Finite element simulation method of beam_plate shell structure

A technology of board and shell structure and simulation method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficulties in engineering practice and poor versatility, and reduce hidden troubles, reduce experiment costs, and network good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

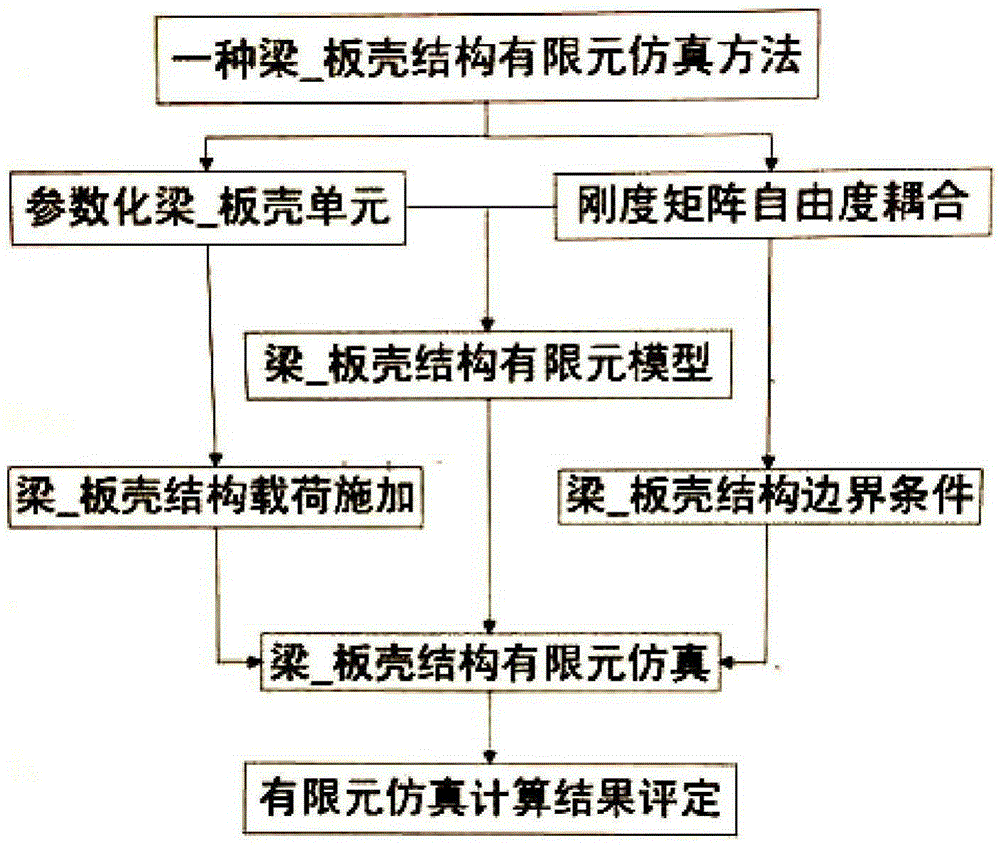

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0025] A kind of beam-shell structure finite element simulation method of the present invention comprises the following steps:

[0026] Beam element and shell element research and establishment of finite element model;

[0027] The determination of the boundary conditions of the beam-shell model;

[0028] Perform static strength calculation and modal analysis;

[0029] Evaluation of calculation results.

[0030] The invention is based on the parameterized beam-plate-shell structure, applies the coupling technology of the degree of freedom of the stiffness sheet, establishes the finite element model of the beam-plate-shell structure, and determines the load application mode and result evaluation method of the finite element model according to the characteristics of the beam-plate-shell structure.

[0031] The technical core of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com