Triple-gear process of one-time heating continuous forging precision forming through bridge

A triple gear, precision forming technology, applied in the direction of manufacturing tools, metal processing equipment, wheels, etc., can solve the problems of gear pitting, short service life, high production cost, etc., to improve the surface structure of refined grains, improve the structure structure Guarantee, good effect of precision forging forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

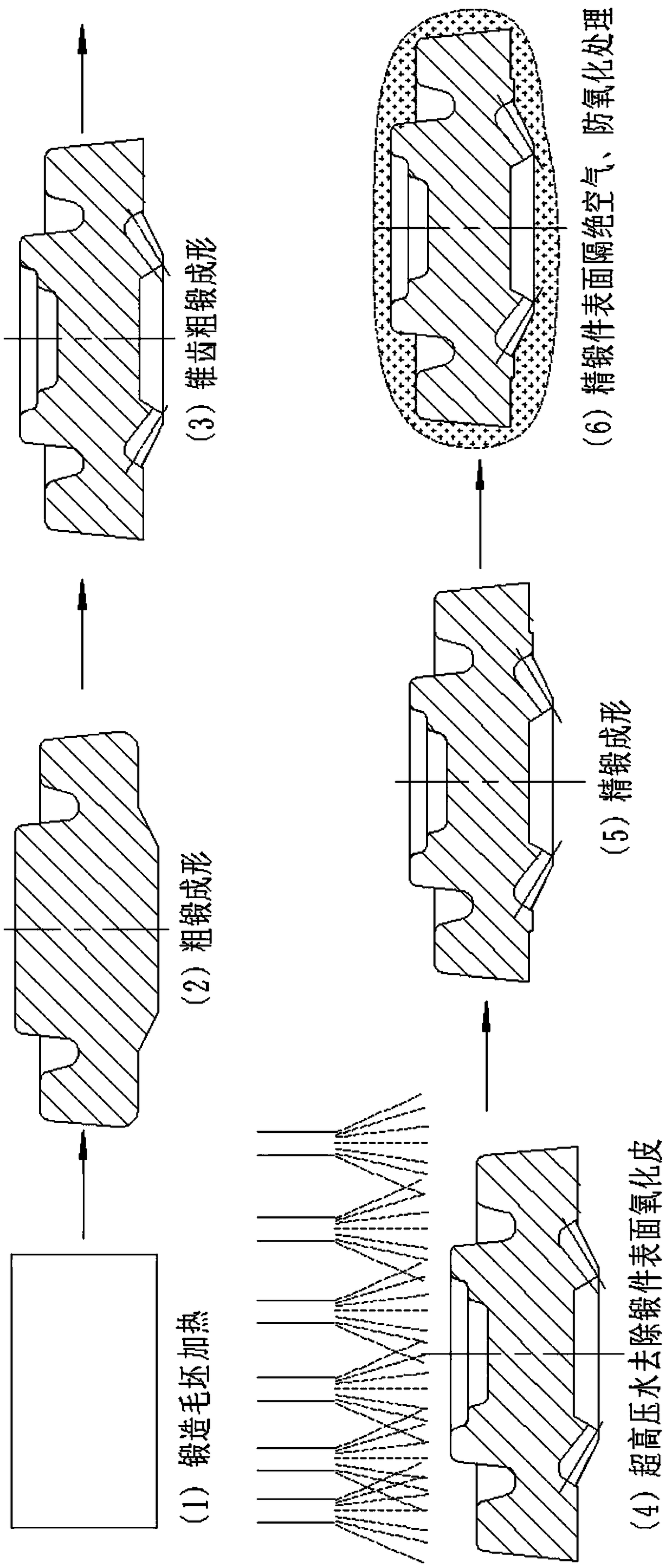

[0031] The process of one-time heating continuous forging precision forming through-bridge triple gear of the present invention is special in that it includes the following process steps in sequence:

[0032] (1) Forging blank heating

[0033] The forging blank is heated to the pre-forging temperature of 1050°C in the intermediate frequency furnace;

[0034] (2) rough forging

[0035] Using the screw press forging equipment, put the aforementioned forging blank into the forming die cavity, and carry out rough forging. The outline size of the rough forging should be close to the outline dimension of the final forging, so as to facilitate the forging and forming of the subsequent bevel tooth profile;

[0036] (3) Rough forging of bevel teeth

[0037] Using the screw press forging equipment, the aforementioned rough forging is put into the bevel tooth forming die cavity, and the bevel tooth shape is rough forged to form a rough forging with the bevel tooth shape;

[0038] (4) ...

Embodiment 2

[0045] The process of one-time heating continuous forging precision forming through-bridge triple gear of the present invention is special in that it includes the following process steps in sequence:

[0046] (1) Forging blank heating

[0047] The forging blank is heated to the pre-forging temperature of 1060°C in the intermediate frequency furnace;

[0048] (2) rough forging

[0049] Using the screw press forging equipment, put the aforementioned forging blank into the forming die cavity, and carry out rough forging. The outline size of the rough forging should be close to the outline dimension of the final forging, so as to facilitate the forging and forming of the subsequent bevel tooth profile;

[0050] (3) Rough forging of bevel teeth

[0051] Using the screw press forging equipment, the aforementioned rough forging is put into the bevel tooth forming die cavity, and the bevel tooth shape is rough forged to form a rough forging with the bevel tooth shape;

[0052] (4) Ul...

Embodiment 3

[0059] The process of one-time heating continuous forging precision forming through-bridge triple gear of the present invention is special in that it includes the following process steps in sequence:

[0060] (1) Forging blank heating

[0061] The forging blank is heated to the pre-forging temperature of 1040°C in the intermediate frequency furnace;

[0062] (2) rough forging

[0063] Using the screw press forging equipment, put the aforementioned forging blank into the forming die cavity, and carry out rough forging. The outline size of the rough forging should be close to the outline dimension of the final forging, so as to facilitate the forging and forming of the subsequent bevel tooth profile;

[0064] (3) Rough forging of bevel teeth

[0065] Using the screw press forging equipment, the aforementioned rough forging is put into the bevel tooth forming die cavity, and the bevel tooth shape is rough forged to form a rough forging with the bevel tooth shape;

[0066] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com