row and the third row are provided with four semi-cylindrical bevel teeth I3, and the four semi-cylindrical bevel teeth I3 in the first and third rows are aligned longitudinally. The second row is provided with three semi-cylindrical bevel teeth I3. The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com