Part clamping device for automobile production

A technology for clamping devices and parts, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of weak stability and general clamping effect of tubular parts, etc., to improve stability, increase practicability, and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

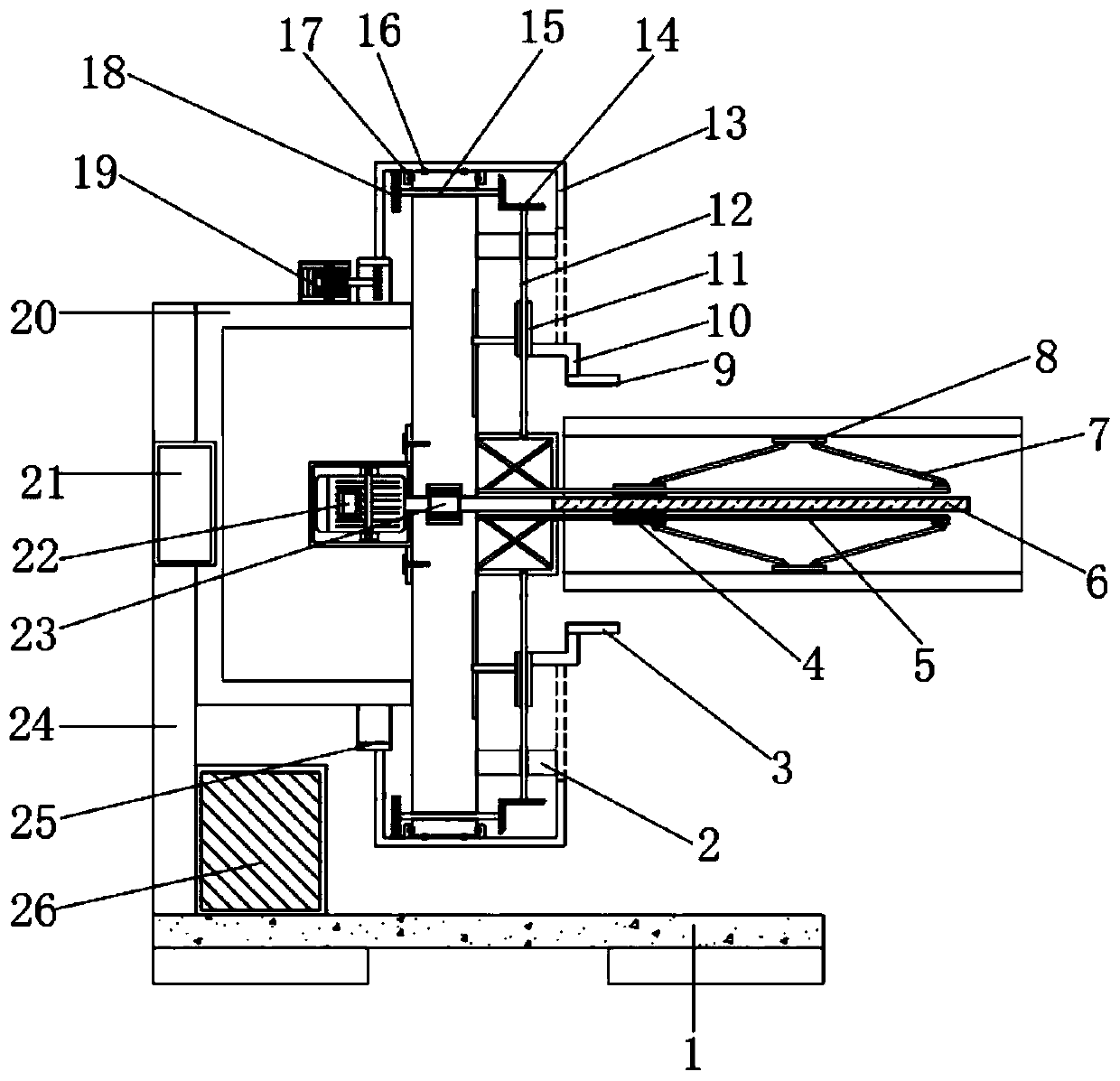

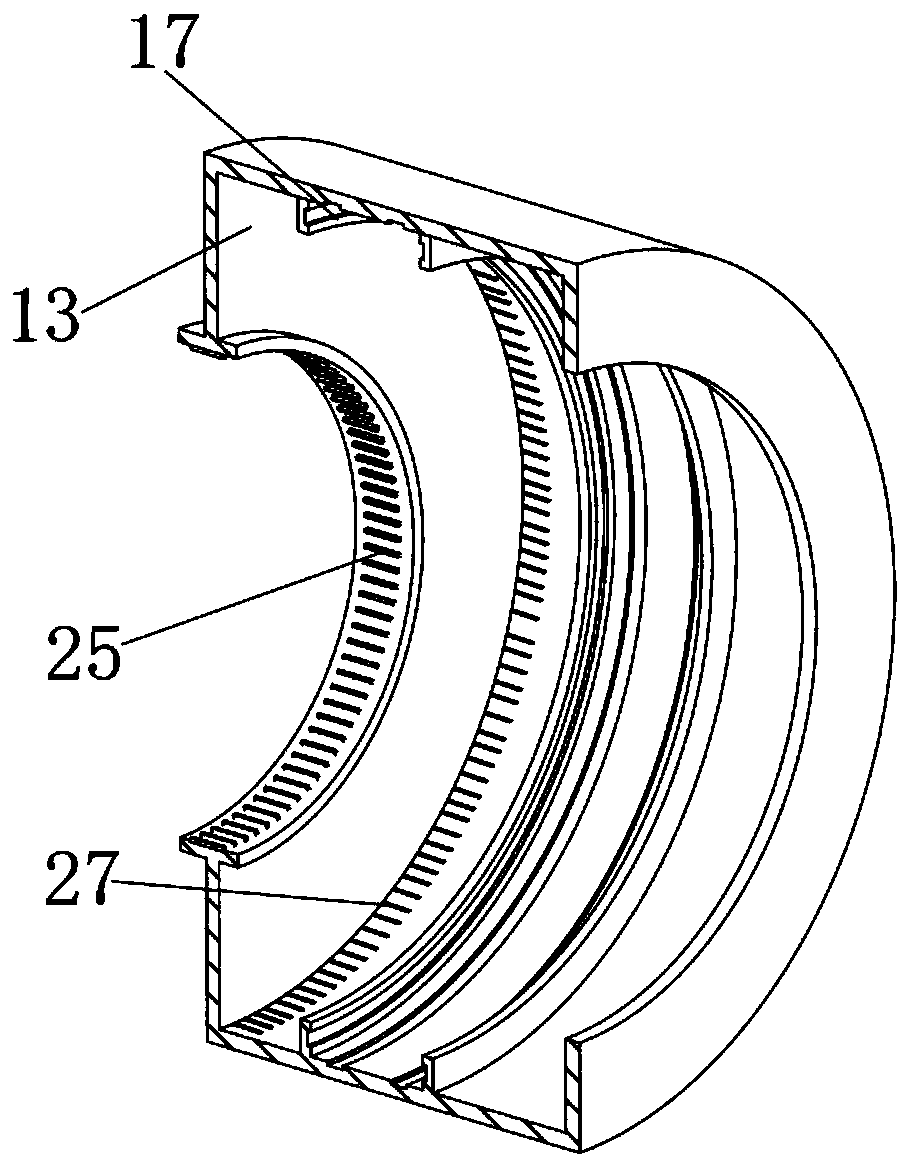

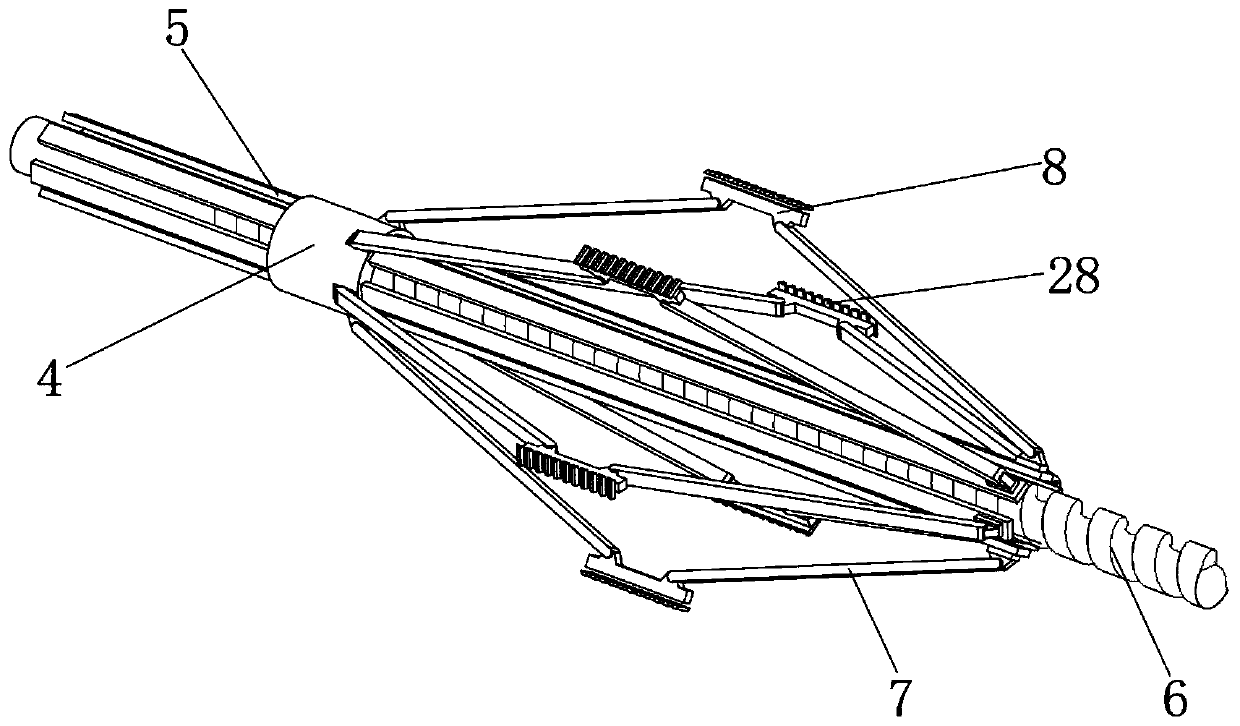

[0030] refer to Figure 1-5 , a kind of parts clamping device for automobile production, comprising a base 1 welded with feet at four corners of the bottom and a fixed plate 24 vertically welded to one end of the top of the base 1, one side of the fixed plate 24 is welded with a fixed bracket 20, and the fixed bracket The other end of 20 is welded with disc, and the circumference outer wall of disc is provided with turntable 13, and the opposite side of turntable 13 and fixed support 20 is equipped with driving mechanism, and the circular place of disc is equipped with internal supporting mechanism, and disc An external pressure fixing mechanism is installed at the edge of the outer pressure fixing mechanism, and a transmission mechanism is installed between the turntable 13 and the external pressure fixing mechanism. The inner support mechanism includes a threaded rod 6 connected to the center of the circular plate through bearing rotation, and one end of the threaded rod 6 is...

Embodiment 2

[0041] refer to figure 1 and Figure 5 , a kind of parts clamping device for automobile production. Compared with Embodiment 1, this embodiment also includes rubber anti-slip strips 9 distributed equidistantly on the inner wall of the arc-shaped groove, and the cross-section of the rubber anti-slip strips 9 is rectangular. .

[0042] When the present invention is used, by providing the rubber anti-slip strip 9 with a rectangular cross section in the arc groove, the stability of the device when clamping parts can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com