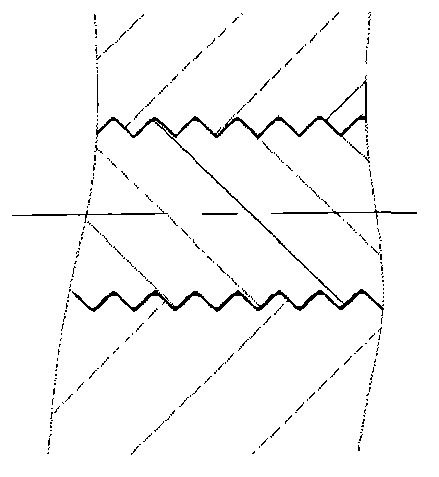

Planetary roller and lead screw pair

A planetary roller and screw pair technology, which is applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as stagnation, rollers and nuts coming out of the axial direction, and achieve smoothness and bearing capacity. Effect of improved meshing quality and high load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

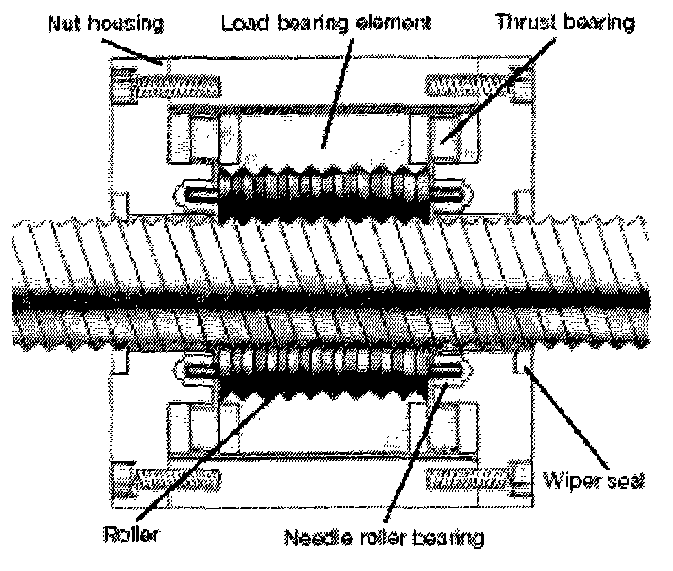

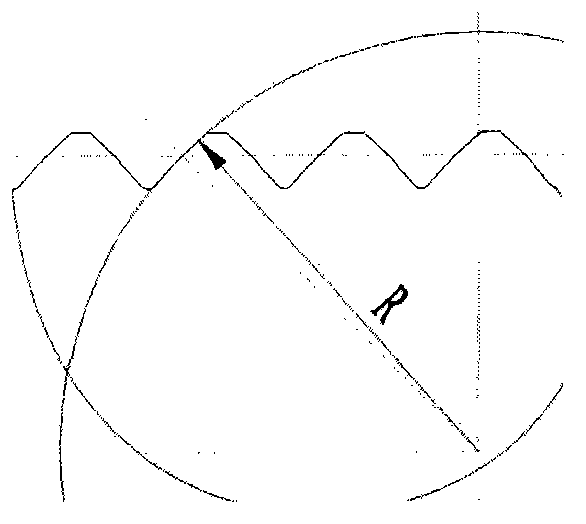

[0028] Embodiment: The planetary roller screw pair of the present invention is adopted, wherein the nut 3 and the screw rod 1 adopt an isosceles right-angled triangular thread in the normal direction of the alveolar, and the roller 2 adopts an arc-shaped normal direction of the teeth. The nominal pitch diameter of the screw 1 is 30mm, the actual pitch diameter is 29.51mm, the nominal pitch diameter and the actual pitch diameter of the roller 2 are both 10mm, the nominal pitch diameter and the actual pitch diameter of the nut 3 are both 50mm, and the threads of the three elements are all right-handed. The radius of the arc section of the roller 2 is 7.071mm. The above-mentioned planetary roller screw pair has been tested to prove that the efficiency of the planetary roller screw pair reaches more than 90%, the forward and reverse transmission is flexible, the axial clearance is 0-0.03mm, and the accuracy and service life of the servo system are good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Middle diameter | aaaaa | aaaaa |

| Middle diameter | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com