Spherical involute spiral Archimedes spiral bevel gear cutting method and machine tool

A technology of Archimedes spiral and spherical involute, applied in the direction of gear cutting machine, gear tooth manufacturing device, gear tooth manufacturing tool, etc., can solve the problems such as loss of spherical involute meshing, principle error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

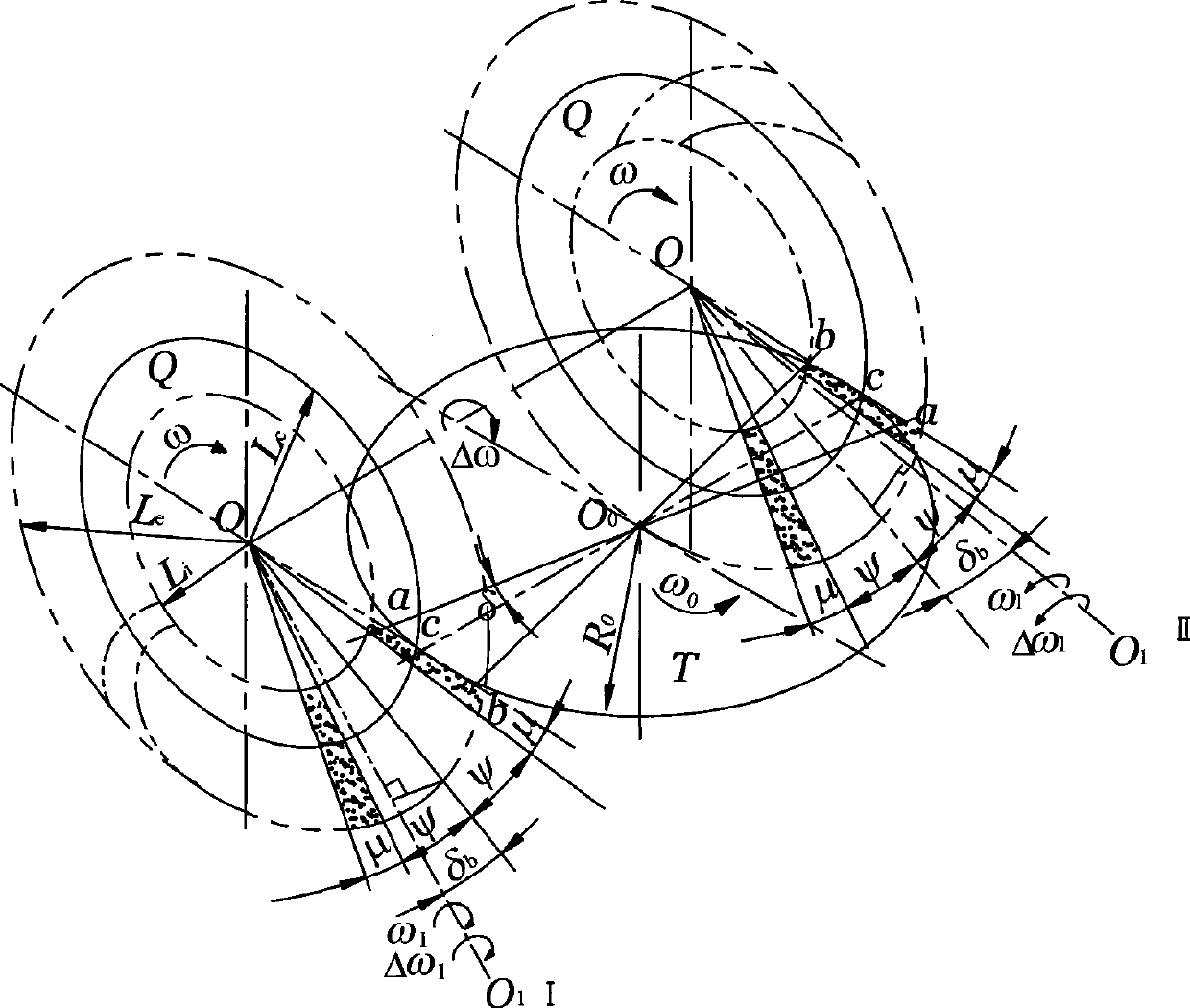

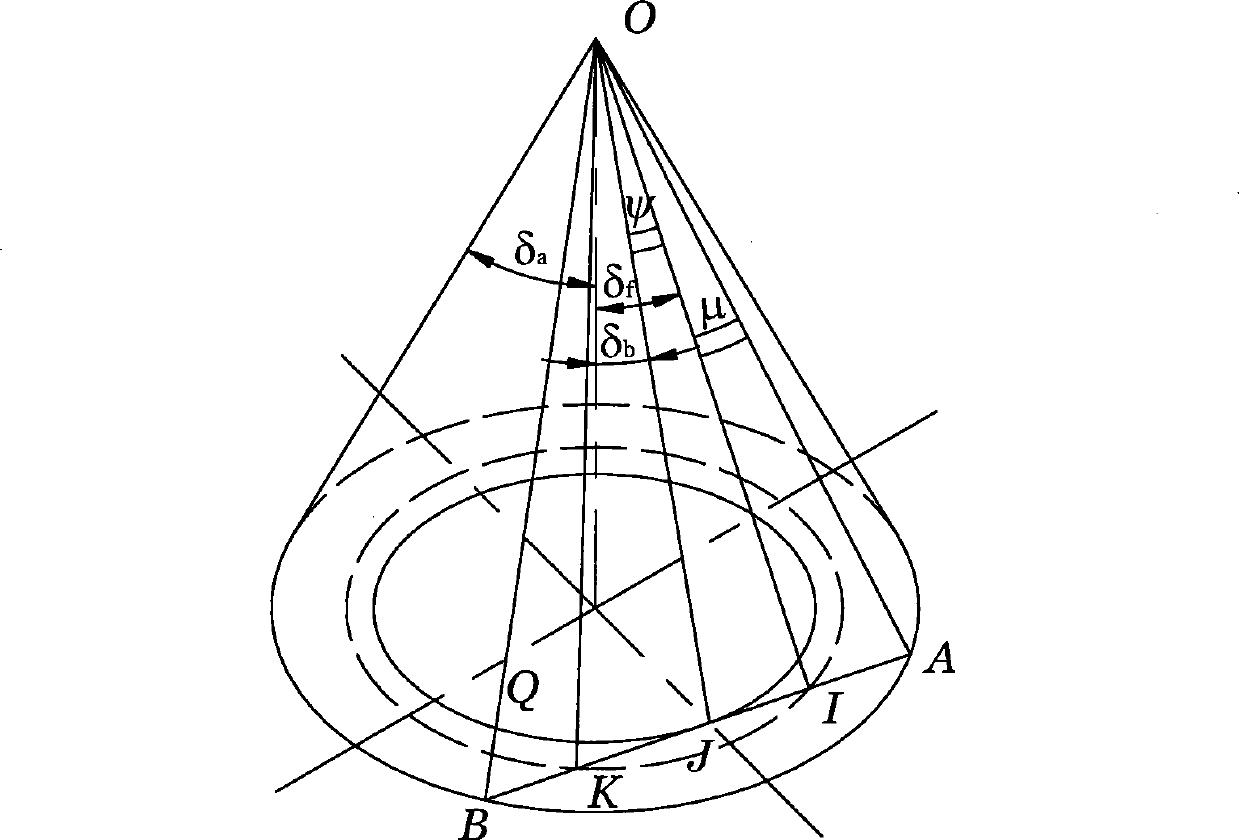

[0161] Teeth parameters:

[0162]

z m

(mm) α

() Lc

(mm) b

(mm)

β c

()

δ

() small wheel 11 9 20 100 40 30 (left-handed) 2345 big wheel 25 9 20 100 40 30 (right-handed) 6615

[0163] Cutting gear adjustment parameters:

[0164]

δ b

() δ a

() δ f

() ψ

() mu

() small wheel 22°14' 29°25' 20°44' 0° 31°25' big wheel 59°20' 69°16' 60°35' 14°16' 31°25'

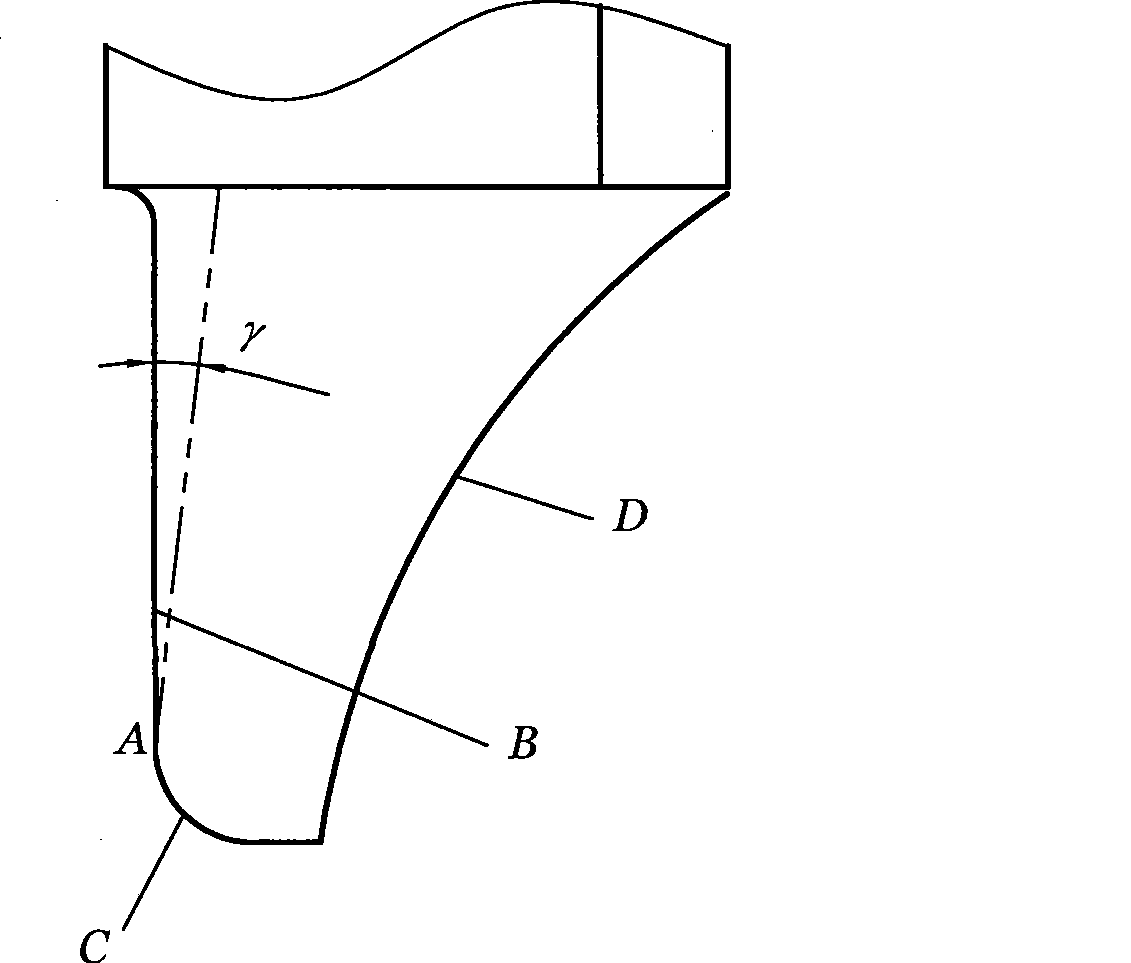

[0165] Cutter disc and cutter parameters:

[0166]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com