Cycloidal engagement pair with uniform-gap engagement of full hydraulic steering gear and processing method thereof

A technology of cycloid meshing and steering gear, applied in the field of cycloid meshing pair and uniform meshing cycloid meshing pair, can solve the problems such as bearing capacity and rotation accuracy are not the goal pursued, not suitable for cycloid pair, etc., to solve the problem of rotating The effect of inflexibility, improved meshing quality, and flexible rotor rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

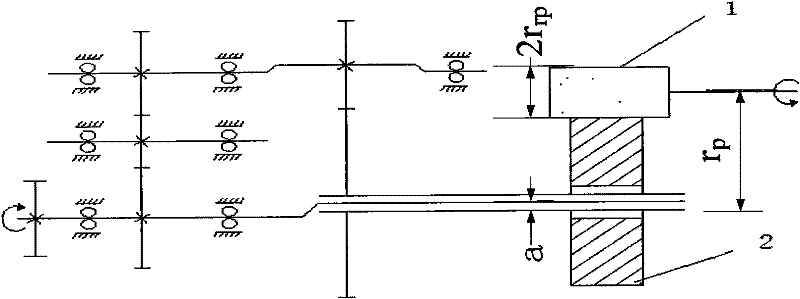

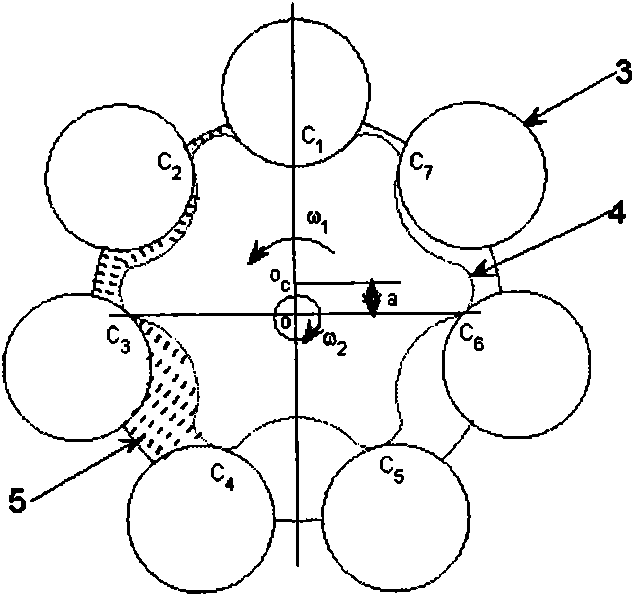

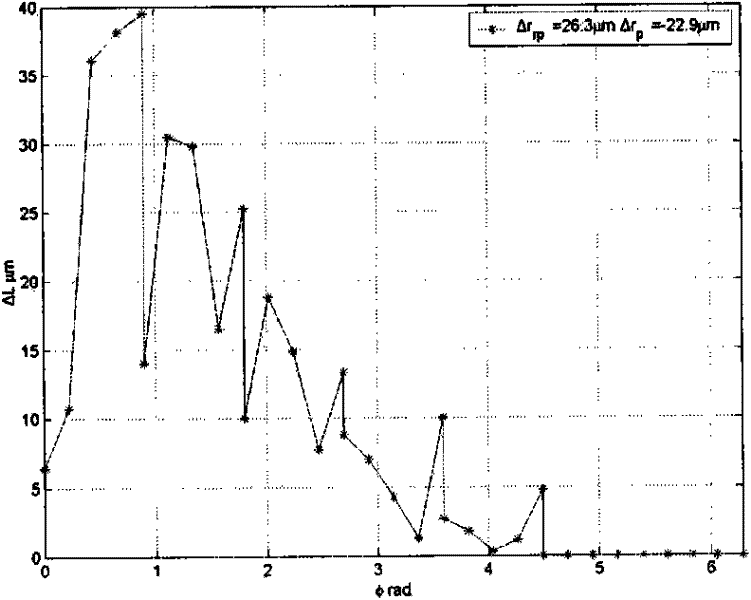

[0043] This embodiment takes the cycloidal pair in the BZZ full hydraulic steering gear as an example, its basic tooth profile parameters: z p =7r p =34mm r rp = 11.1 mm α = 3.8 mm. If the cycloidal wheel adopts positive equidistant plus negative displacement, the design variable is equidistant plus displacement modification, and the objective function is the approximating corner modification. Volume, it can be obtained that Δδ=0.005rad (Δδ is the angle modification amount), and the constraint condition is that the meshing clearance is greater than zero. Design" article, the amount of modification can be obtained by Δr rp =0.0263mmΔr p=-0.0229mm(Δr p Indicates the displacement modification amount). And adopt the even-gap meshing modification of the present invention, the amount of even-gap meshing modification is the average value of the equidistant plus displacement distance cycloid pair tooth side clearance determined through optimization, and the calculation formula i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com