Patents

Literature

59results about How to "Improve mesh quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

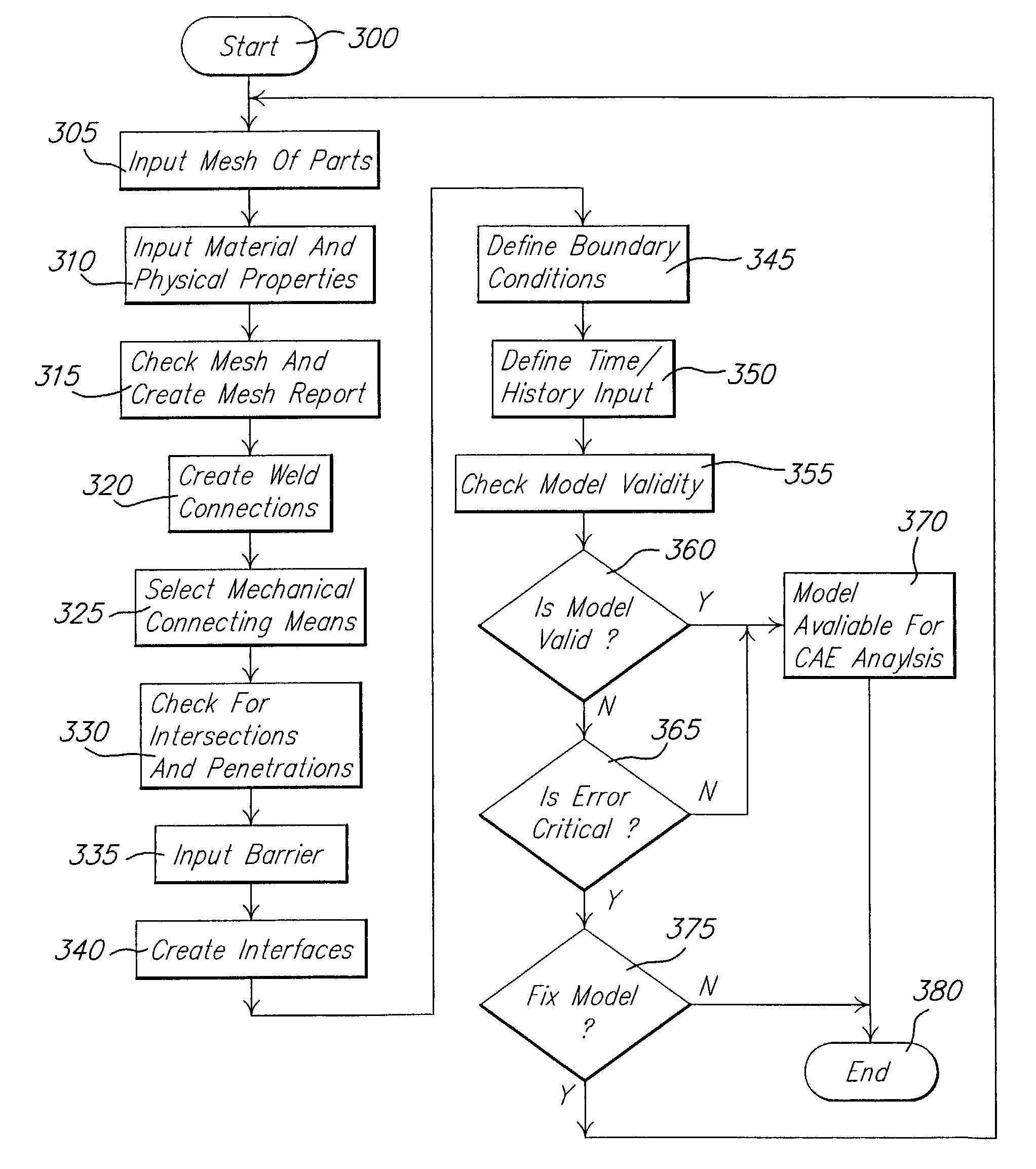

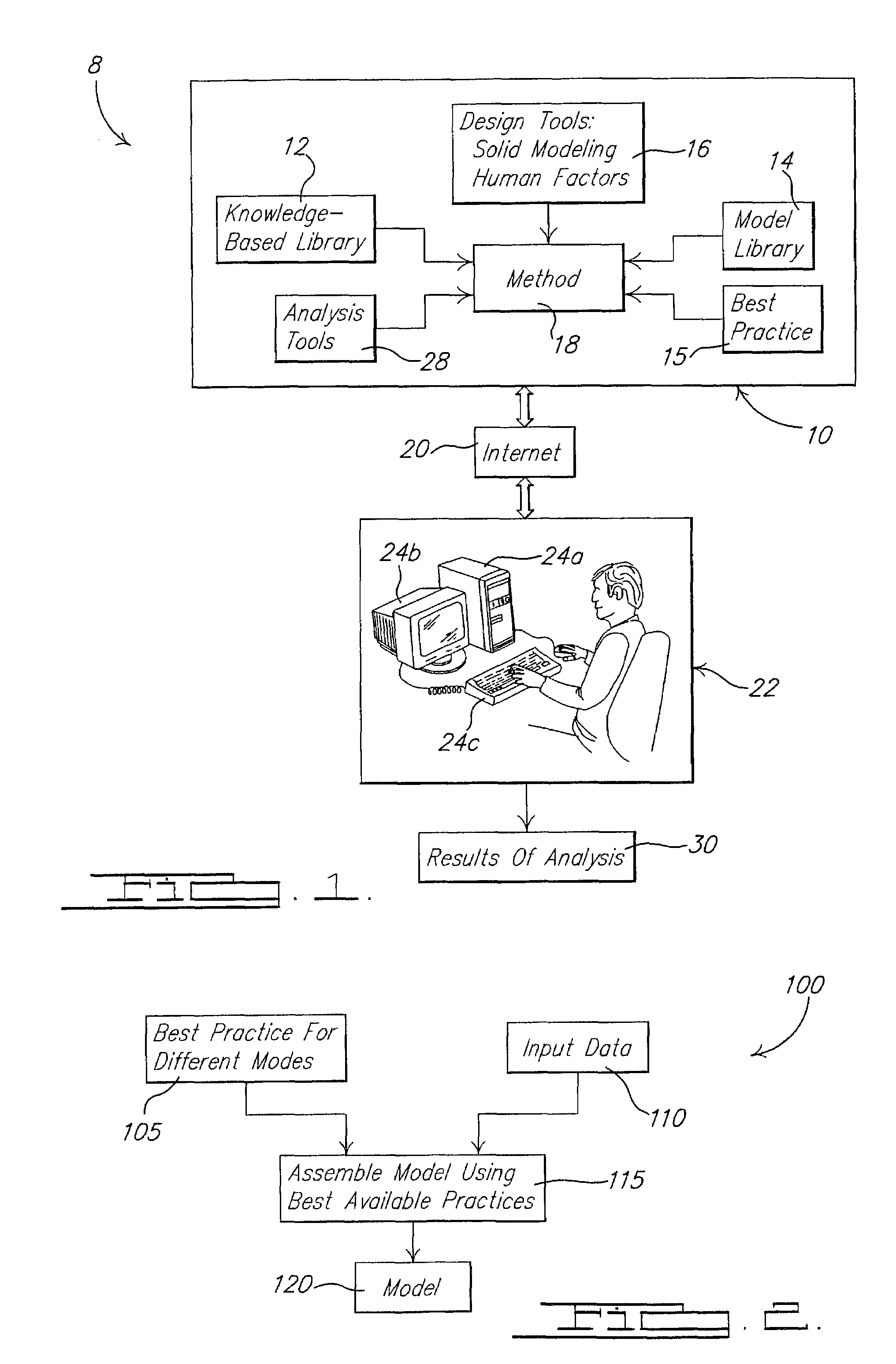

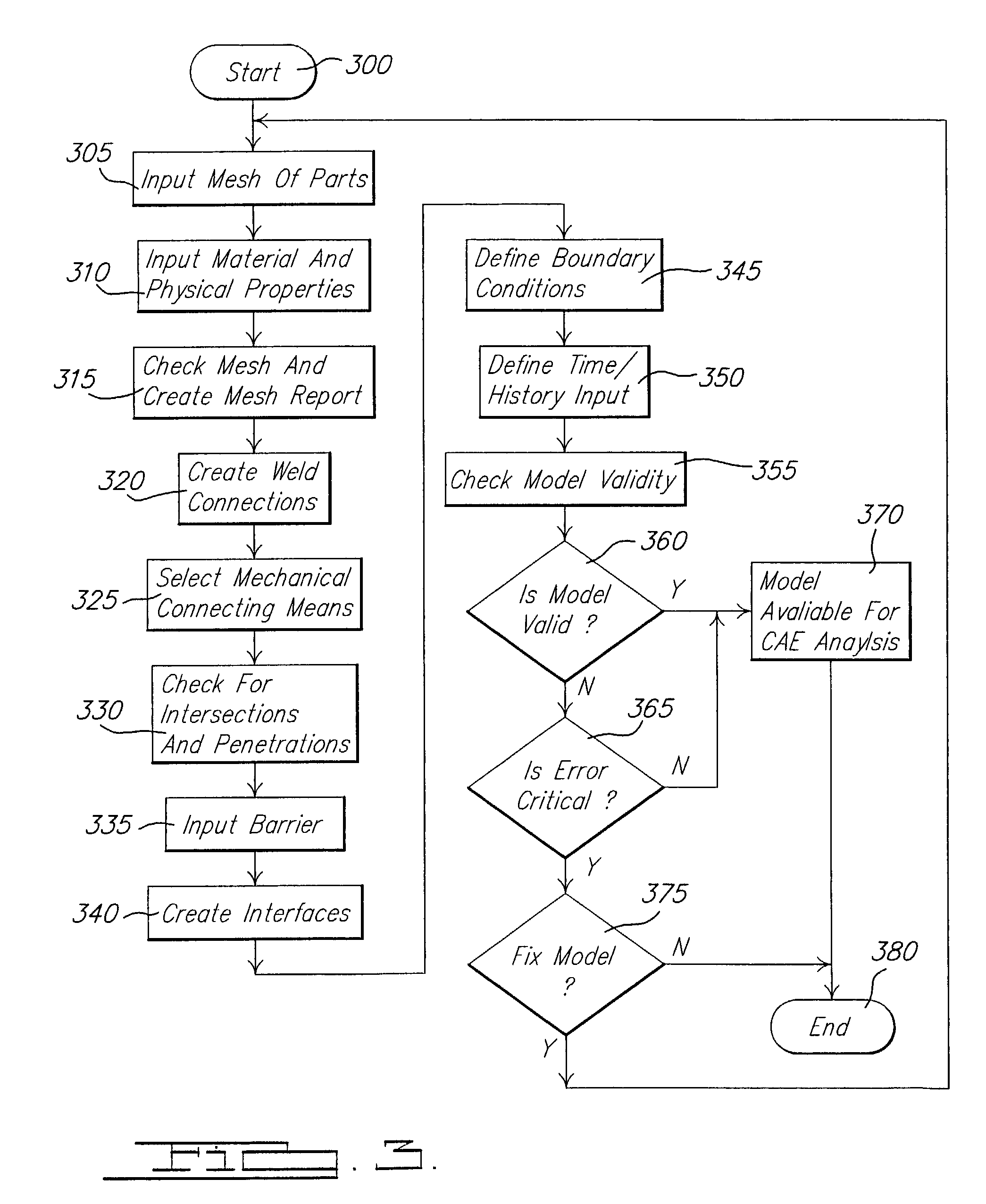

System and method of interactively assembling a model

ActiveUS7467074B2Improve efficiencyImprove model qualityGeometric CADDesign optimisation/simulationAssembly softwareComputerized system

A system and method for assembling a mesh model for engineering analysis by a user is provided. The system includes a user computer system, a remotely located computer system and a data storage means. The method includes the steps of selecting a plurality of component parts having a best practice mesh model format and selecting a predetermined property for each of the selected component parts, wherein the predetermined property is selected from a best practice library stored on the data storage means. The method also includes the steps of determining if the mesh model for each of the selected component parts meets a predetermined mesh quality condition using a best practice mesh quality checking software program. The method further includes the steps of selecting a best practice connecting means for connecting the selected component parts, wherein the connecting means is selected from a best practice library of mesh models of connecting means stored in the data storage device, and assembling the selected component parts together using the connecting means and the best practice properties into a new mesh model using a best practice mesh assembly software program, and the assembled mesh model is available for further analysis.

Owner:FORD MOTOR CO

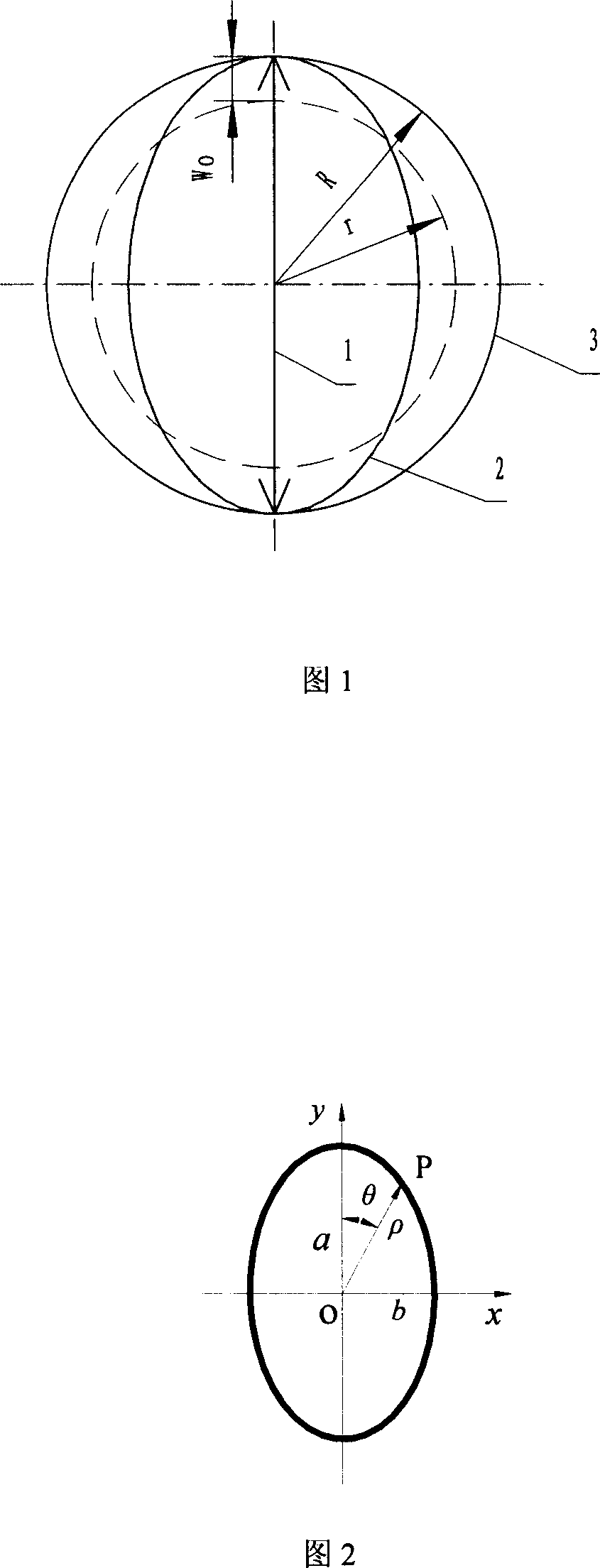

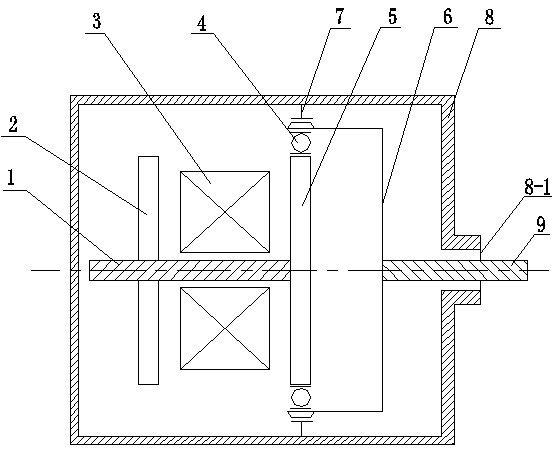

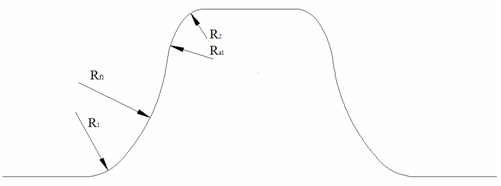

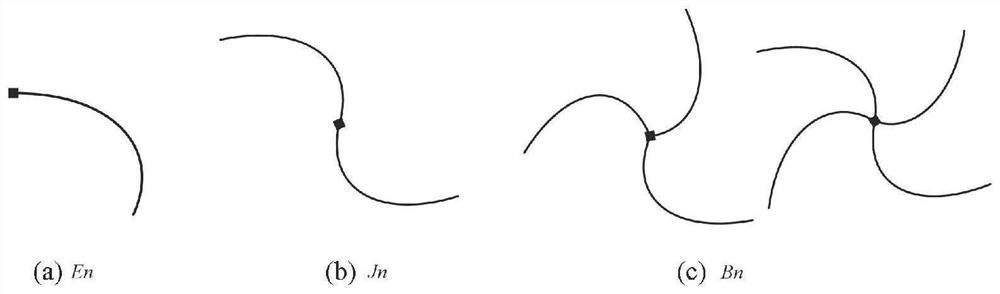

Harmonic gear power transmission with double circular arc tooth outline

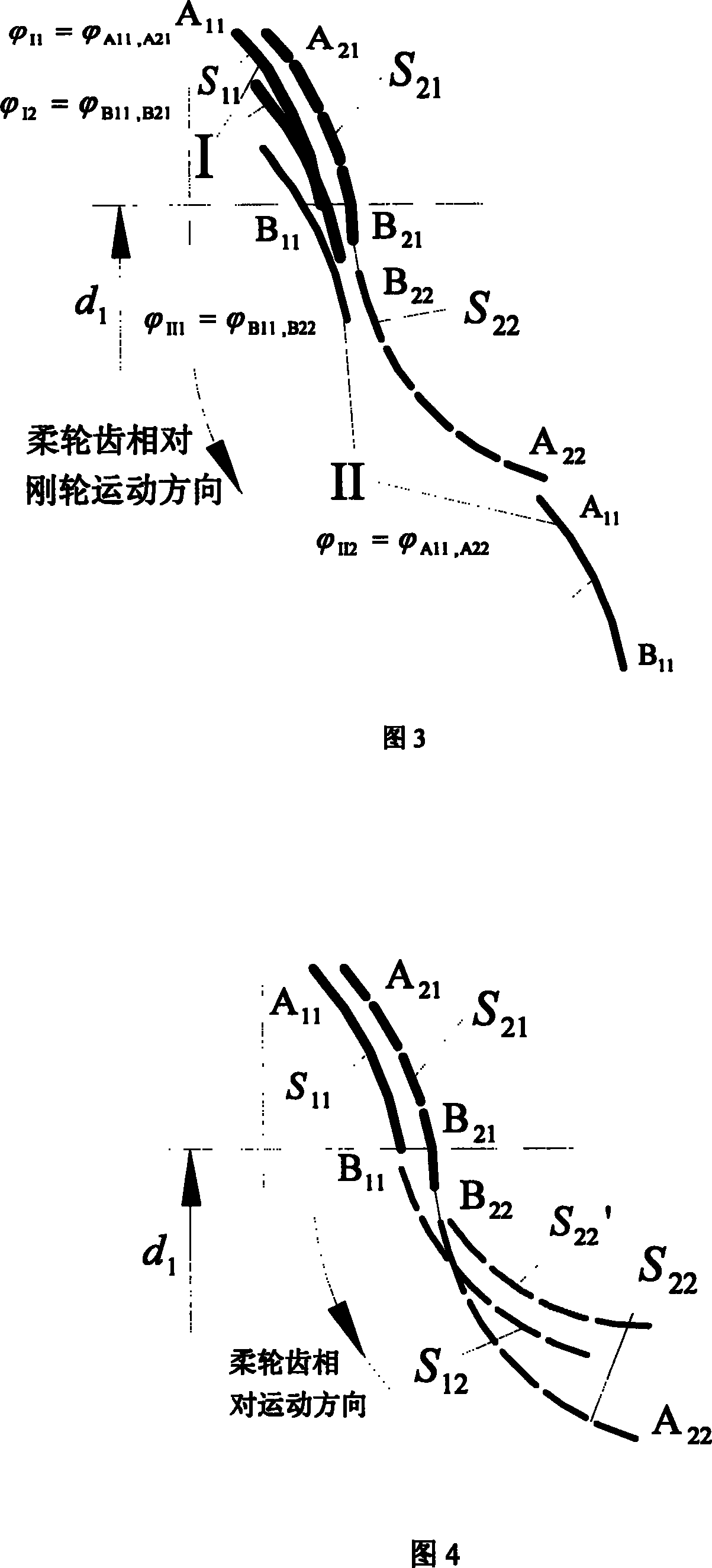

InactiveCN101135357AImprove carrying capacityIncreased torsional stiffnessToothed gearingsStress conditionsHarmonic

The harmonic wave gear driver with two-arc teeth profile comprises wave generator, flexible wheel and rigid wheel. The wave generator is in form of elliptic cam, the flexible wheel and the rigid wheel has a two-arc teeth profile respectively which can realize conjugation motion. The driver can effectively improve the stress condition of the flexible wheel tooth-root and drive quality and increase load-bearing ability and torque rigidity of harmonic wave driver, and further lower minimum drive ratio of harmonic wave driver. Advantages: good processing property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

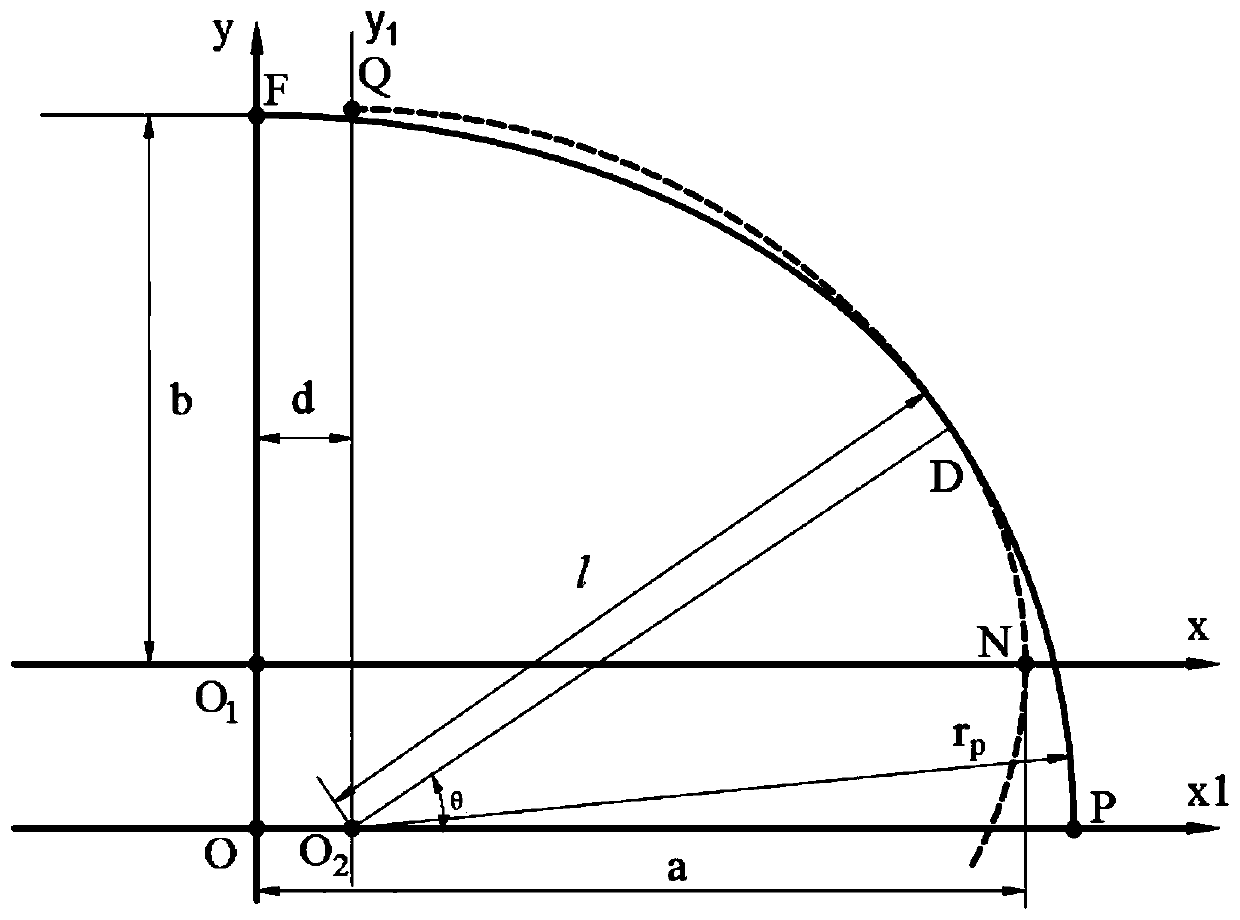

Design method of hypoid gear pair

InactiveCN101982673ASimplify the design processImprove tooth surface accuracyToothed gearingsPortable liftingState of artEngineering

The invention discloses a design method of a hypoid gear pair, aiming at solving the problem of difficulty in designing the hypoid gear pair by using the prior art. The design method of the hypoid gear pair comprises the following steps: 1, taking a plane as a hypoid gear pair transmission forming principle for a big gear tooth surface; 2, determining the geometric technical parameters of a big gear tooth surface shape; 3, determining the geometric technical parameters of a small gear tooth surface shape; and 4, since the gear parameters refers to right-handed rotation of a big gear and left-handed rotation of a small gear, when the big gear is in right-handed rotation and the small gear is in left-handed rotation, dereferencing opposite numbers for the parameters related to the y axle in the parameters. The determination of the geometric technology parameters of the big gear tooth surface shape comprises the following steps: definition of representing the geometric parameters of the big gear tooth surface shape, determination of the coordinates of an M point, determination of the component expression formula of a vector shown in the specification, solution of a tooth-shaped unit vector shown in the specification, solution of another tooth-shaped unit vector shown in the specification, solution of the normal vector shown in the specification one side tooth surface sigma2, determination of the equation of the one side tooth surface sigma2, determination of the equation of the other side tooth surface sigma1, determination of the equation of a tooth surface sigma1theta and formation of the gear teeth of the gear in array.

Owner:JILIN UNIV

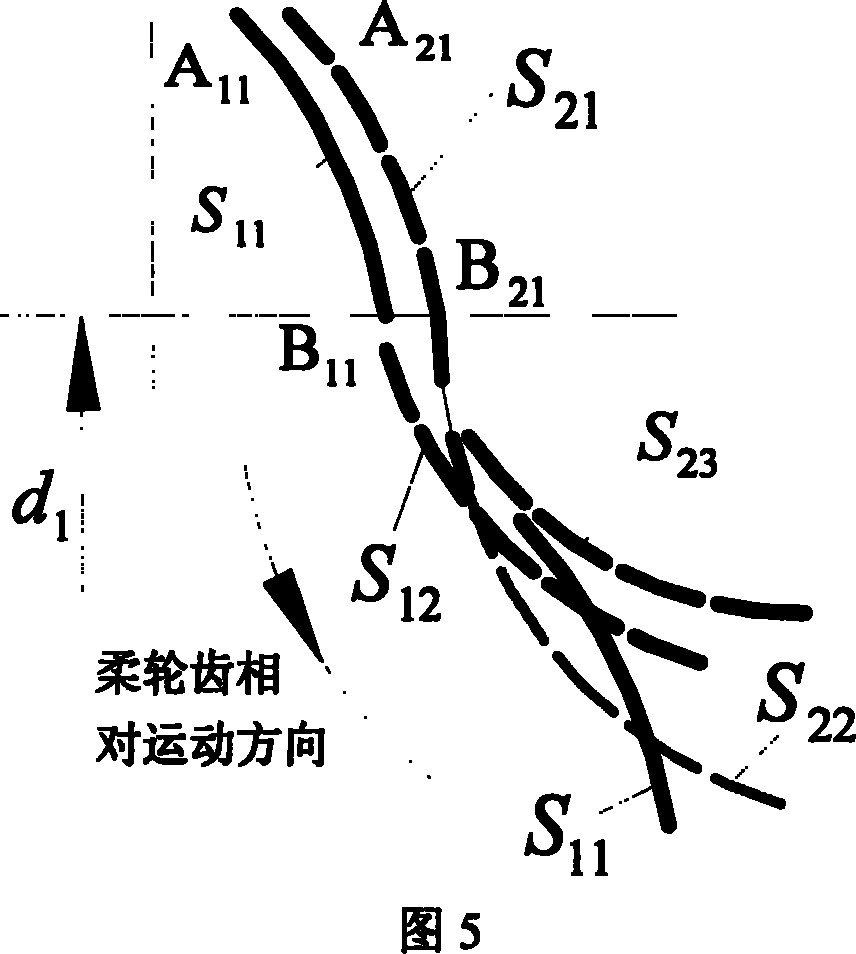

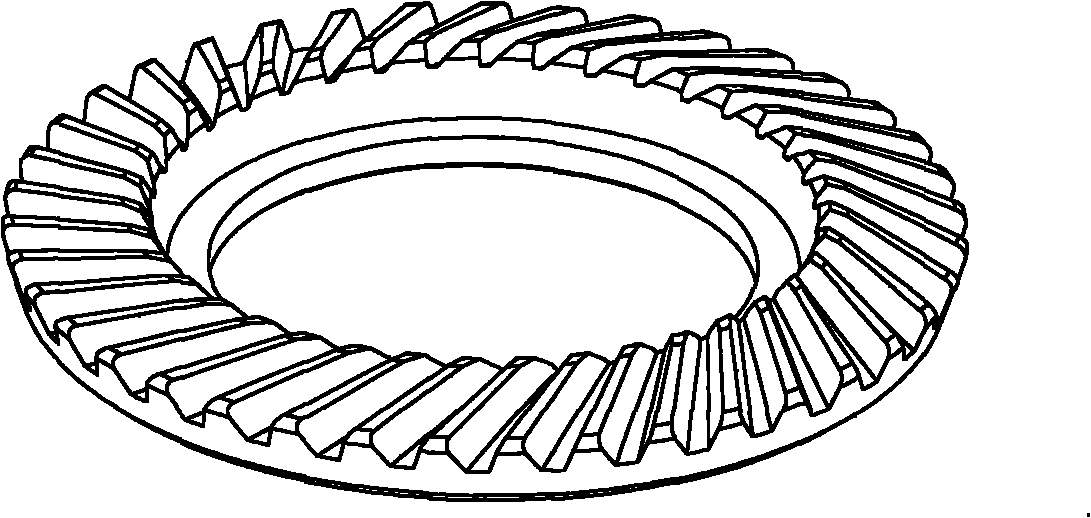

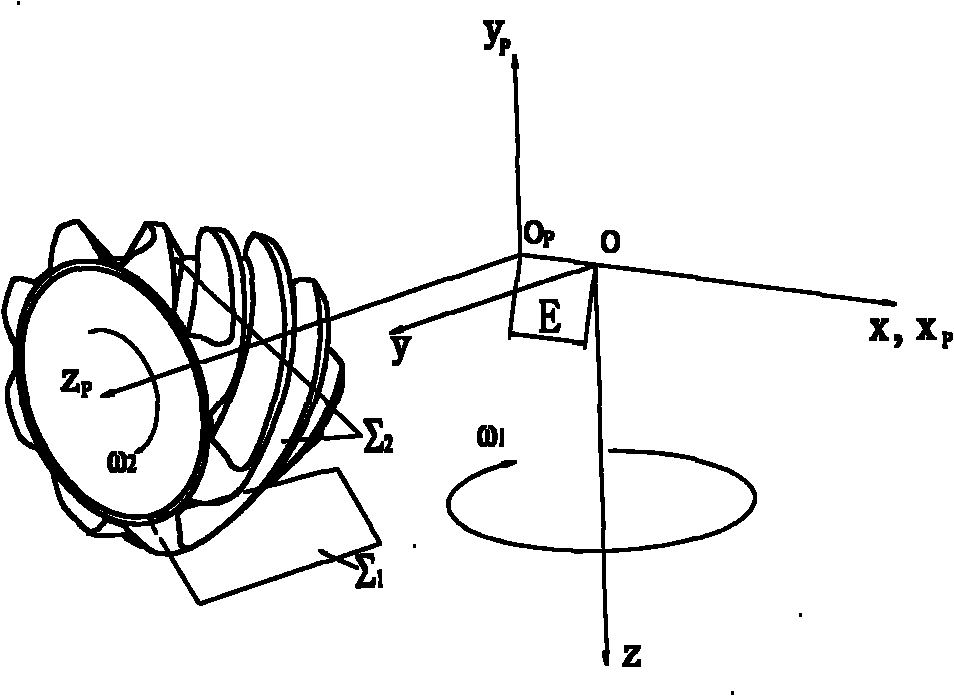

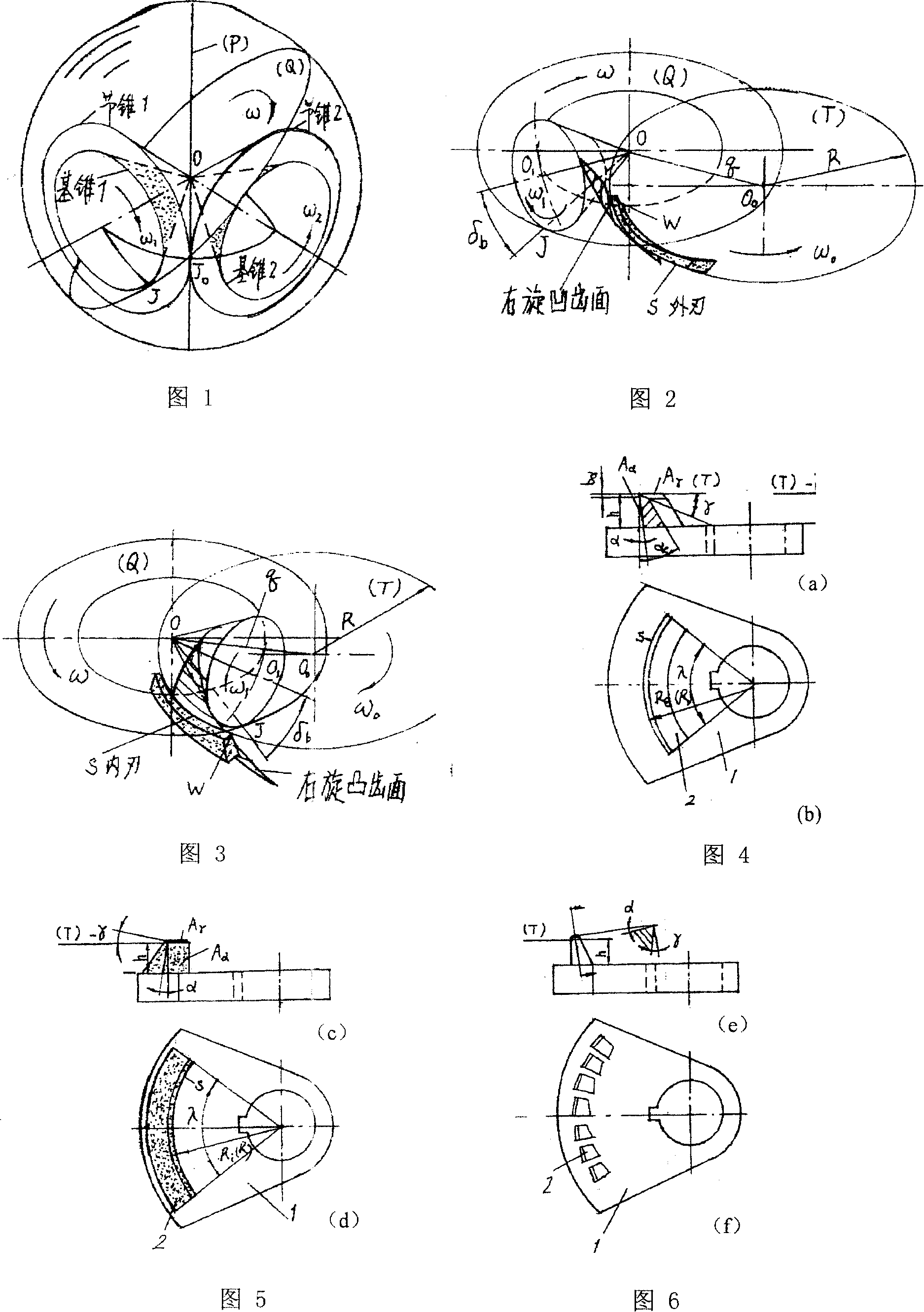

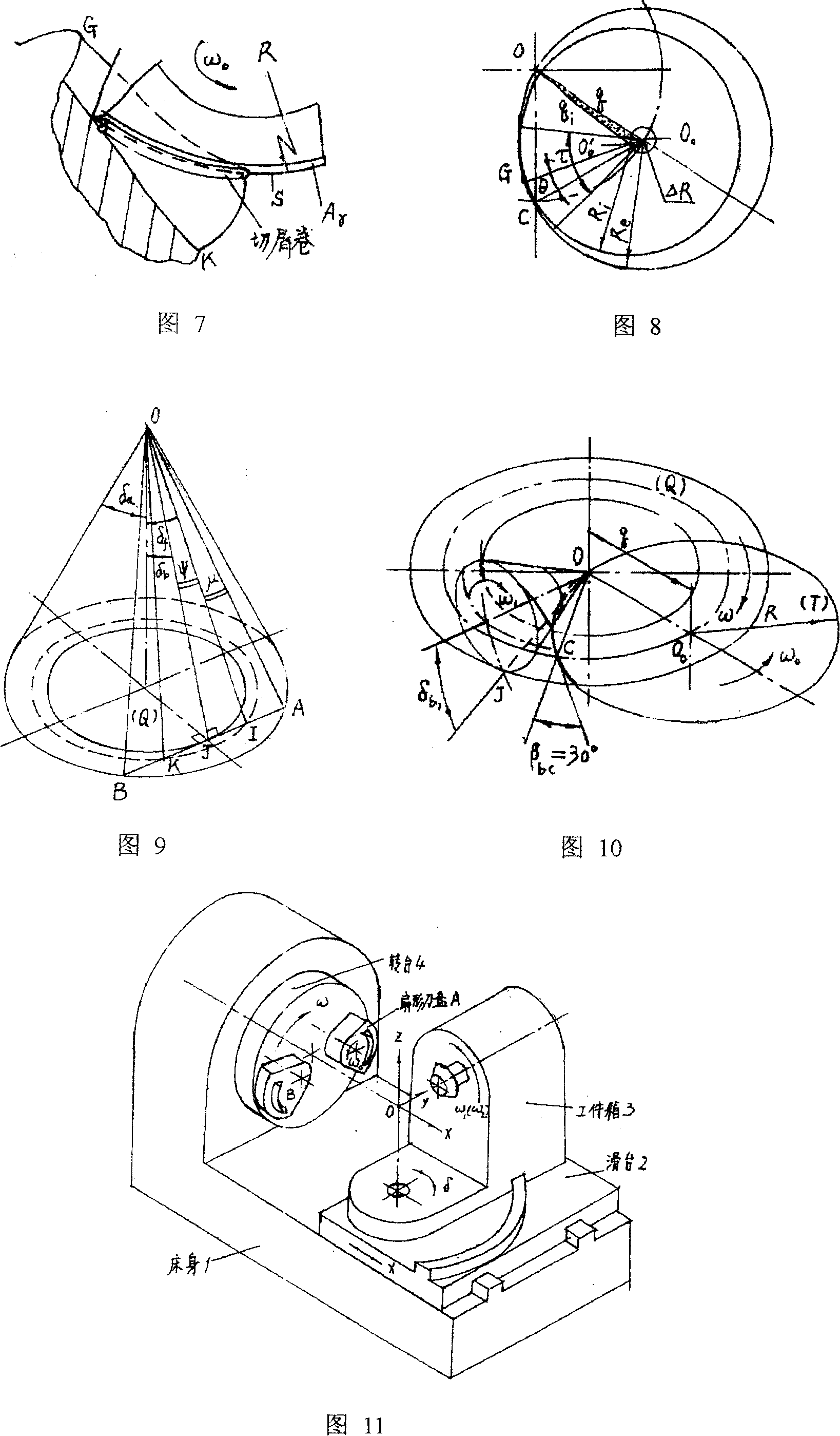

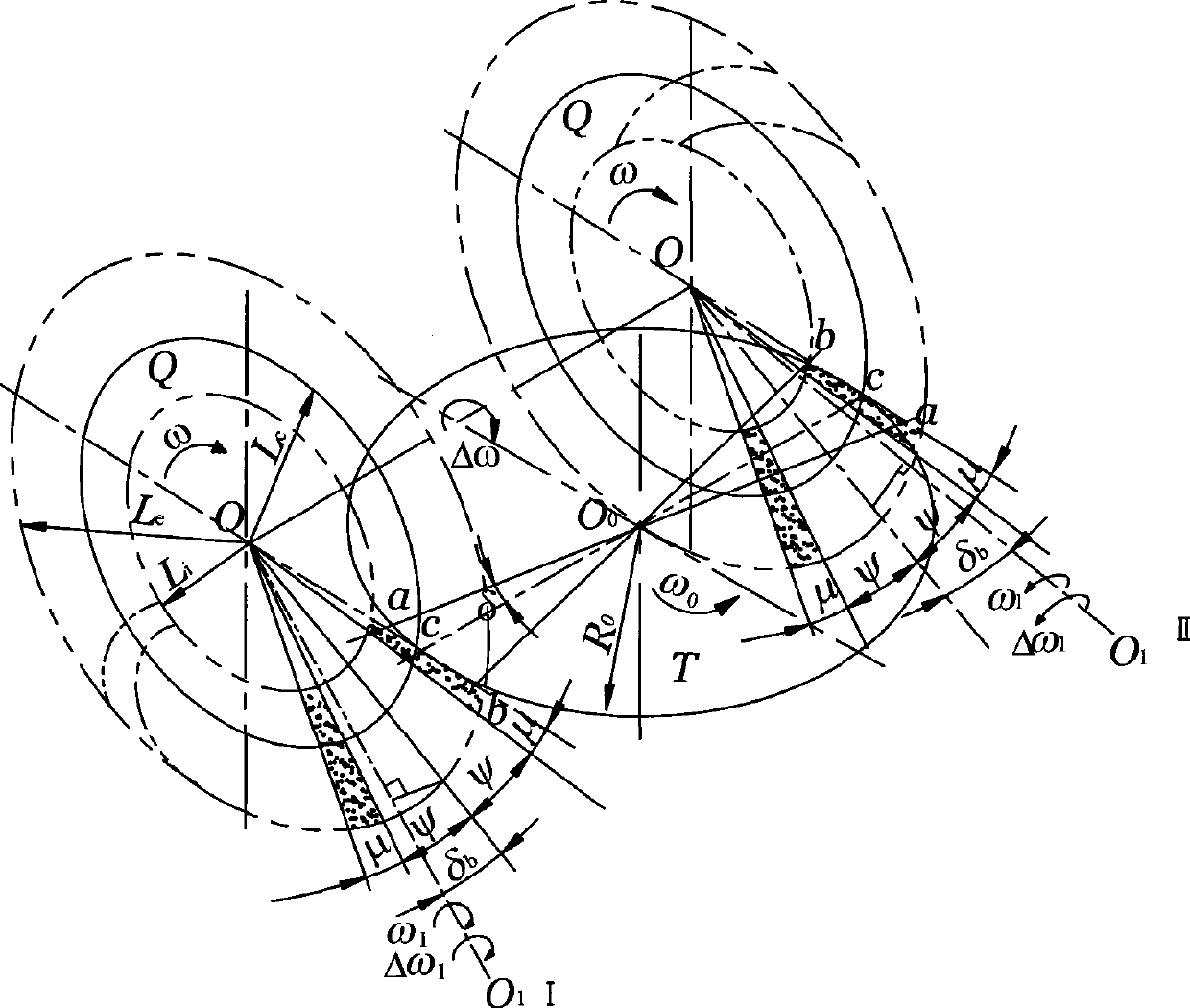

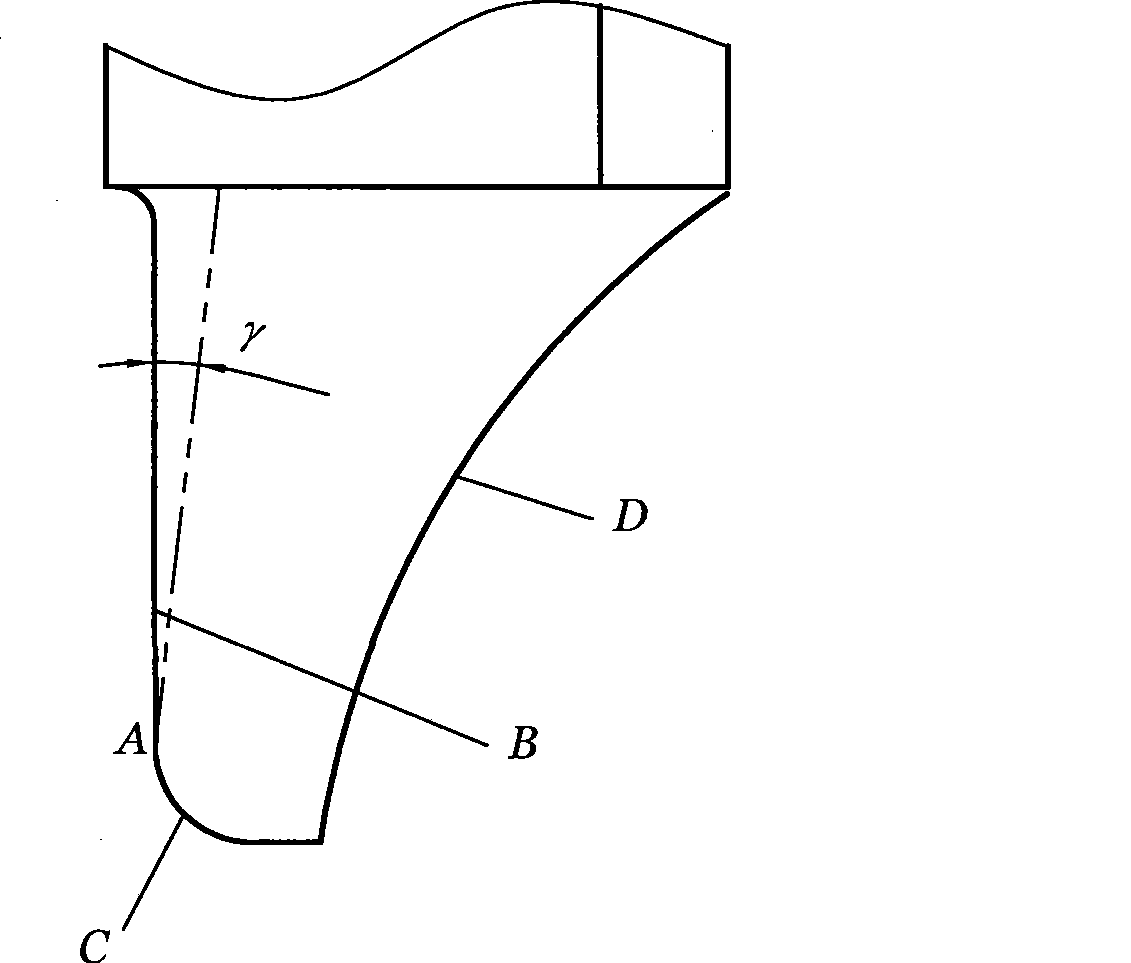

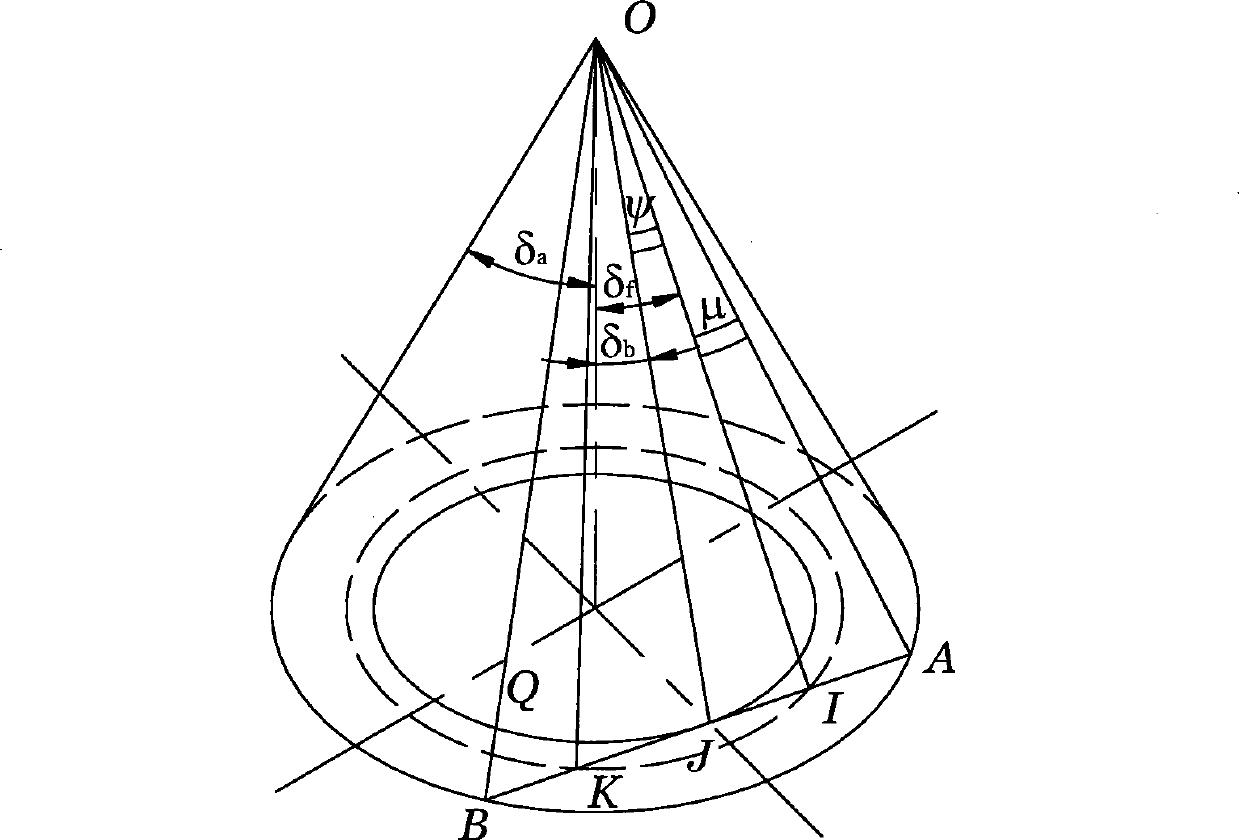

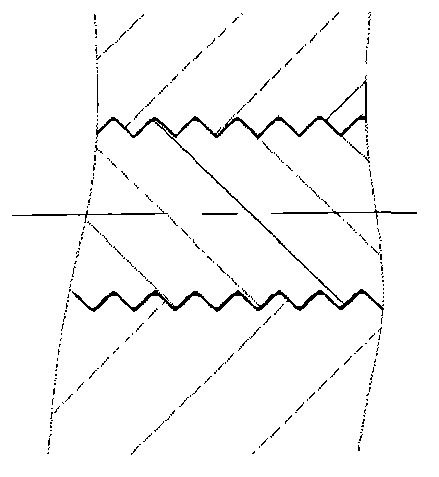

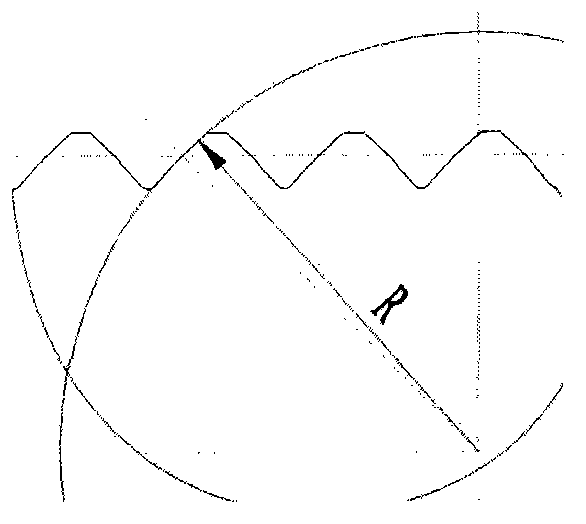

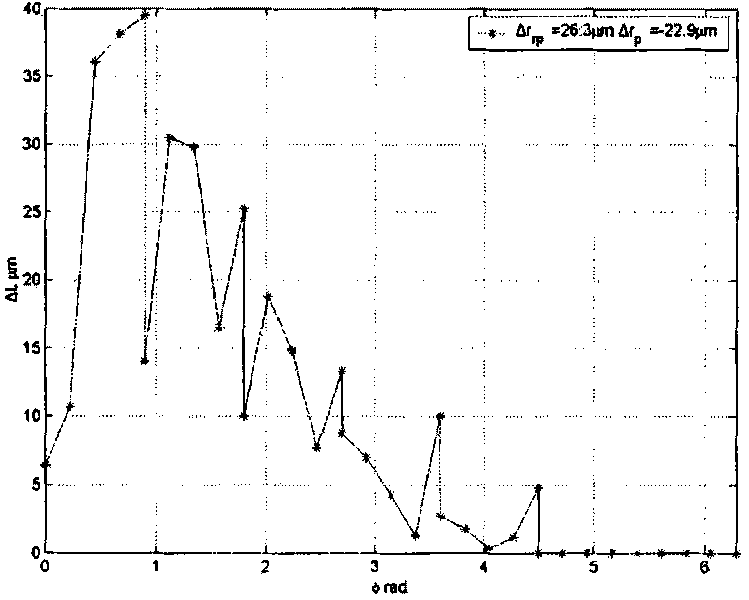

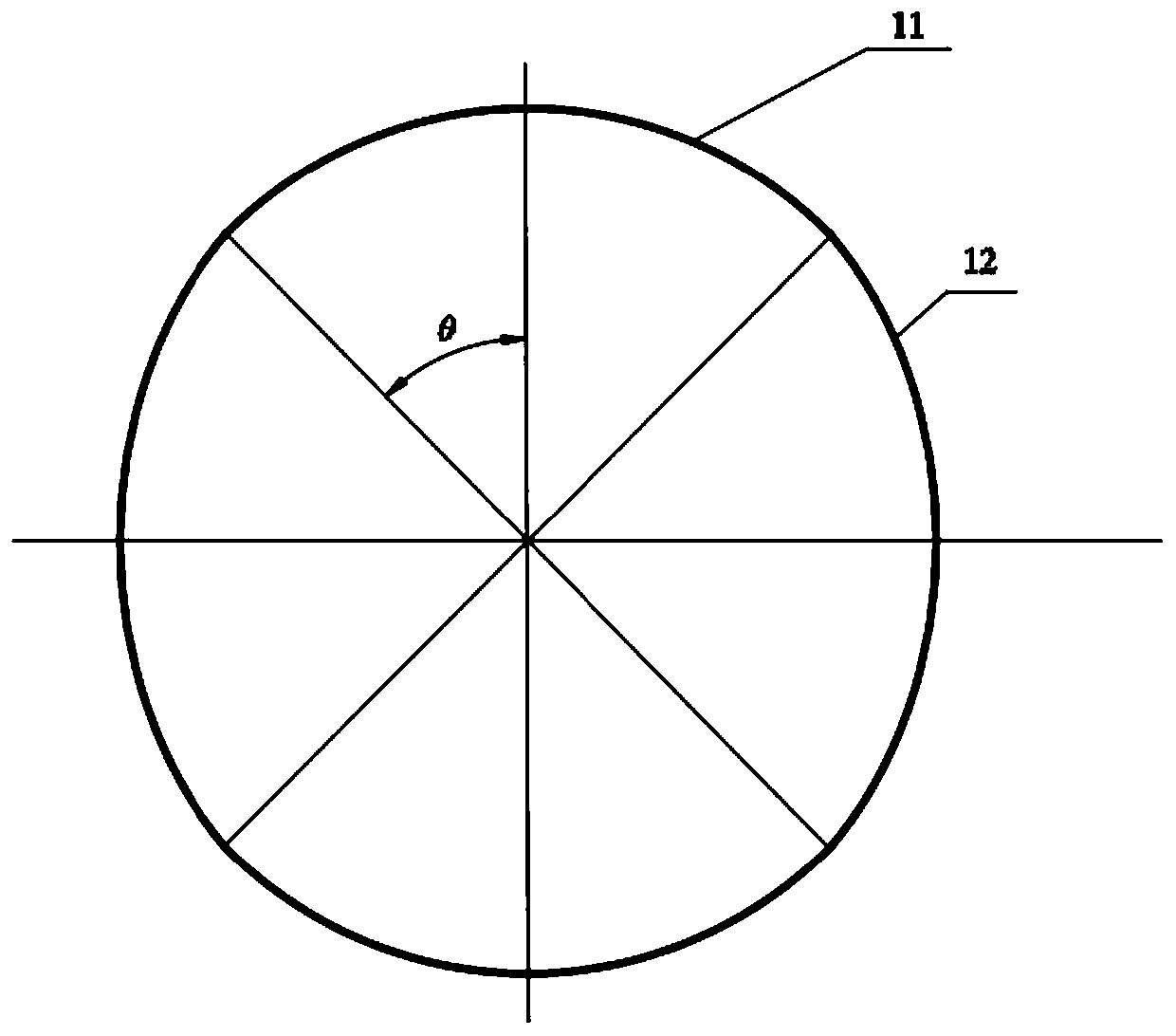

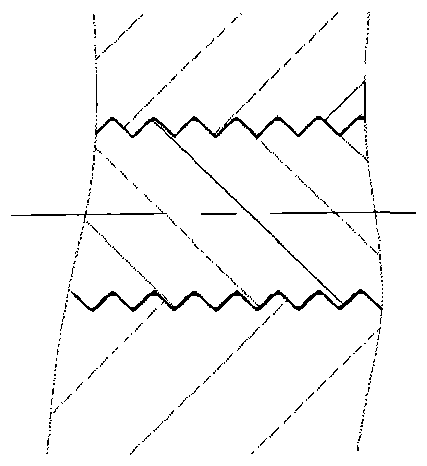

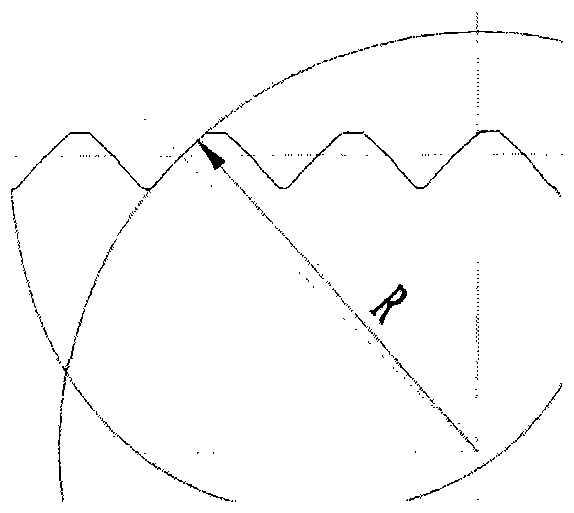

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

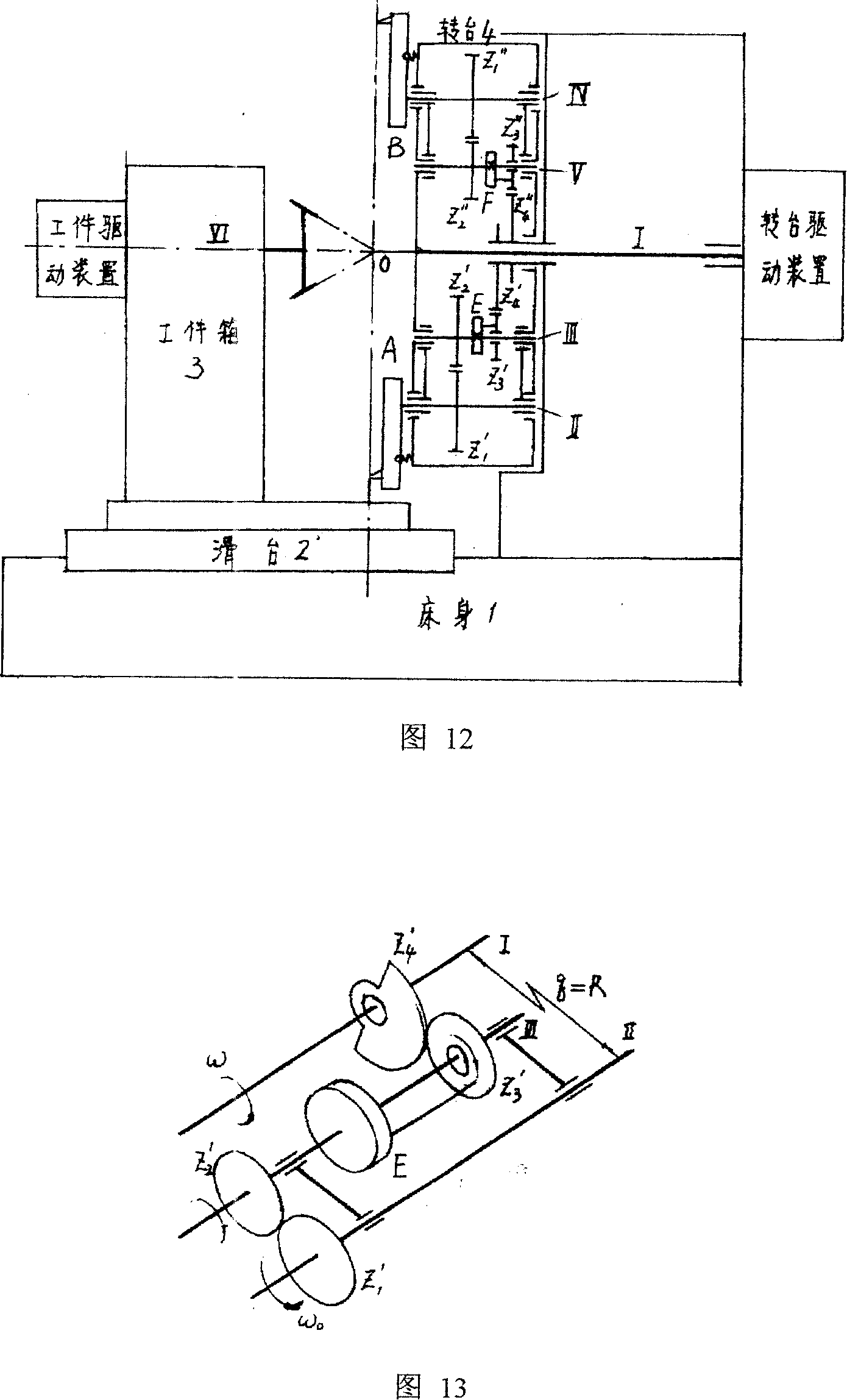

Spherical involute spiral Archimedes spiral bevel gear cutting method and machine tool

InactiveCN101391324AImprove mesh qualityEasy to controlGear teeth manufacturing toolsGear-cutting machinesEngineeringGreat circle

The invention discloses a tooth cutting method for a bevel gear with spherical involute toothed archimedes spiral teeth and a machine tool thereof. The method overcomes the disadvantages that the current tooth cutting method forms principle errors, has complex revision calculation, trial cutting and adjustment of a machine tool, and the like. The tooth cutting method adopts a machine tool with double stations and a single cutter head, which can continuously tooth dividing. When teeth are cut, the I station at one side of the cutter head completes the rough cutting of tooth sockets and the finishing cutting of the concave tooth surfaces of teeth; then the II station at the other side of the cutter head completes the finishing cutting of the convex tooth surfaces of the teeth, each cutter tooth straight edge on a cutting tooth cutter head envelopes and cuts out the side surfaces of the teeth, the circular arc edge of tooth top cuts out the tooth root, and the rough cutting concave edge cuts off the margins of the tooth sockets; and when the teeth are cut, a cutter head shaft and the tooth blank shaft are in a spatial cross position, the rotating end surface of the cutter head is perpendicular to the tangent plane of the gear blank base cone, the cutter head, the gear blank and the big circular plane of an imaginary spherical surface rotate in an uniform speed, the cutter head is in the rotary feed when cutting the teeth, and the continuous hobbling base cone toothed portion is the spiral bevel gear of Archimedes. The invention provides a machine tool, a cutter head and a cutter tooth for realizing the tooth cutting method.

Owner:JILIN UNIV

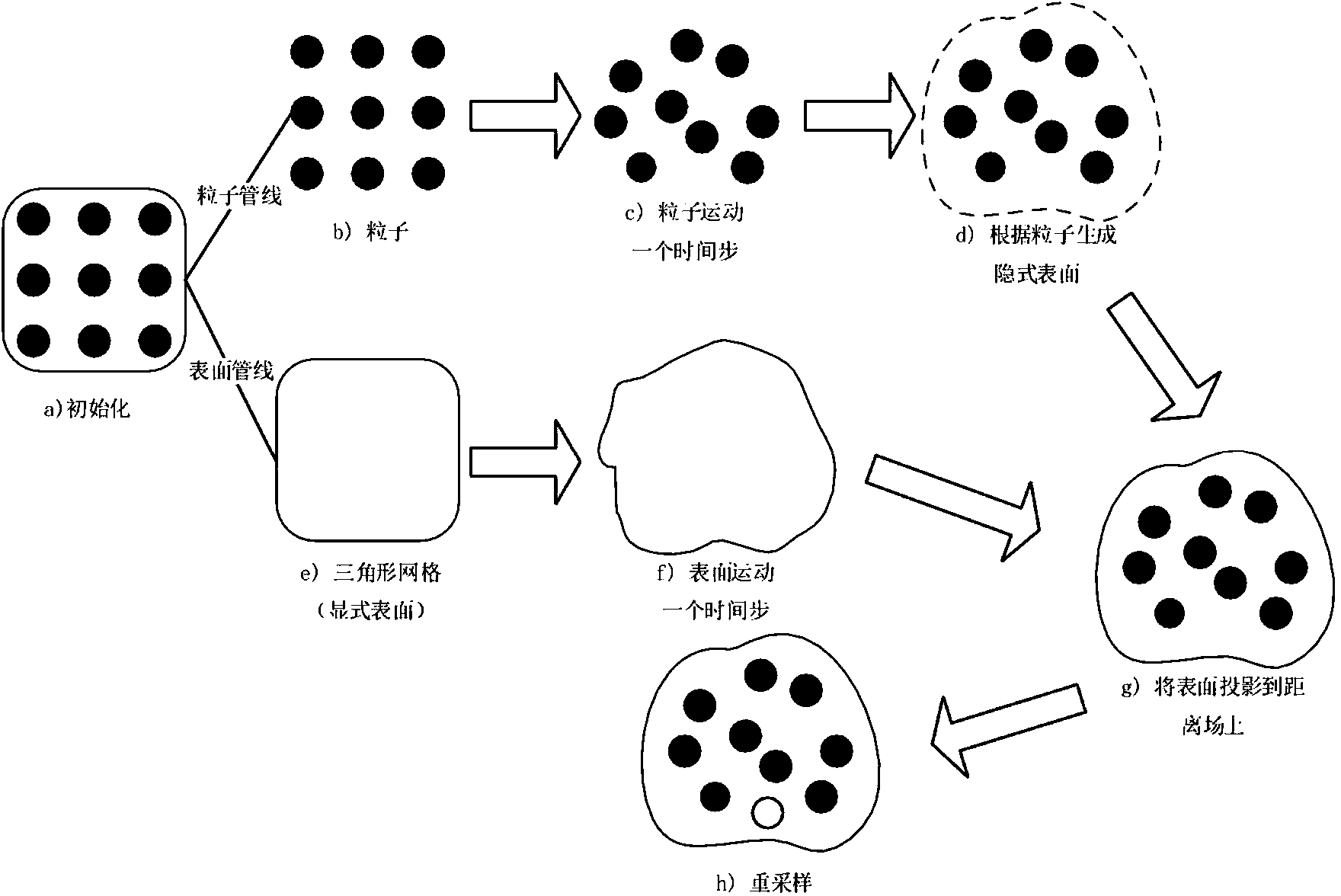

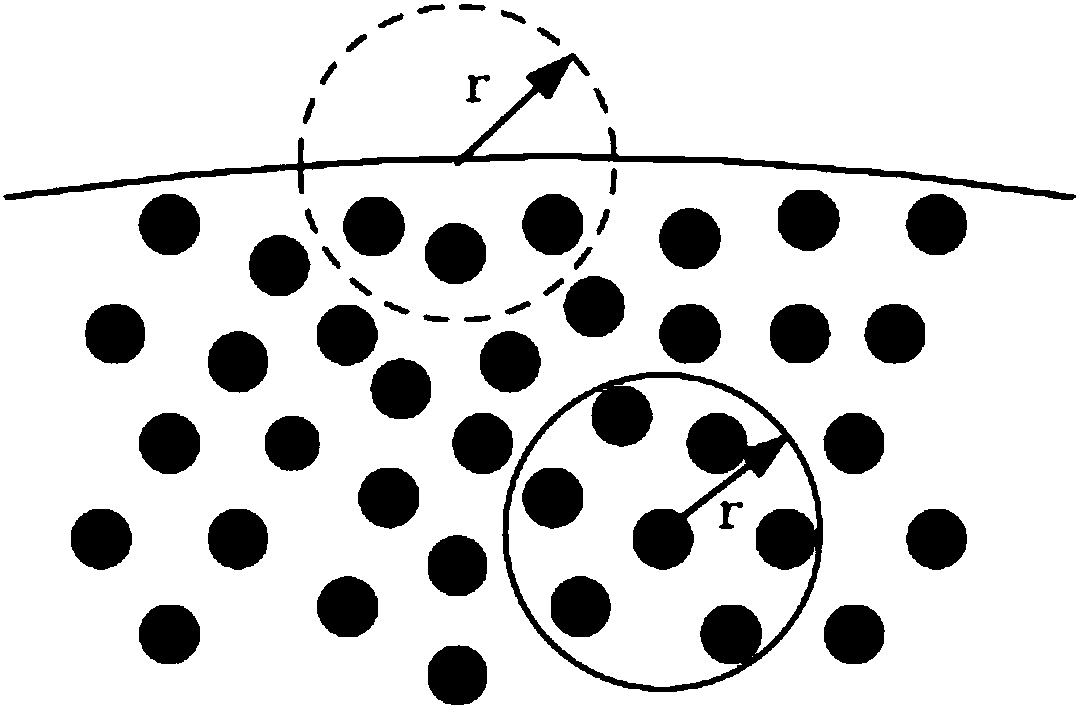

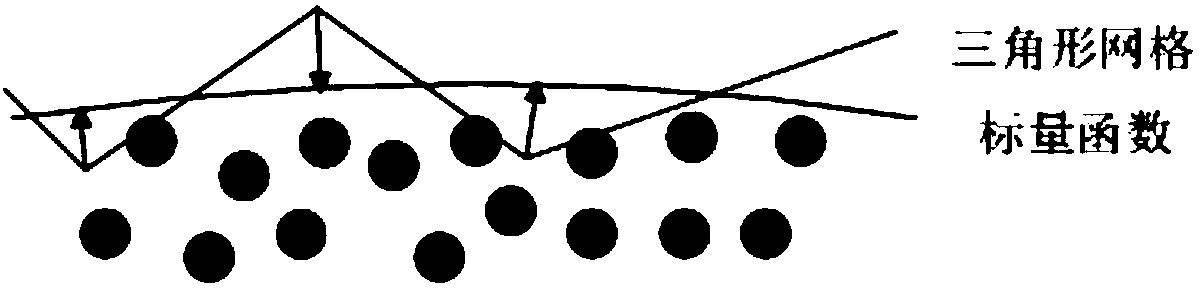

Fluid simulation method for combining SPH and dynamic surface mesh

ActiveCN103714575AImprove mesh qualityThe effect of details is improvedAnimation3D modellingSimulationComputer science

The invention relates to a fluid simulation method for combining SPH and a dynamic surface mesh. The method makes a display surface track fluid sampled through a particle system, self-crosslinking and topological changes are automatically processed in the simulation process, and quality of a triangular mesh is maintained; according to the method, a new self-adaptation resampling method based on the display surface is provided. SPH simulation displays very fine and thin characteristics with difficulty, and particularly, under the condition that the particle resolution ratio is not sufficient, even unnatural voids can further be formed. On the basis of traditional SPH, if people want to embody better details, the particle resolution ratio can be increased, but calculation cost for time and space can be correspondingly increased. According to the method, on the basis of the self-adaptation resampling method of the display surface, very refined fluid surface details can be simulated, so that the simulation effect is improved, and meanwhile simulation efficiency and speed can be improved.

Owner:PEKING UNIV

Involute harmonic gear shaping method and harmonic reducer

The invention discloses an involute harmonic gear shaping method, and comprises the following shaping steps that A) a flexible gear shaping step: (1) calculating the gear modulus of the flexible gearthrough a formula; (2) obtaining the tooth profile basic elements of the flexible gear according to the calculation, and drawing the original involute tooth profile of the flexible gear; (3) obtaininga left tooth surface involute tooth profile curve before the flexible gear is not modified according to the tooth profile basic element parameters of the flexible gear, and calculating the shape corrected parameters of the tooth profile of the flexible gear, shaping the tooth top part of the original involute tooth profile of the flexible gear so as to form a smooth curve; and (4) determining a tooth direction correcting parameter according to the tooth width of the flexible gear and the constraint condition that the flexible gear is engaged in or out of the meshing moment and does not generate tooth top interference, correcting the tooth shape in the tooth direction, and completing the final design of the tooth shape. The invention further discloses a harmonic reducer. The harmonic reducer comprises a flexible gear, a rigid gear and a wave generator; and the machining and manufacturing parameters are obtained through calculation according to the shaping method. According to the method and the device, the motion performance of the harmonic gear can be improved, and the manufacturing cost is low.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

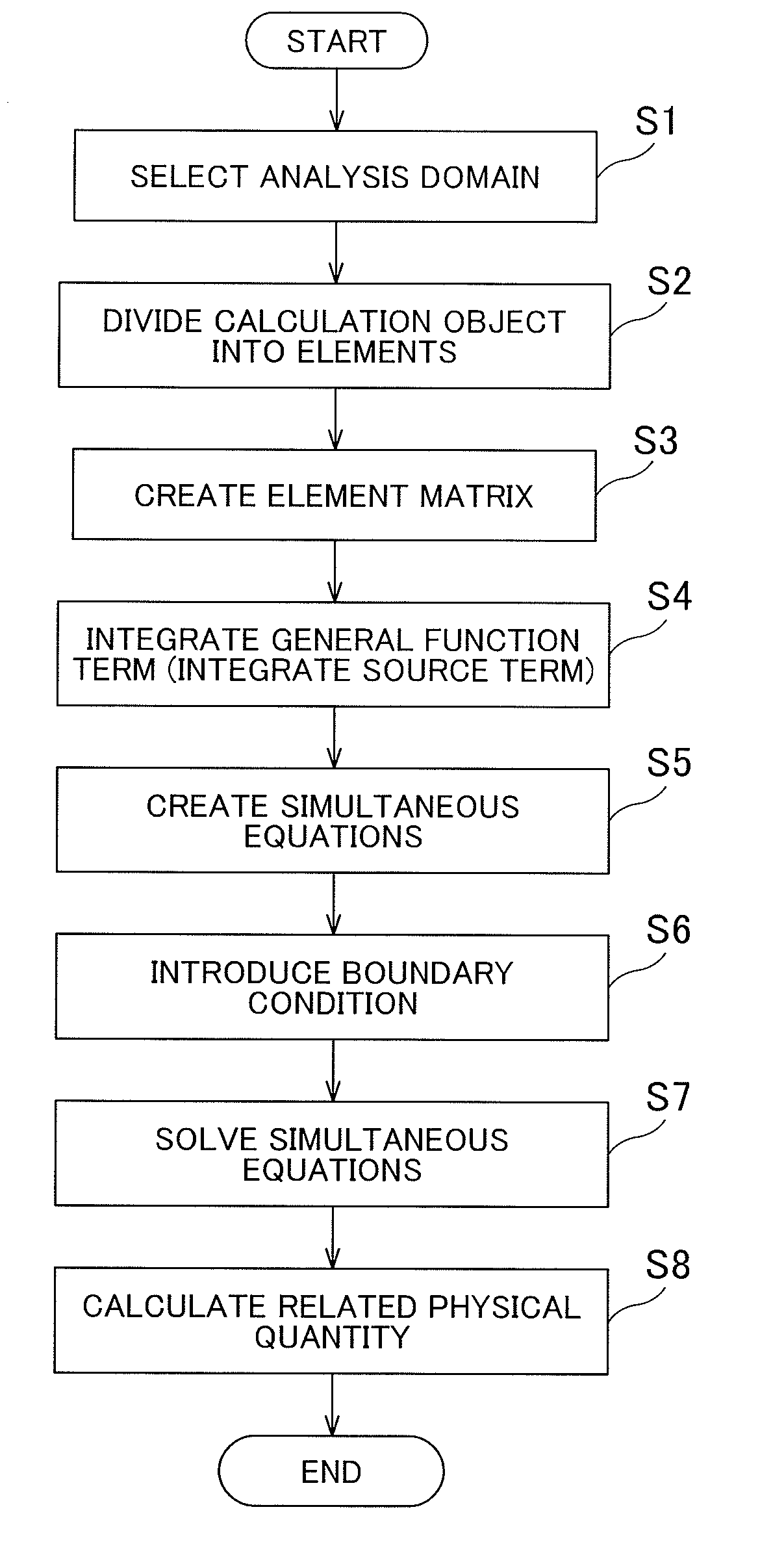

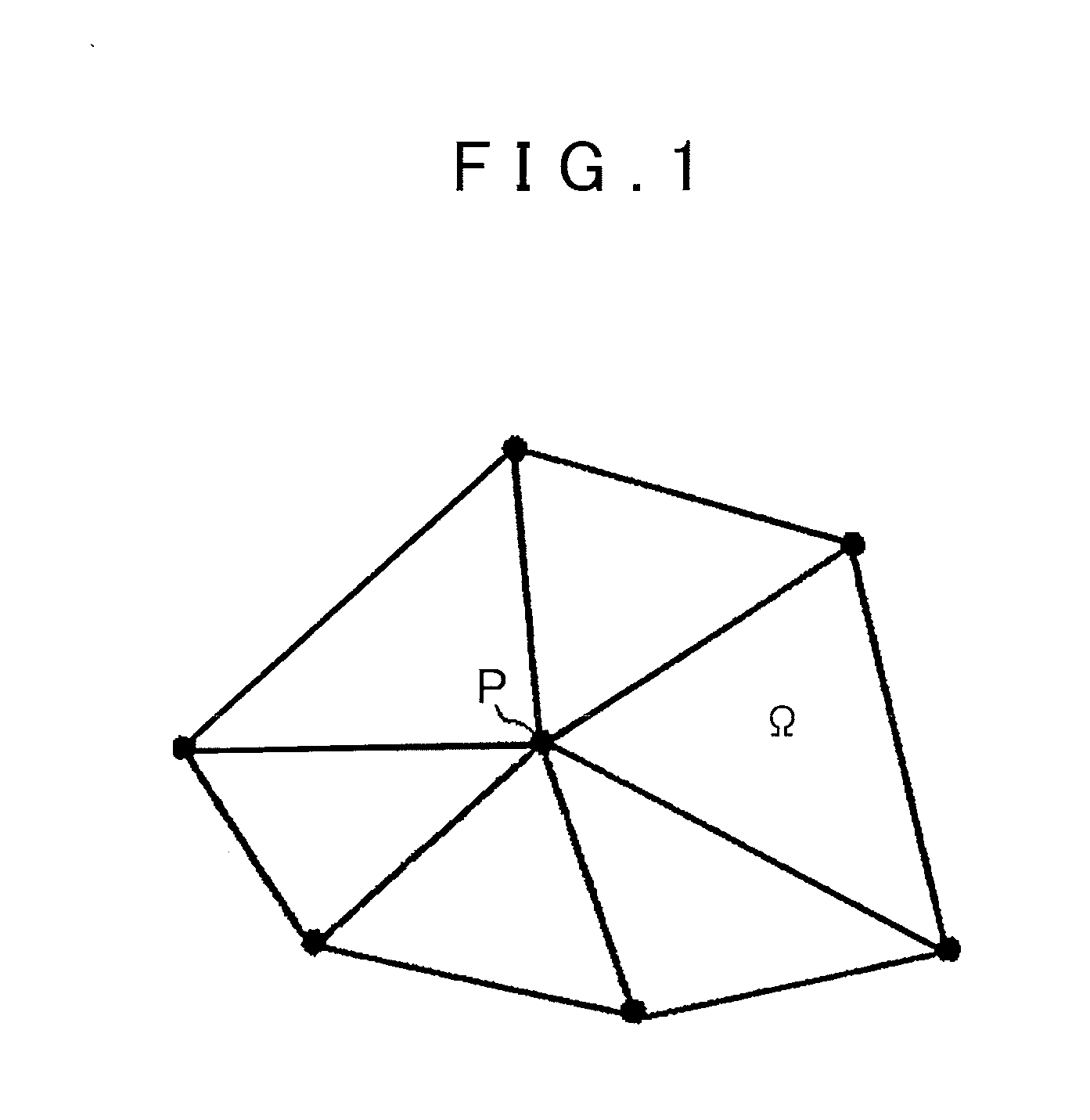

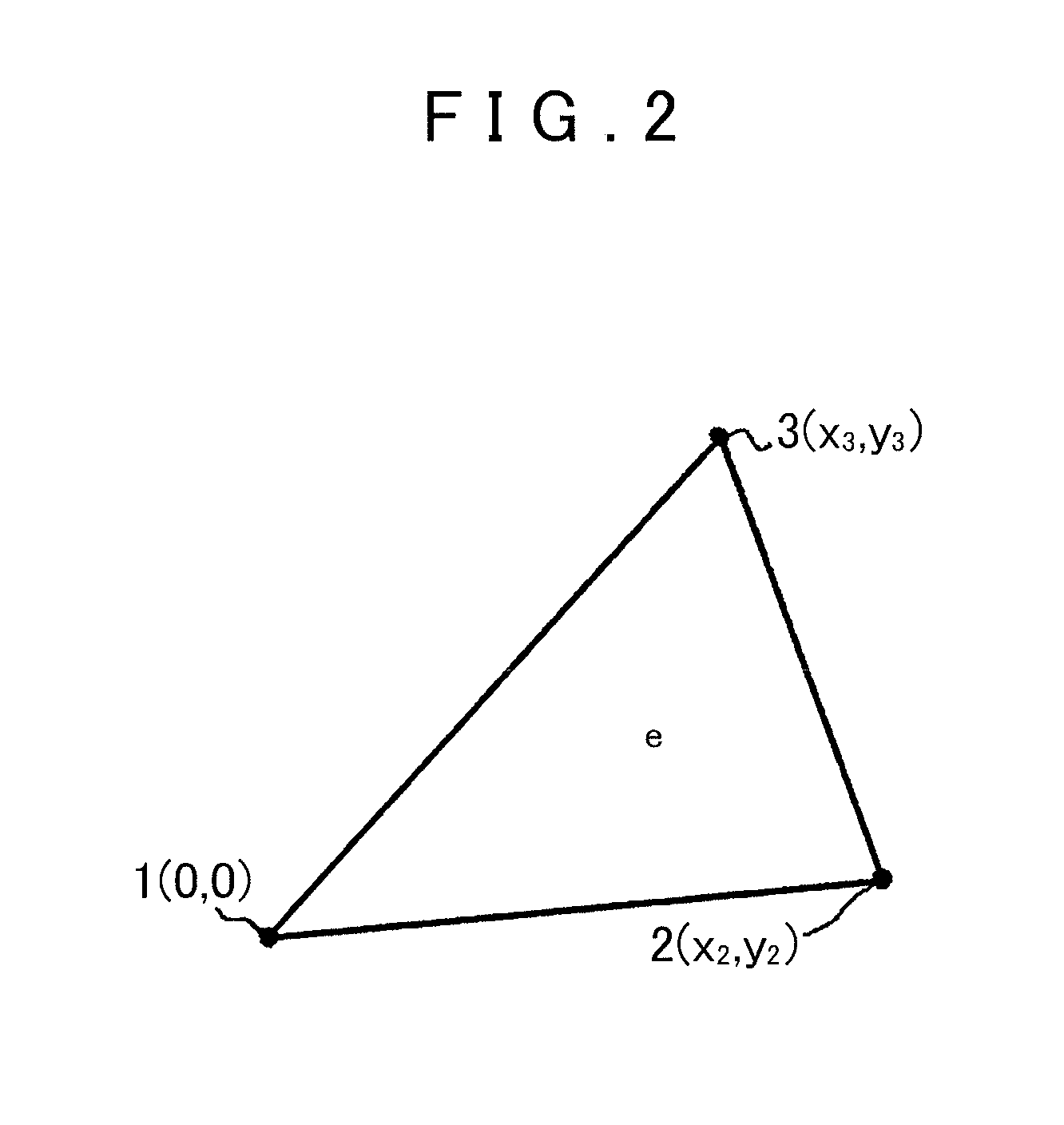

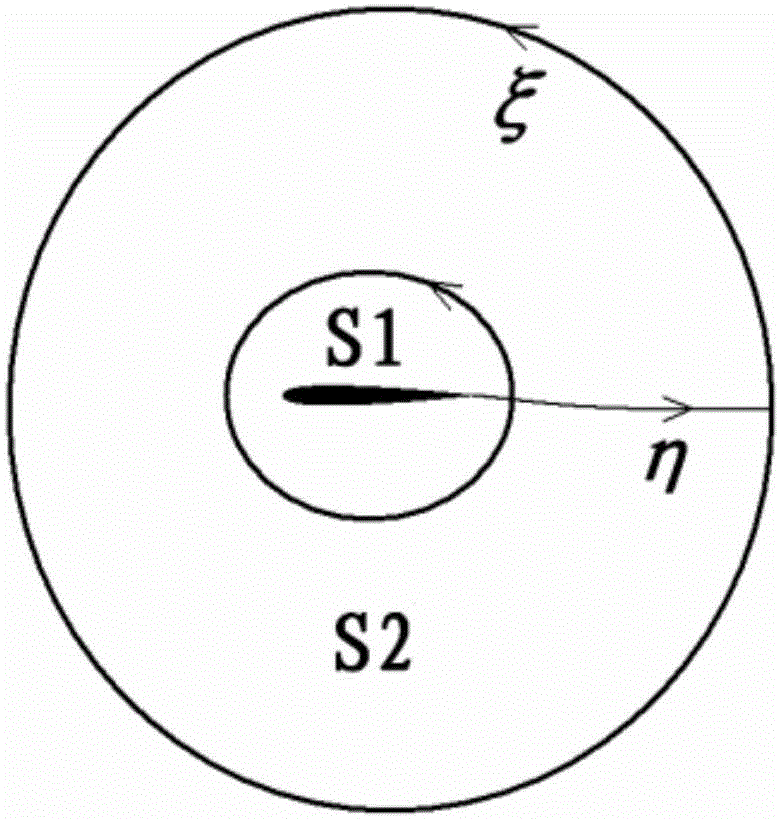

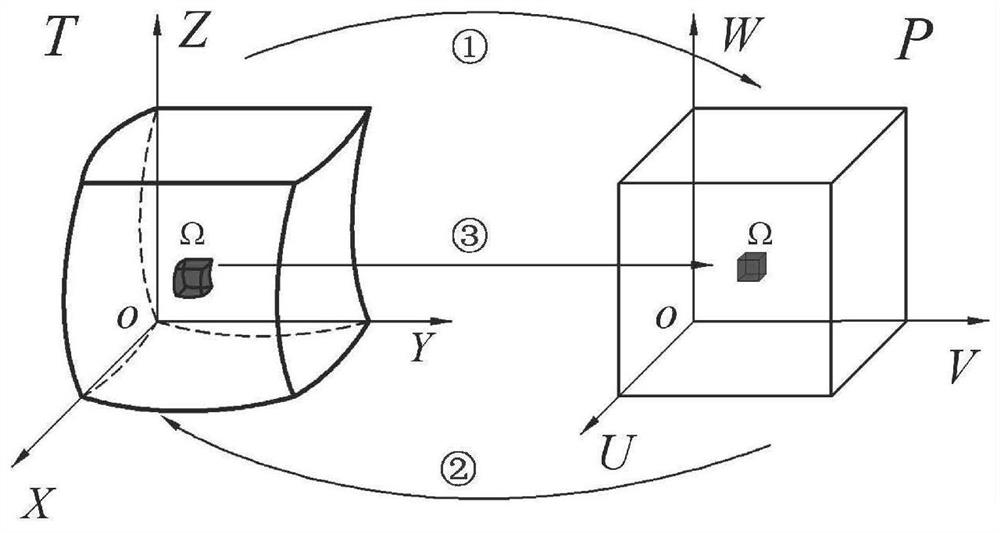

Analysis method using finite element method, and analytical computation program using finite element method

InactiveUS20120059865A1Inaccurate analysisIncrease in amount of calculationDesign optimisation/simulationDigital function generatorsGeneral functionExtended finite element method

An analysis method using a finite element method includes: selecting an analysis domain to be analyzed; dividing the analysis domain into elements as calculation objects; creating a matrix of each element; integrating a general function term as a product of a Galerkin weight function and a general function; creating simultaneous equations, based on the sum of matrices of respective elements and the sum of values obtained by integrating the general function term, and obtaining a numerical solution from the simultaneous equations. In integrating the general function term, the concept of a nodal domain defined based on a result of discretization of a second-order differential term according to a Galerkin finite element method is introduced, and the general function term using a typical value of the element is integrated.

Owner:AISIN AW CO LTD

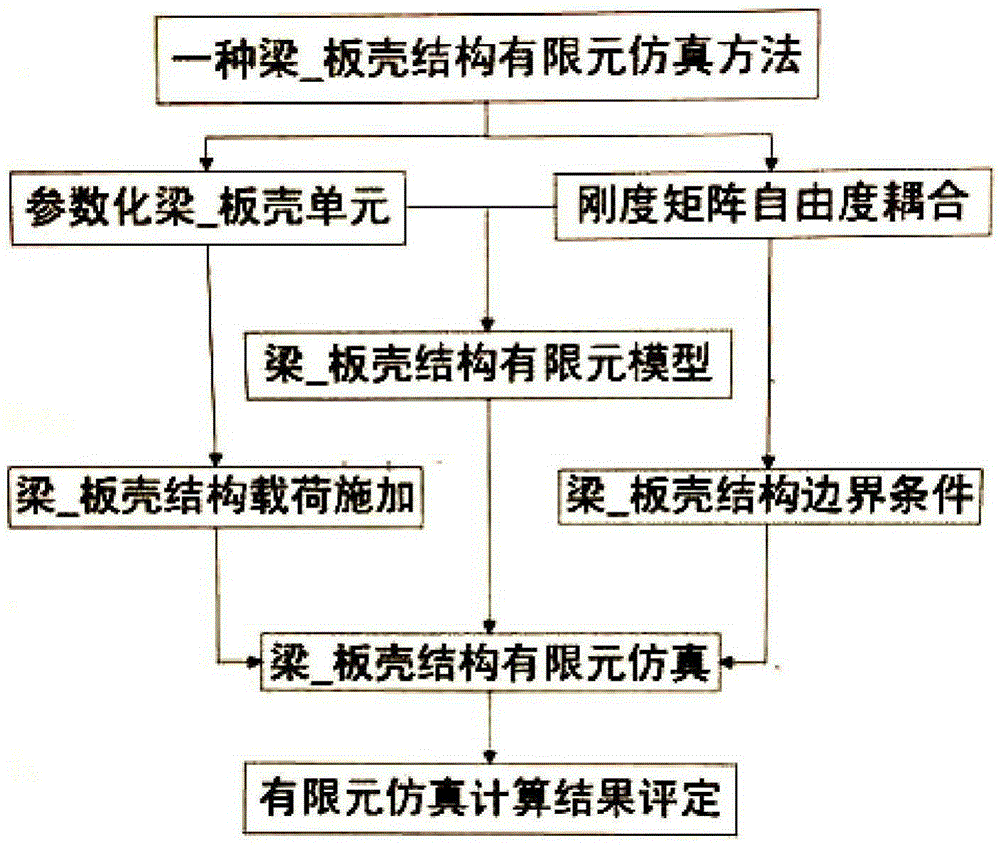

Finite element simulation method of beam_plate shell structure

InactiveCN105302994AImprove mesh qualitySimple resultSpecial data processing applicationsElement modelEngineering

The invention relates to a finite element simulation method of a beam_plate shell structure. The finite element simulation method comprises the steps of establishing the research of a beam unit and a plate shell unit, and a finite element model; determining the boundary conditions of a beam_plate shell model; carrying out strength calculation and mode analysis; and evaluating the calculation result, wherein the establishment of the research of the beam unit and the beam_plate shell unit and the finite element model comprises the steps of researching the beam unit and setting real constants based on cross-section shape, namely carrying out parameterization on the beam_plate shell unit; researching the characteristics of the plate shell unit and the coupling characteristics of plate shell unit and the beam unit, namely coupling stiffness matrix degree of freedom; and creating the finite element model of the beam_plate shell structure by applying the parameterized beam_plate shell unit and the stiffness matrix degree of freedom. The finite element simulation method has the advantages of good grid quality, intuitive result and the like, and is beneficial to promoting the design level, shortening the design period, reducing the experiment expense, and reducing the potential fault danger.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

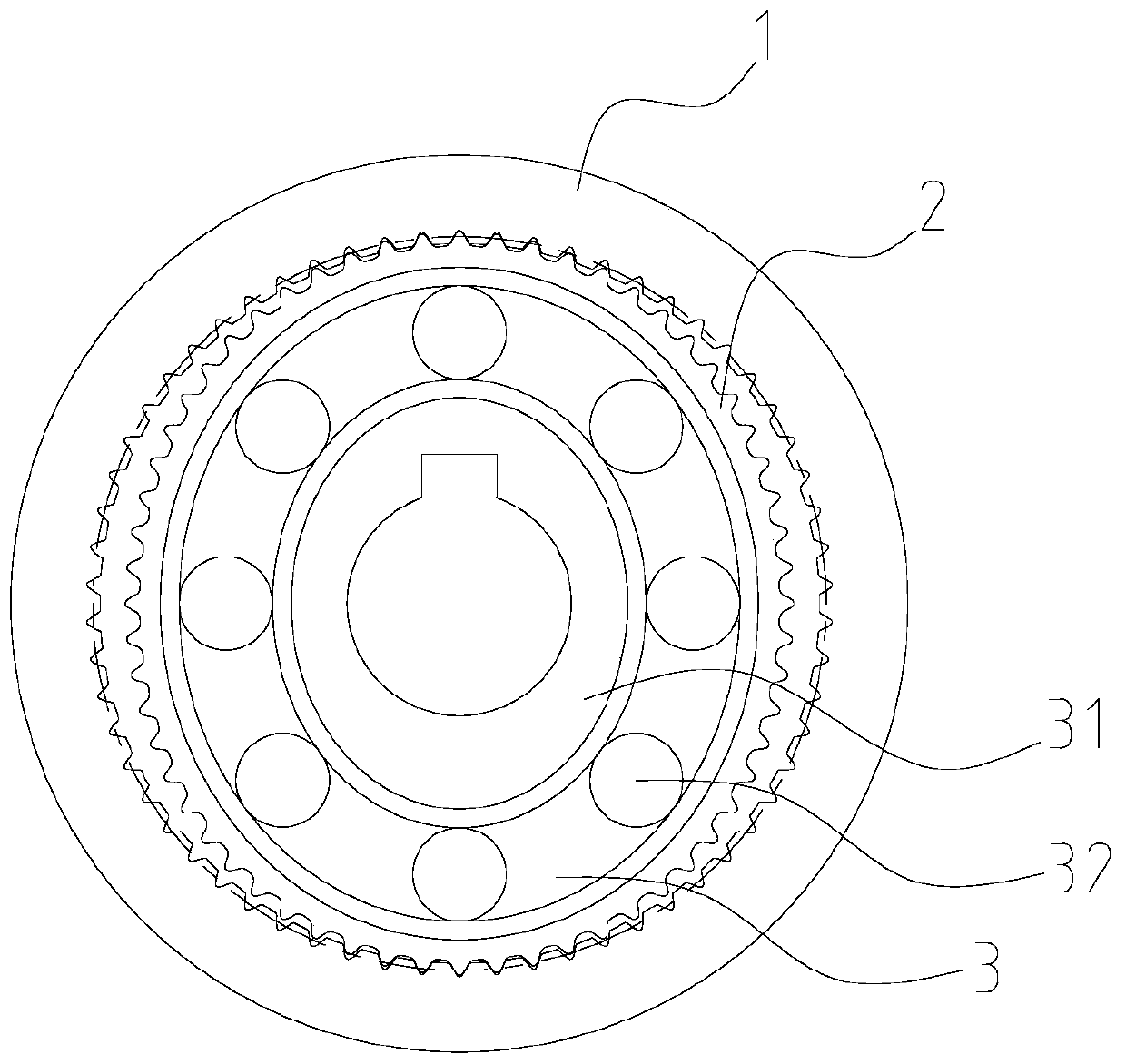

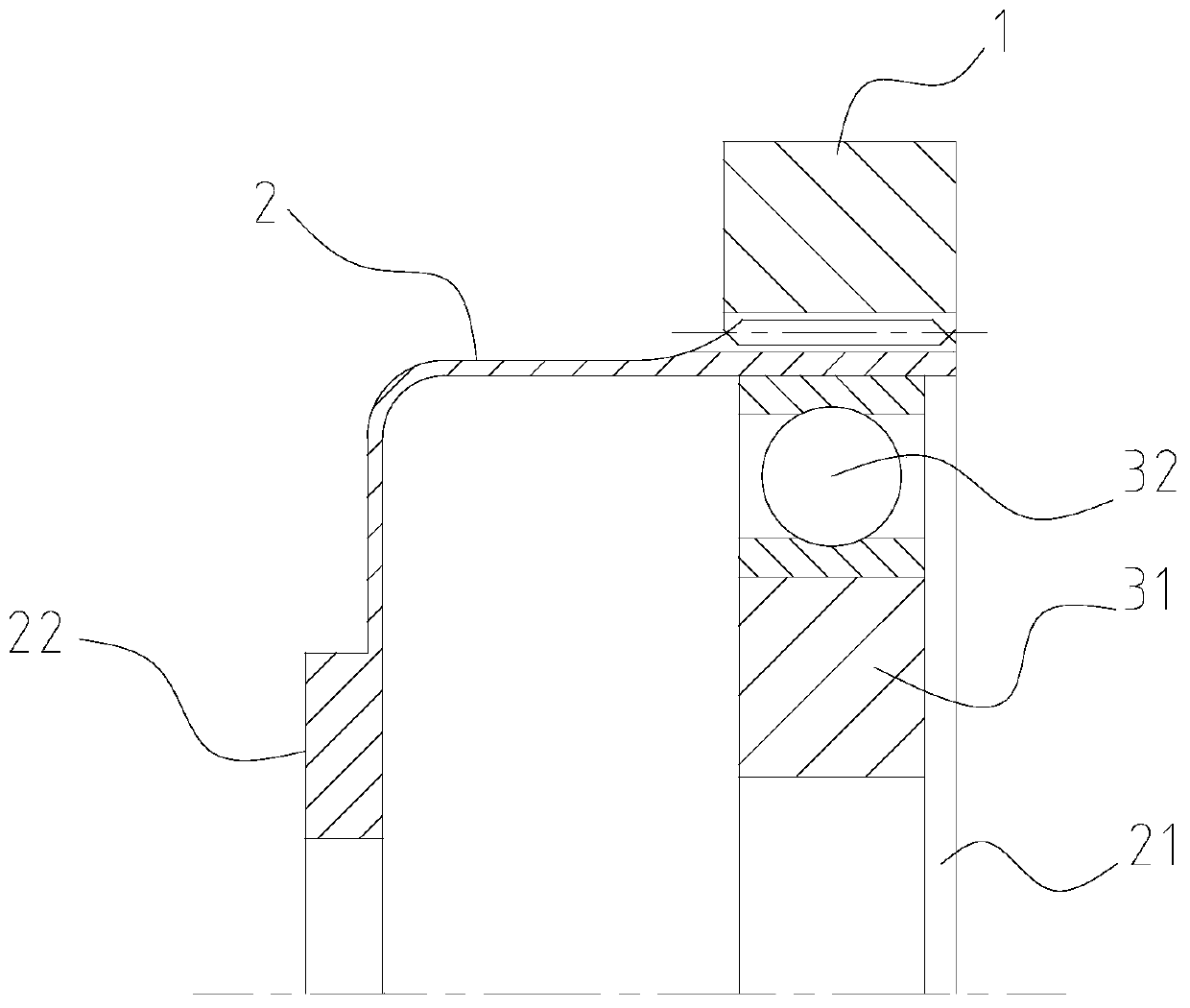

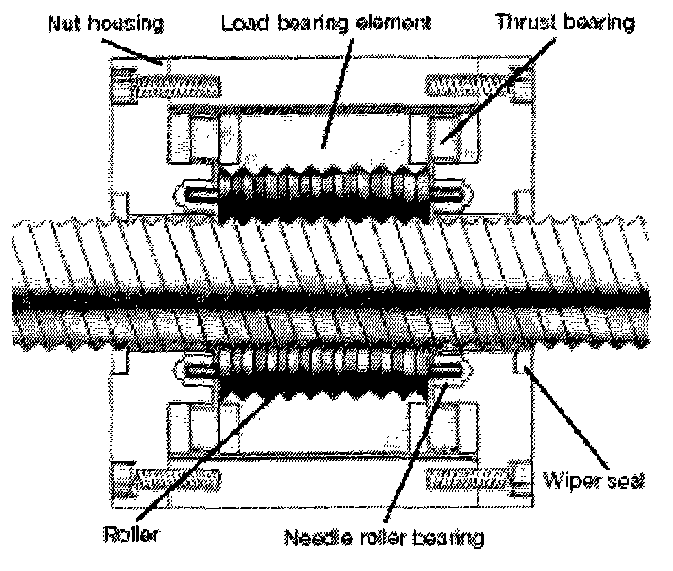

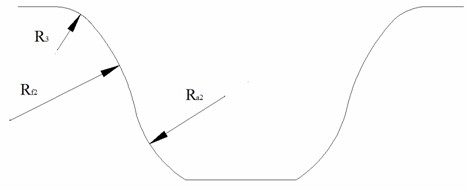

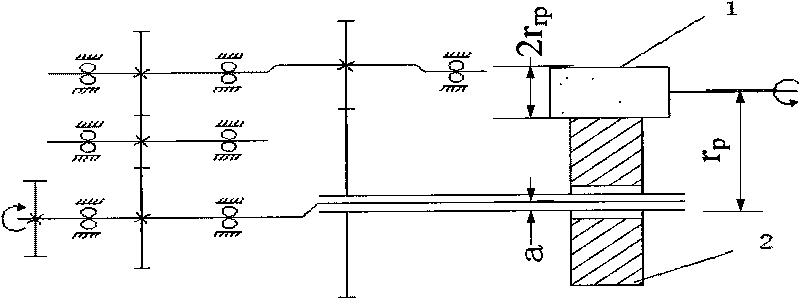

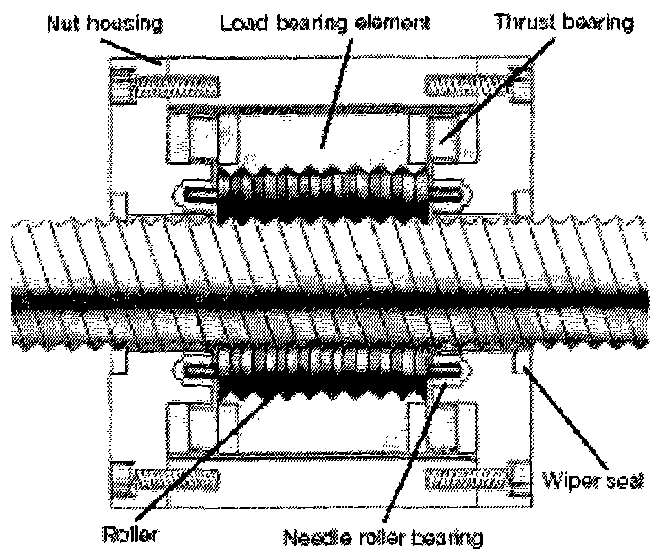

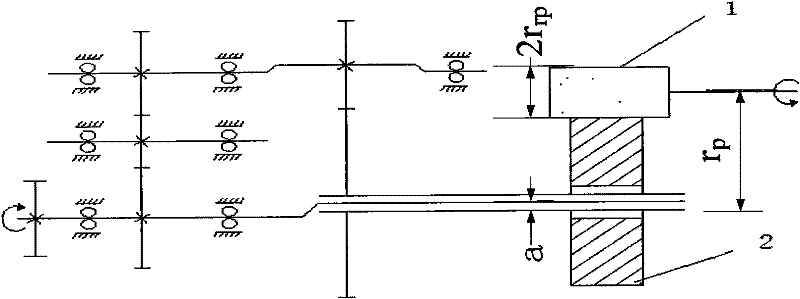

Planetary roller and lead screw pair

ActiveCN102900821AImprove mesh qualityReduce the difficulty of processingGearingRight triangleEngineering

The invention belongs to linear kinetic pairs, and particularly relates to a planetary roller and lead screw pair. The planetary roller and lead screw pair solves problems of axial releasing and jamming of an existing roller and an existing nut, the meshing quality is improved, and the difficulty in machining process is lowered. Normal sections of a nut (3) and lead screws (1) in the planetary roller and lead screw pair are in shapes of isosceles right triangles and are provided with threaded grooves, normal sections of threads of rollers (2) are arc-shaped, and circle centers of arcs of the normal sections of the threads of the rollers (2) are positioned on axes of the rollers, and actual pitch diameters of threads of the lead screws (1) are smaller than nominal pitch diameters obtained from a computational formula.

Owner:CHINA NORTH VEHICLE RES INST

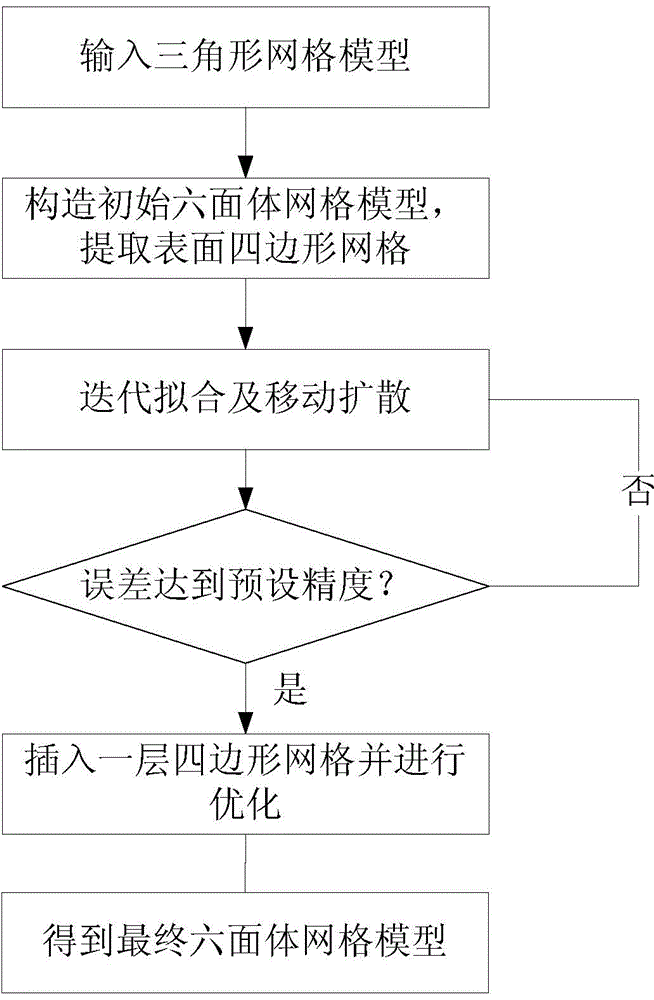

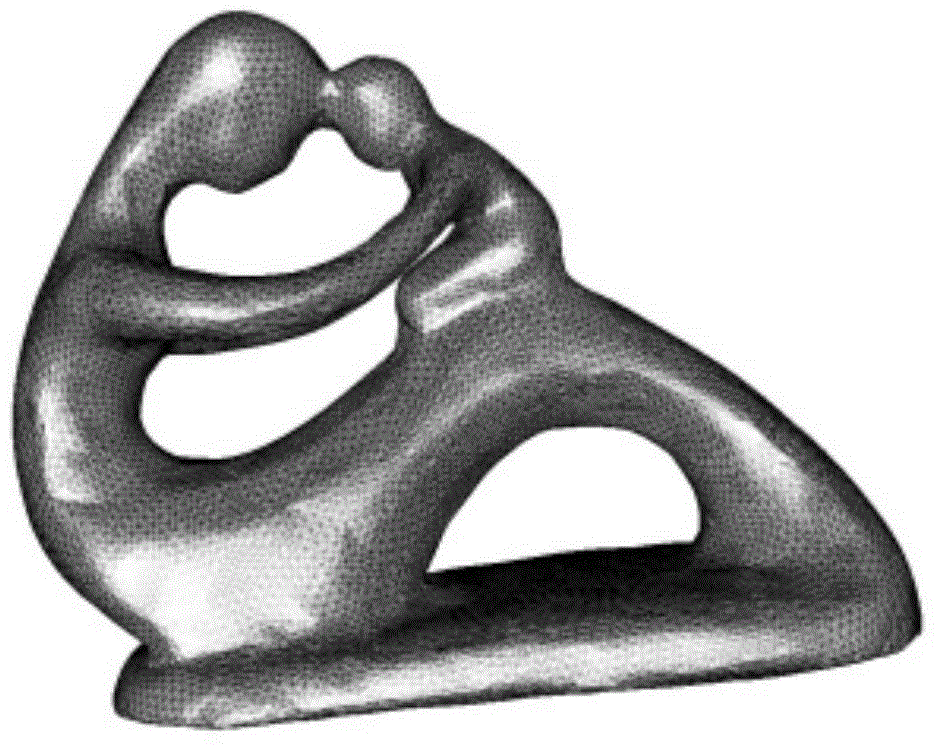

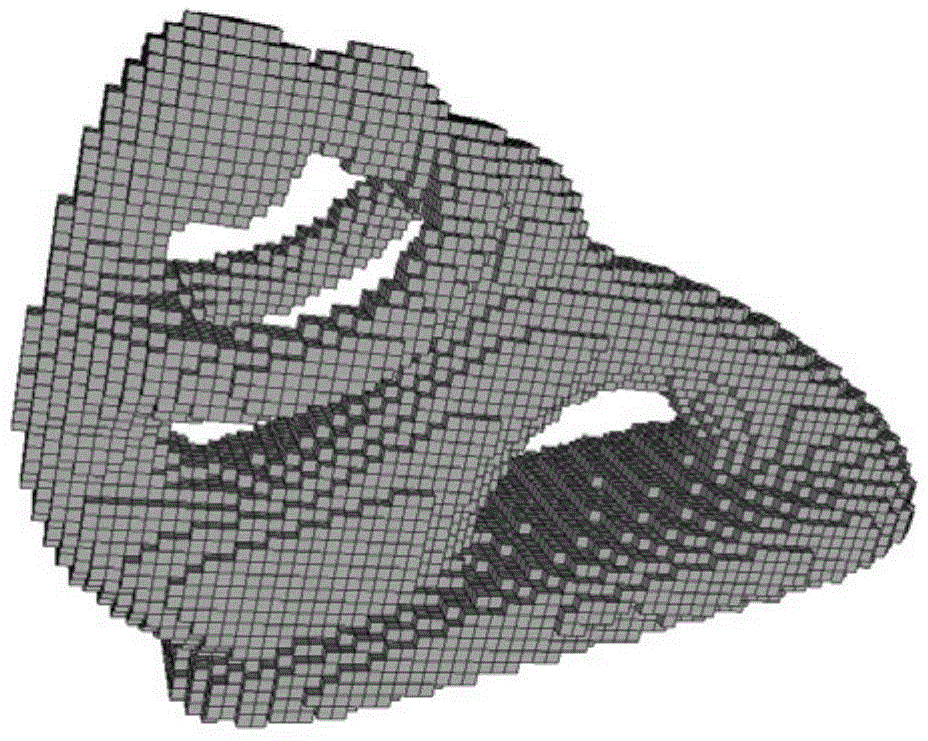

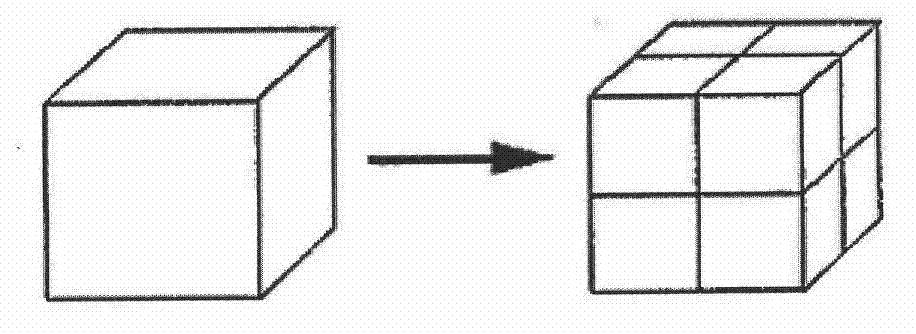

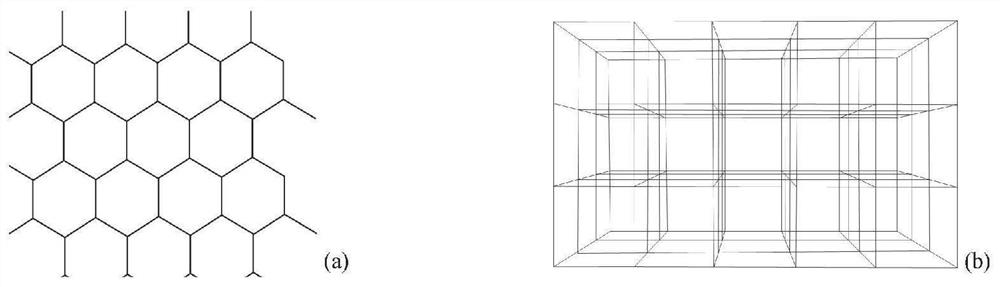

Iteration generation method of hexahedral mesh model

InactiveCN103824331AQuality assuranceImprove mesh quality3D modellingDiffusionComputer graphics (images)

The invention discloses an iteration generation method of a hexahedral mesh model. The iteration generation method comprises the following steps: step one, inputting a triangular mesh model, constructing an initial hexahedral mesh model according to the triangular mesh model, and extracting a surface quadrilateral mesh from the initial hexahedral mesh model; step 2, carrying out iterative fitting of the surface quadrilateral mesh of the initial hexahedral mesh model on the triangular mesh model and carrying out mobile diffusion on mesh peaks of the surface quadrilateral mesh so as to obtain an intermediate hexahedral mesh model that is divided into multiple layers of quadrilateral meshes; and step three, inserting a layer of quadrilateral mesh between the surface quadrilateral mesh of the intermediate hexahedral mesh model and the internal first-layer quadrilateral mesh and optimizing all layers of the quadrilateral meshes except the surface quadrilateral mesh so as to obtain a final hexahedral mesh model. According to the invention, with the method, a hexahedral mesh with the guaranteed quality can be obtained; and the automation degree is improved.

Owner:ZHEJIANG UNIV

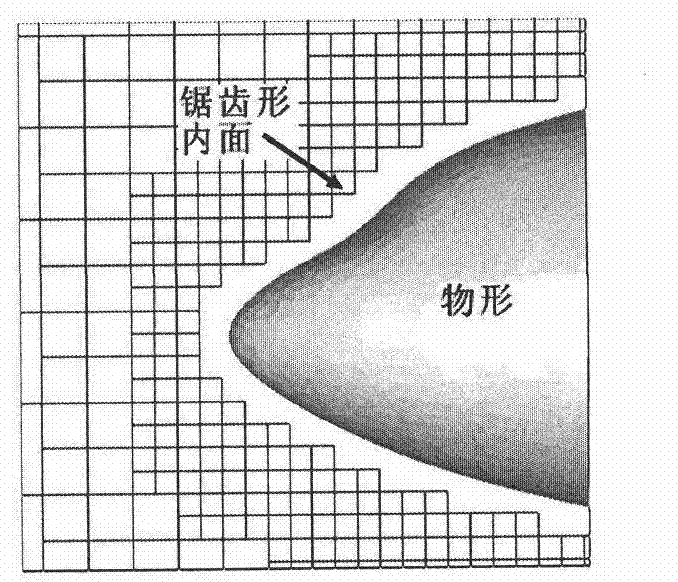

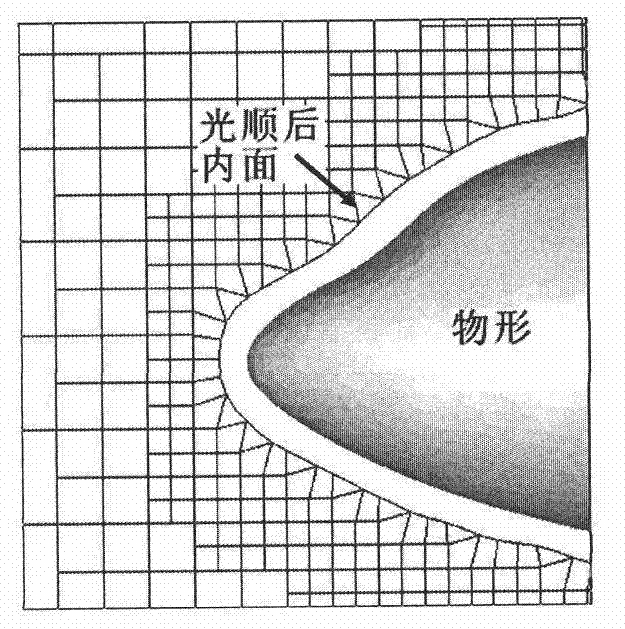

Method for correcting intersecting line of unstructured Cartesian grid

The invention discloses a method for correcting an intersecting line of an unstructured Cartesian grid. The method comprises the following steps of: describing the shape of an object to generate a background grid; setting grid generation parameters; generating an n-ary tree structure according to the background grid and the set parameters; deleting units within the shape of the object and units intersected with the shape of the object to generate a saw-toothed inner surface; fairing the saw-toothed inner surface to obtain a faired inner surface; performing intersecting line correction and projection on the faired inner surface; and calculating a grid flux, and outputting grid information. The problem of object surface distortion possibly caused by the steps of fairing, projection and the like when the grid is generated in computational fluid mechanics is solved, and a finally generated computational grid object surface can be ensured to be approximate to an original object shape in an intersecting line inverse projection and correction way.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

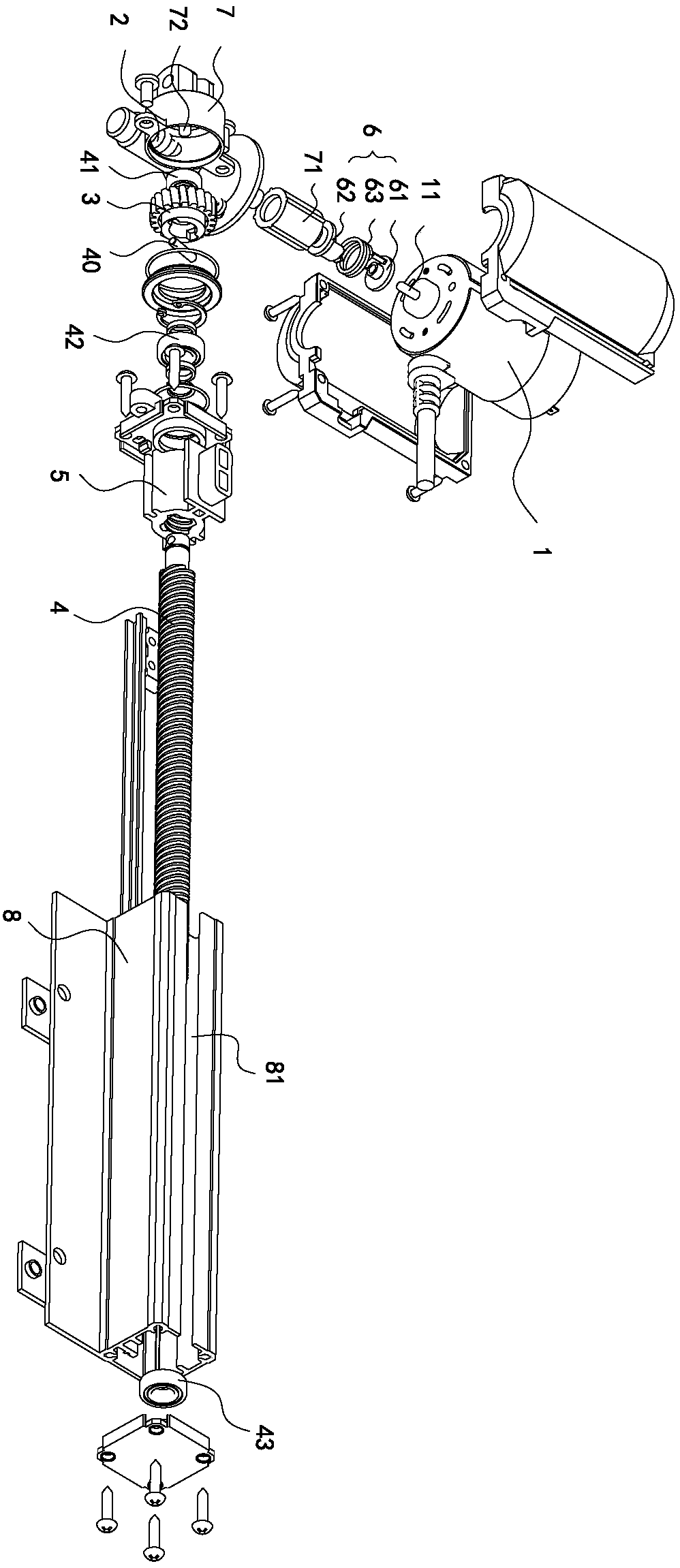

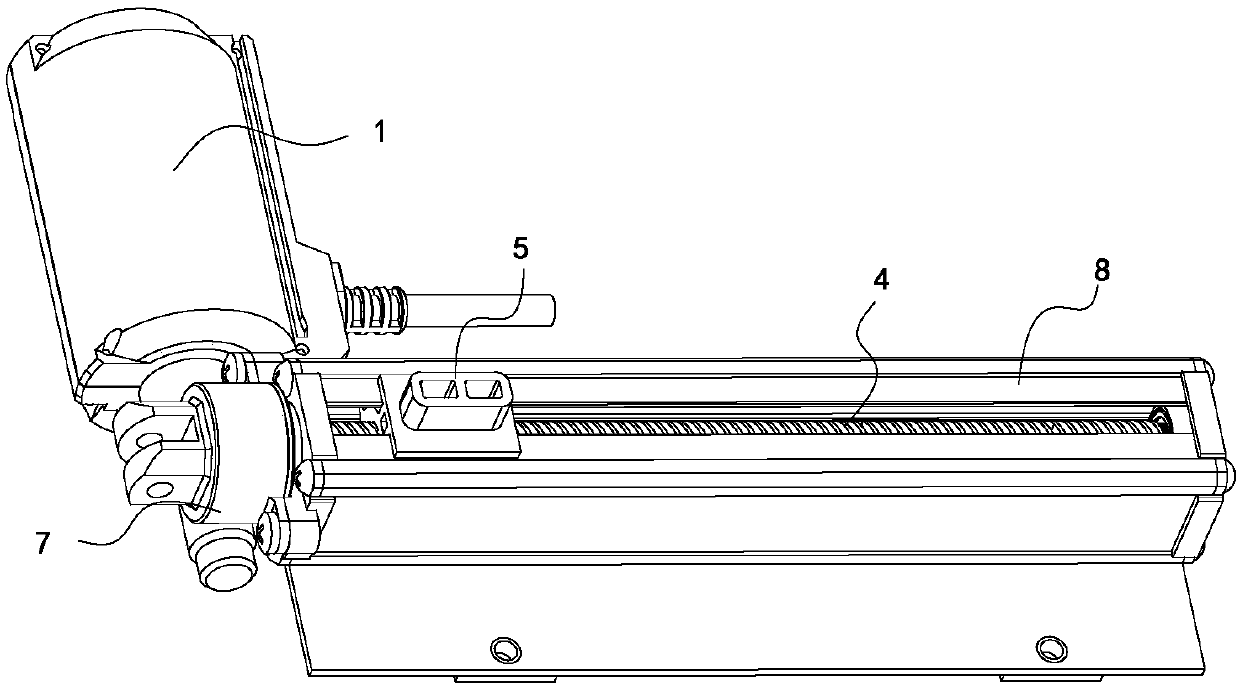

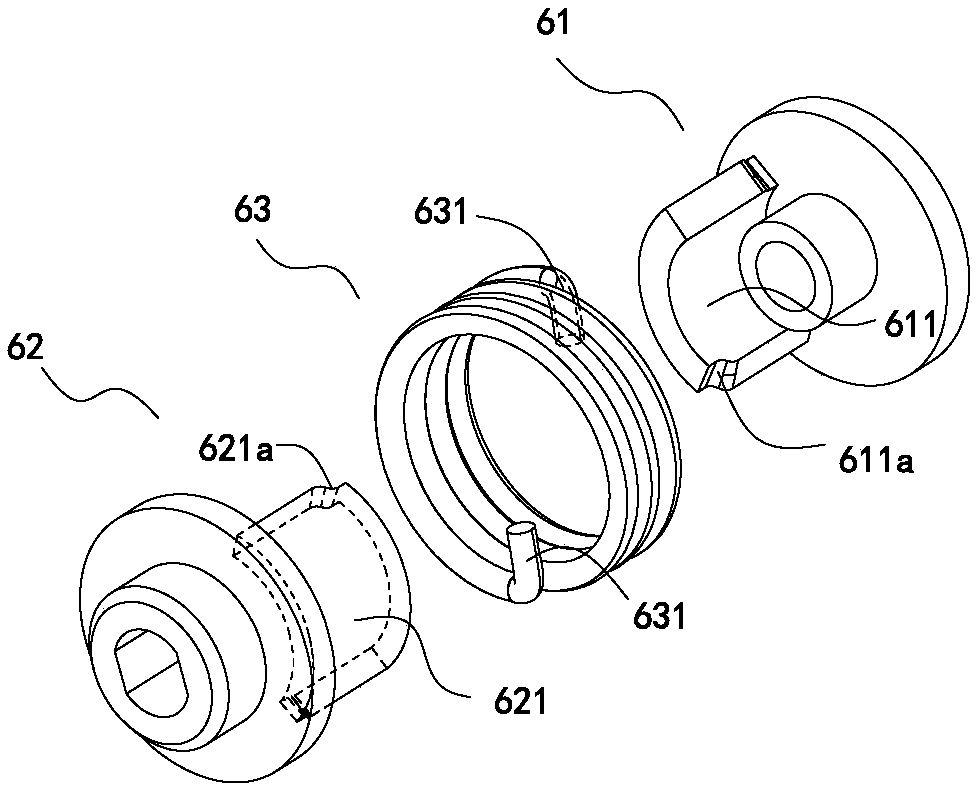

Electric push rod

PendingCN107676445ADoes not affect meshing qualityImprove mesh qualityGearingMechanical energy handlingGear driveDrive motor

The invention discloses an electric push rod, and belongs to the technical field of linear transmission. The electric push rod comprises a motor, a transmission worm, a transmission worm gear, a screwrod and a transmission nut, wherein the motor drives the transmission worm to rotate; the transmission worm gear drives the screw rod to rotate; engagement transmission is formed between the transmission worm and the transmission worm gear; the motor comprises an output shaft; the output shaft and the transmission worm are arranged in a splitting manner; and the output shaft and the transmissionworm are in transmission connection through a backstop. The electric push rod disclosed by the invention has the following advantages: vibration and transmission noise at the transmission worm are reduced; and meanwhile, the self-locking capacity of the electric push rod during reverse movement is also improved.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

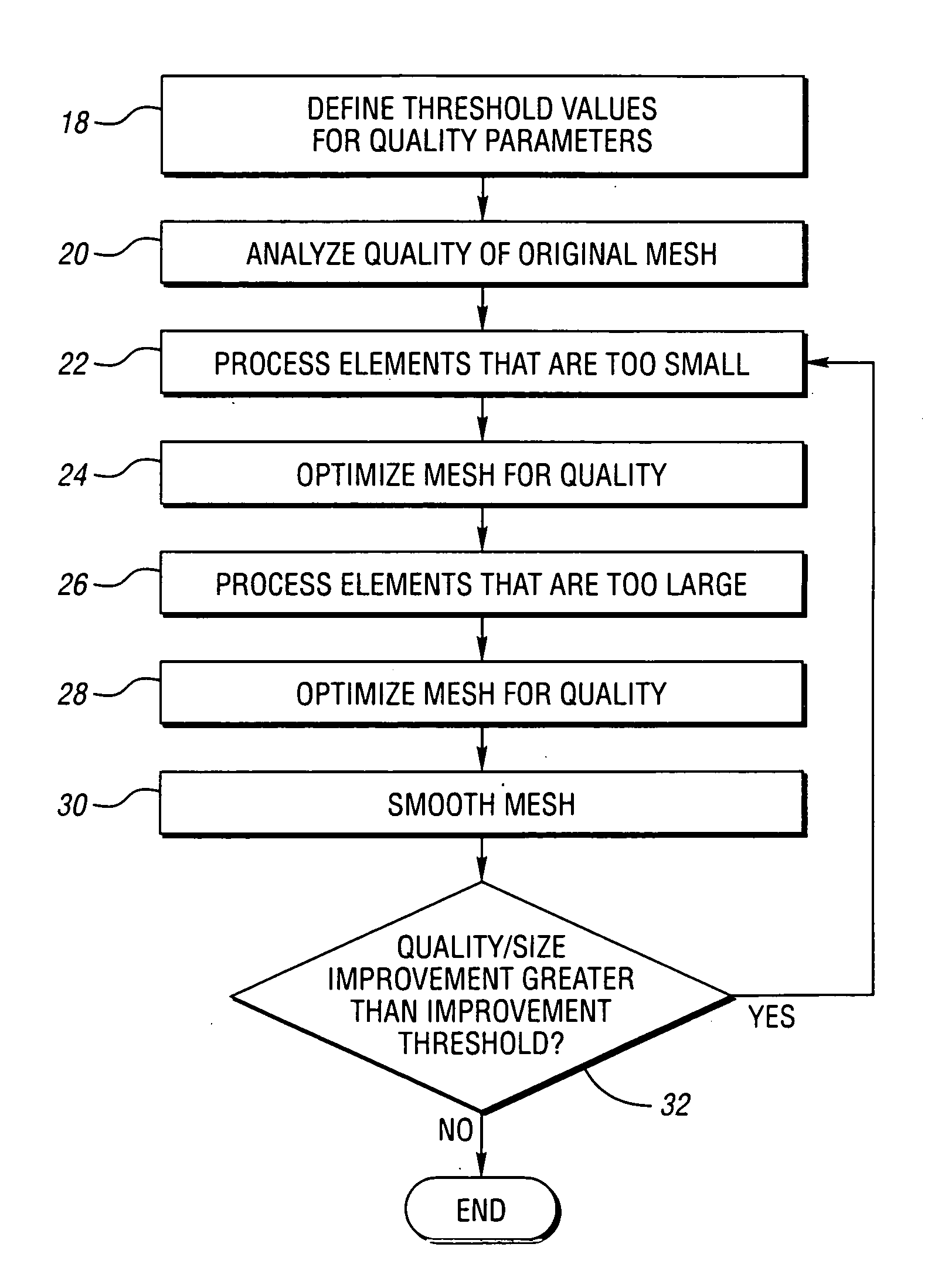

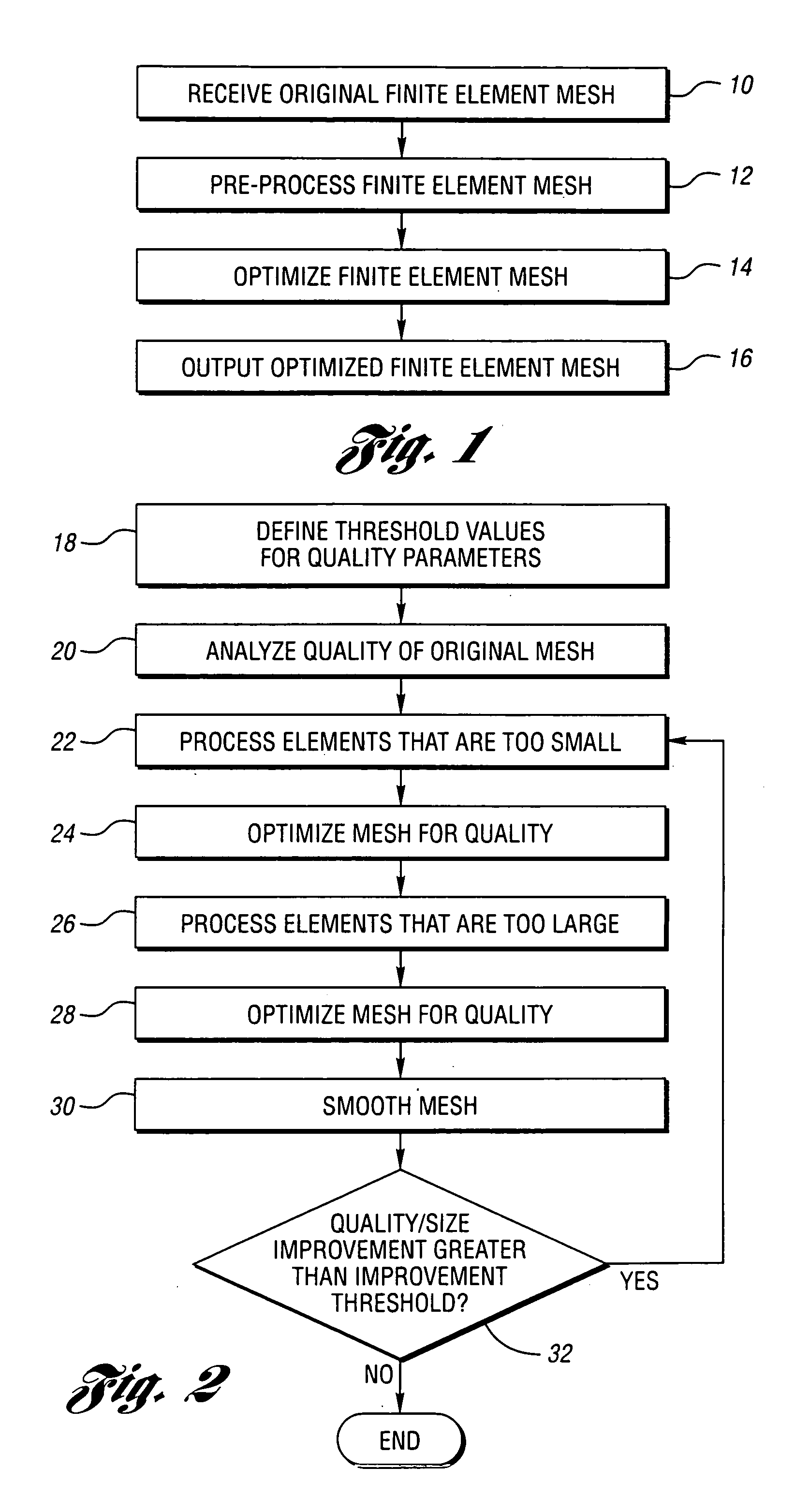

Method and system for optimizing a finite element mesh

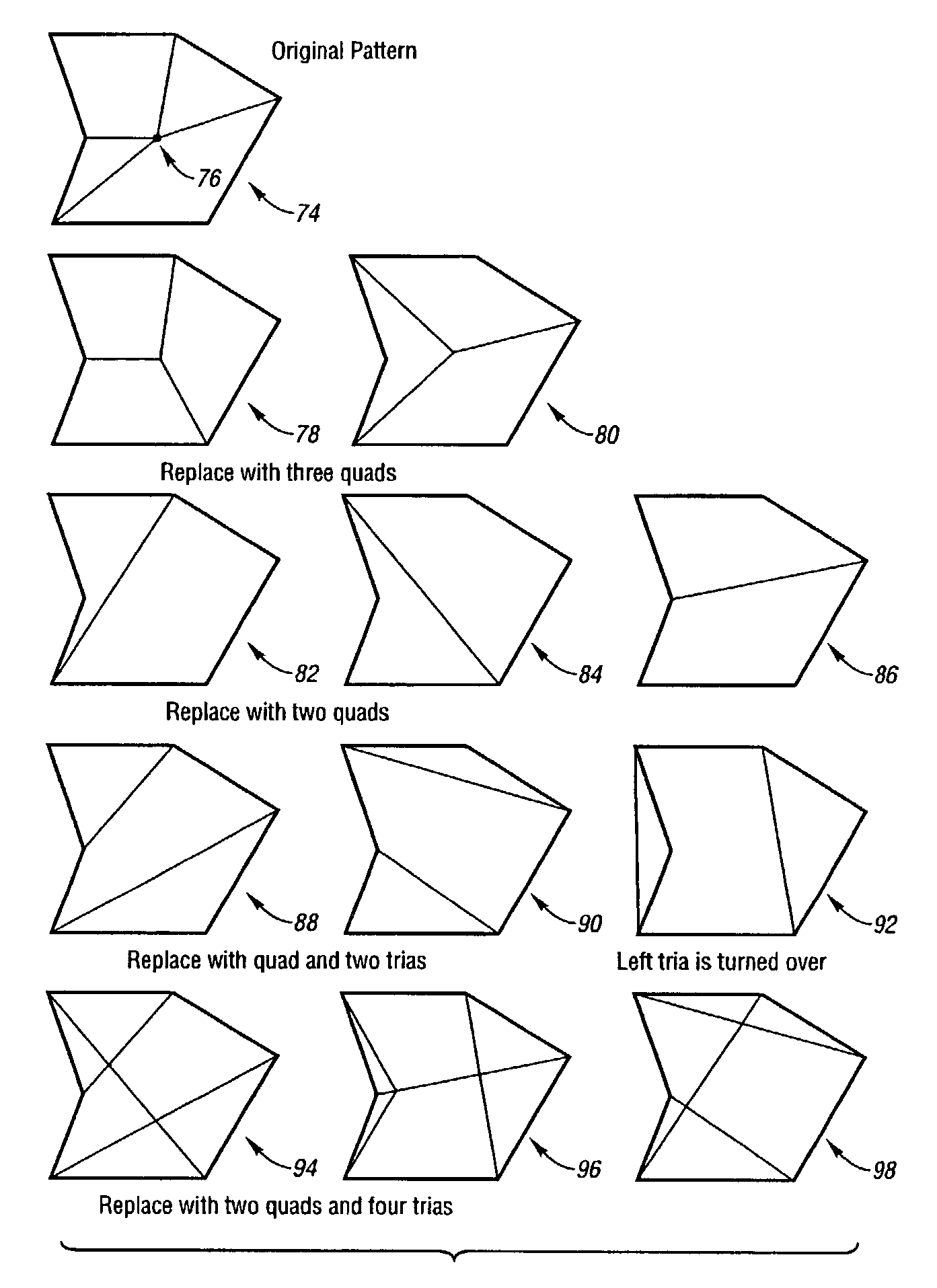

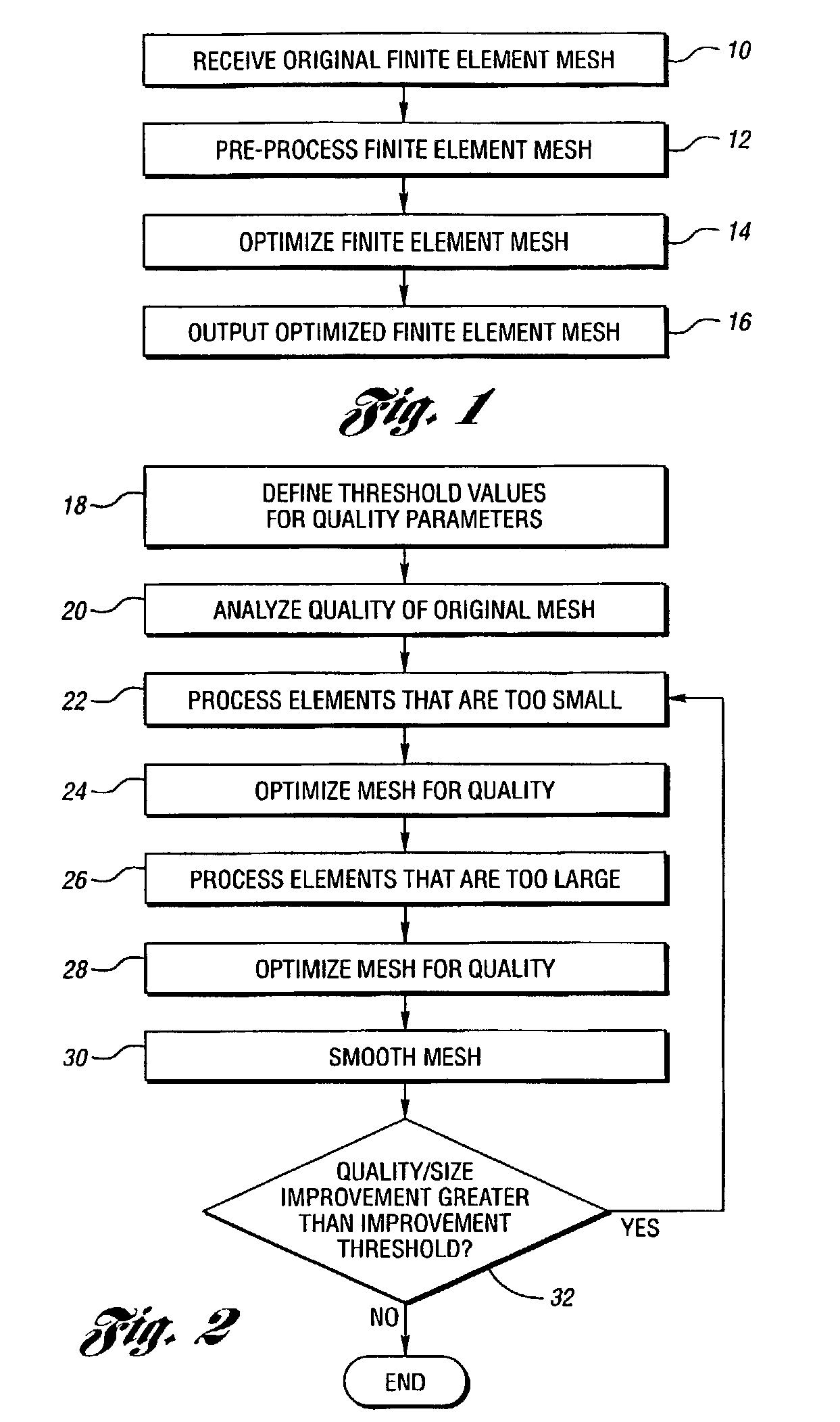

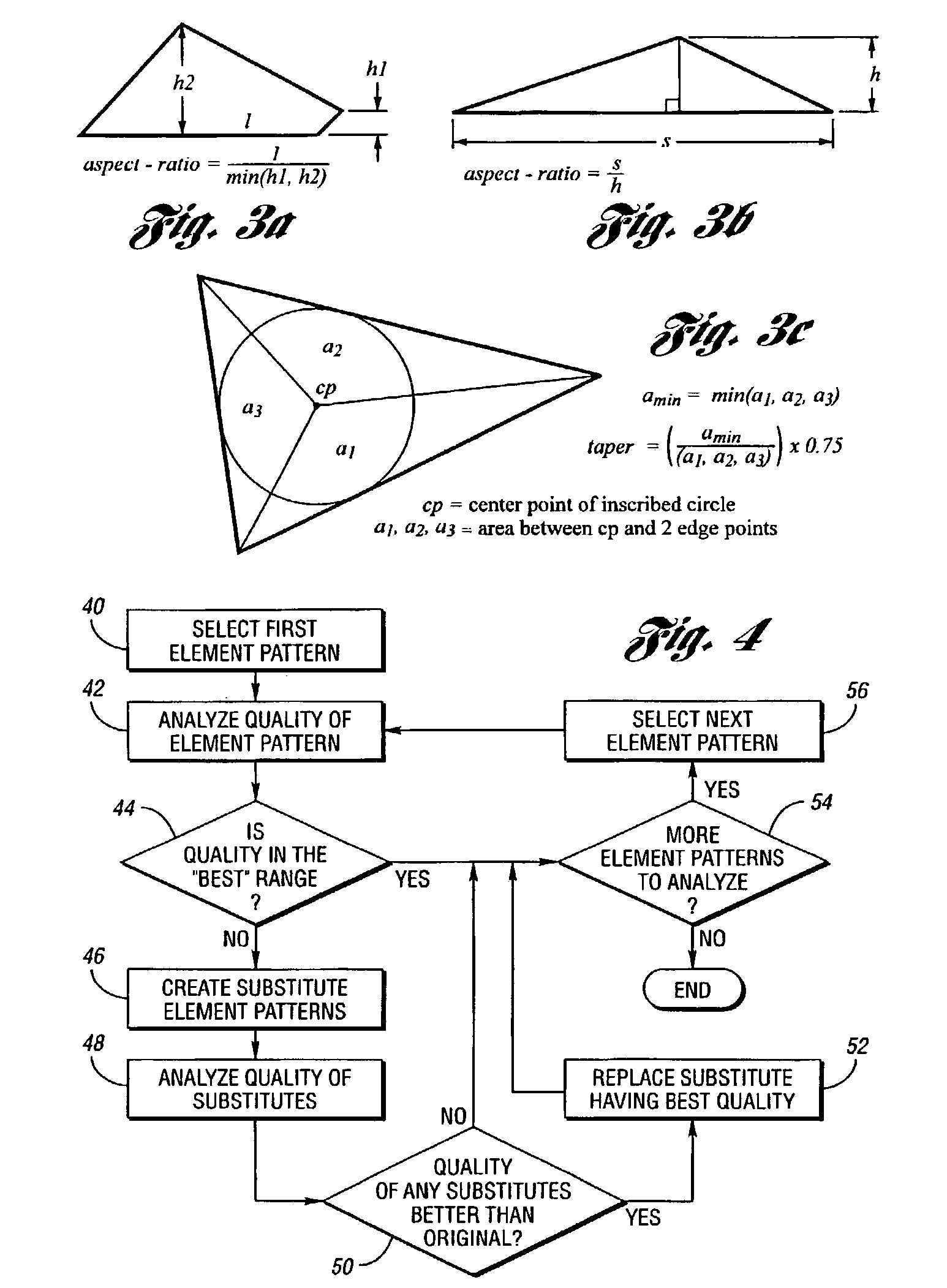

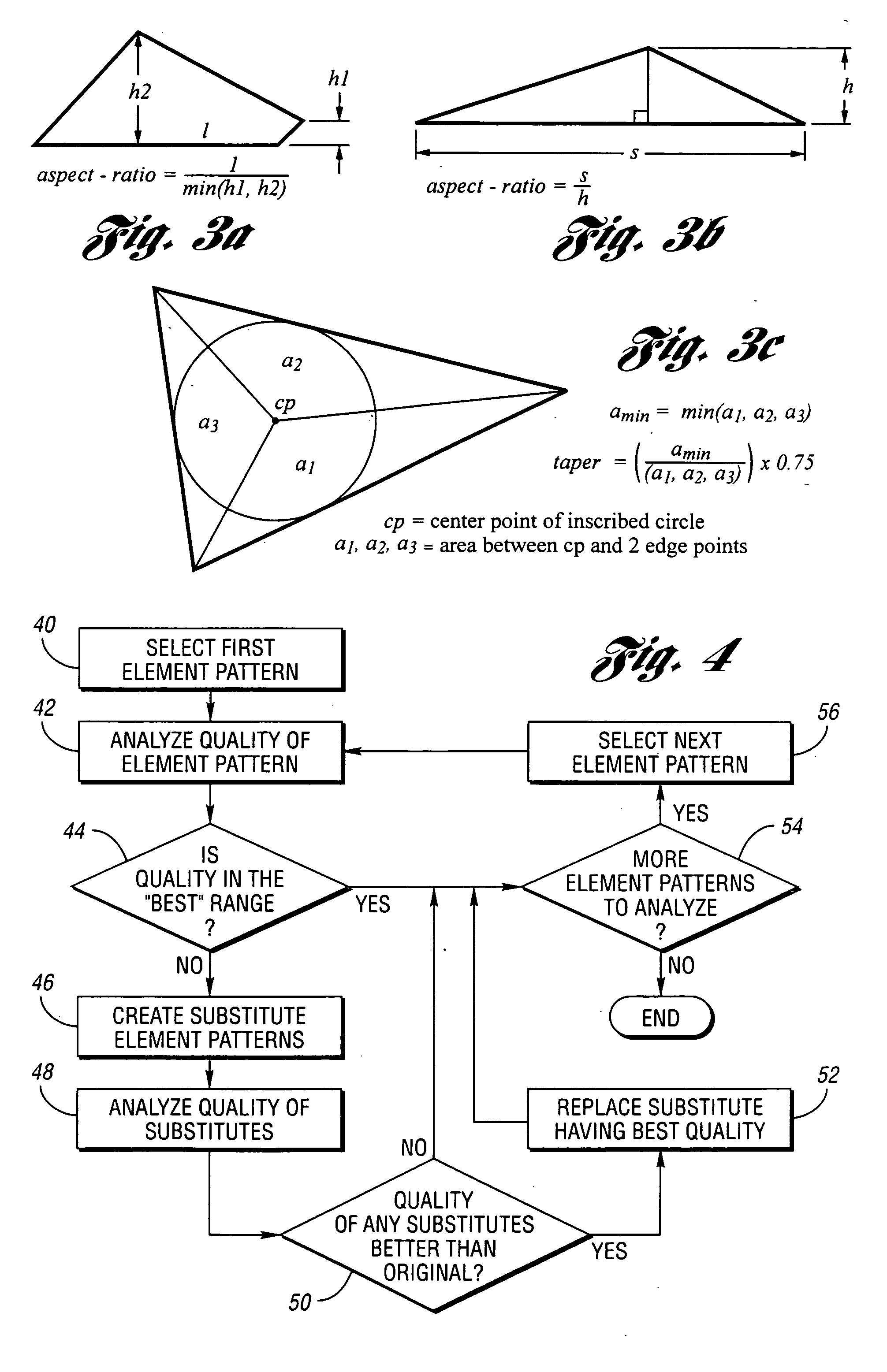

InactiveUS6970165B2Quality improvementHigh overall substitute element quality3D-image rendering3D modellingAlgorithmMesh grid

Computer-implemented method and system for optimizing a finite element mesh. Computing devices are configured to calculate a quality score for at least one original element in a finite element mesh based upon two or more quality attributes simultaneously. A quality score for at least one substitute element for the original element is calculated based upon the two or more quality attributes. If one or more substitute element(s) have a quality score that is better than the quality score of the original element(s), the original element(s) is / are replaced with the substitute element(s) having the best quality score. A quality score may be calculated for each of a plurality of combinations of one or more substitute elements. Input may be provided specifying at least one quality threshold value for comparing the two or more element quality parameters (skew, warp, aspect ratio, etc.).

Owner:FORD MOTOR CO

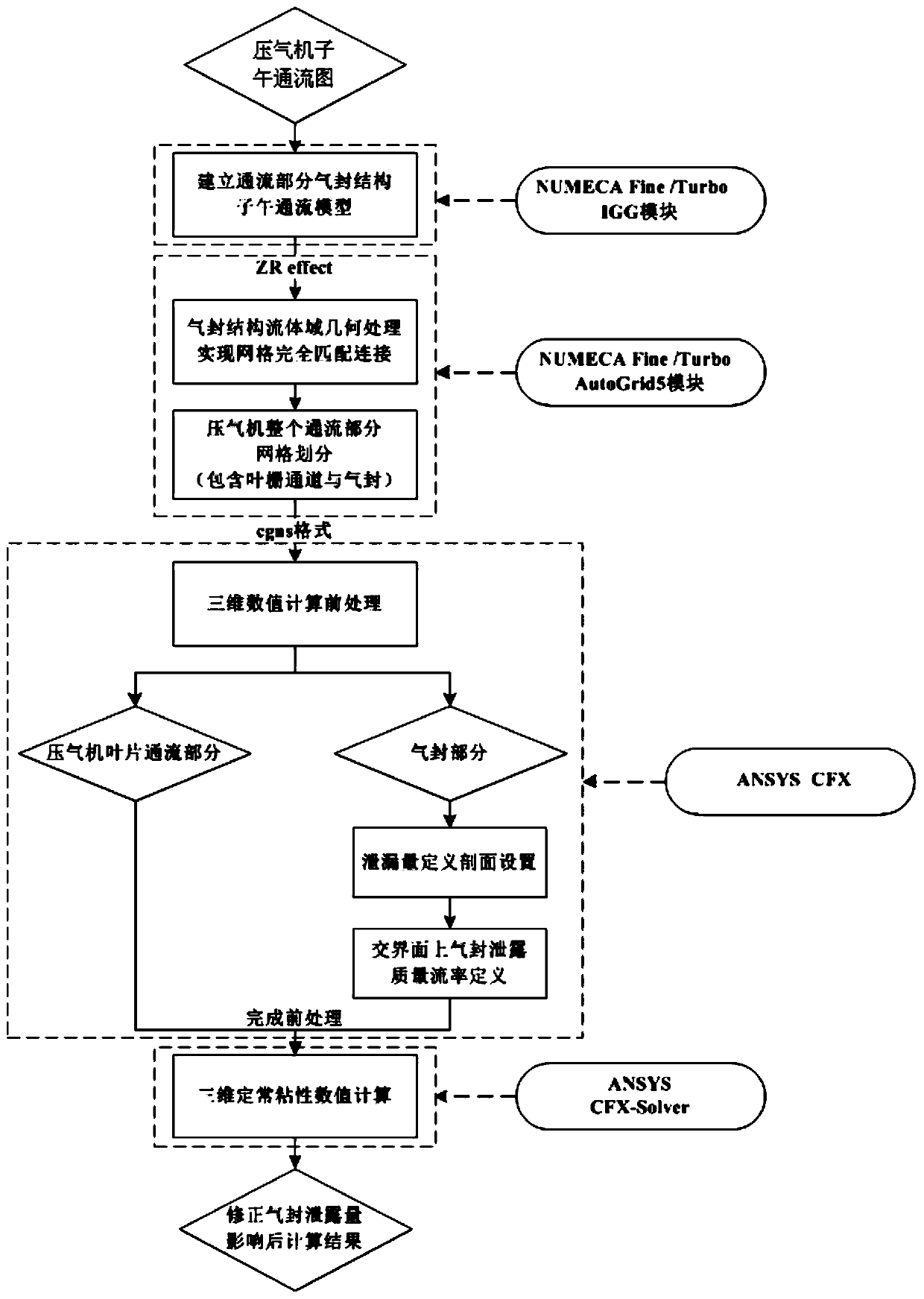

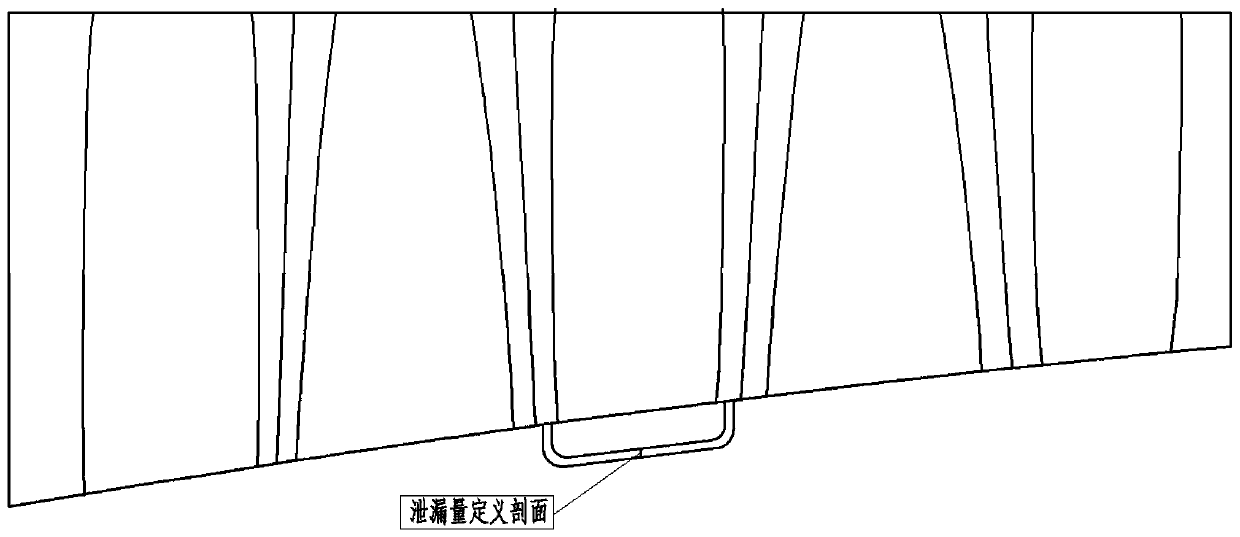

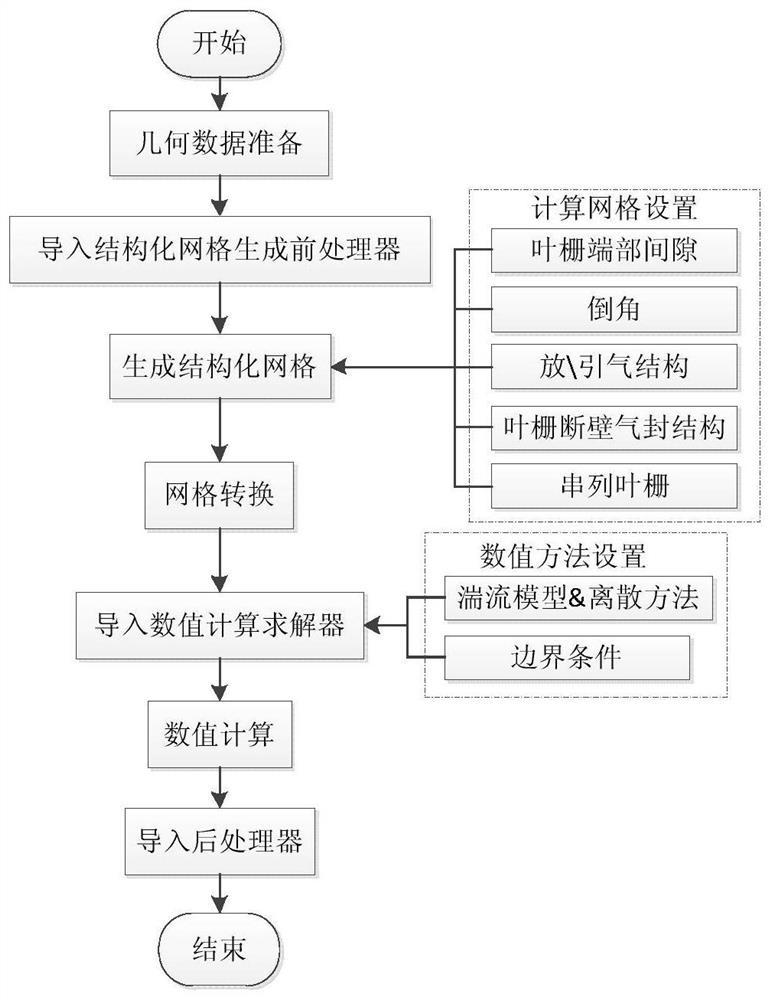

Compressor characteristic prediction method based on modified gas seal leakage amount influence numerical model

ActiveCN110083968ASimple structureImprove mesh qualityGeometric CADGas-turbine engine testingNumerical modelsImpeller

The invention provides a compressor characteristic prediction method based on a modified air seal leakage amount influence numerical model, and belongs to the technical field of compressor pneumatic design and computational analysis. The objective of the invention is to solve the problem of compressor performance prediction result deviation caused by gas leakage of a through-flow part gas seal structure in a characteristic prediction process of a compressor. The method comprises the following steps: firstly, simplifying a through-flow part air seal structure, establishing a meridian through-flow model of the air seal structure, and completing grid dispersion of a whole compressor through-flow part fluid domain; adding a correction numerical model of the gas seal leakage rate to a corresponding position of a through-flow part of the gas compressor during calculation pretreatment, and completing specific numerical definition of the gas seal structure leakage rate on an interface; and carrying out three-dimensional steady viscosity numerical solution on the whole through-flow part fluid domain of the gas compressor to obtain a gas compressor performance prediction result after the through-flow gas seal leakage amount is corrected. The method is suitable for the performance prediction process of similar impeller machinery such as an industrial compressor with an air seal structure.

Owner:中国船舶重工集团公司第七0三研究所

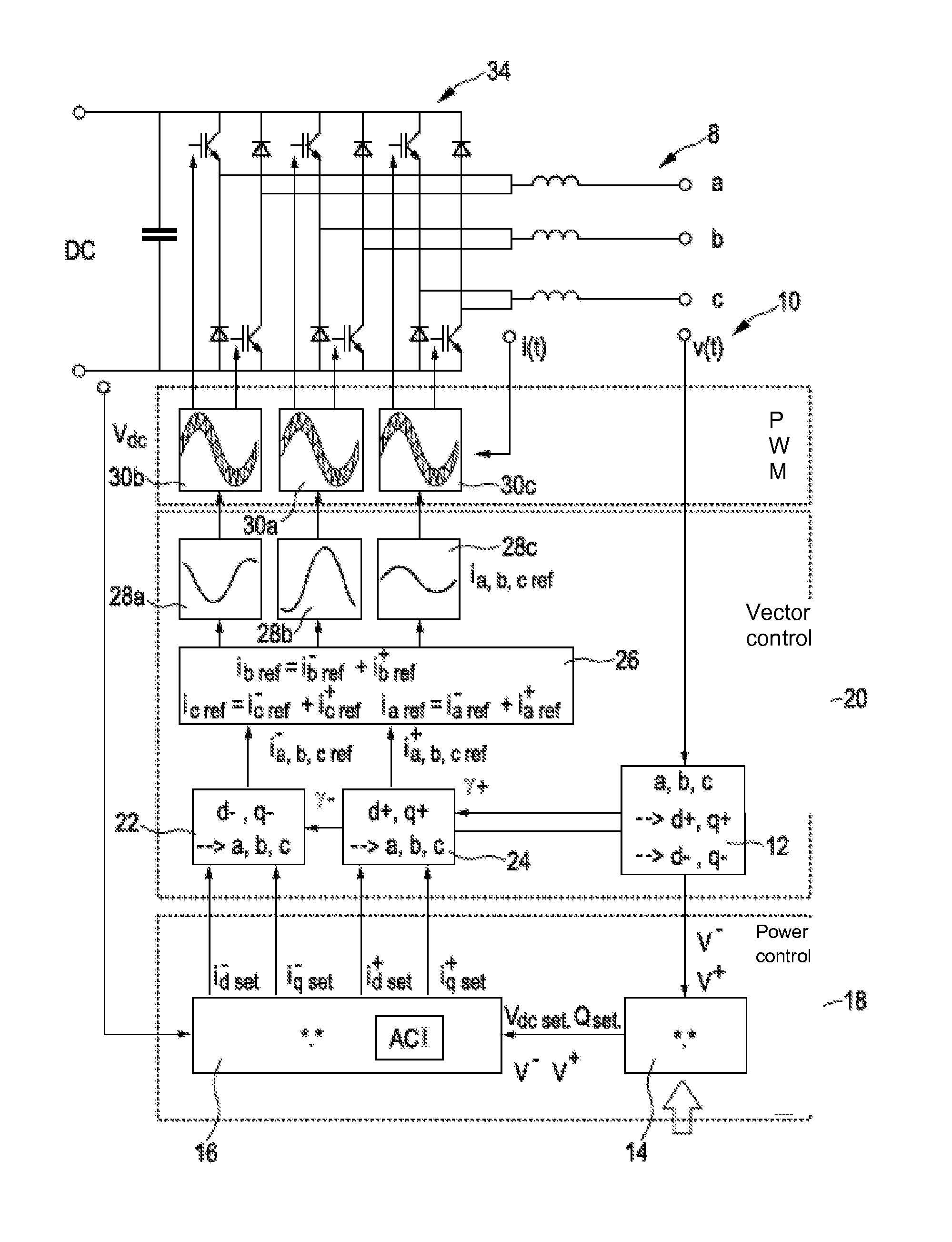

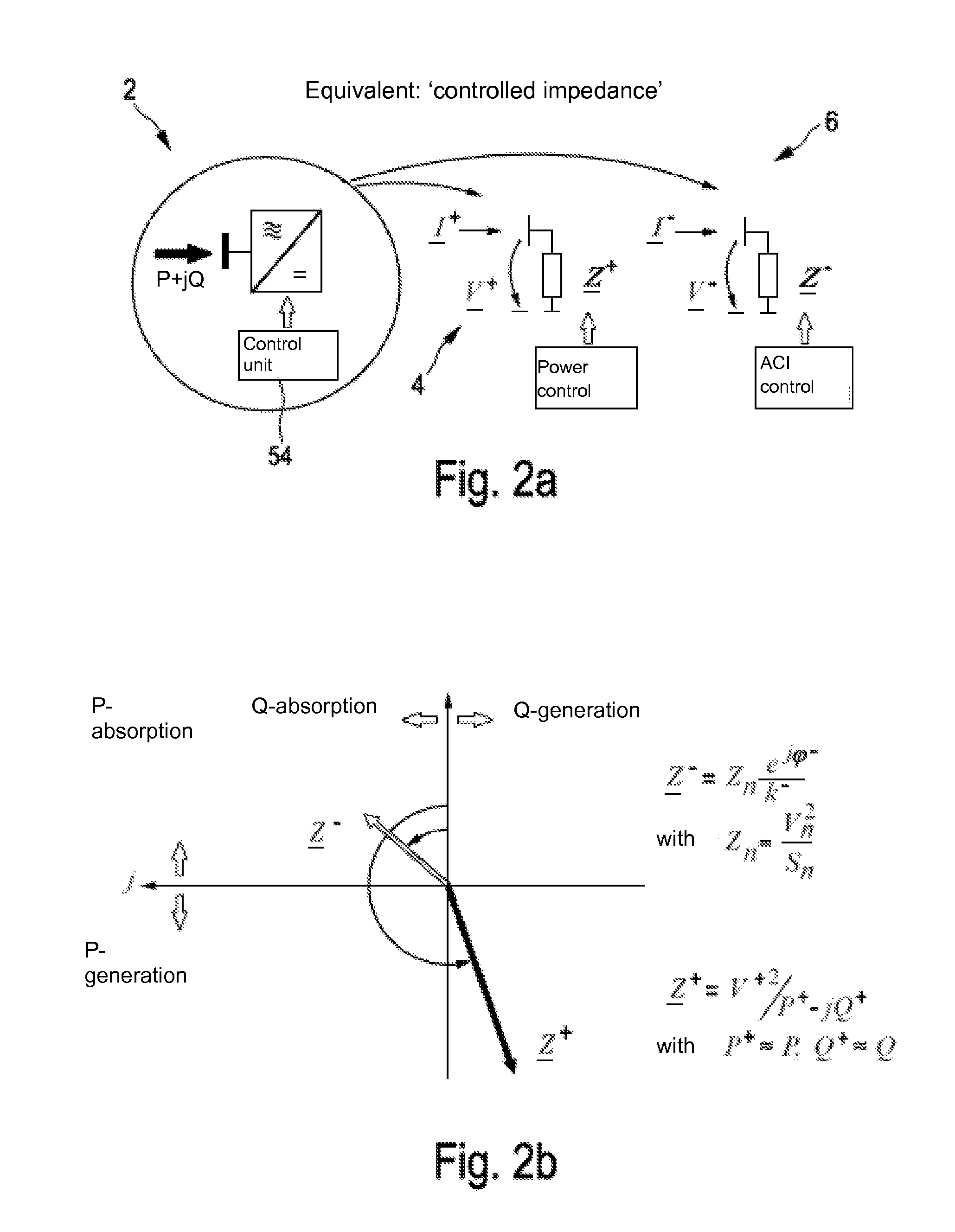

Wind power installation and method for injecting electrical energy

ActiveUS20150300320A1Improve mesh qualityWind motor controlSingle network parallel feeding arrangementsPower gridGrid connection

The present invention relates to a method for injecting electrical energy into an electrical, three-phase grid, comprising the steps of: injecting current by means of an injection unit at a grid connection point, detecting an asymmetry in the grid, in particular a negative sequence component in the grid, injecting an asymmetrical current portion into the grid for, at least, partial compensation of the detected asymmetry, with injection of the asymmetrical current portion taking place such that the injection unit behaves like a consumer.

Owner:WOBBEN PROPERTIES GMBH

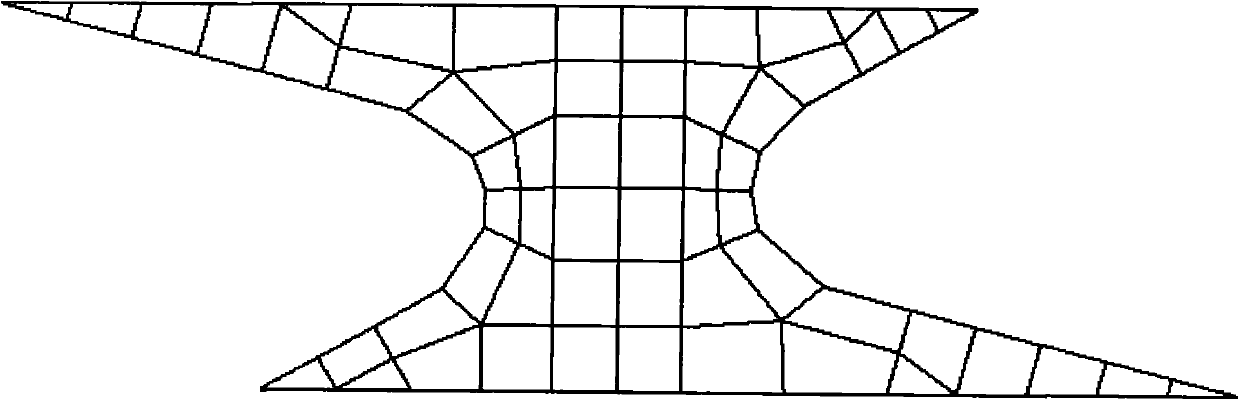

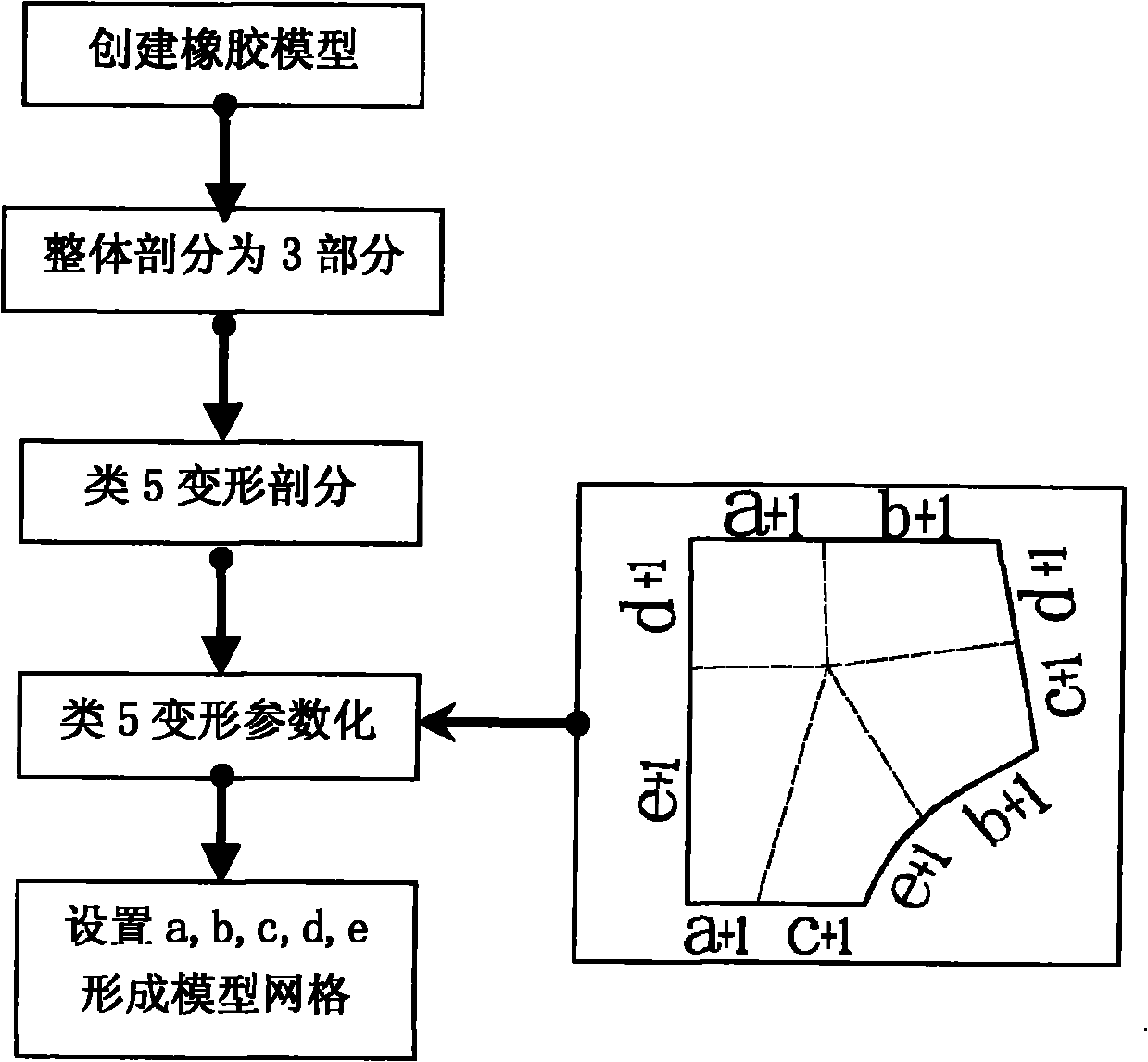

Method for forming annular deformation parameterized rubber grid suitable for large deformation

InactiveCN101887476AImprove mesh qualityAccurate stress resultsSpecial data processing applicationsDistortionGrid density

The invention discloses a method for forming an annular deformation parameterized rubber grid suitable for large deformation. The method comprises the following steps of: sectioning an entire model into a left region, a middle region and a right region; sectioning the left region and the right region which produce large deformation easily and have serious grid distortion into four pentagon-like regions in all; performing parameterized grid setting at each local pentagon-like region; and making the number of grids on each side meet the following requirements: a, b, c, d and e are greater than 0 and e+b is more than or equal to a+2c+d / 2, wherein the grid layout and the grid state after the forming of the grid, which meet the requirements of the formula, form the annular pentagon-like deformation rubber grid with different grid densities and the same grid layout through parameterized adjustment of the number of the grids according to the requirements on the size of the model and the analysis quality.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Double-arc harmonic wave robot joint

InactiveCN102615653AImprove mesh qualityImprove carrying capacityJointsLow noiseManufacturing technology

The invention discloses a double-arc harmonic wave robot joint, and relates to the technical field of manufacturing of robots, in particular to the technical field of designing of robot joints. The inside of a joint shell is connected with a rigid double-arc gear; a flexible double-arc cup-shaped gear is engaged in the rigid double-arc gear; the inside of the flexible double-arc cup-shaped gear is connected with a wave generator through a flexible bearing and a double-arc harmonic wave speed reducer; a control end of the wave generator of the double-arc harmonic wave speed reducer is connected with a rotor of a synchronous alternating current servo motor; the center of the flexible double-arc cup-shaped gear is connected with an output bar; and the output bar is inserted into a through hole of the joint shell in a clearance mode. By the double-arc harmonic wave robot joint, the stress condition and the transmission engagement quality of a double-arc cup-shaped gear tooth root can be improved, and the bearing capacity and the torsion rigidity of the robot joint can be improved. The double-arc harmonic wave robot joint has the characteristics of stably and accurately moving, along with low noise and low heat radiation in the movement process.

Owner:YANGZHOU HARMONIC DRIVE TECH

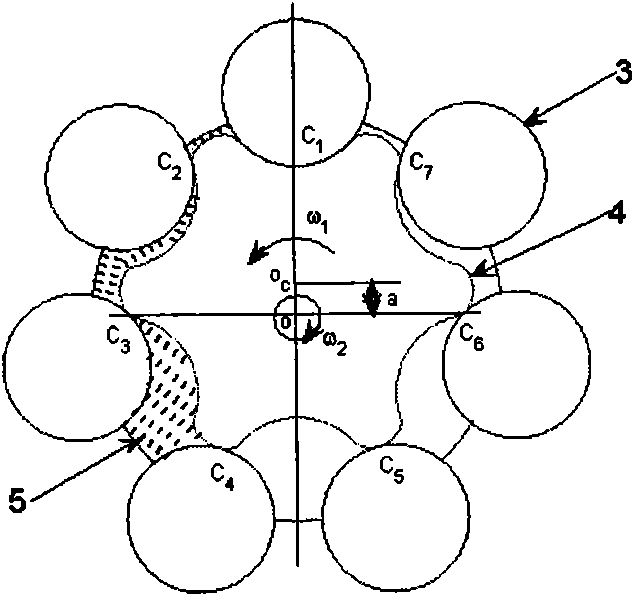

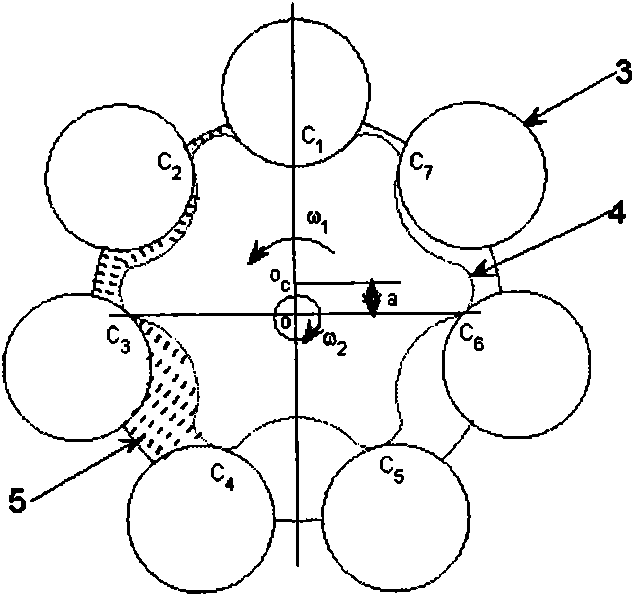

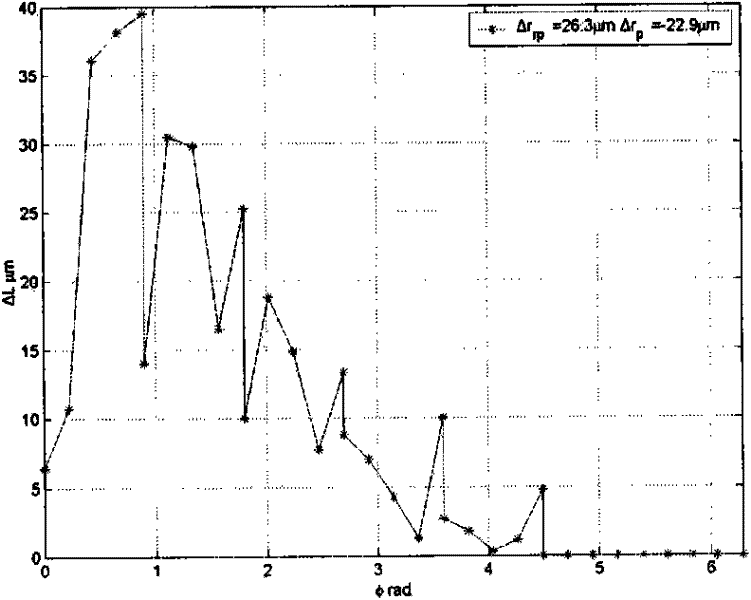

Cycloidal engagement pair with uniform-gap engagement of full hydraulic steering gear and processing method thereof

ActiveCN101709729AAchieve even clearance meshingSmall amount of modificationHydraulic steering gearsFluid-pressure actuatorsGear grindingEngineering

The invention relates to a cycloidal engagement pair with uniform-gap engagement in a full hydraulic steering gear and a processing method thereof, and belongs to the technical field of hydraulic transmission. The cycloidal engagement pair is formed by the matching of a cylindrical pin wheel and a cycloidal gear which form a tie bar-free planetary gear train; the profile of the cycloidal gear is a closed curve determined by a specific curve equation; and when the modification and the generating gear grinding are performed, the radius of a grinding wheel is dressed to be equal to the sum of the radius of the pin wheel and the uniform-gap engagement modification amount to ensure that the central distance between the grinding wheel and a mandrel of a spline is equal to the radius of a pitch circle of the pin wheel. The adoption of the technical scheme of the invention shows that the rotation of a rotor is more flexible. At the same time, the sealing performance is improved, so the effect of attaining two objectives by a single move is achieved. Therefore, the cycloidal engagement pair contributes to solving the problems of inflexible rotation and locking of cycloidal gears of cycloidal pairs of full hydraulic steering gears, and can ensure that the engagement quality is improved and the steering gears work more steadily and longer service life. During the production, only one technological parameter needs to be adjusted, and no equipment is added, so the cycloidal engagement pair is practical and feasible.

Owner:ZHENJIANG HYDRAULICS

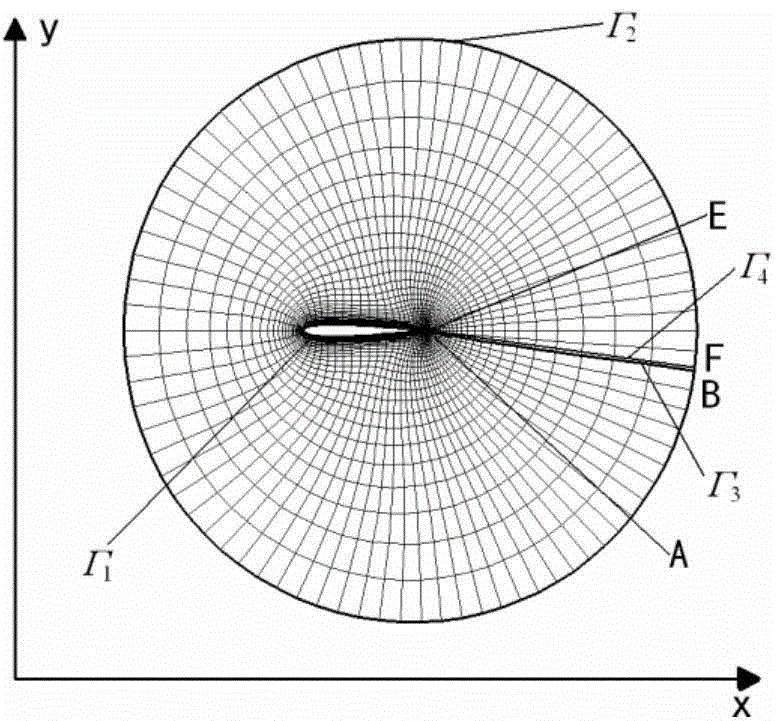

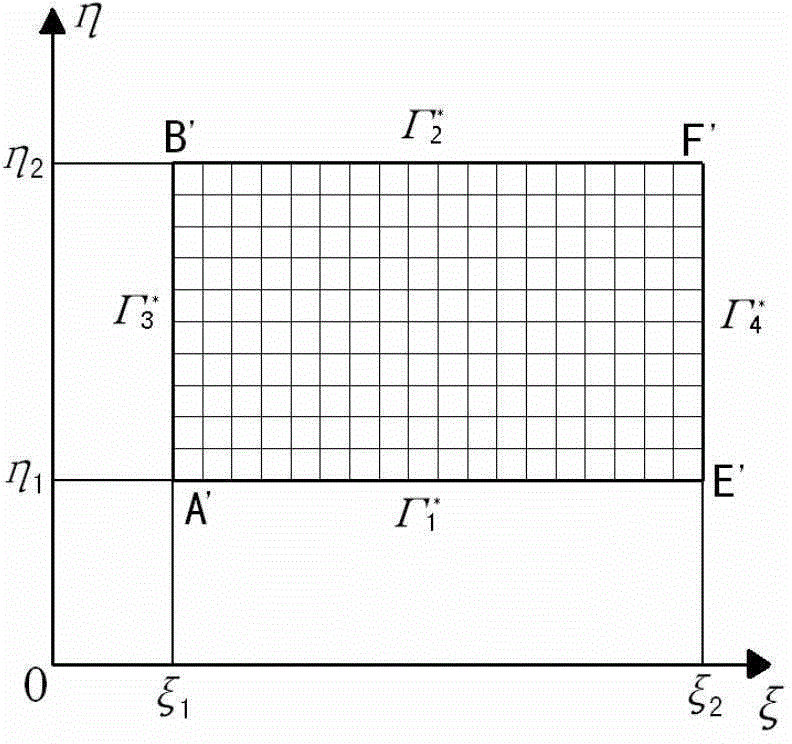

Grid structure generation method for fixation of outer boundary

InactiveCN105843977AGuaranteed mesh qualityImprove mesh qualitySpecial data processing applicationsForced oscillationSix degrees of freedom

The invention belongs to the technical field of CFD grid generation, in particular to a grid structure generation method used for forced oscillation and six-degree-of-freedom freely-flying CFD calculations.The method comprises following steps: (1) generating an initial grid and dividing the initial grid into two sections including an inner boundary and an outer boundary; (2) solving a source item of the initial grid; (3) rotating the inner-boundary grid, designating a rotary axis and a rotation angle in order to obtain the internal grid in the new state; and (4) solving a grid for the smooth outer boundary of an elliptical equation.The grid structure generation method for fixation of the outer boundary has following beneficial effects: the grid generated by the invention keeps the outer boundary stationary and ensures features such as orthogonality and normal height of the grid at the wall surface; the outer-boundary grid demonstrates smooth quality by solving the elliptical equation; and the grid quality can be ensured after large-angle rotation.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

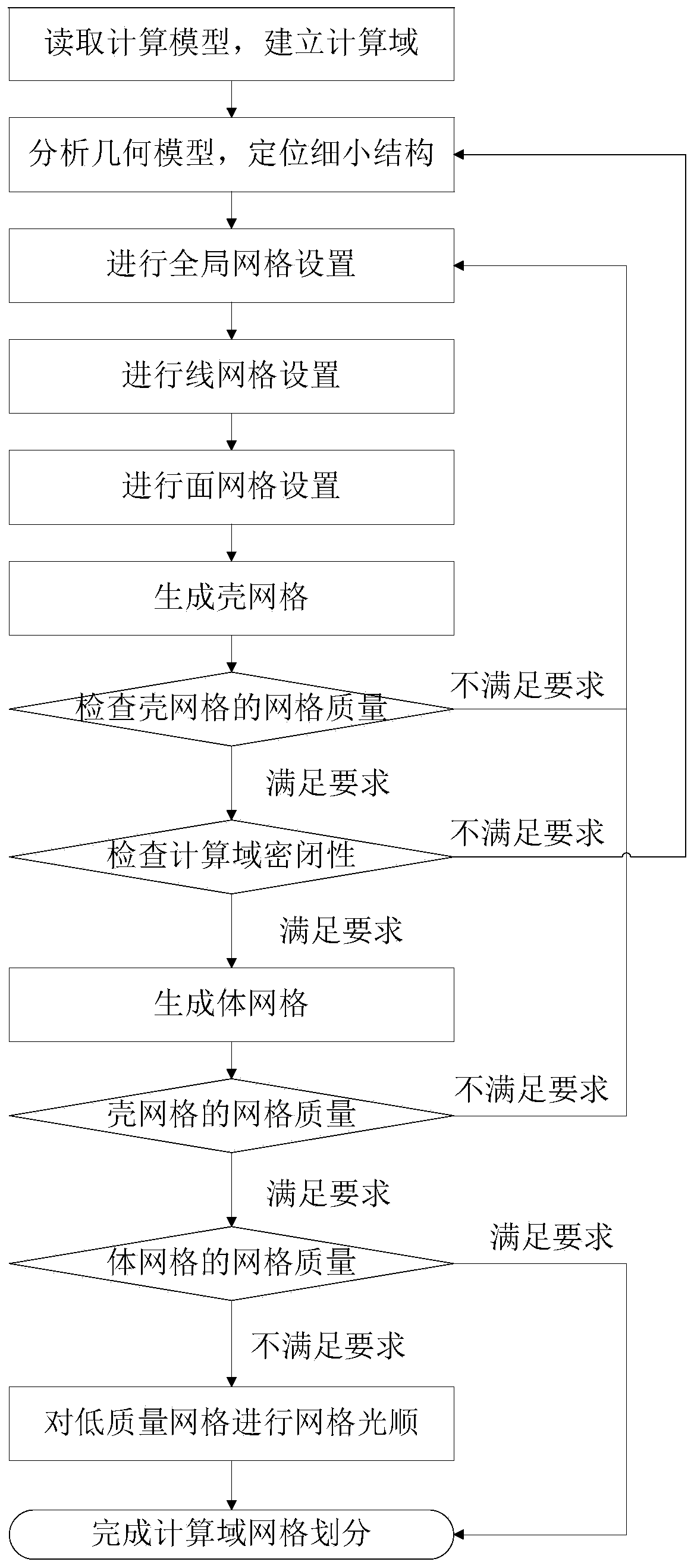

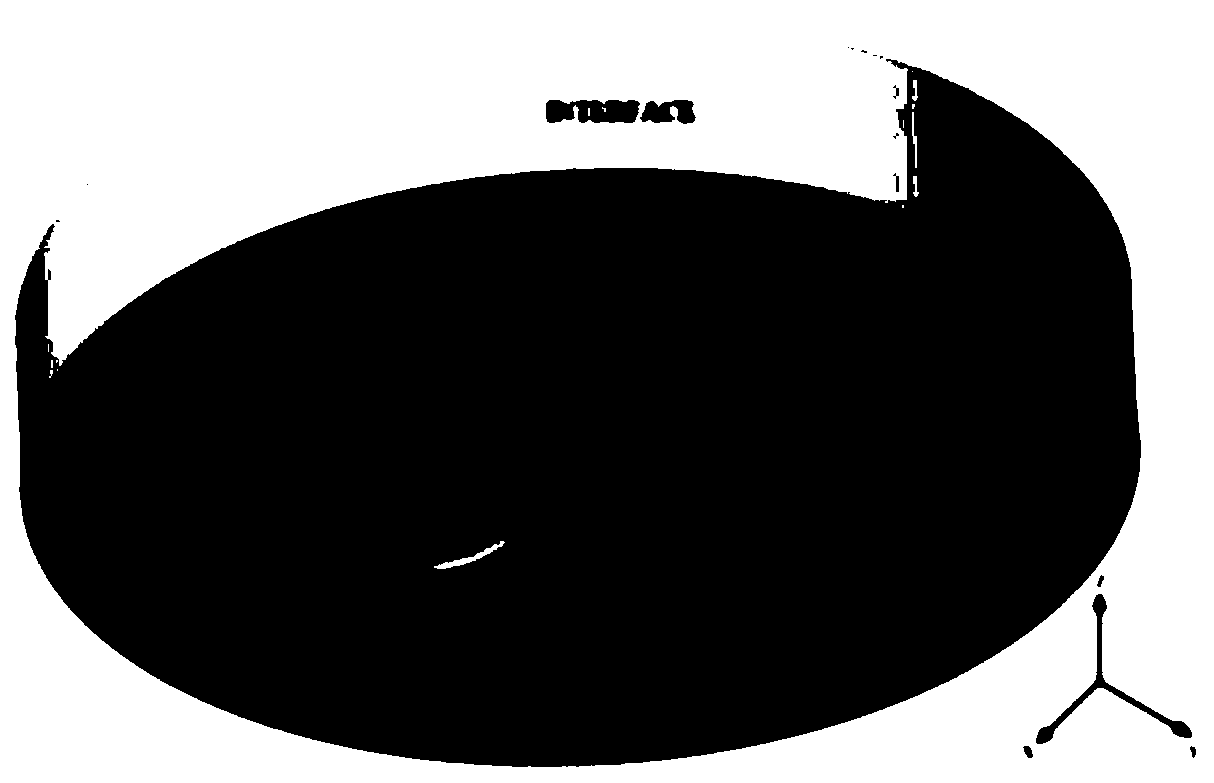

Dimension increasing type computing fluid grid generation method based on line and plane body

ActiveCN110188395AImprove mesh qualityImprove timelinessGeometric CADDesign optimisation/simulationComputer resourcesFine structure

The invention discloses a dimension increasing type computing fluid grid generation method based on a line and plane body, which comprises the following steps: firstly, carrying out geometrical characteristic analysis on a calculation domain and a model, obtaining a fine structure needing refining processing, and sequentially setting grid parameters according to a dimension increasing sequence ofthe line, the plane and the body under the condition of finishing global grid setting. After the generation of the shell grid is completed, the grid quality of the shell grid is checked for the firsttime, if the grid quality does not meet the preset requirement, lines and the shell grid are reset and drawn, and if the grid quality meets the requirement, volume grid division is carried out. According to the method disclosed by the invention, under the condition that the number of grids is not greatly increased, the grid quality at local details of the geometry can be improved, so that computerresources can be saved, and the timeliness of CFD simulation is improved.

Owner:GUANGDONG OCEAN UNIVERSITY

Harmonic gear power transmission with double circular arc tooth outline

InactiveCN101135357BImprove carrying capacityIncreased torsional stiffnessToothed gearingsStress conditionsGear wheel

The harmonic wave gear driver with two-arc teeth profile comprises wave generator, flexible wheel and rigid wheel. The wave generator is in form of elliptic cam, the flexible wheel and the rigid wheel has a two-arc teeth profile respectively which can realize conjugation motion. The driver can effectively improve the stress condition of the flexible wheel tooth-root and drive quality and increaseload-bearing ability and torque rigidity of harmonic wave driver, and further lower minimum drive ratio of harmonic wave driver. Advantages: good processing property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

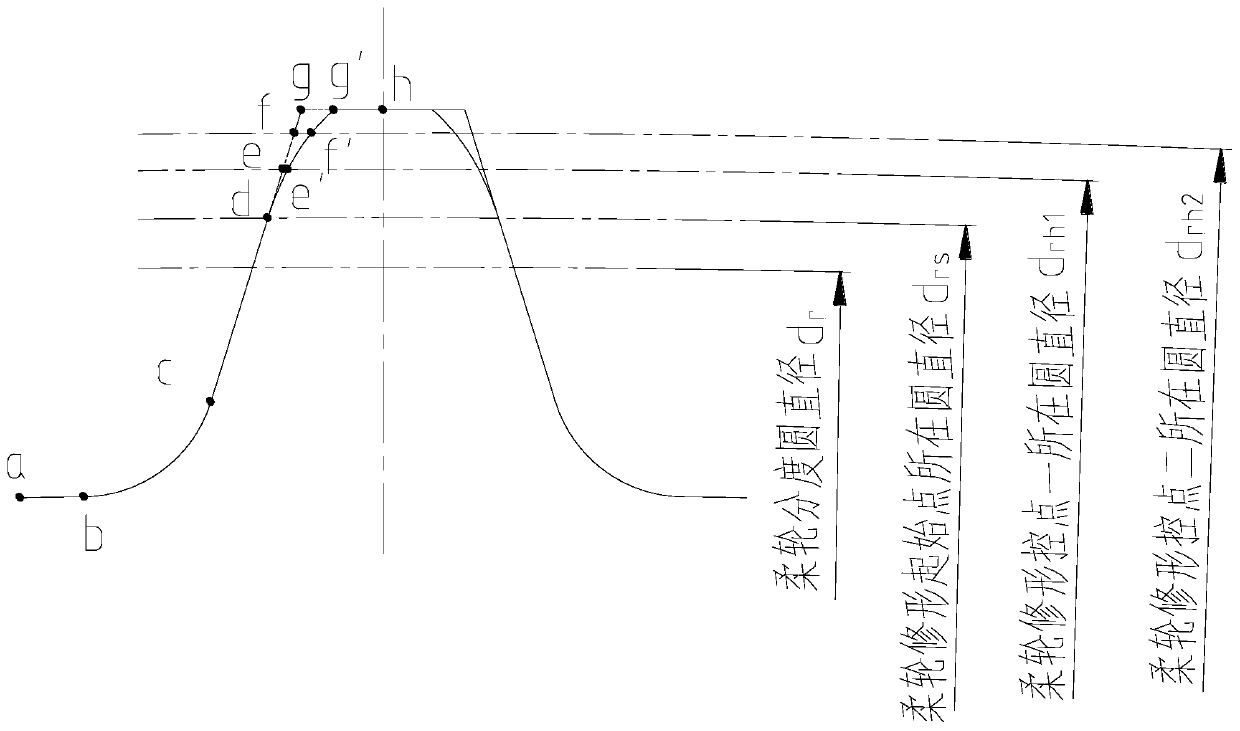

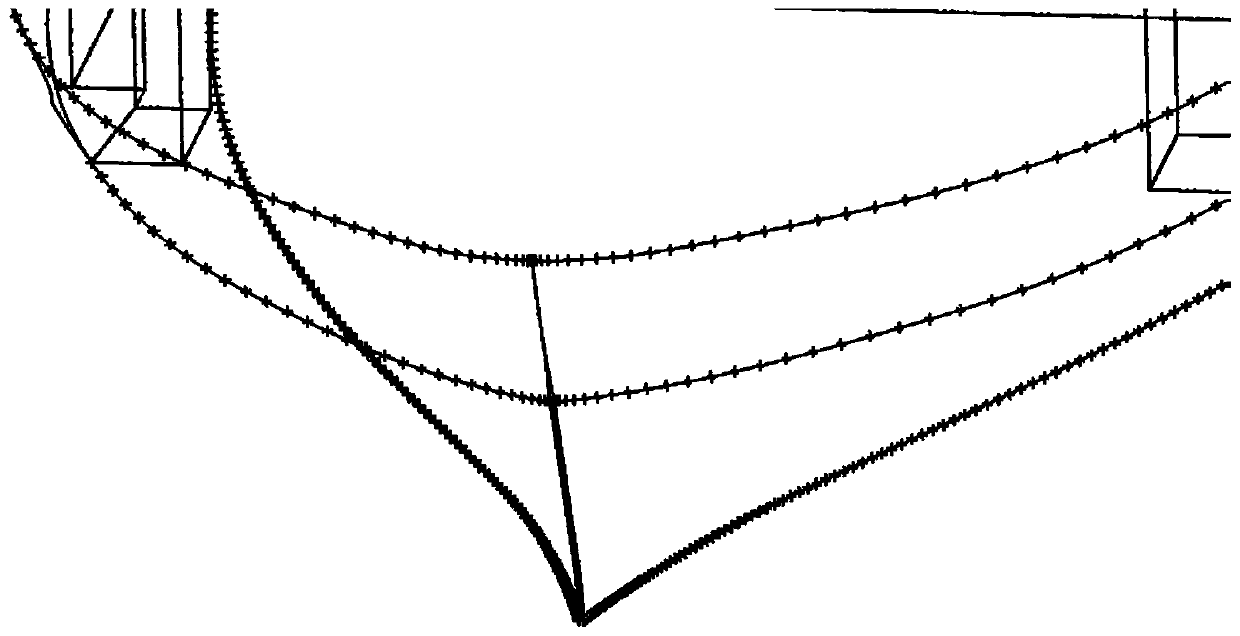

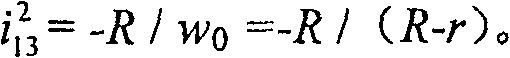

Modified wave cam and design method thereof, wave generator and harmonic reducer

The invention provides a design method of a modified wave cam. The design method comprises the following steps that a quarter elliptic curve is initially confirmed; the position of the horizontal coordinate of the circle center of a quarter arc is confirmed; the position of the vertical coordinate of the circle center of the quarter arc is confirmed; a quarter curve of the outline of the modifiedwave cam is initially confirmed; the quarter curve of the outline of the modified wave cam is confirmed; the curve is offset inwards; and the complete outline curve of the modified wave cam is confirmed. The modified wave cam is designed out according to the above design method. A wave generator comprises the above modified wave cam and a flexible bearing arranged on the outer edge of the modifiedwave cam. A harmonic reducer at least comprises the above wave generator, a flexible wheel, a rigid wheel and a modified wave cam. According to the modified wave cam designed through the design method and the harmonic reducer, gear tooth interference is avoided, the maximum stress and stress concentration of the flexible wheel in alternating stress changes are reduced, the tooth engagement area between the flexible wheel and the rigid wheel is added, the bearing capacity and precision of the harmonic reducer are improved, and the service life of the harmonic reducer is prolonged.

Owner:HUBEI KEFENG TRANSMISSION EQUIP CO LTD

Complex lattice structural body parametric modeling method

The invention discloses a parameterization modeling method for a complex lattice structure body. The parameterization modeling method comprises the steps that firstly, a framework model of a lattice structure is given; dividing the node into three node types, namely a branch node, a connection node and a tail end node; and the branch nodes are comprehensively constructed by using an inner hexahedron group generation mechanism based on skeleton perception and an outer hexahedron group mapping mechanism based on transition curved surface sampling fitting interpolation. And connecting nodes are constructed by using a lofting body model of a multi-section group. And a tail end node is constructed by using a stretching body or swept body model of a single section group. And the node model is matched with the skeleton topological information, and a lattice structural body parameterized model is obtained through splicing and periodic array. According to the method, the parametric modeling problem of the complex lattice structure body is well solved, and the model can be directly applied to isogeometric analysis, so that a good model support is provided for realizing modeling and simulation integration of the complex lattice structure.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A planetary roller screw pair

ActiveCN102900821BSolve the problem of axial prolapse and stagnationImprove mesh qualityGearingRight triangleRoller screw

The invention belongs to linear kinetic pairs, and particularly relates to a planetary roller and lead screw pair. The planetary roller and lead screw pair solves problems of axial releasing and jamming of an existing roller and an existing nut, the meshing quality is improved, and the difficulty in machining process is lowered. Normal sections of a nut (3) and lead screws (1) in the planetary roller and lead screw pair are in shapes of isosceles right triangles and are provided with threaded grooves, normal sections of threads of rollers (2) are arc-shaped, and circle centers of arcs of the normal sections of the threads of the rollers (2) are positioned on axes of the rollers, and actual pitch diameters of threads of the lead screws (1) are smaller than nominal pitch diameters obtained from a computational formula.

Owner:CHINA NORTH VEHICLE RES INST

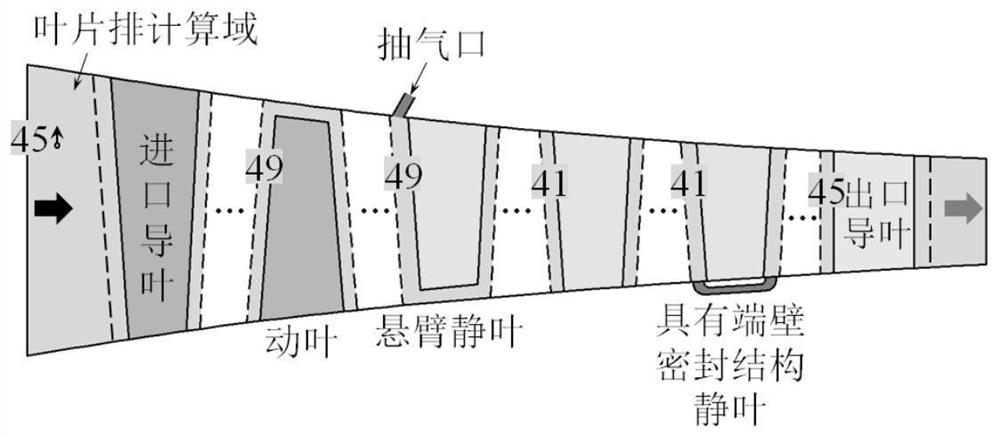

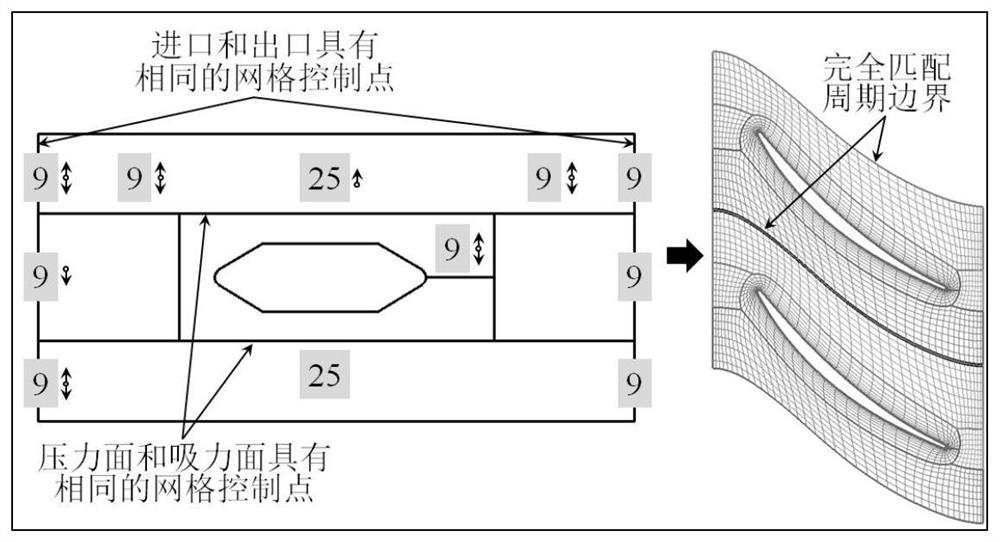

Axial flow compressor surge boundary calculation method based on full three-dimensional numerical simulation

ActiveCN112287580AImprove mesh qualityThe number of grid nodes is smallGeometric CADDesign optimisation/simulationData transmissionImpeller

The invention provides an axial flow compressor surge boundary calculation method based on full three-dimensional numerical simulation. The axial flow compressor surge boundary calculation method comprises calculation grid model setting and numerical calculation method setting. Calculation grid model setting and numerical calculation method setting are respectively based on IGG / AutoGrid 5 softwareand ANSYS / CFX software. Grid data transmission is carried out between the two different kinds of software through a grid converter self-programming program. The whole calculation process integrates the advantages of different software, and aims to provide an appropriate grid model and an appropriate numerical calculation method for accurately predicting the surge boundary of the gas compressor. The grid generated by the grid setting method provided by the invention is high in quality, the number of grid nodes is small, and the actual geometric structure characteristics of some air compressorsare comprehensively considered. The numerical value setting method provided by the invention is not influenced by the unsmooth profile of the blade profile structure of the gas compressor, and is relatively good in robustness and wide in applicability. The method can be widely applied to the pneumatic design process of turbomachinery such as an axial-flow compressor, an axial-flow compressor, anaxial-flow fan and an axial-flow fan.

Owner:中国船舶重工集团公司第七0三研究所

Cycloidal engagement pair with uniform-gap engagement of full hydraulic steering gear and processing method thereof

ActiveCN101709729BFlexible rotationStable jobHydraulic steering gearsFluid-pressure actuatorsGear grindingEngineering

The invention relates to a cycloidal engagement pair with uniform-gap engagement in a full hydraulic steering gear and a processing method thereof, and belongs to the technical field of hydraulic transmission. The cycloidal engagement pair is formed by the matching of a cylindrical pin wheel and a cycloidal gear which form a tie bar-free planetary gear train; the profile of the cycloidal gear is a closed curve determined by a specific curve equation; and when the modification and the generating gear grinding are performed, the radius of a grinding wheel is dressed to be equal to the sum of the radius of the pin wheel and the uniform-gap engagement modification amount to ensure that the central distance between the grinding wheel and a mandrel of a spline is equal to the radius of a pitch circle of the pin wheel. The adoption of the technical scheme of the invention shows that the rotation of a rotor is more flexible. At the same time, the sealing performance is improved, so the effectof attaining two objectives by a single move is achieved. Therefore, the cycloidal engagement pair contributes to solving the problems of inflexible rotation and locking of cycloidal gears of cycloidal pairs of full hydraulic steering gears, and can ensure that the engagement quality is improved and the steering gears work more steadily and longer service life. During the production, only one technological parameter needs to be adjusted, and no equipment is added, so the cycloidal engagement pair is practical and feasible.

Owner:ZHENJIANG HYDRAULICS

Method and system for optimizing a finite element mesh

InactiveUS20060028467A1Quality improvementImprove mesh quality3D-image rendering3D modellingAlgorithmQuality Score

Computer-implemented method and system for optimizing a finite element mesh. Computing devices are configured to calculate a quality score for at least one original element in a finite element mesh based upon two or more quality attributes simultaneously. A quality score for at least one substitute element for the original element is calculated based upon the two or more quality attributes. If one or more substitute element(s) have a quality score that is better than the quality score of the original element(s), the original element(s) is / are replaced with the substitute element(s) having the best quality score. A quality score may be calculated for each of a plurality of combinations of one or more substitute elements. Input may be provided specifying at least one quality threshold value for comparing the two or more element quality parameters (skew, warp, aspect ratio, etc.).

Owner:FORD MOTOR CO

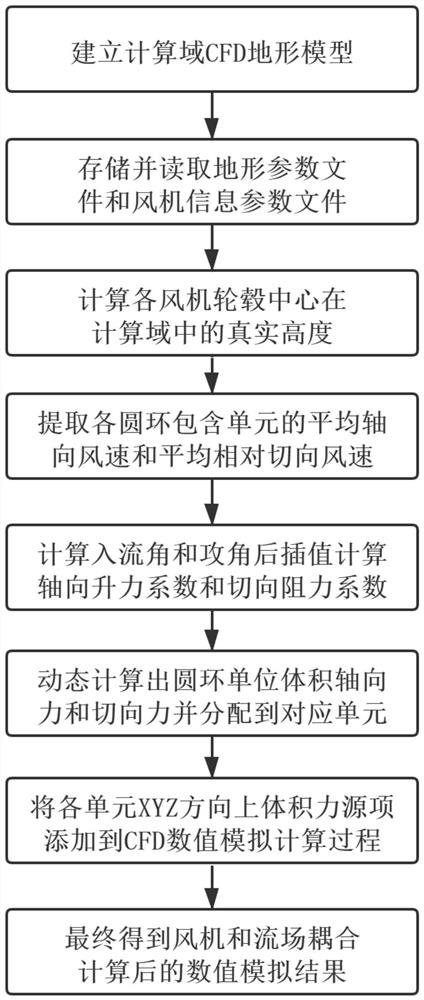

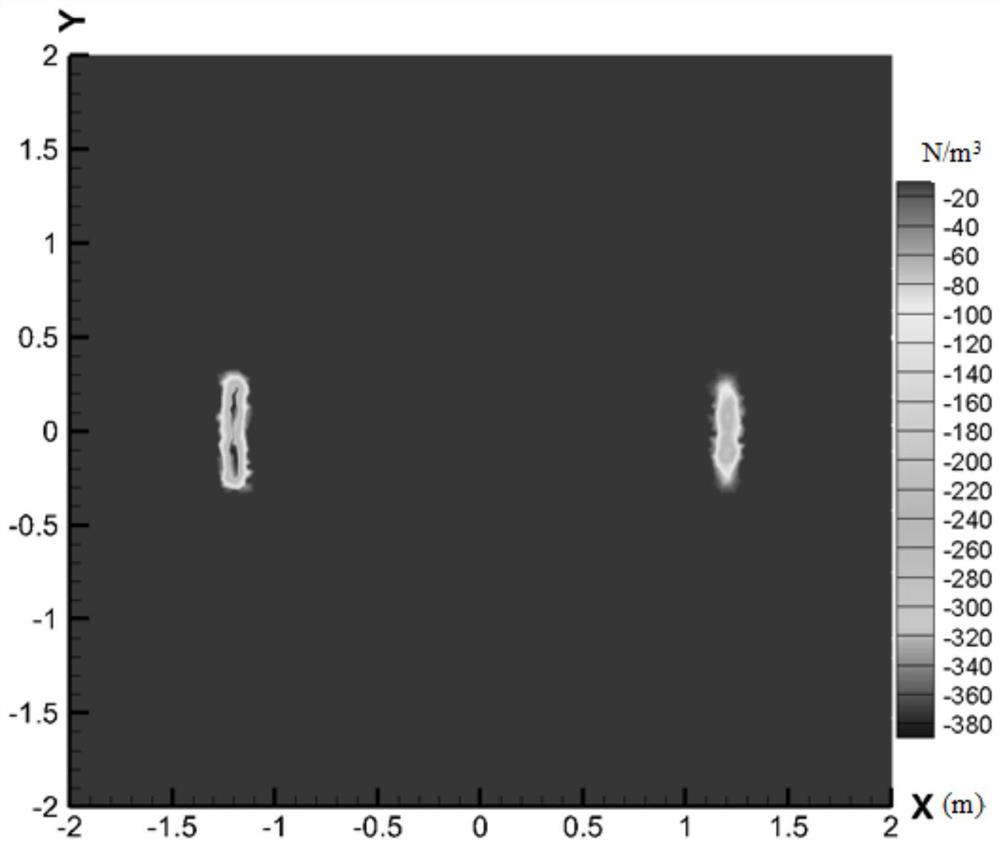

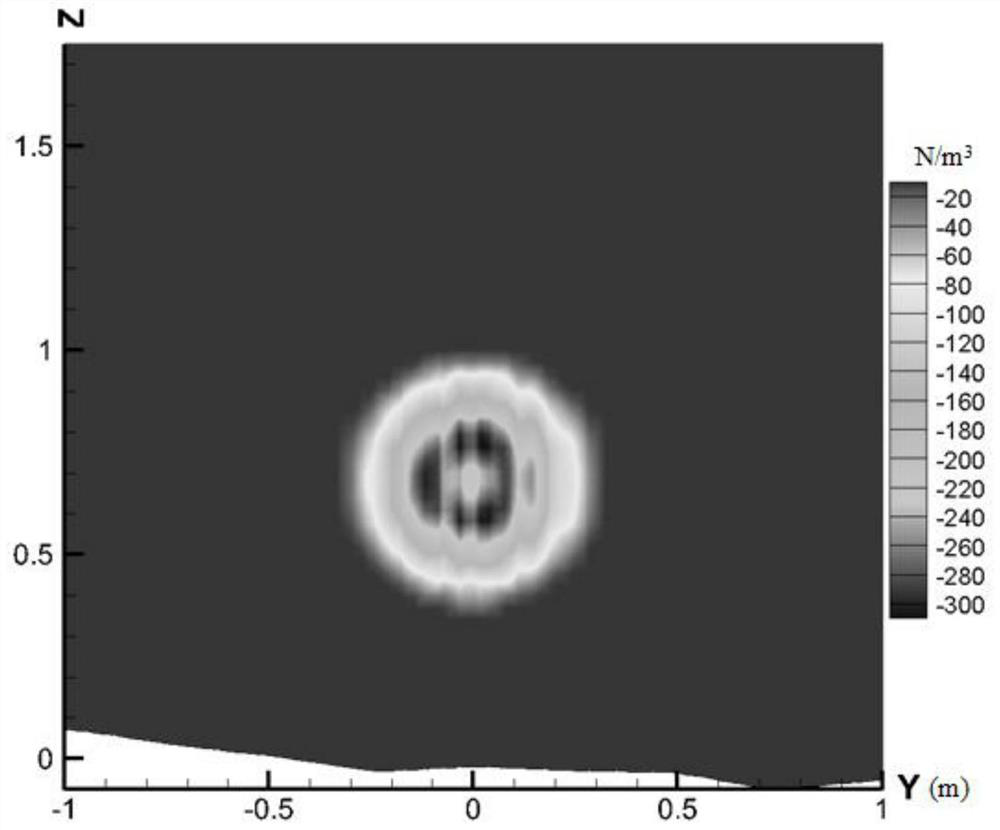

Wind power plant fan wake flow dynamic coupling simulation method

PendingCN112966454ASimulation is accurateReal wake effectsDesign optimisation/simulationCAD numerical modellingWind engineeringEngineering

The invention belongs to the field of computational wind engineering, and particularly discloses a wind power plant fan wake flow dynamic coupling simulation method, which comprises the following steps of: S1, dividing a computational domain into a plurality of grid units, further establishing a computational domain grid model, and simultaneously obtaining relevant parameters of a fan; s2, dividing the fan actuating disc into a plurality of radially equidistant circular rings, respectively calculating axial force and tangential force corresponding to each circular ring according to the wind speed, distributing the axial force and tangential force to each grid unit contained in the circular rings to obtain a resistance item of each grid unit, and establishing a corresponding relation model of the wind speed and the resistance item; and S3, based on the computational domain grid model, carrying out numerical simulation on the fan wake flow, adding a resistance item to a corresponding grid unit during simulation, and dynamically calculating and updating the resistance item according to the changed wind speed and the corresponding relation model. The resistance item is correspondingly and dynamically added according to the incoming flow wind speed, the disturbance effect of the flow field and the draught fan on the flow field can be calculated in a coupling mode, and the wake flow distribution condition of the draught fan is truly reflected.

Owner:HUAZHONG UNIV OF SCI & TECH

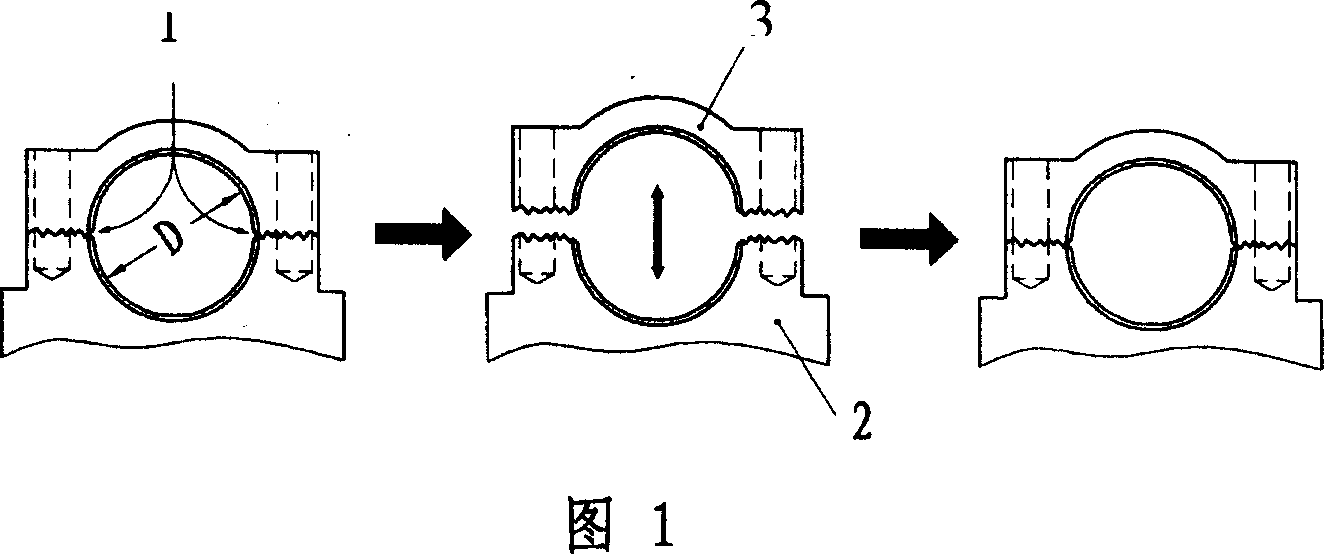

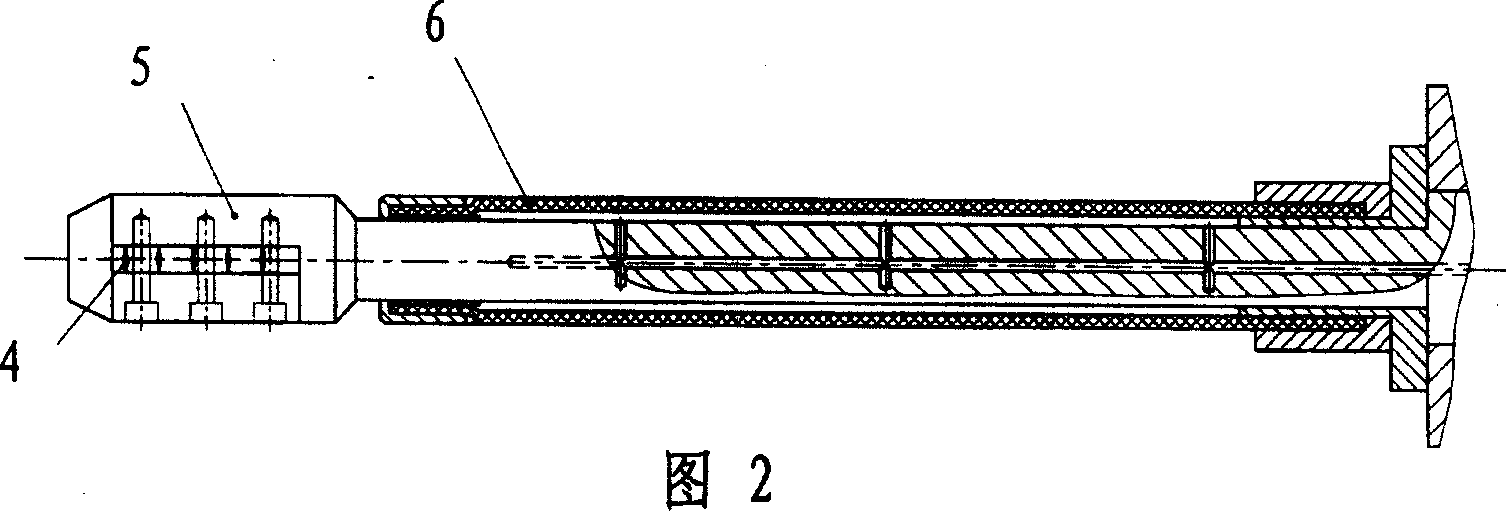

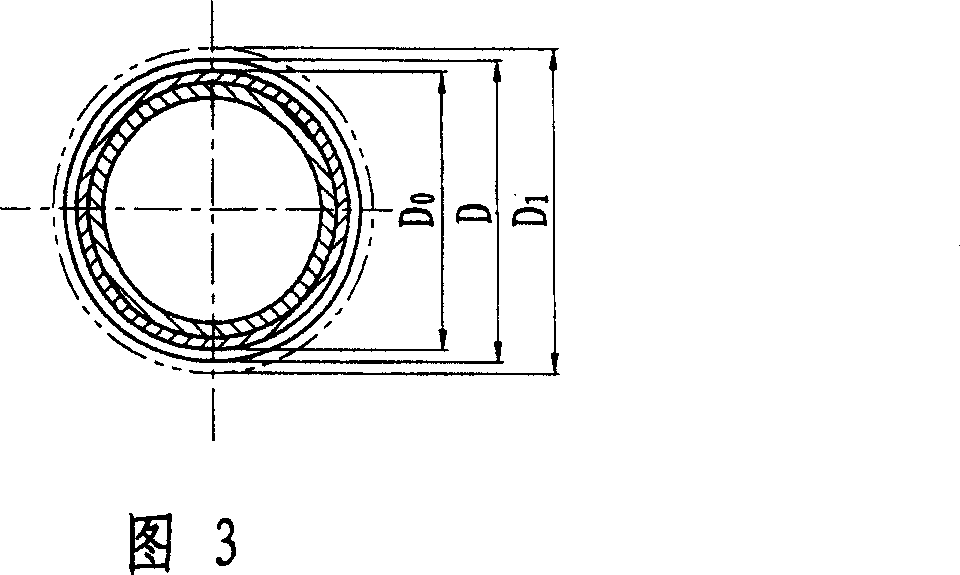

Engine crankcase bearing block splitting working method and apparatus

InactiveCN100343012CCracking processing is conveniently realizedReduce distortionCasingsCrankshaft bearingsCrankcaseControl theory

The present invention relates to an engine crankcase body bearing seat processing method and its special-purpose equipment. Its processing method includes: a. in the crankcase body bearing seat splitting process always utilizing back pressure mechanism to apply can retain a certain back pressure to bearing seat; b. utilizing slide block mechanism with broach bar to implement splitting channel processing of two sides of bearing seat hole centre place; and c. utilizing pressuried high-pressure liquor to make the bearing seat hole be broken and separated from splitting channel position and from crankcase body bearing seat. Its processing equipment is formed from main machine and back pressure mechanism. Said equipment also comprises crankcase body positioning plate and positioning clamping mechanism, slide block body and pressurizing cylinder, etc.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com