Electric push rod

An electric push rod, motor-driven technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increasing the vibration and noise of worm gears and affecting the meshing quality of worm gears, and achieves noise reduction, meshing quality improvement, and transmission. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

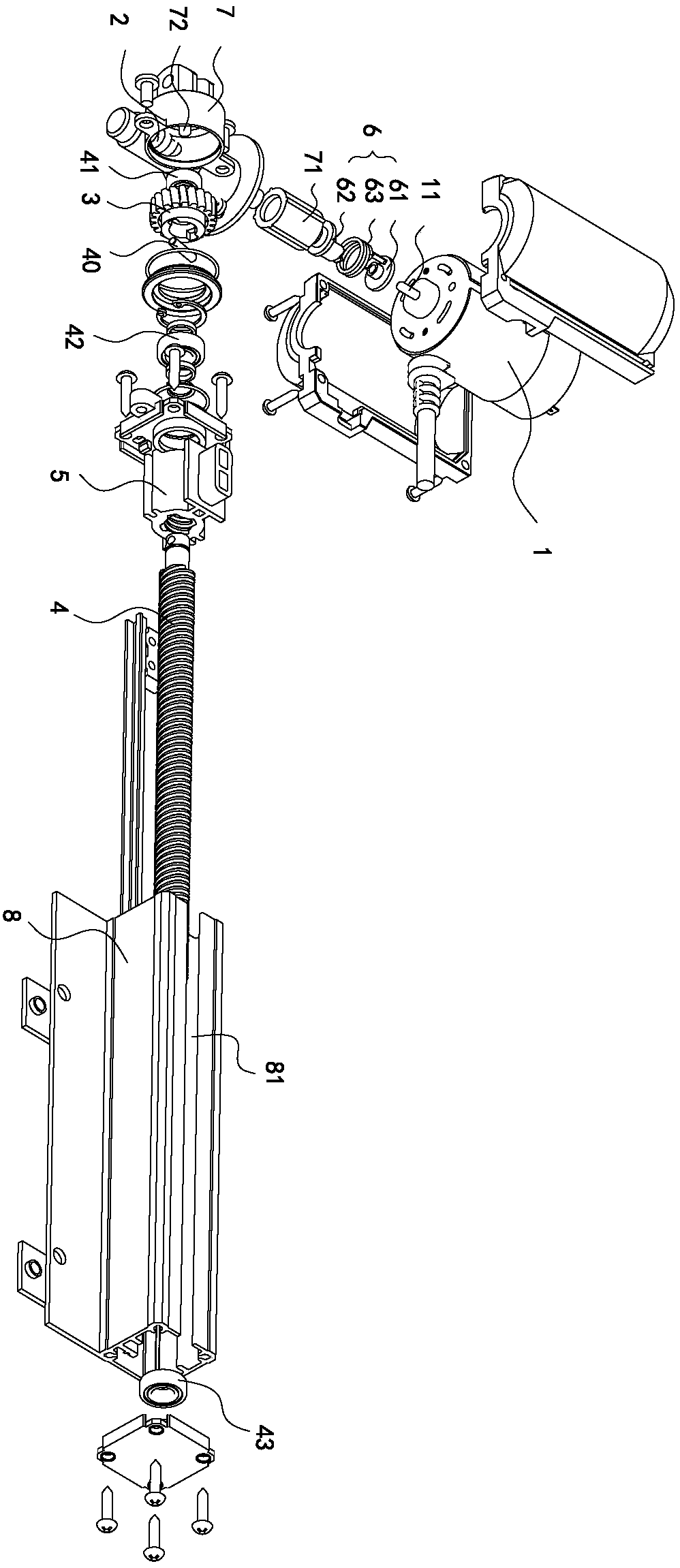

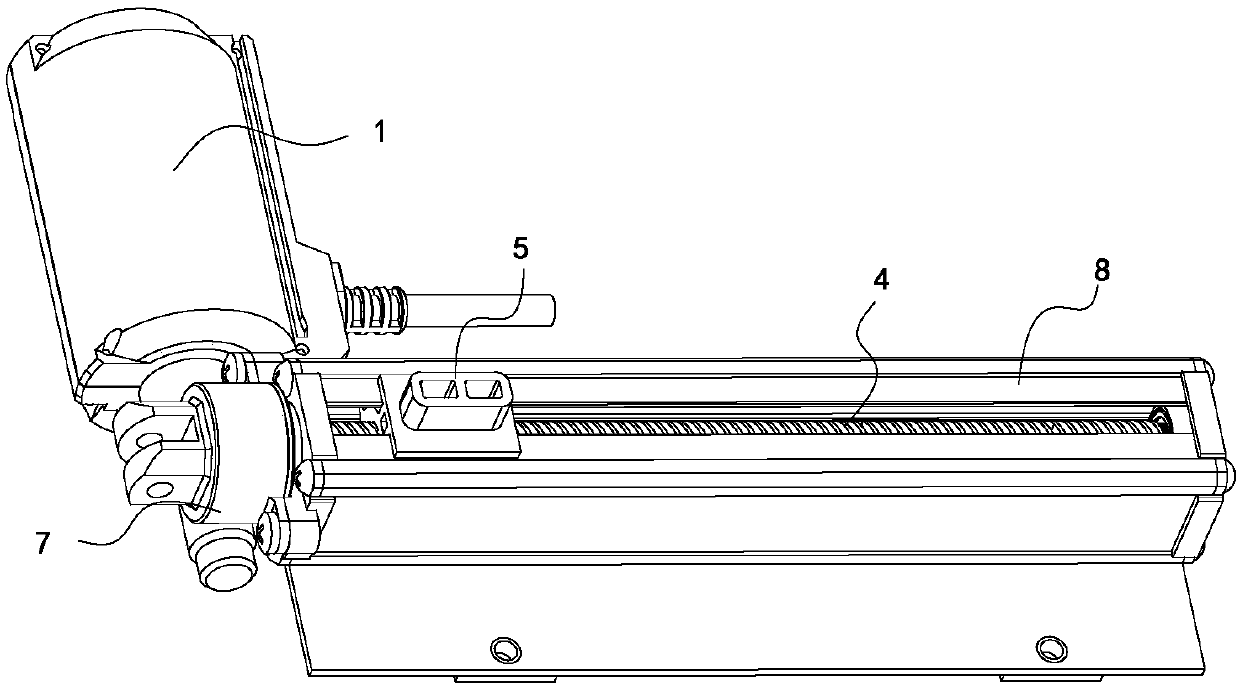

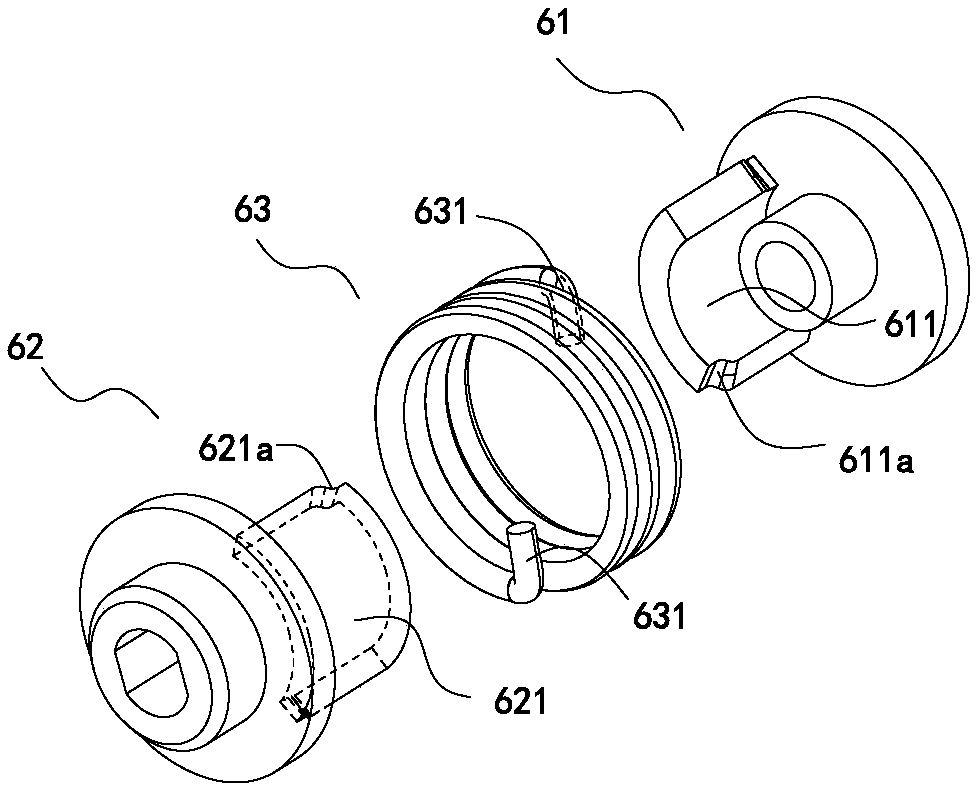

[0030] Such as Figure 1 to Figure 7 As shown, an electric push rod shown in this embodiment includes a motor 1, a transmission worm 2, a transmission worm wheel 3, a screw 4 and a transmission nut 5, the rotation of the motor 1 drives the transmission worm 2 to rotate, and the transmission worm 2 is connected with the transmission When the worm gear 3 is meshed, the rotation of the transmission worm 2 drives the transmission worm 3 to rotate, and the rotation of the transmission worm 3 drives the screw 4 to rotate. The screw 4 is connected to the transmission nut 5. When the screw 4 itself rotates, the transmission nut 5 moves The axial direction of the screw rod 4 moves relatively, thereby converting the rotational motion of the motor 1 into the linear reciprocating motion of the transmission nut 5, and the transmission nut 5 can be used to connect other components to push related components to move, such as lifting tables, medical bed etc.

[0031] In the present invention...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the connection structure between the transmission worm wheel and the screw rod is connected by a spline, that is, a spline groove is provided on the transmission worm wheel, and the end of the screw rod is provided with a The splines matched with the spline grooves can be axially inserted into the spline grooves to realize the transmission of the two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com