Patents

Literature

31results about How to "Efficient Machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

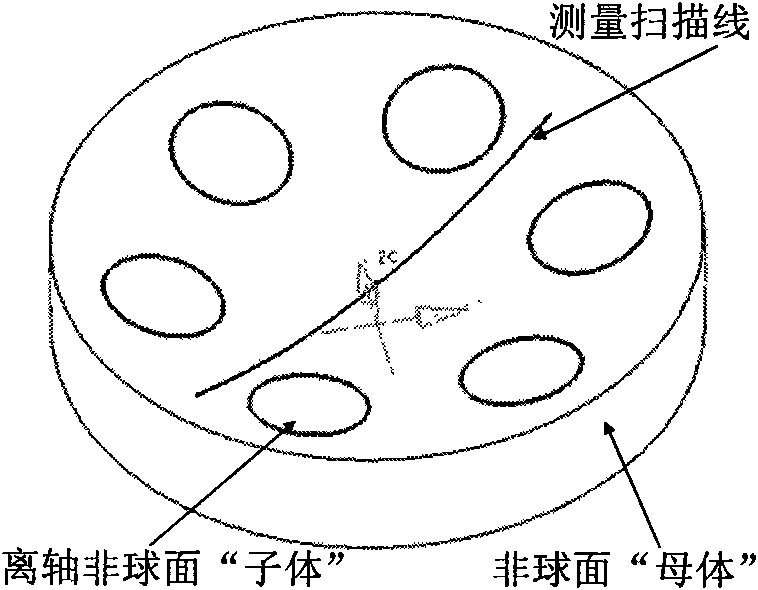

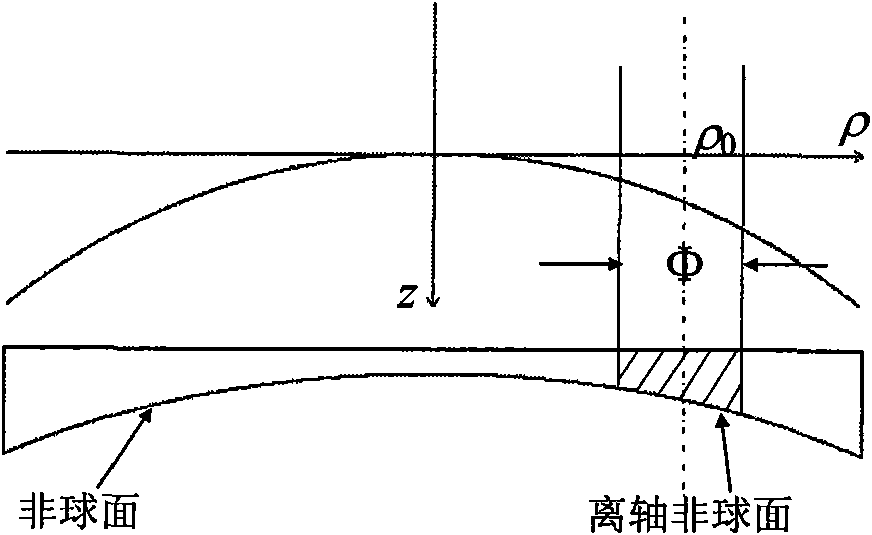

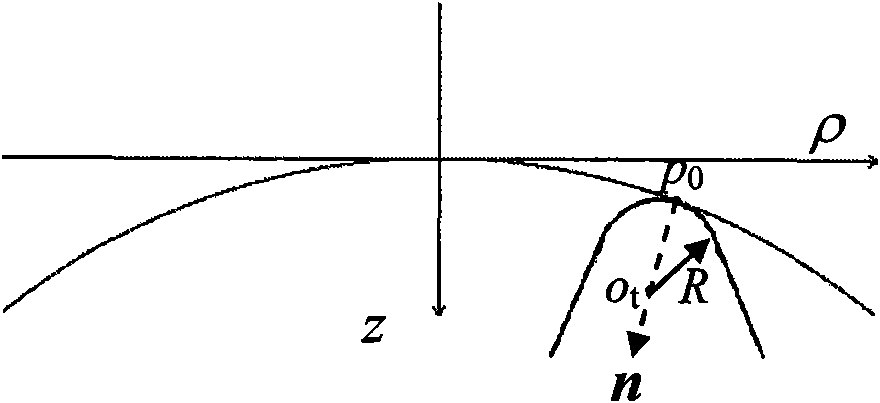

Method for improving shape accuracy and processing efficiency of off-axis aspheric mirror

InactiveCN101670442AEasy to processConsistent processabilityTurning machinesManufacturing technologyComputer science

The invention belongs to the technical field of optical device manufacturing and relates to a method for improving shape accuracy and processing efficiency of an off-axis aspheric mirror, comprising the following steps: (1) designing a rotary aspheric surface as well as a primary and secondary consubstantial structure for the primary body according to the size and the dimension of the off-axis aspheric mirror to be processed, i.e. a secondary body, and determining the amount of the off-axis aspheric secondary bodies to be processed at one time; (2) disposing through holes on a primary body blank piece; (3) placing all secondary body blank pieces into the through holes and fixing on a lathe after integrating into a cylindrical integrated work piece, and processing a spherical surface closest to the rotary aspheric surface on the integrated work piece; (4) generating a processing path of cutting tools based on the shape of the rotary aspheric surface, reprocessing the spherical surface by utilizing an ultra-precision lathe and carrying out form error analysis and compensating processing according to the measured integrated rotary aspheric surface shape. The provided method is simpleand easy to realize, has the advantages of high-efficiency, easy detachability and high shape accuracy and can realize high-efficient processing on an off-axis aspheric surface with high shape accuracy.

Owner:TIANJIN UNIV

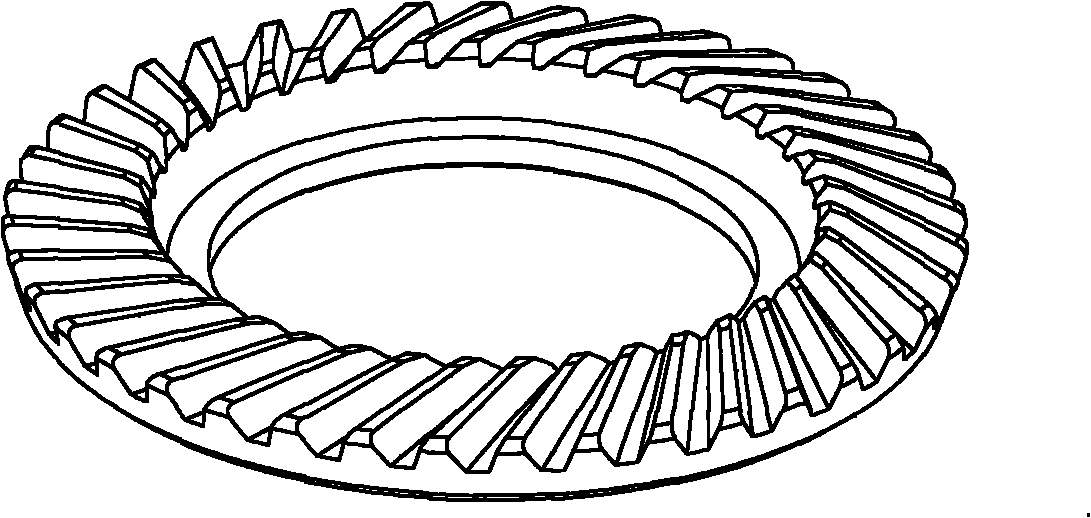

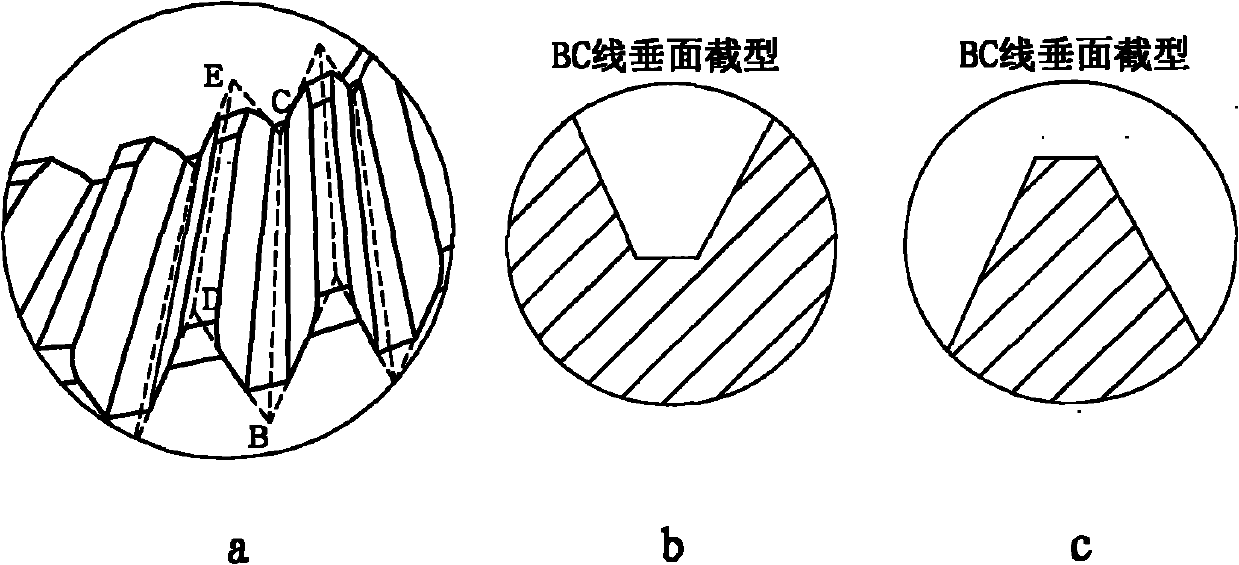

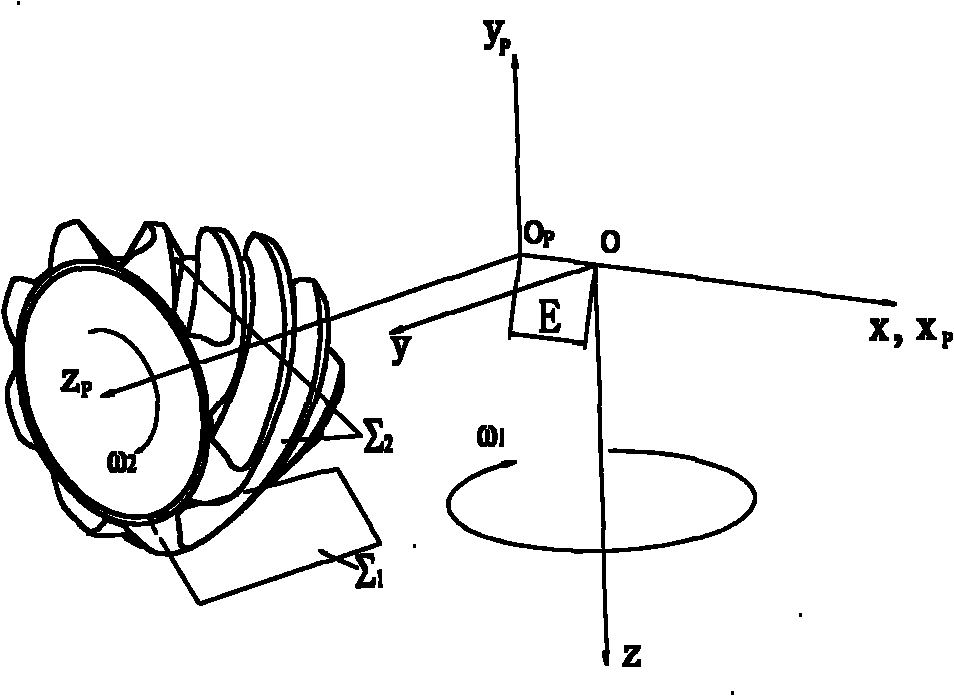

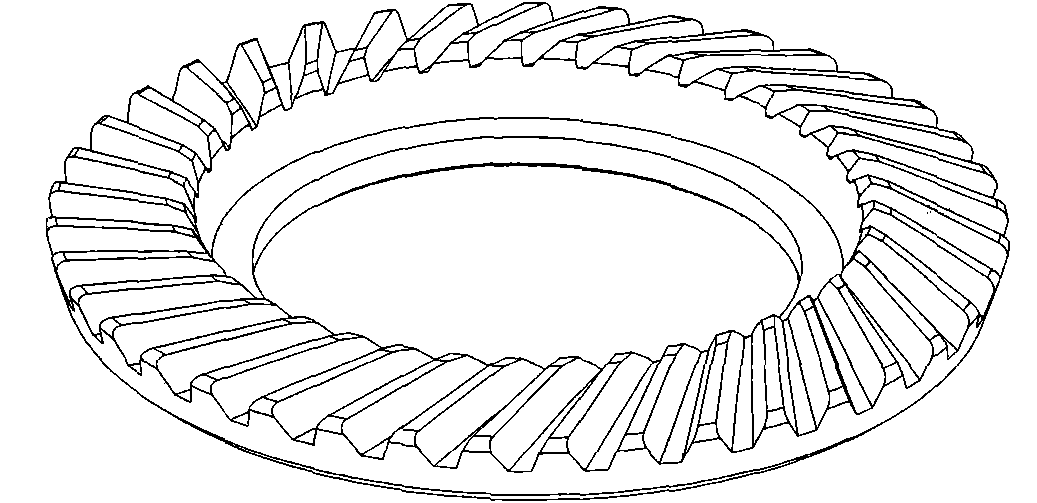

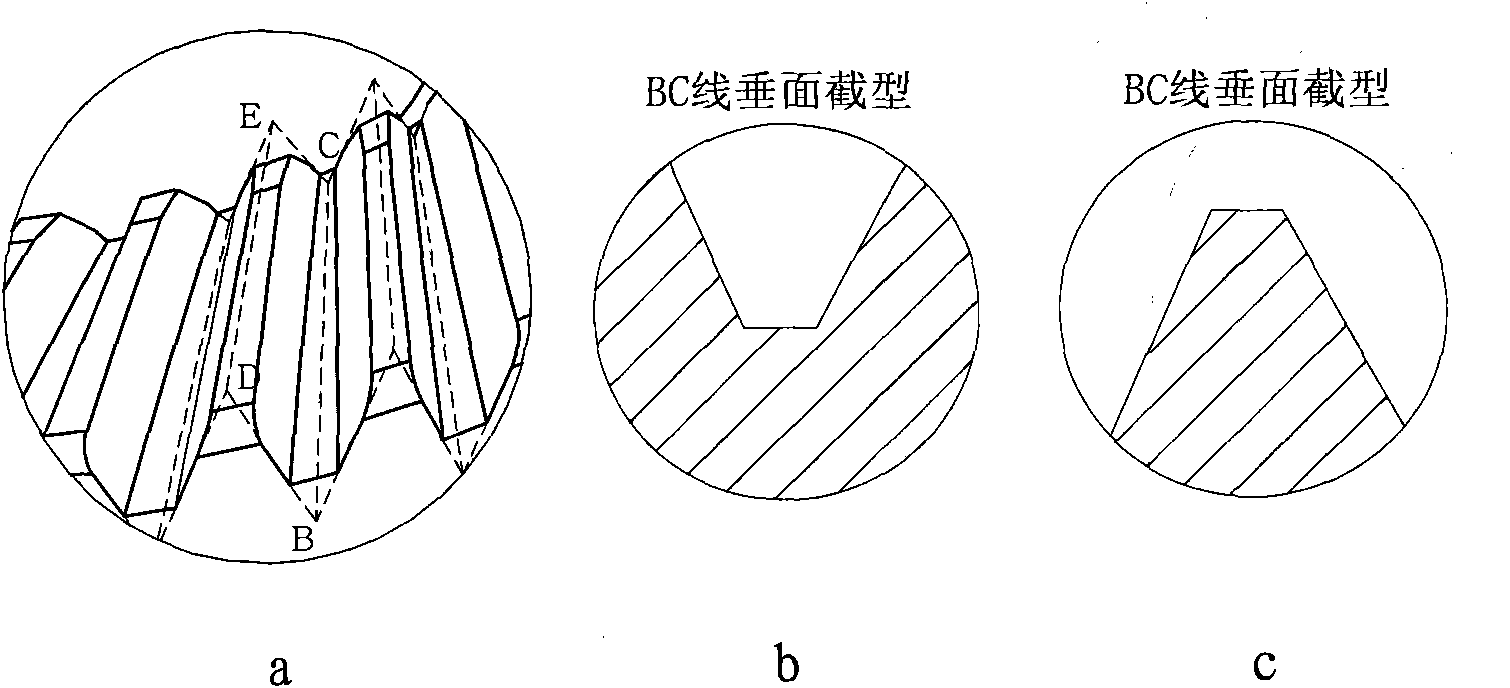

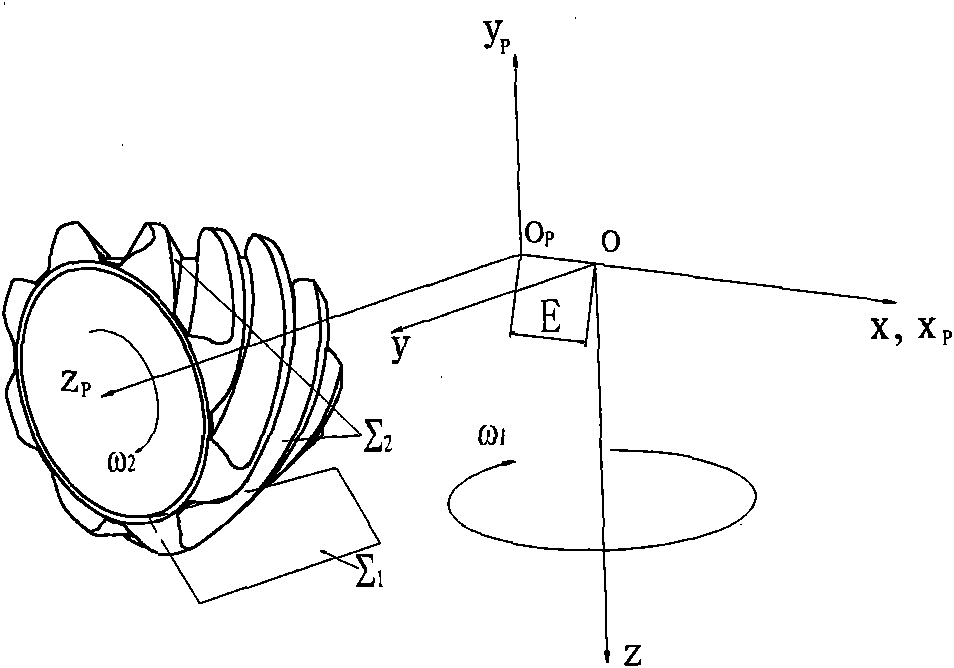

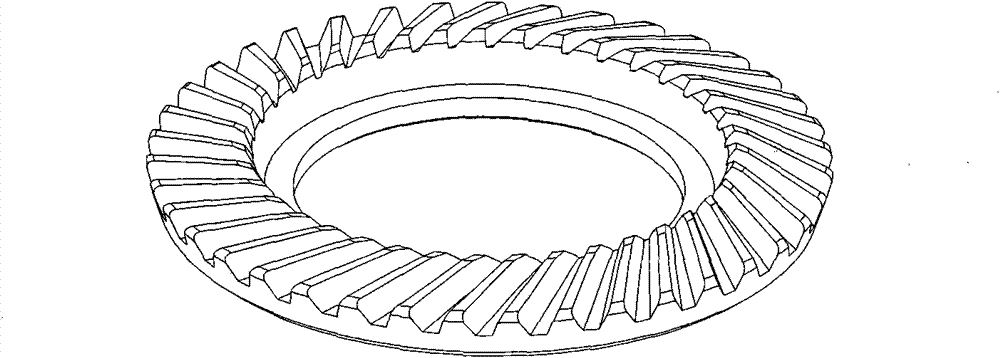

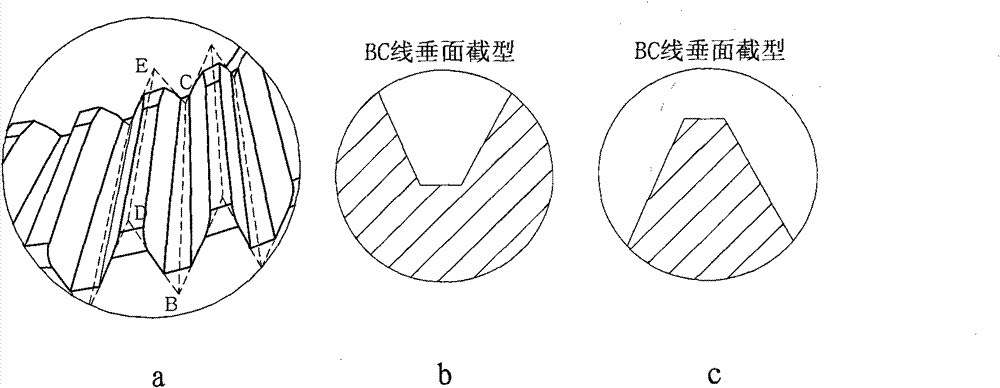

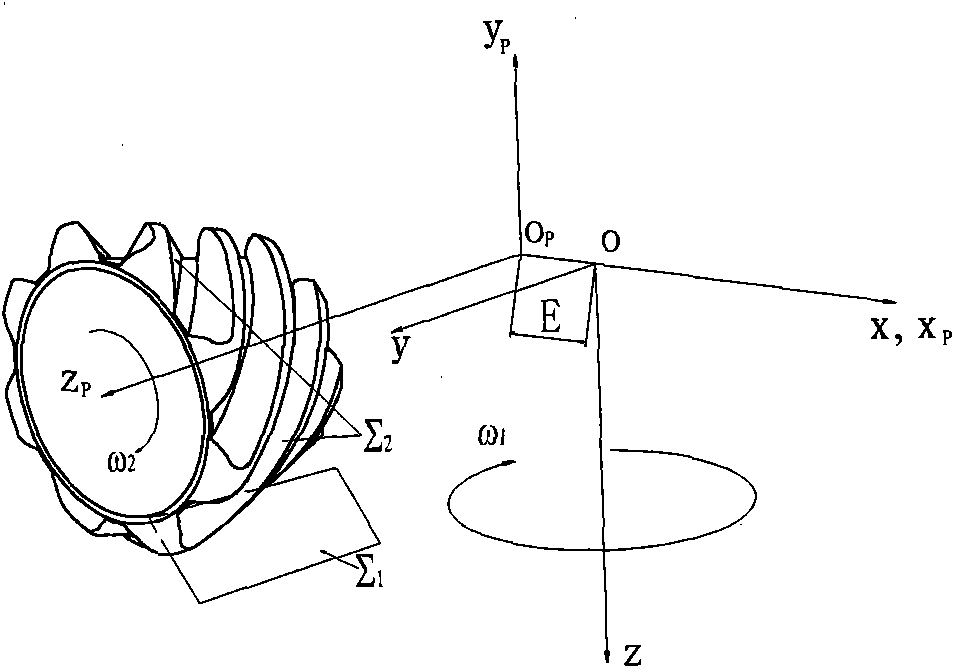

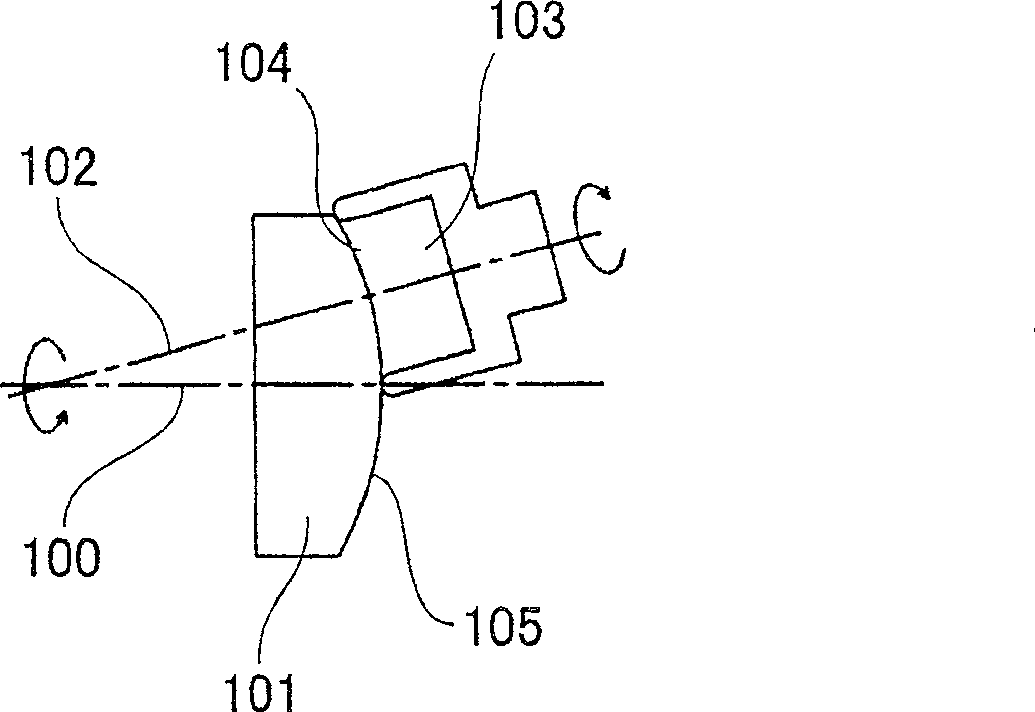

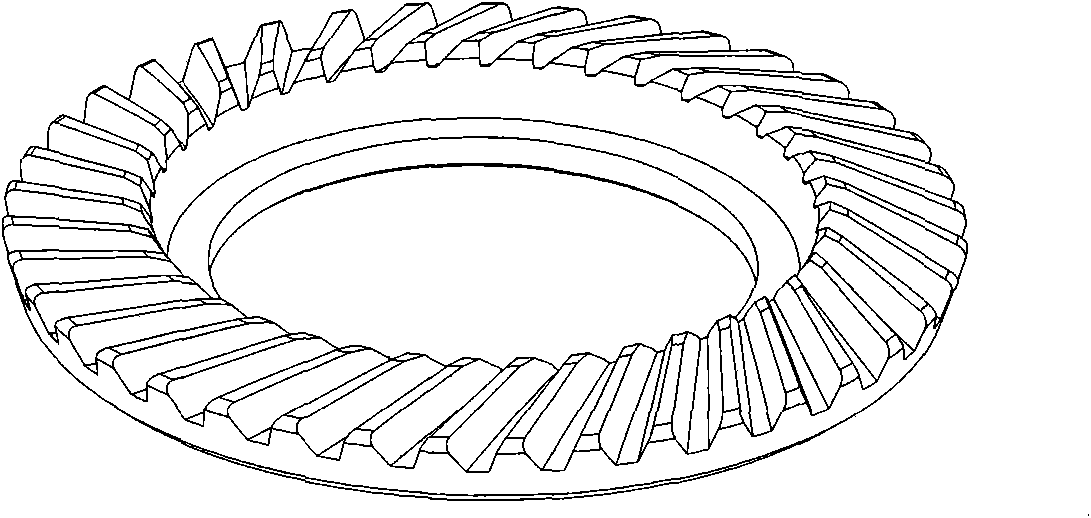

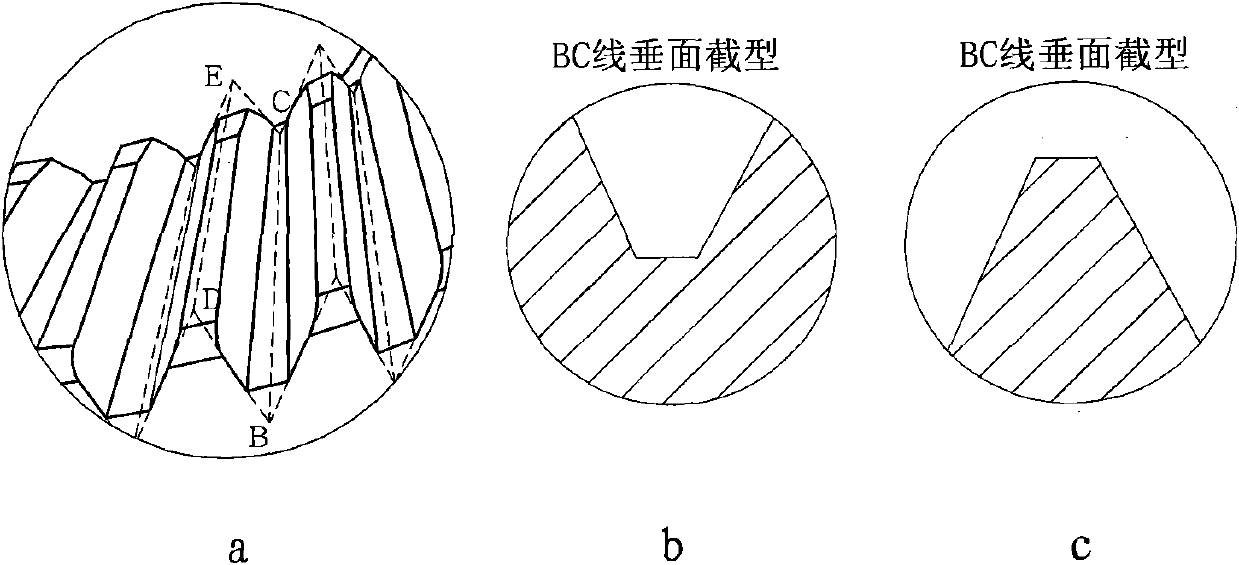

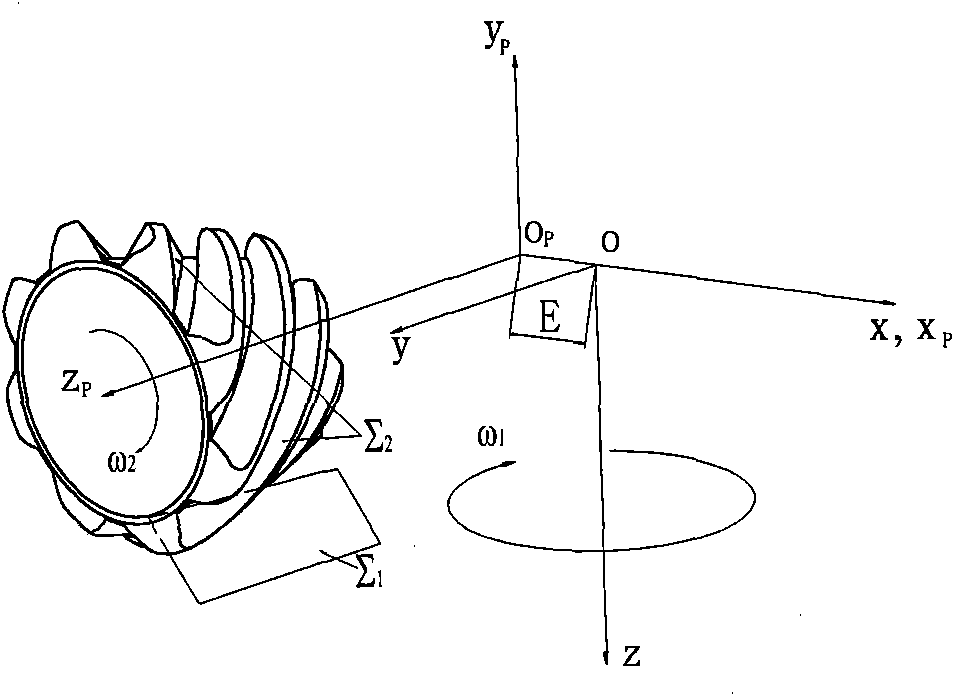

Design method of hypoid gear pair

InactiveCN101982673ASimplify the design processImprove tooth surface accuracyToothed gearingsPortable liftingState of artEngineering

The invention discloses a design method of a hypoid gear pair, aiming at solving the problem of difficulty in designing the hypoid gear pair by using the prior art. The design method of the hypoid gear pair comprises the following steps: 1, taking a plane as a hypoid gear pair transmission forming principle for a big gear tooth surface; 2, determining the geometric technical parameters of a big gear tooth surface shape; 3, determining the geometric technical parameters of a small gear tooth surface shape; and 4, since the gear parameters refers to right-handed rotation of a big gear and left-handed rotation of a small gear, when the big gear is in right-handed rotation and the small gear is in left-handed rotation, dereferencing opposite numbers for the parameters related to the y axle in the parameters. The determination of the geometric technology parameters of the big gear tooth surface shape comprises the following steps: definition of representing the geometric parameters of the big gear tooth surface shape, determination of the coordinates of an M point, determination of the component expression formula of a vector shown in the specification, solution of a tooth-shaped unit vector shown in the specification, solution of another tooth-shaped unit vector shown in the specification, solution of the normal vector shown in the specification one side tooth surface sigma2, determination of the equation of the one side tooth surface sigma2, determination of the equation of the other side tooth surface sigma1, determination of the equation of a tooth surface sigma1theta and formation of the gear teeth of the gear in array.

Owner:JILIN UNIV

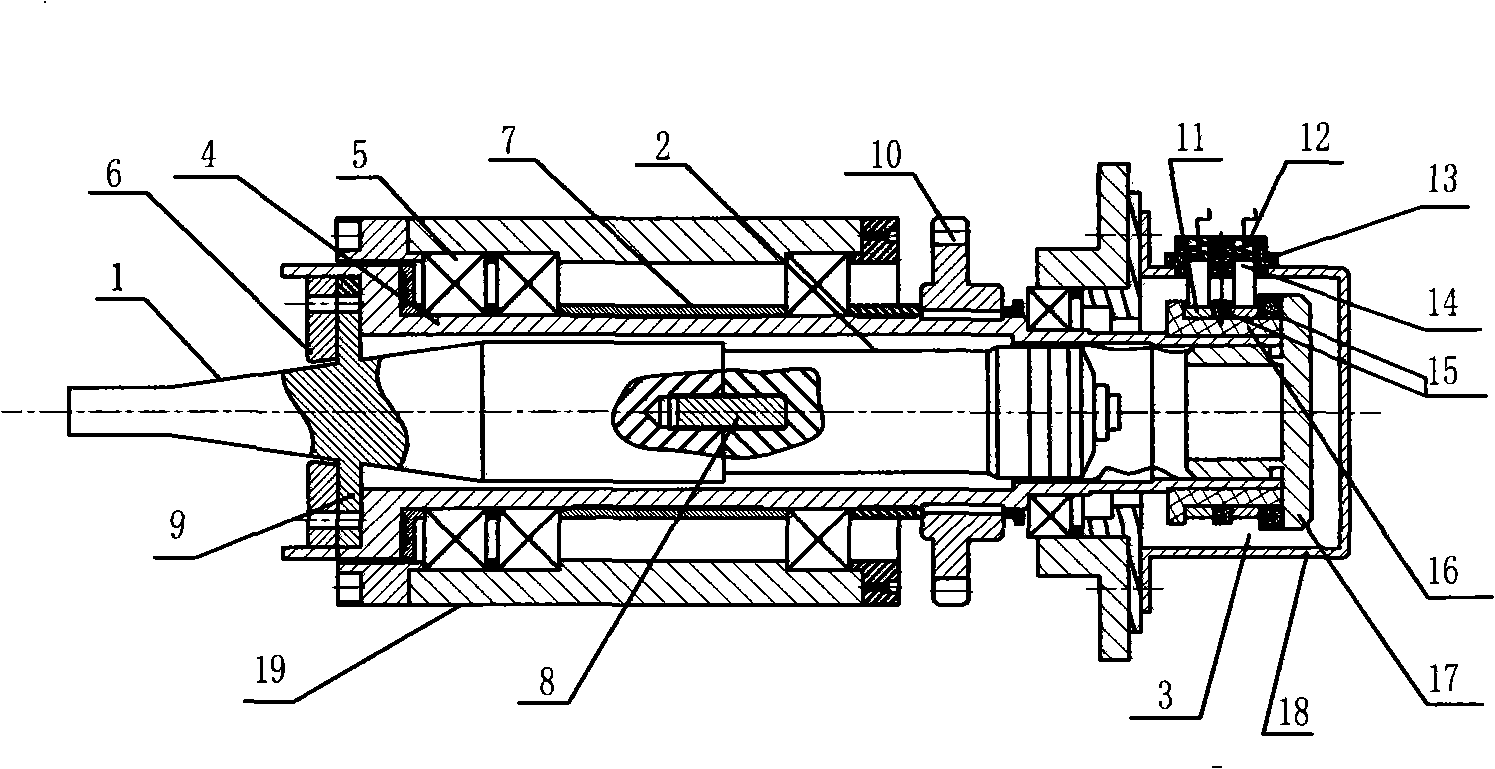

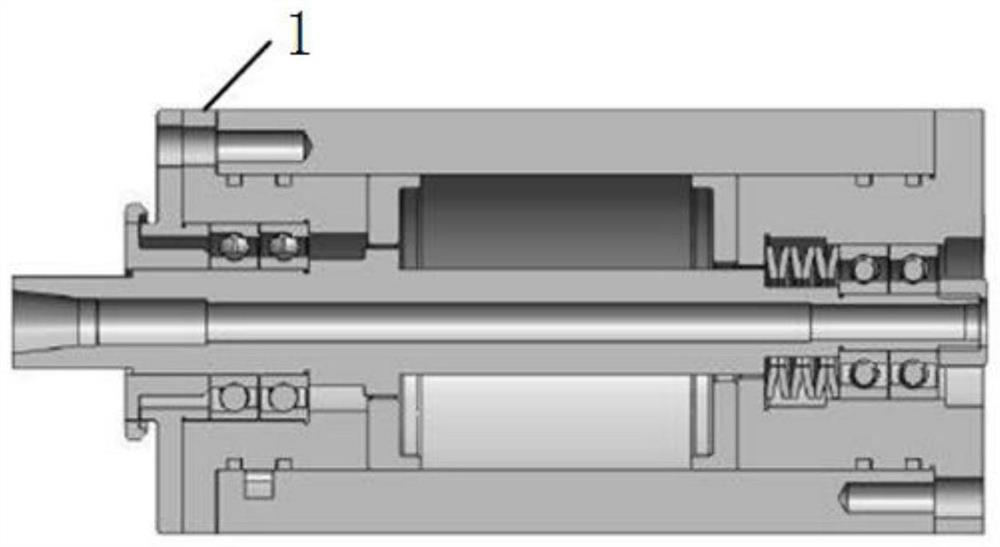

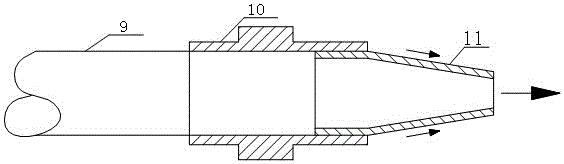

Piezoelectric type ultrasonic rotary main shaft device

InactiveCN101540540AHighlight substantiveGuaranteed wear resistanceDynamo-electric machinesSuperconductor elements usageTransformerTransducer

The invention relates to a piezoelectric type ultrasonic rotary main shaft device, which is provided with a main shaft, a shaft housing, an amplitude transformer, a transducer and a current-collecting device and is characterized in that the main shaft is internal and external composite axes; the external shaft is a hollow shaft and is provided with a supporting bearing; the supporting bearing is compressed and fixed by a front bearing flange and a back bearing flange between the external shaft and the shaft housing; a positioning spacer and a sleeve are arranged between each bearing; the amplitude transformer is provided with a flange part which is connected with the end socket of the external shaft by a flange and a bolt; only the flange at the wave node of the amplitude transformer is connected with the external shaft; the middle part of the external shaft is provided with a drive gear which transfers rotary power. High-frequency vibration signals generated by a supersonic generator provided by the exterior are transferred to the transducer by the current-collecting device of rotary motion; the axial supersonic vibration generated by the piezoelectric chip of the transducer is amplified by the amplitude transformer, and then acts on a tool head. The main shaft device has simple and compact structure, is easy to assemble and maintain, has high ultrasonic energy transmission efficiency, and can process parts with larger size.

Owner:ZHONGBEI UNIV

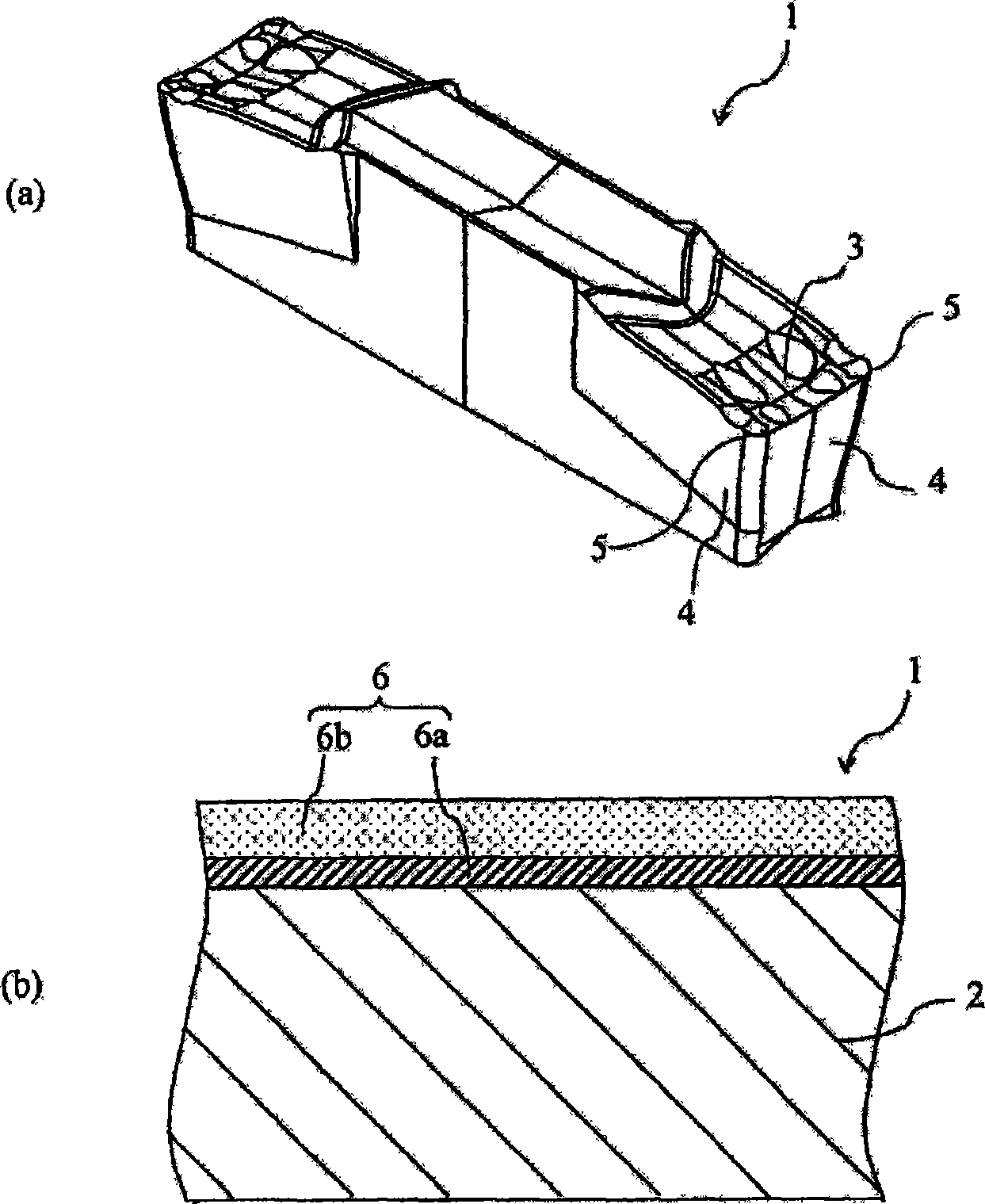

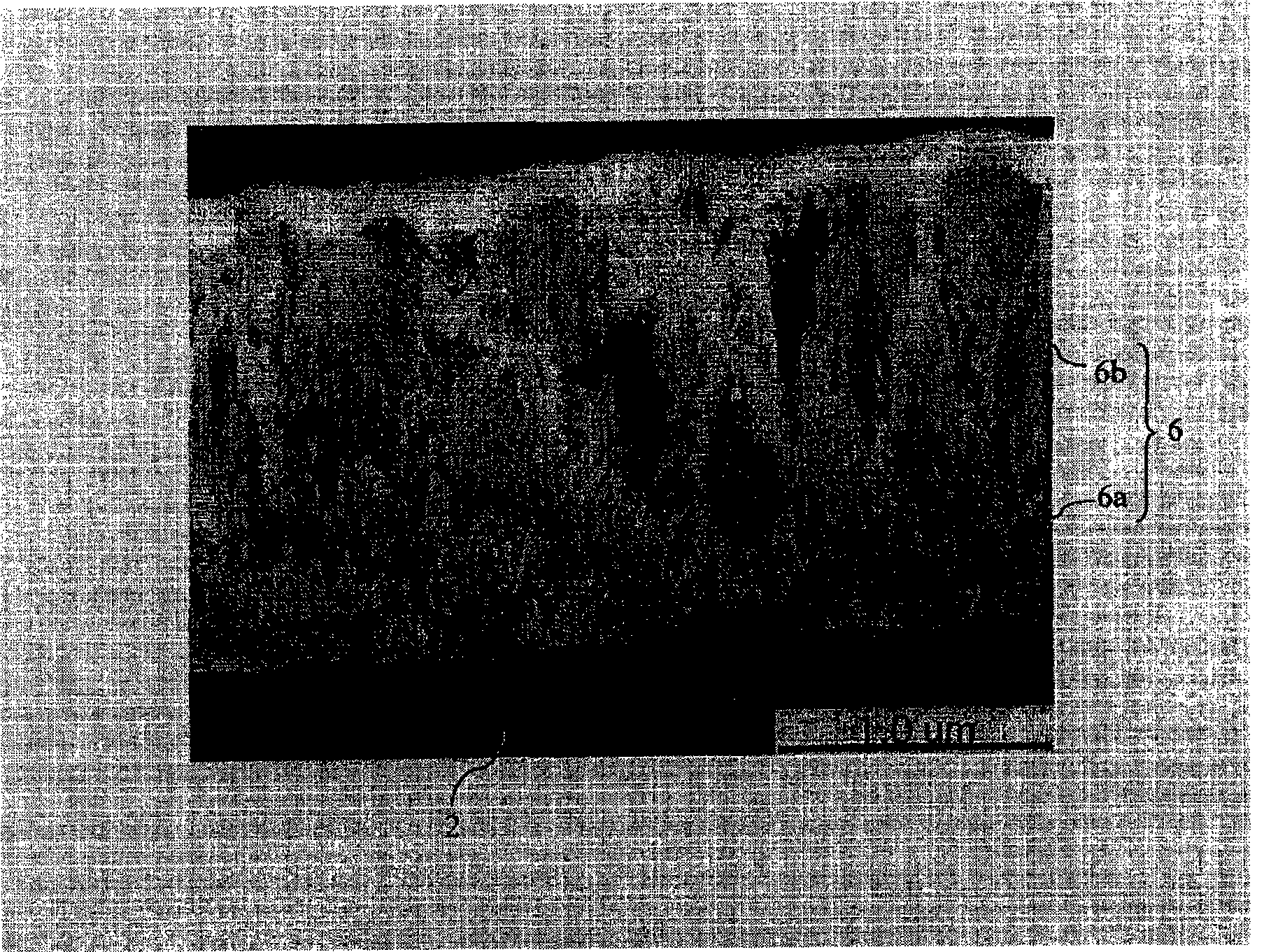

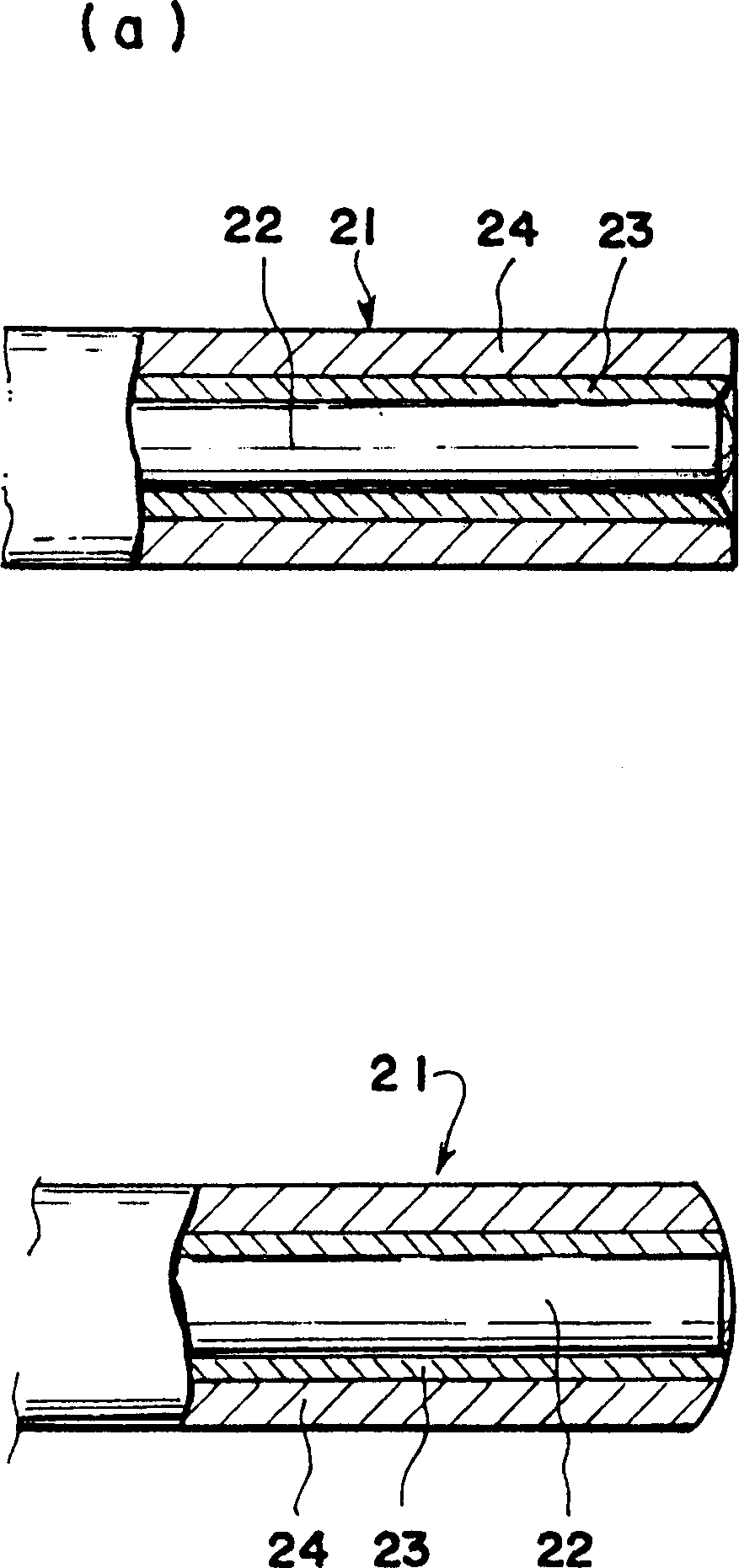

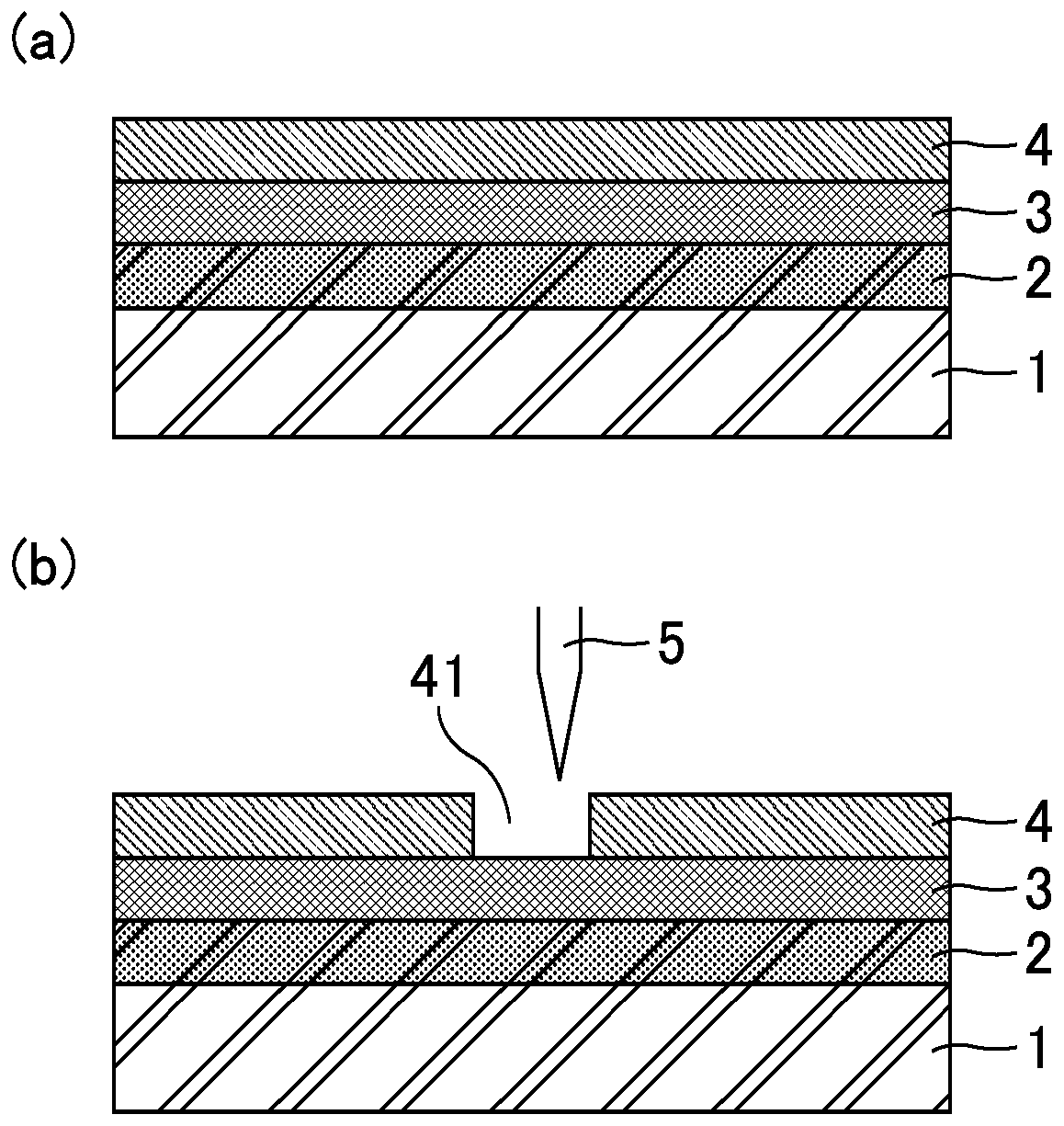

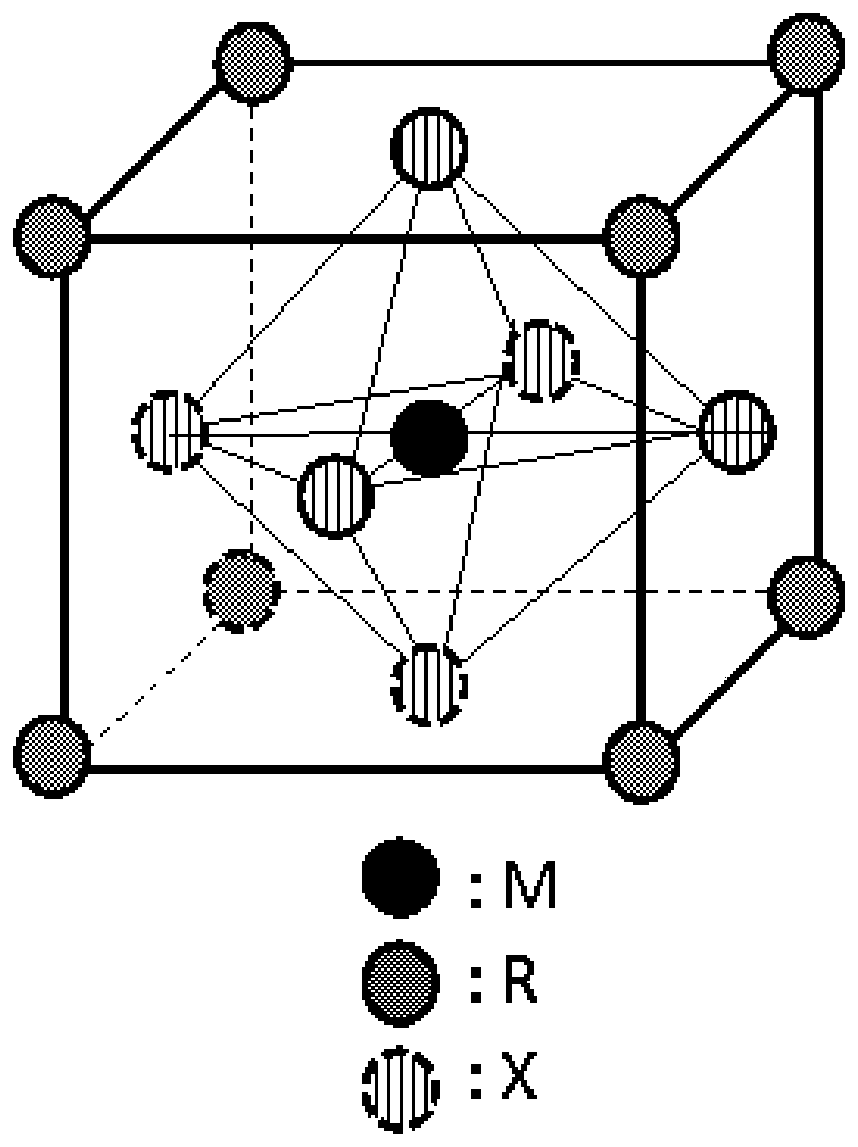

Surface-coated tool

InactiveCN101400465AImprove wear resistanceImprove chip resistanceVacuum evaporation coatingSputtering coatingRare-earth elementCrystallization

A surface coated tool including a substrate, and stacked layers composed of two coating layers represented by the following general formula (1) on the substrate is provided. A first coating layer to be coated on the surface of the substrate, which has a thickness of 0.1 to 1 [mu]m, is composed of a granular crystal having a mean crystal diameter of 0.01 to 0.1[mu]m. A second coating layer to be coated on the surface of the first coating layer, which has a thickness of 0.5 to 5 [mu]m, is composed of columnar crystal grown in a direction perpendicular to the substrate, and the columnar crystal has a mean crystal width of 0.05 to 0.3[mu]m in a direction parallel to the substrate while a mean crystal width thereof is larger than the mean crystal diameter of the first coating layer. [Formula 3] M 1 - a Al a (C b N 1-b ) (1) wherein, M represents at least one metal element selected from the group consisting of the elements of Groups 4, 5 and 6 of the periodic table, Si and rare earth elements, ''a'' satisfies the relation of 0.25 a 0.75, and ''b'' satisfies the relation of 0 b 1.

Owner:KYOCERA CORP

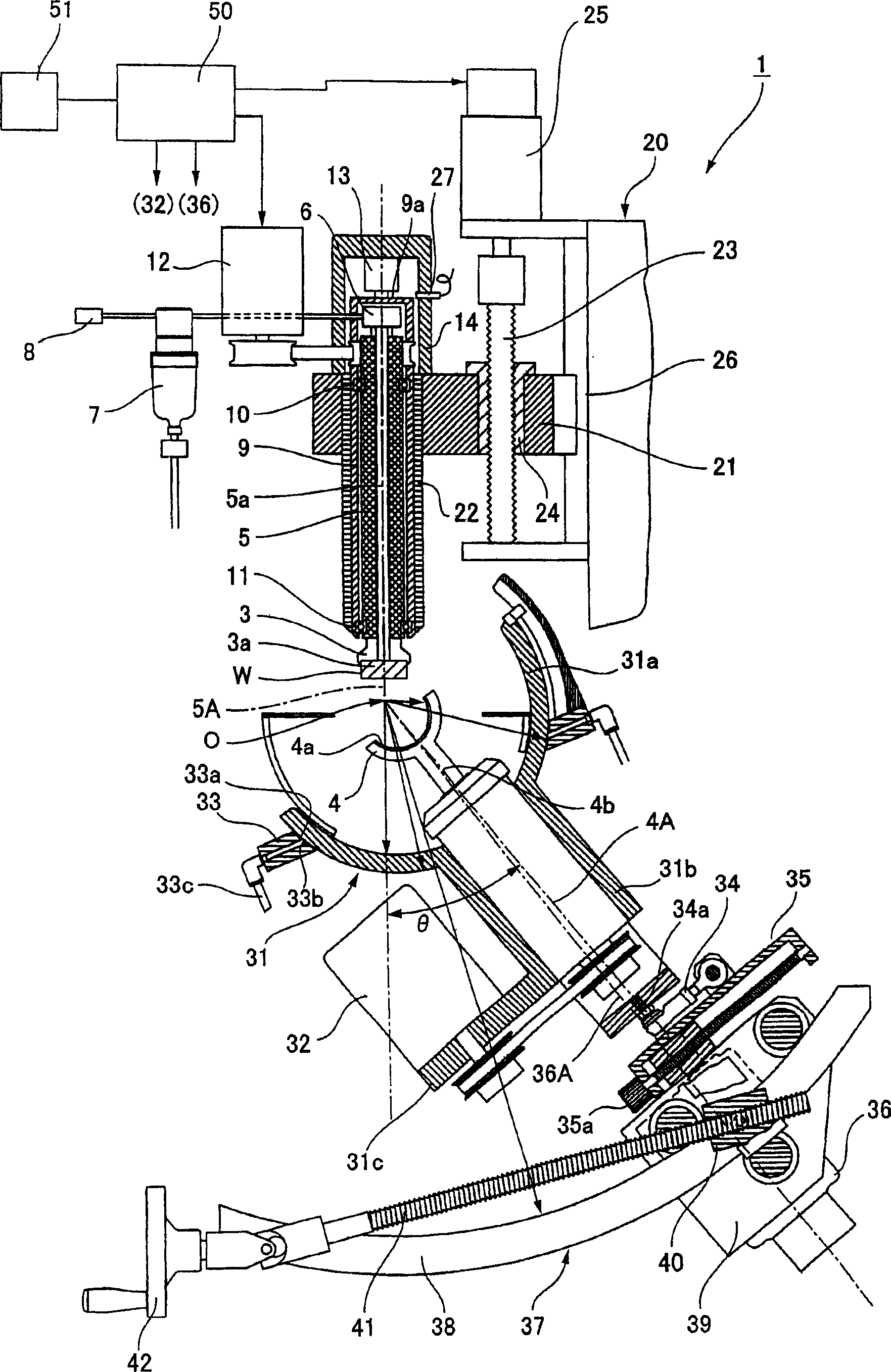

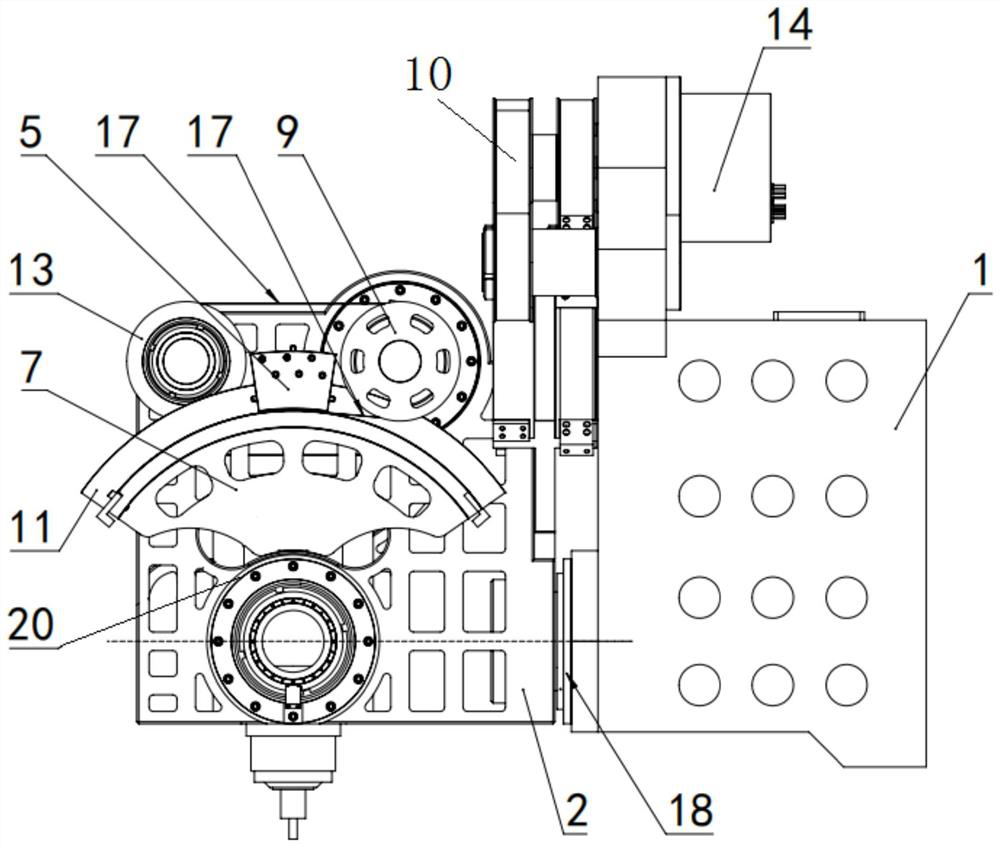

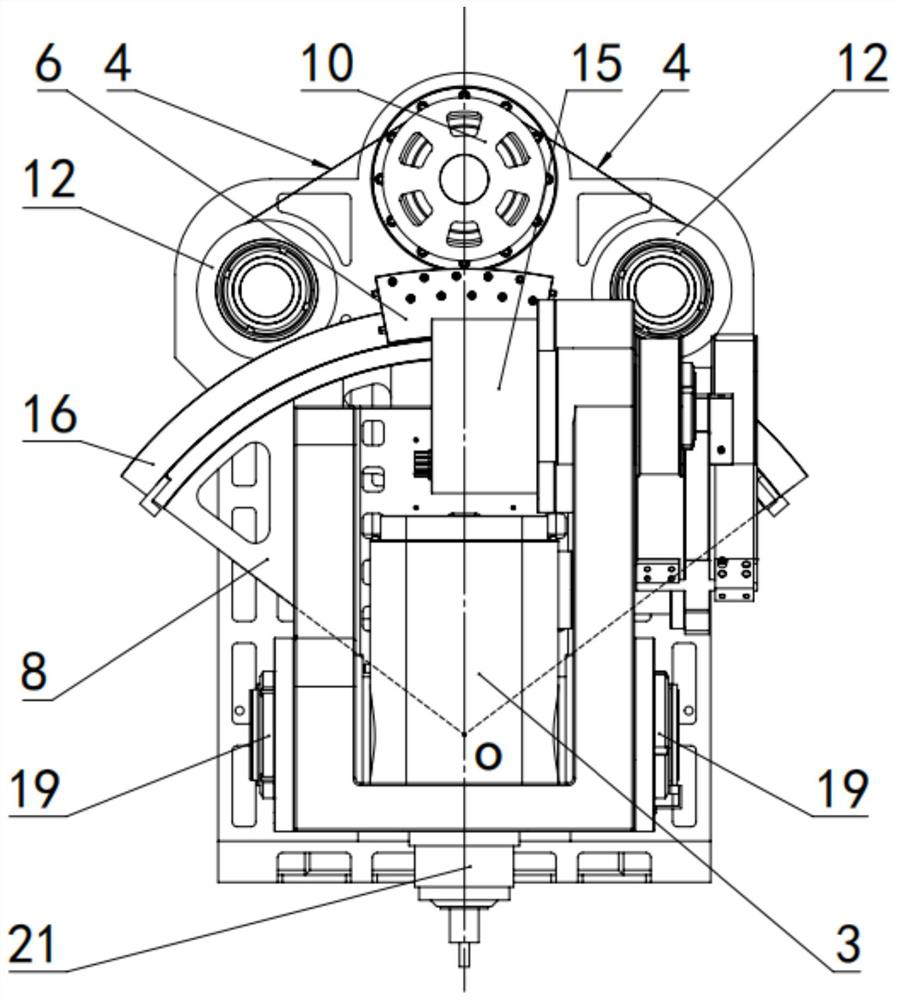

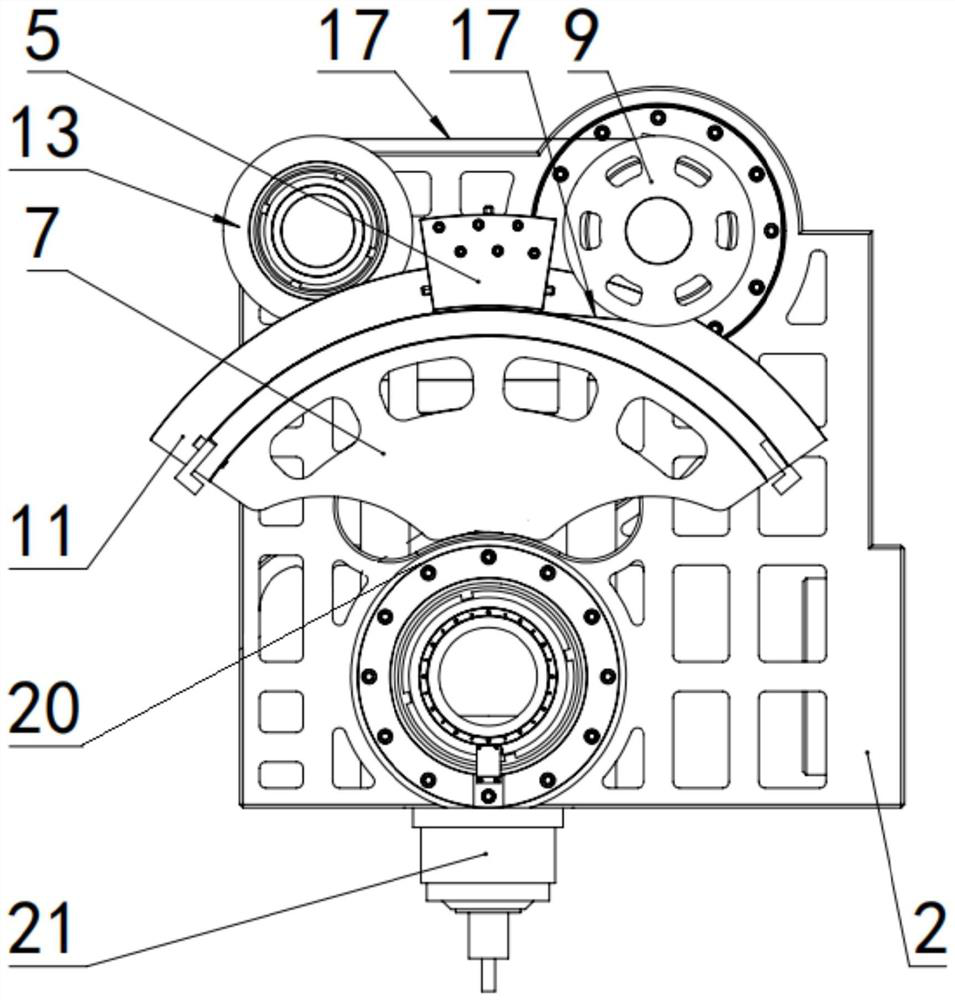

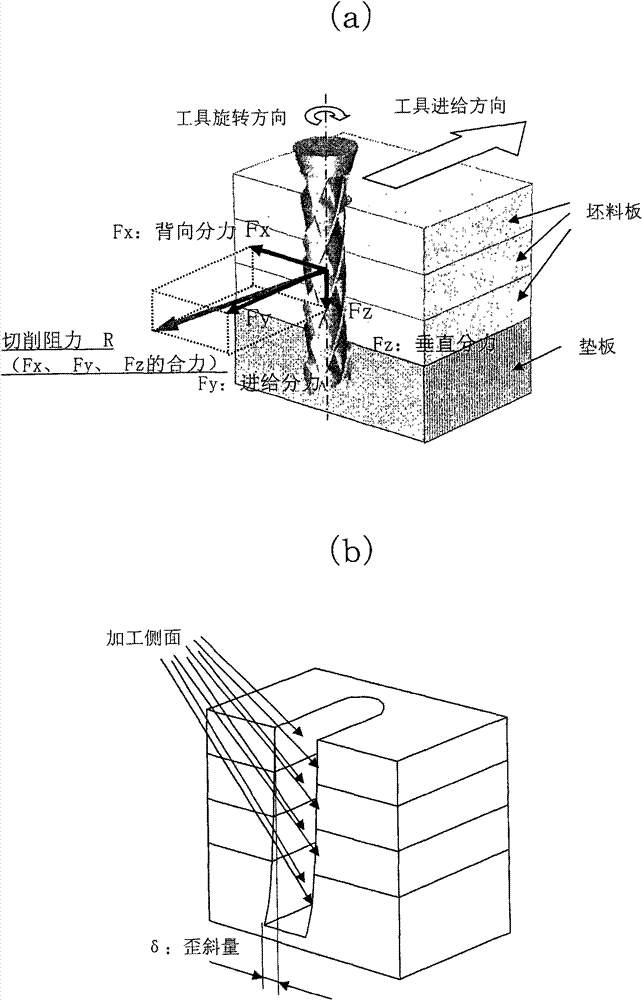

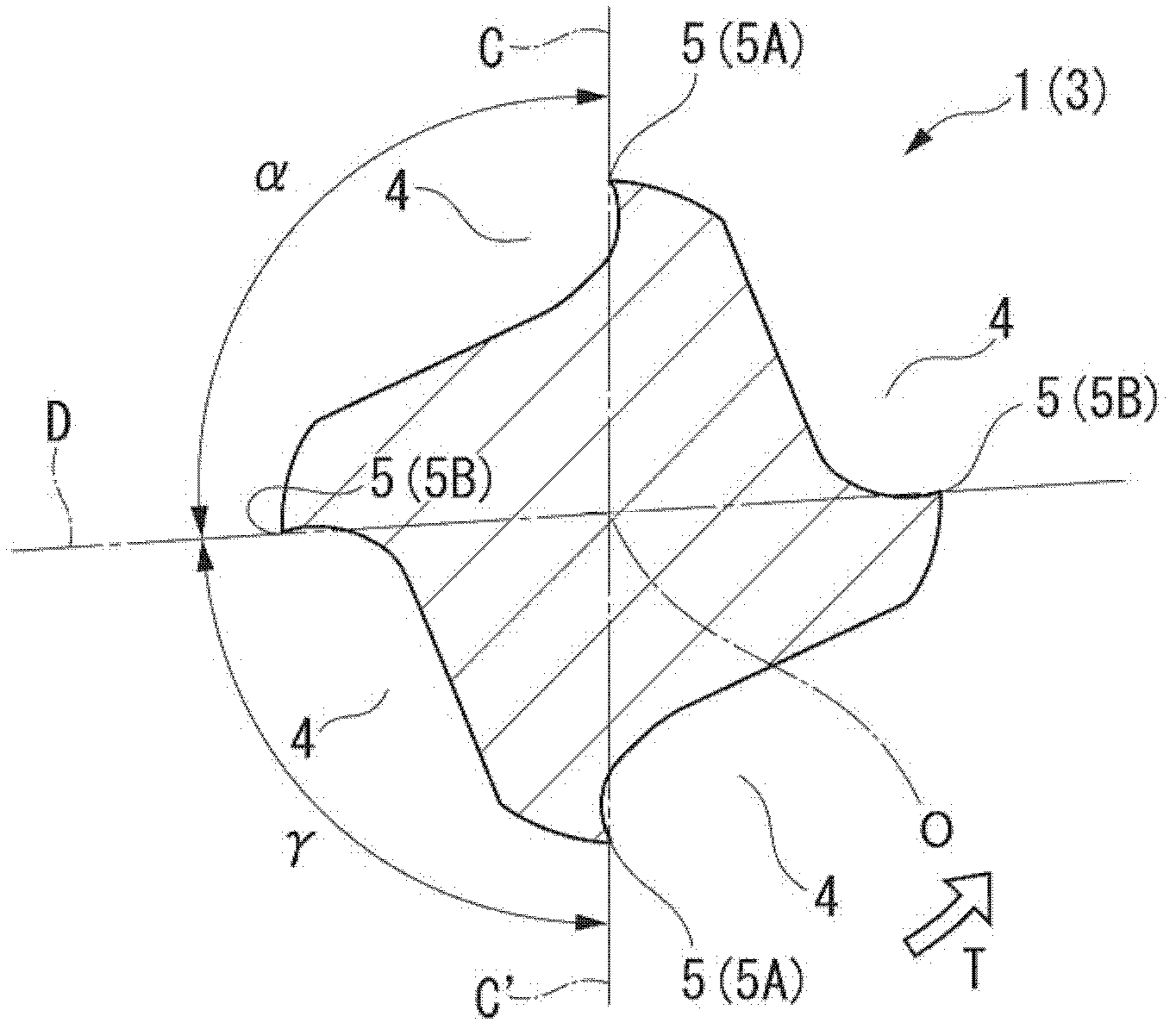

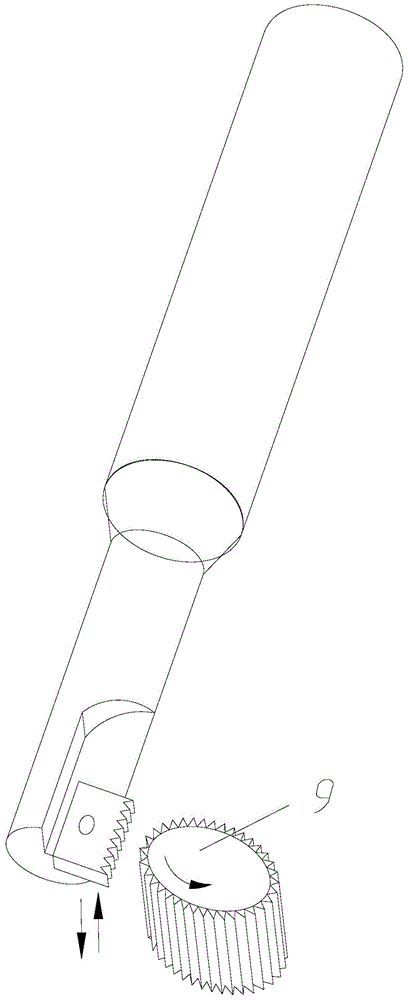

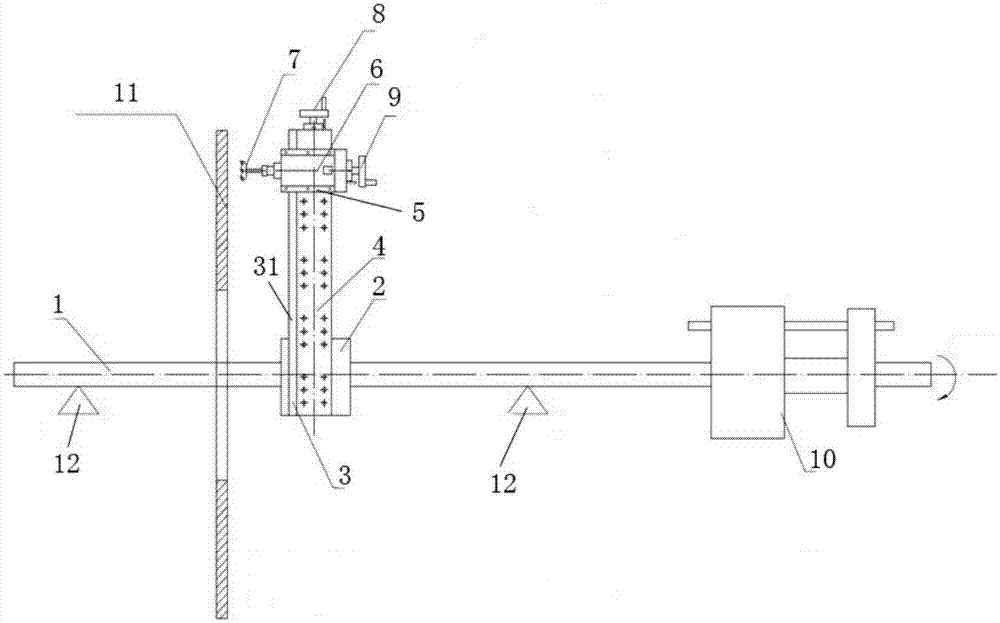

Method and machine tool for machining hypoid gear pair

The invention discloses a method and a machine tool for machining a hypoid gear pair and aims to solve the problem that the hypoid gear pair is difficultly machined in the prior art. The machining method comprises the following steps of: 1, machining a big gear surface, namely 1) machining the right gear surface of a big gear; and 2) machining the left gear surface of the big gear; and 2, machining a small gear surface, namely 1) machining the left gear surface of a small gear; and 2) machining the right gear surface of the small gear. The machining machine tool comprises a workpiece shaft, a power head, a tilting working table, a rotary working table, an XYZ working table and a body, wherein the workpiece shaft replaces an original power spindle head of the conventional machine tool; the rotary working table is fixedly arranged on the XYZ working table and makes rotating axes of the rotary working table and the workpiece shaft coplanar; the tilting working table is fixedly arranged on the rotary working table; an inclined angle chi is formed between the upper surface of the tilting working table and the bottom surface of the tilting working table; and the power head is fixedly arranged on the tilting working table through a bolt, a guide rail and a guide rail groove.

Owner:JILIN UNIV

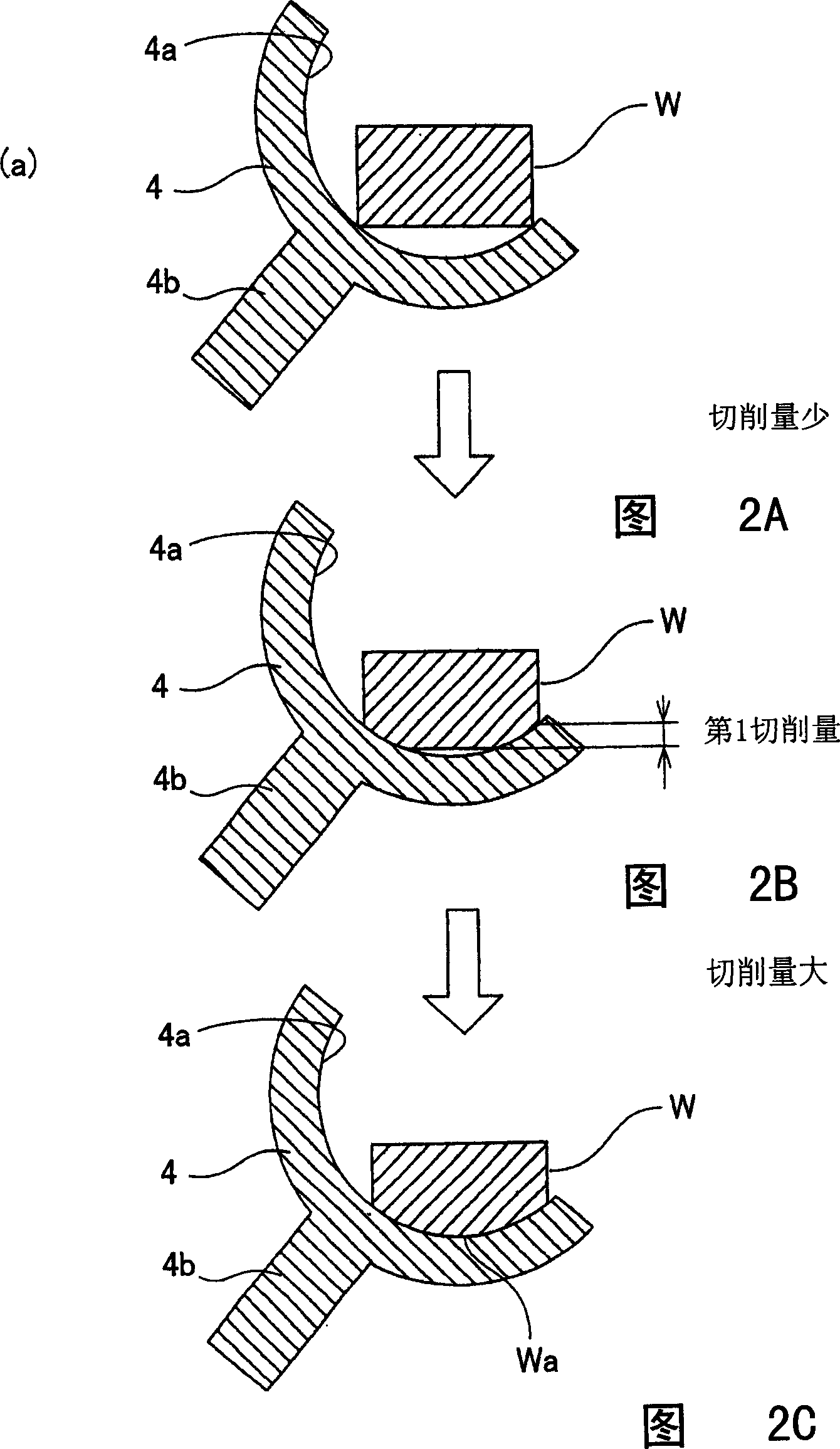

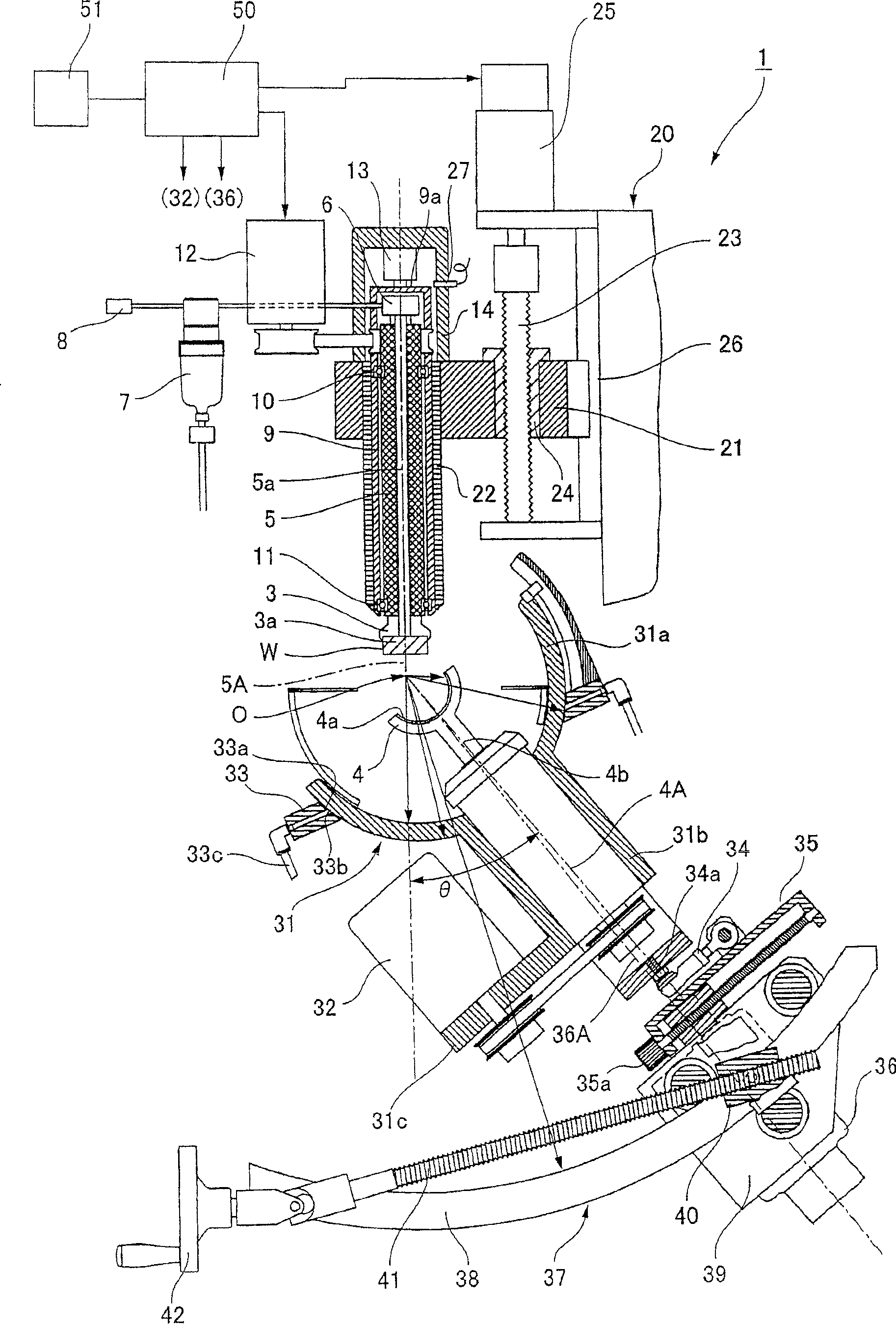

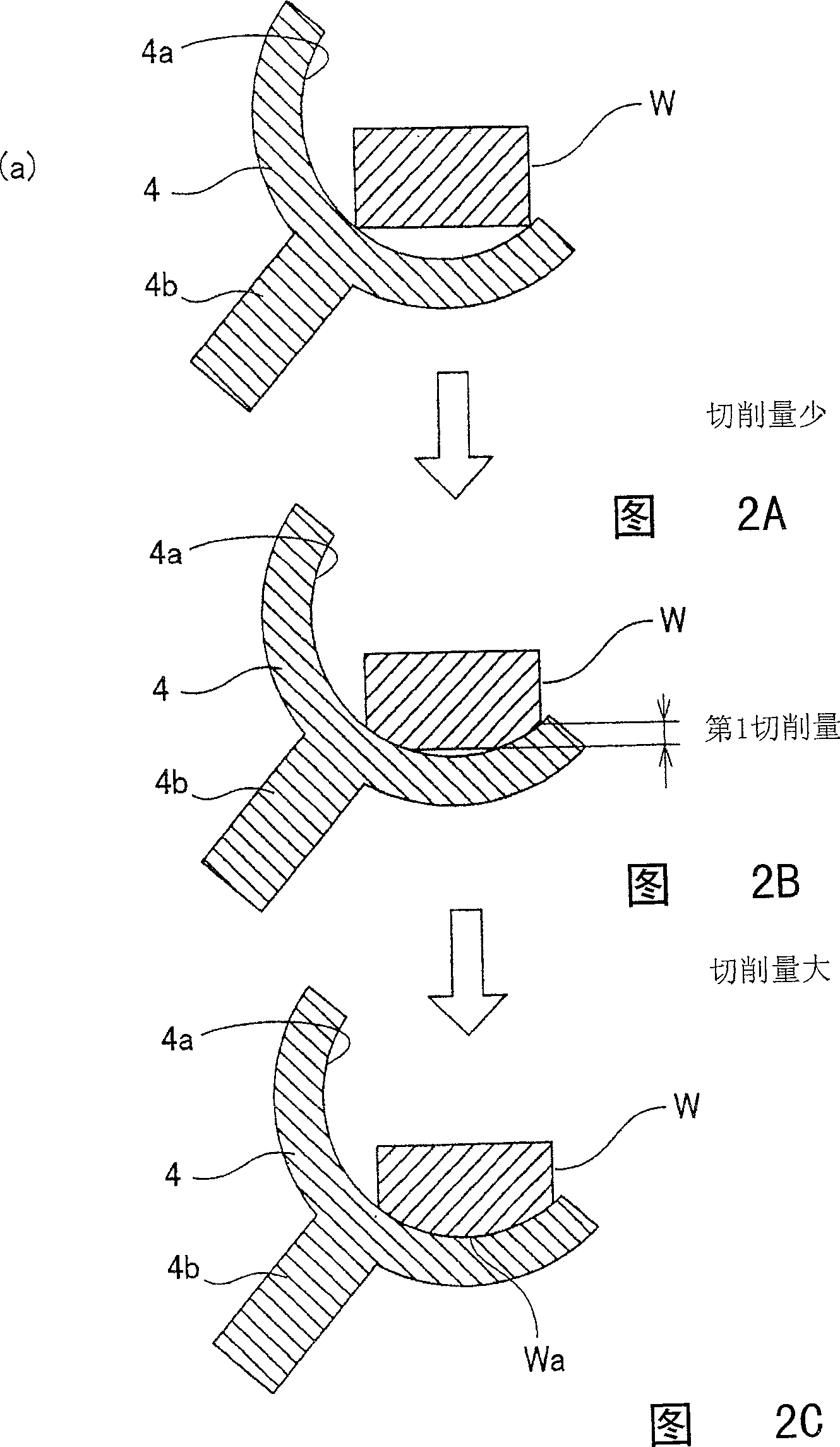

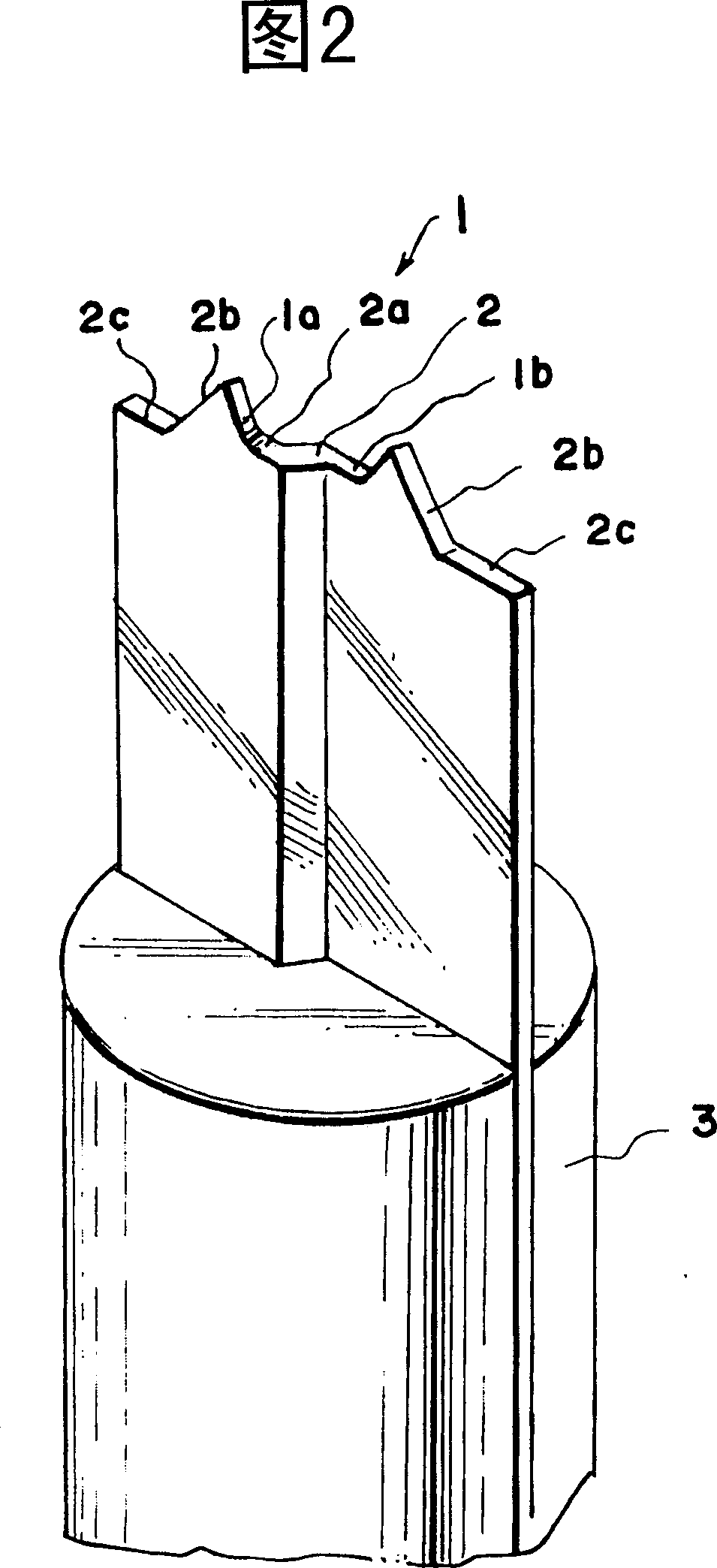

Lens grinding method and device

InactiveCN1836838AEfficient MachiningAvoid wastingOptical surface grinding machinesCircular coneEngineering

In the lens grinding apparatus of the present invention, while the grinding bowl-shaped tool with spherical grinding surface rotates around the rotary central line through the sphere center and the rotary central line performs sphere center swinging to describe one cone with the sphere center as vertex, the lens blank is fed in specified rate in the feeding direction through the sphere center and pushed towards the bowl-shaped tool for grinding, with the cutting speed being altered based on the lens blank feeding speed. The said lens grinding process can cut lens material in high efficiency and grind spherical lens with small curvature in high precision.

Owner:HARUCHIKA

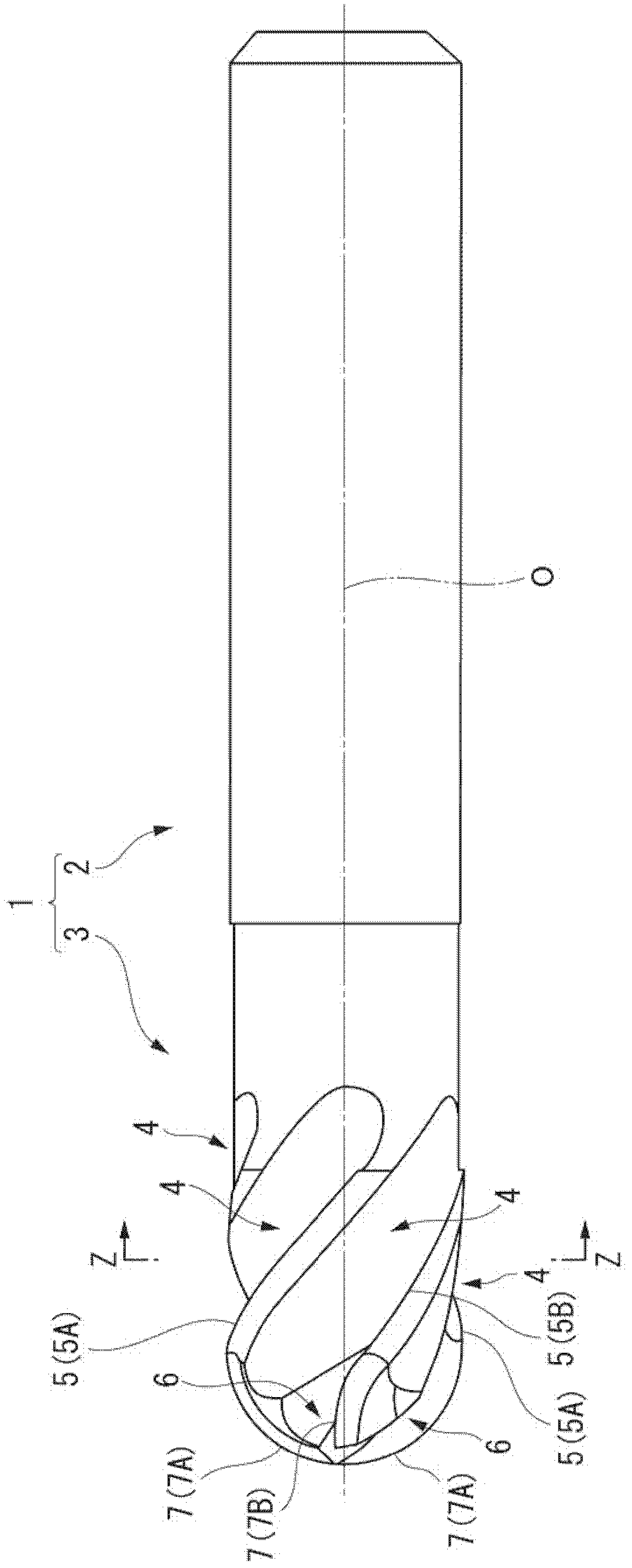

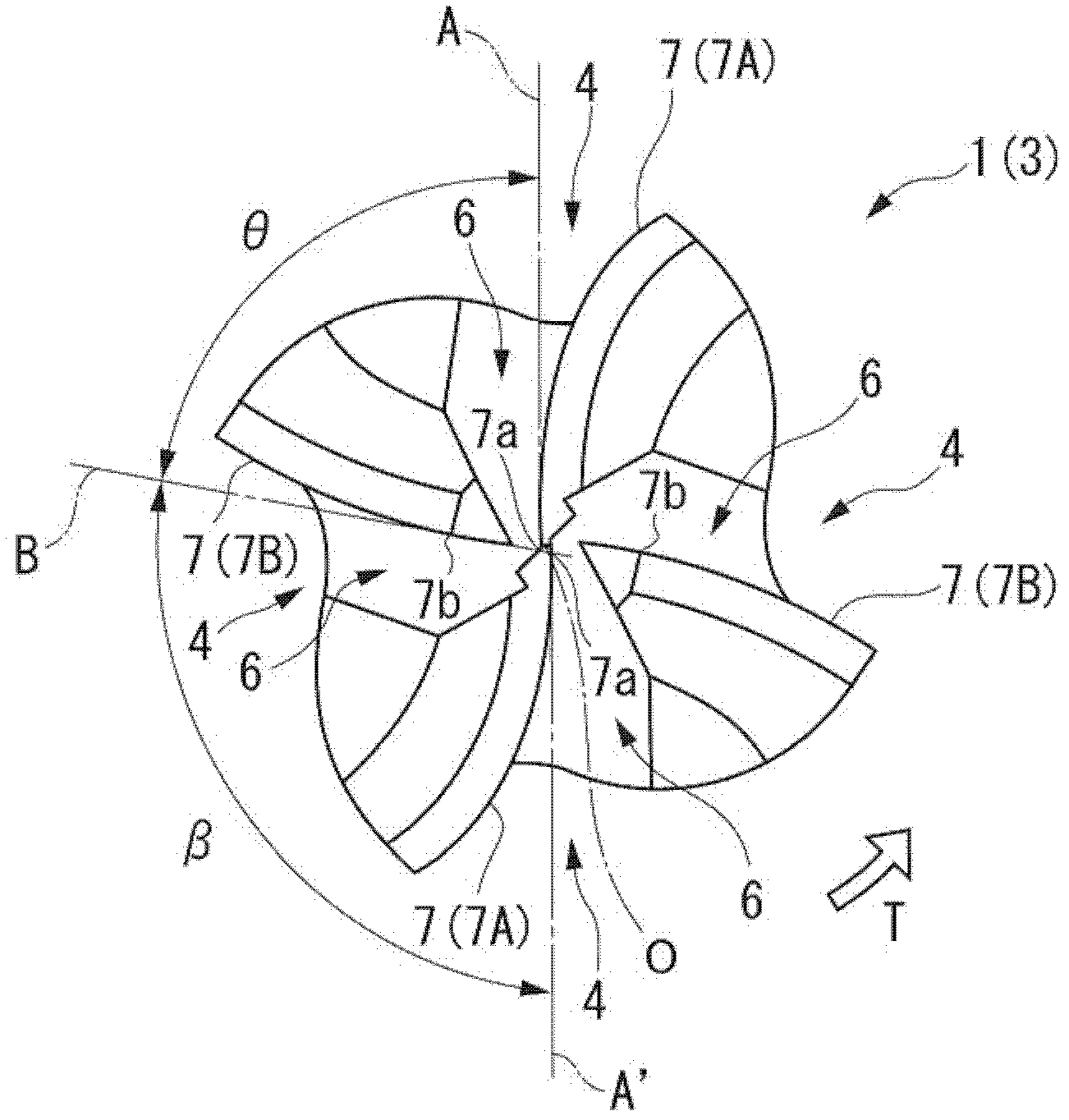

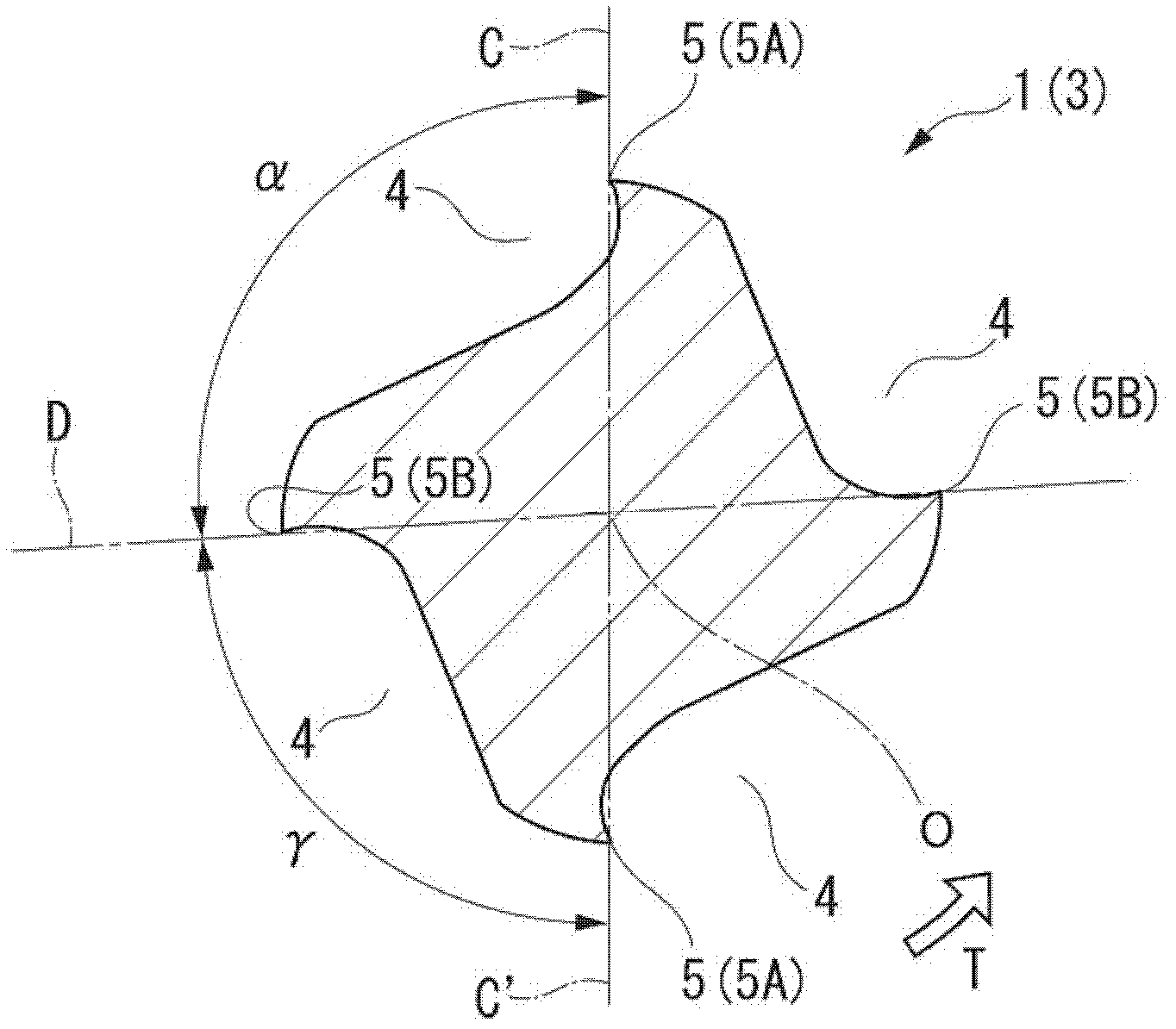

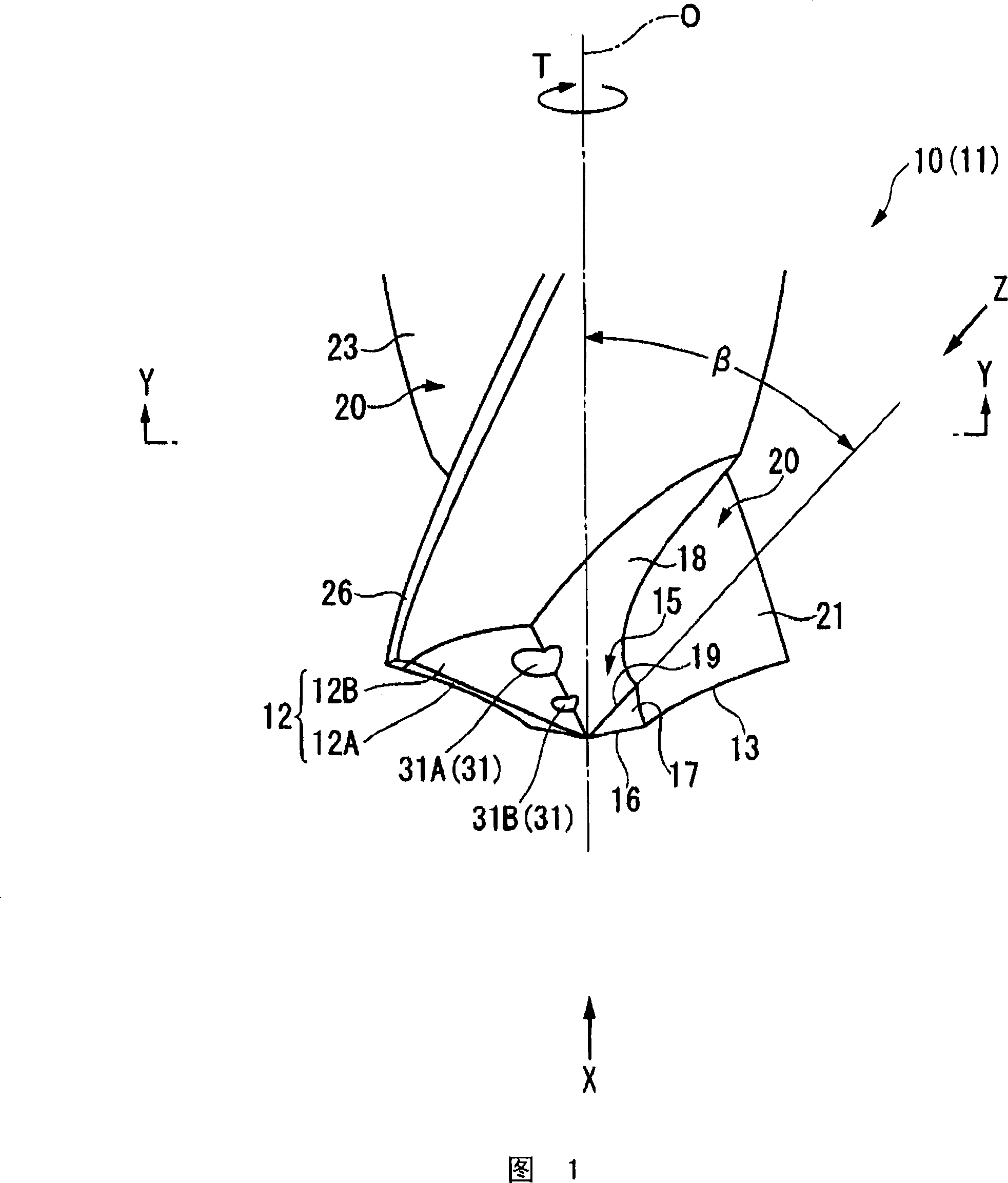

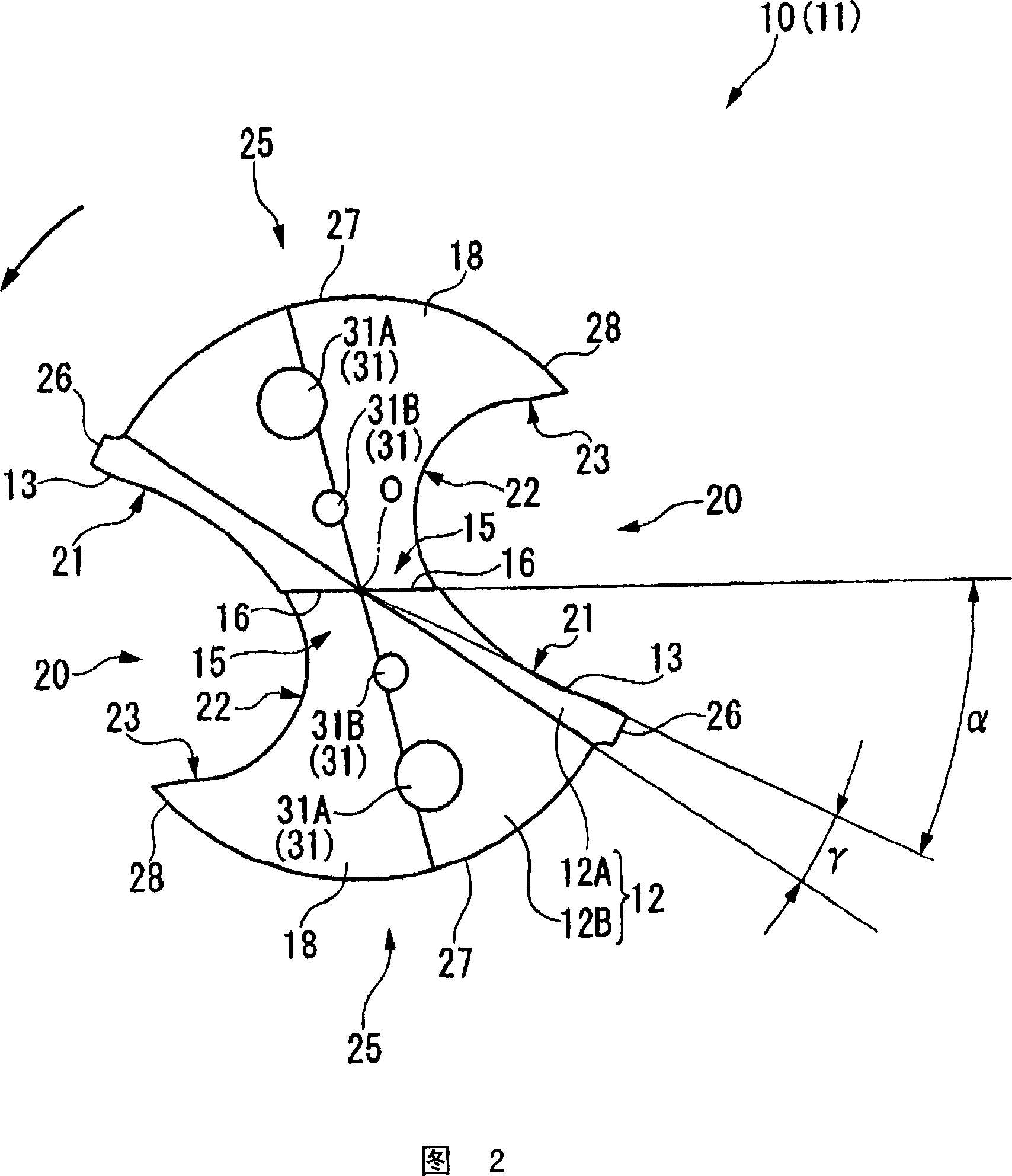

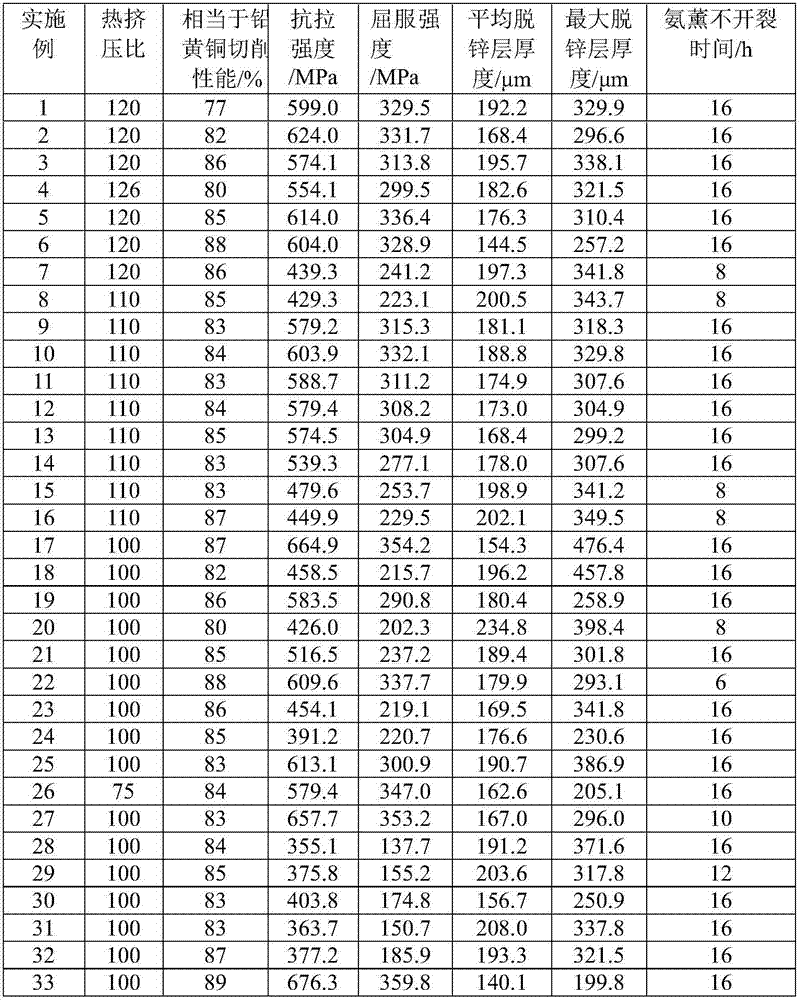

Ball end mill

ActiveCN102497950AIncrease resistanceEasy loadingMilling cuttersShaping cuttersMilling cutterEngineering

In the tip section of an end mill body which is rotated about the axis thereof, a plurality of end cutting edges are formed in such a way as to extend from the inside of the front end of the tip section to the outside of the rear end thereof. In the outer periphery section of the end mill body, there are formed a plurality of peripheral cutting edges which extend to the rear end in such a way as to string out along the outer ends of the end cutting edges. Some of the plurality of end cutting edges are long end cutting edges extending from near that portion of the axis of the end mill body which is in the tip section. The angle which is formed, in an arbitrary cross section intersecting the axis at right angles, by the straight line that connects the axis to a peripheral cutting edge stringing out along a long end cutting edge and by the straight line that connects the axis to a peripheral cutting edge stringing out along the nearest end cutting edge positioned forward of the long end cutting edge in the rotation direction of the end mill, is larger than the angle which is formed, in a view looking at the tip section in the direction of the axis, by the tangent line at the inner end of the aforementioned long end cutting edge and the tangent line at the inner end of the nearest end cutting edge positioned forward of the long end cutting edge in the rotation direction of the end mill.

Owner:MITSUBISHI MATERIALS CORP

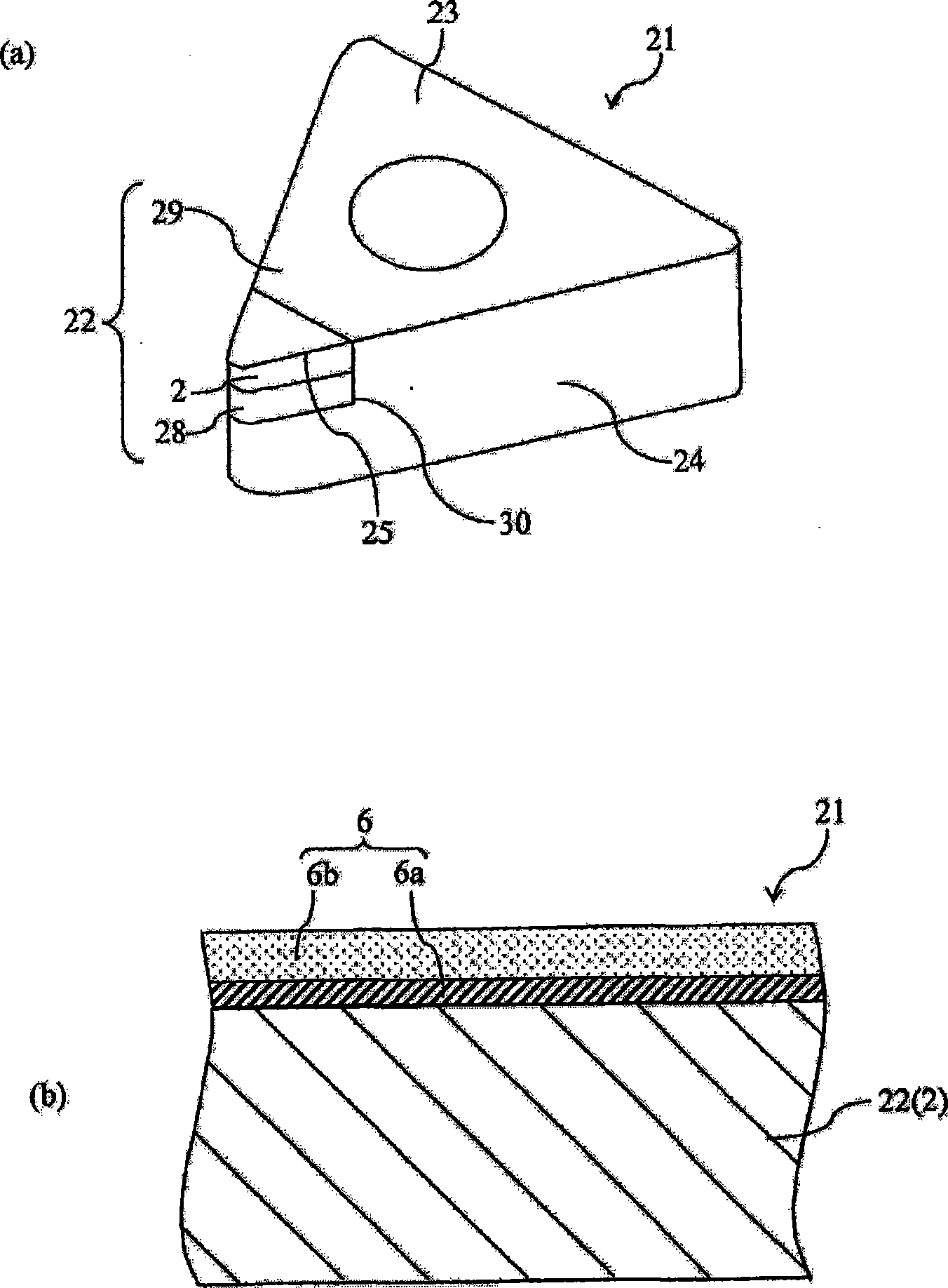

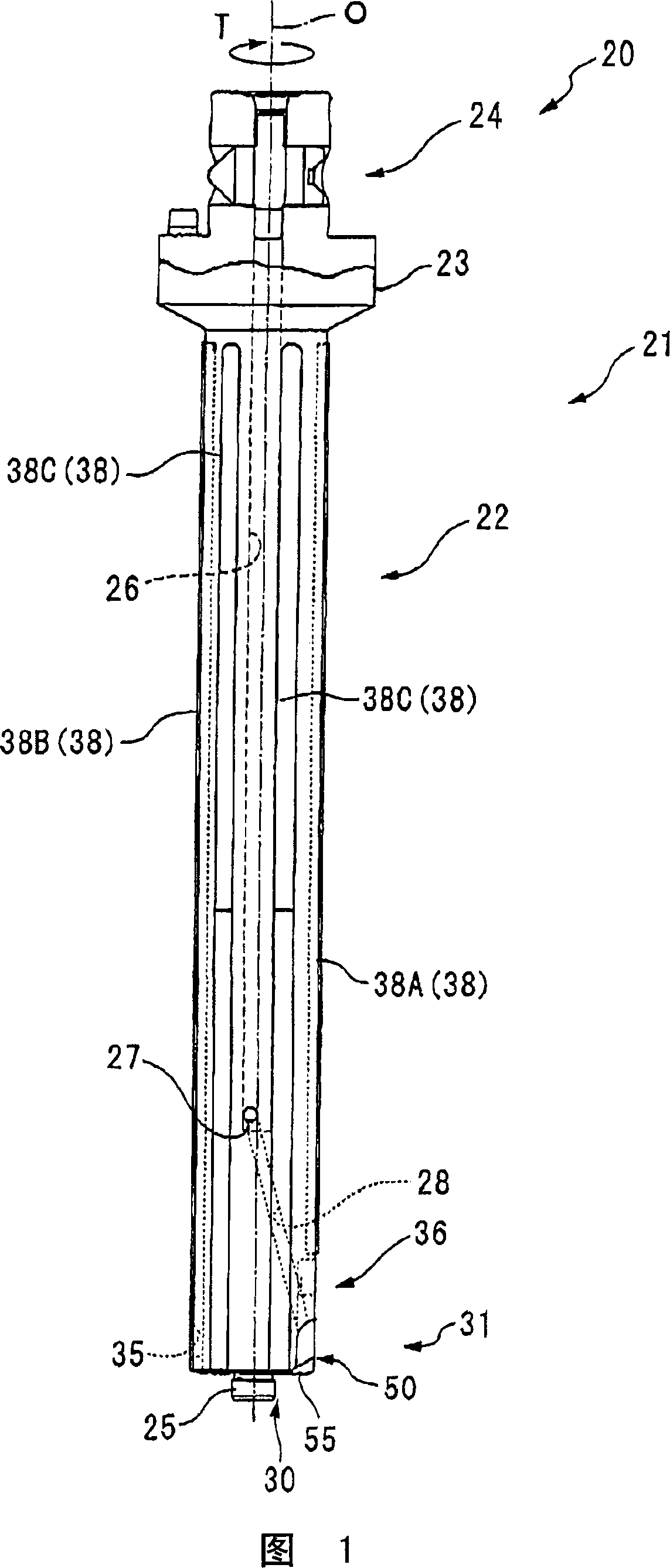

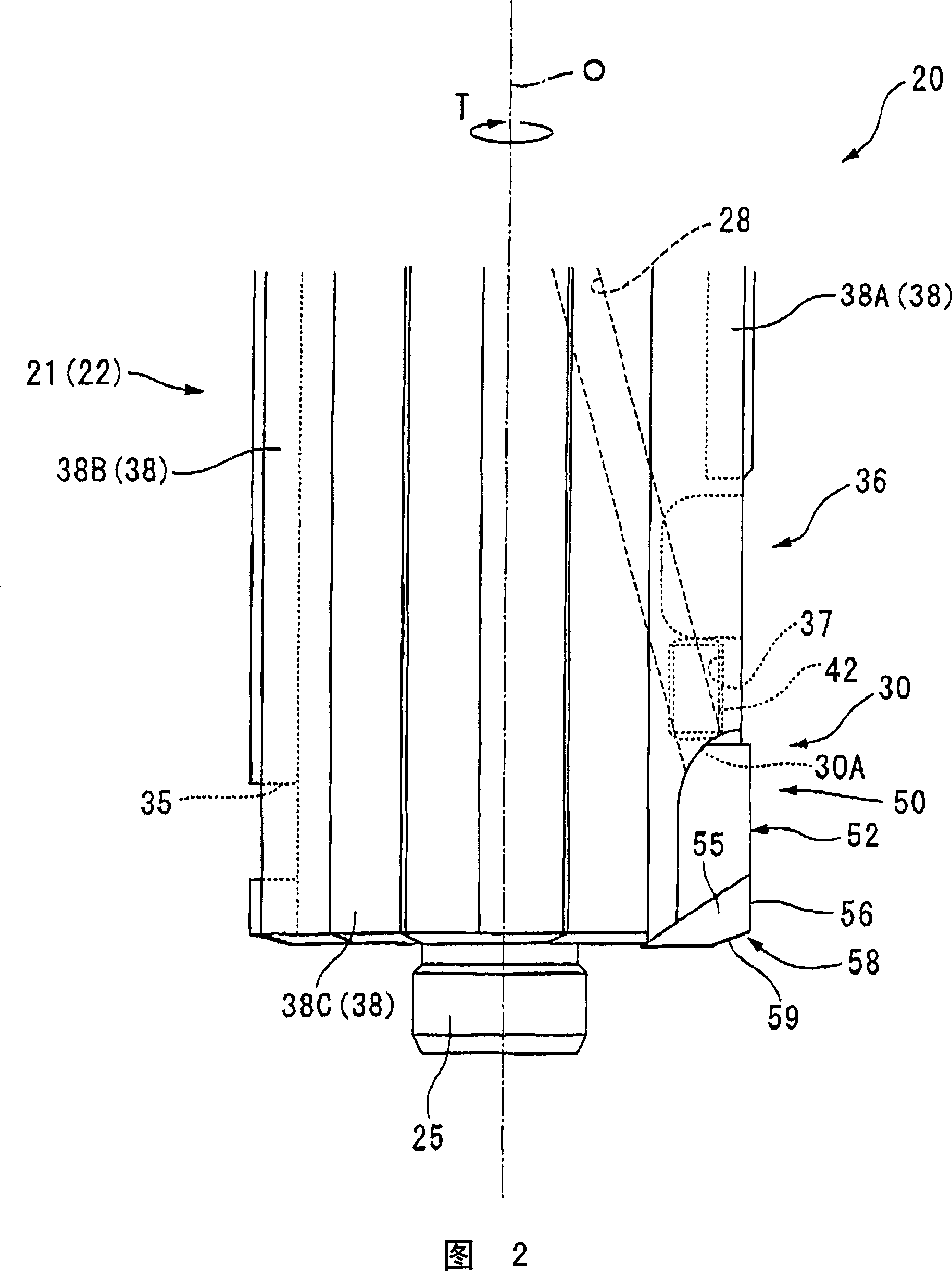

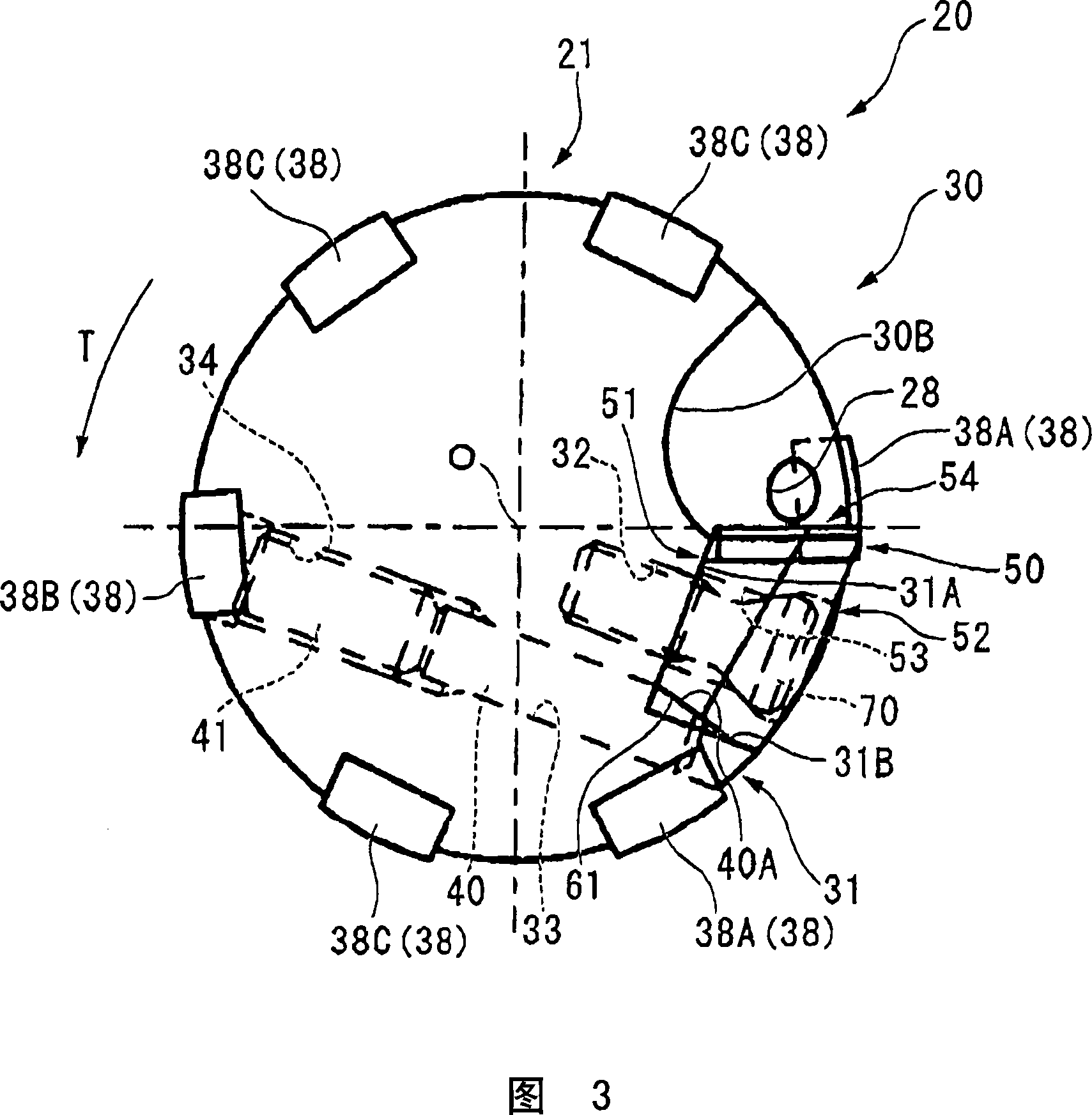

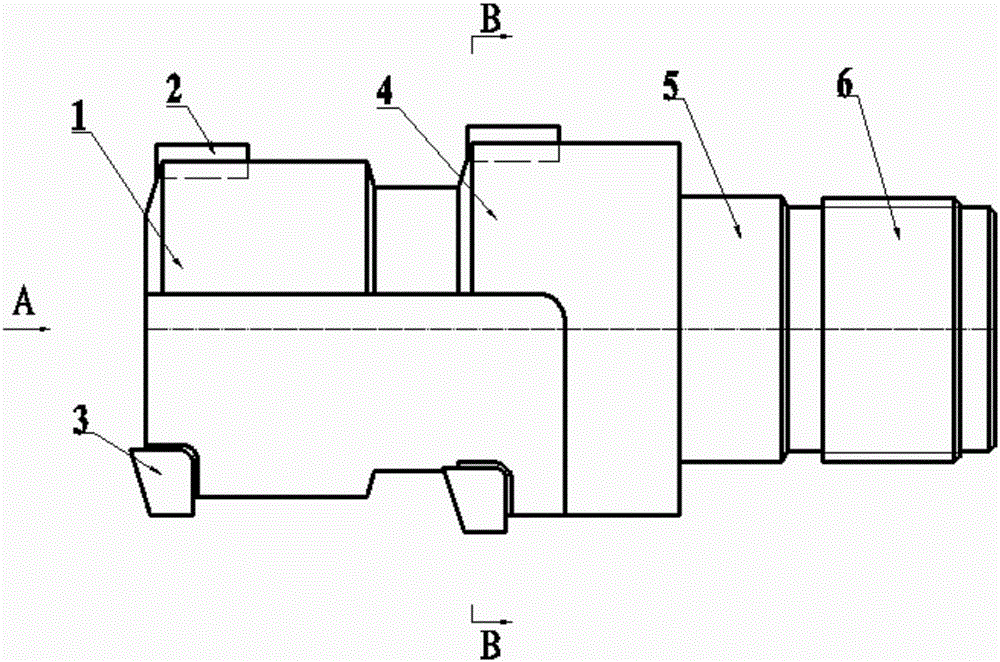

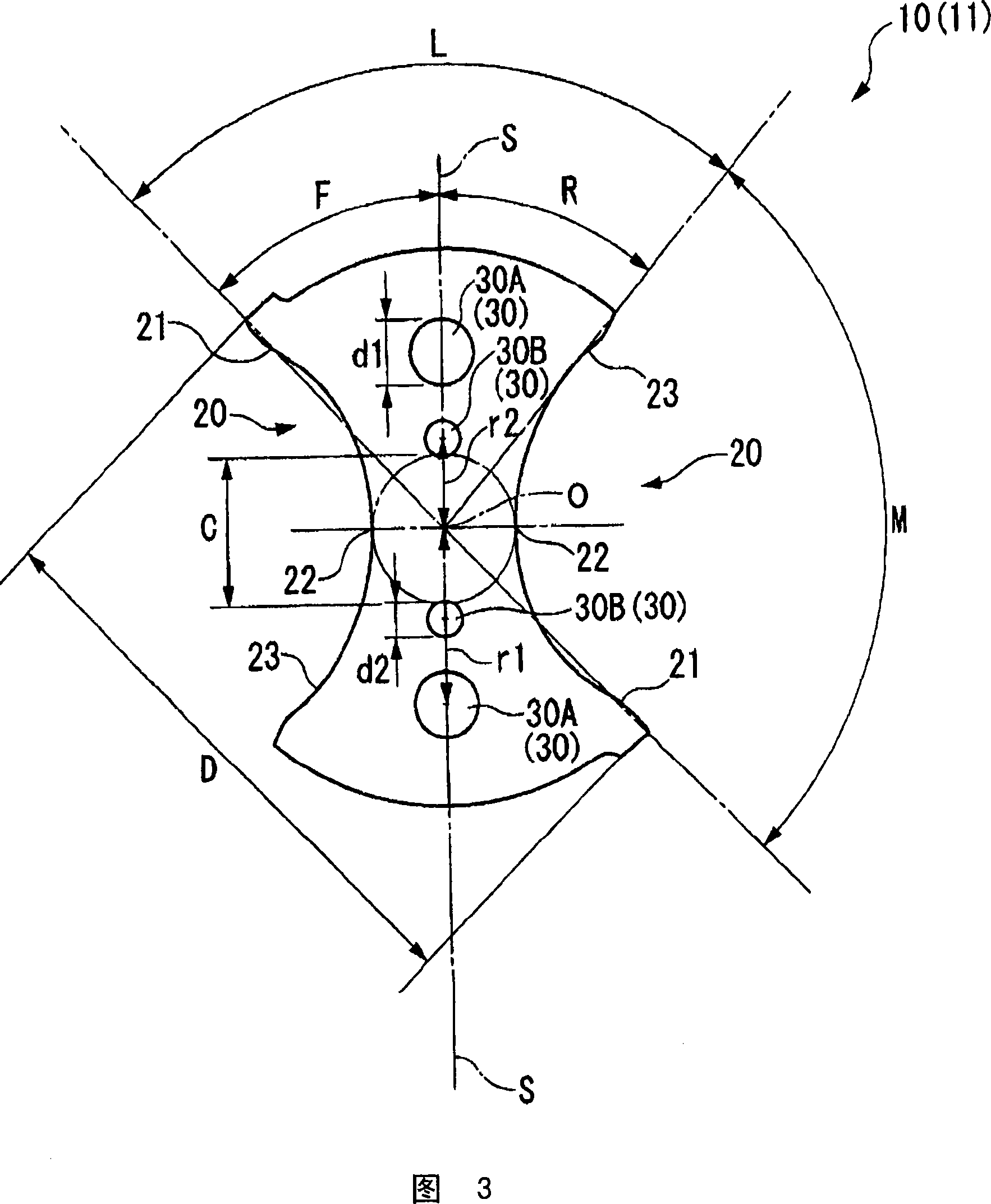

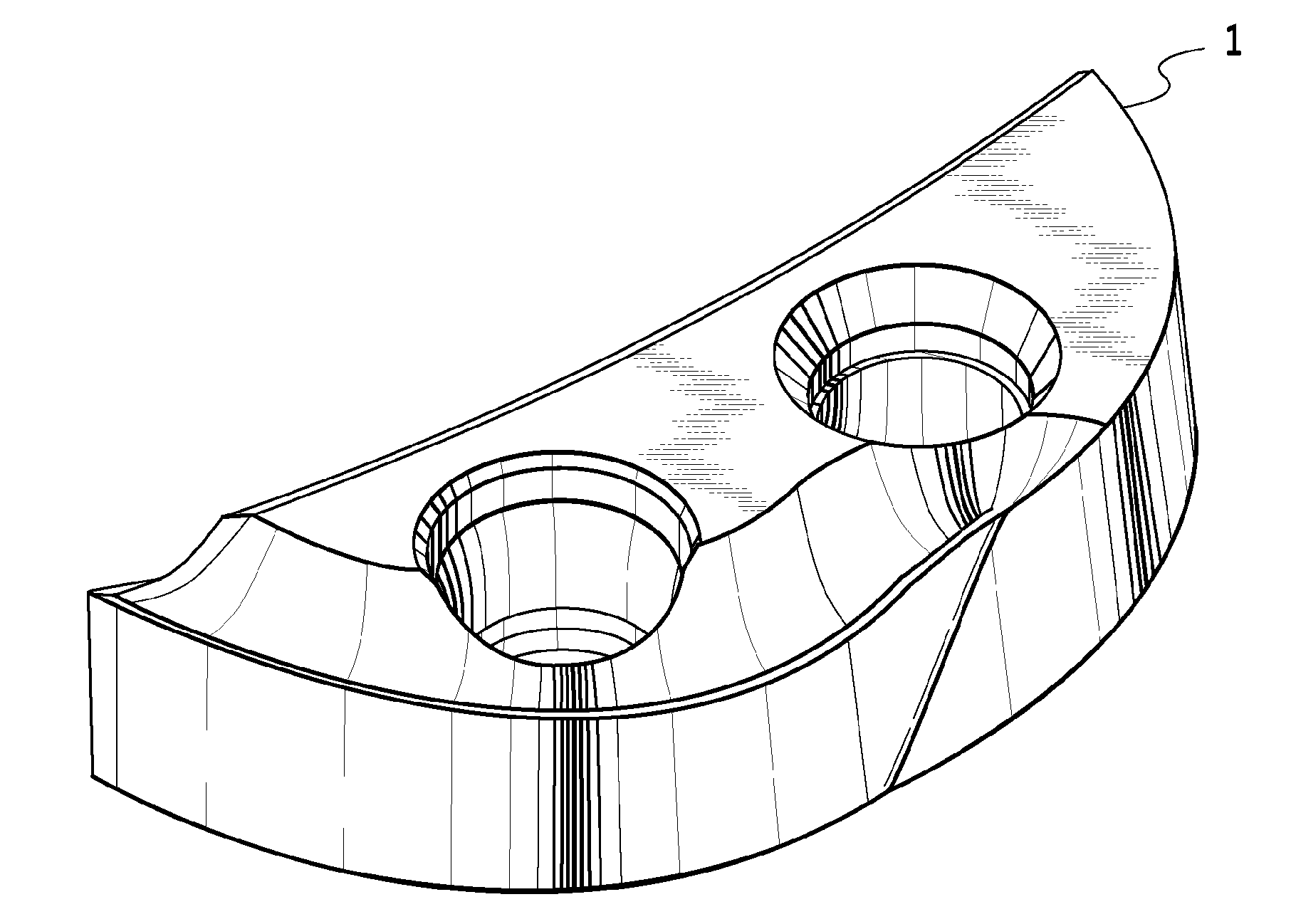

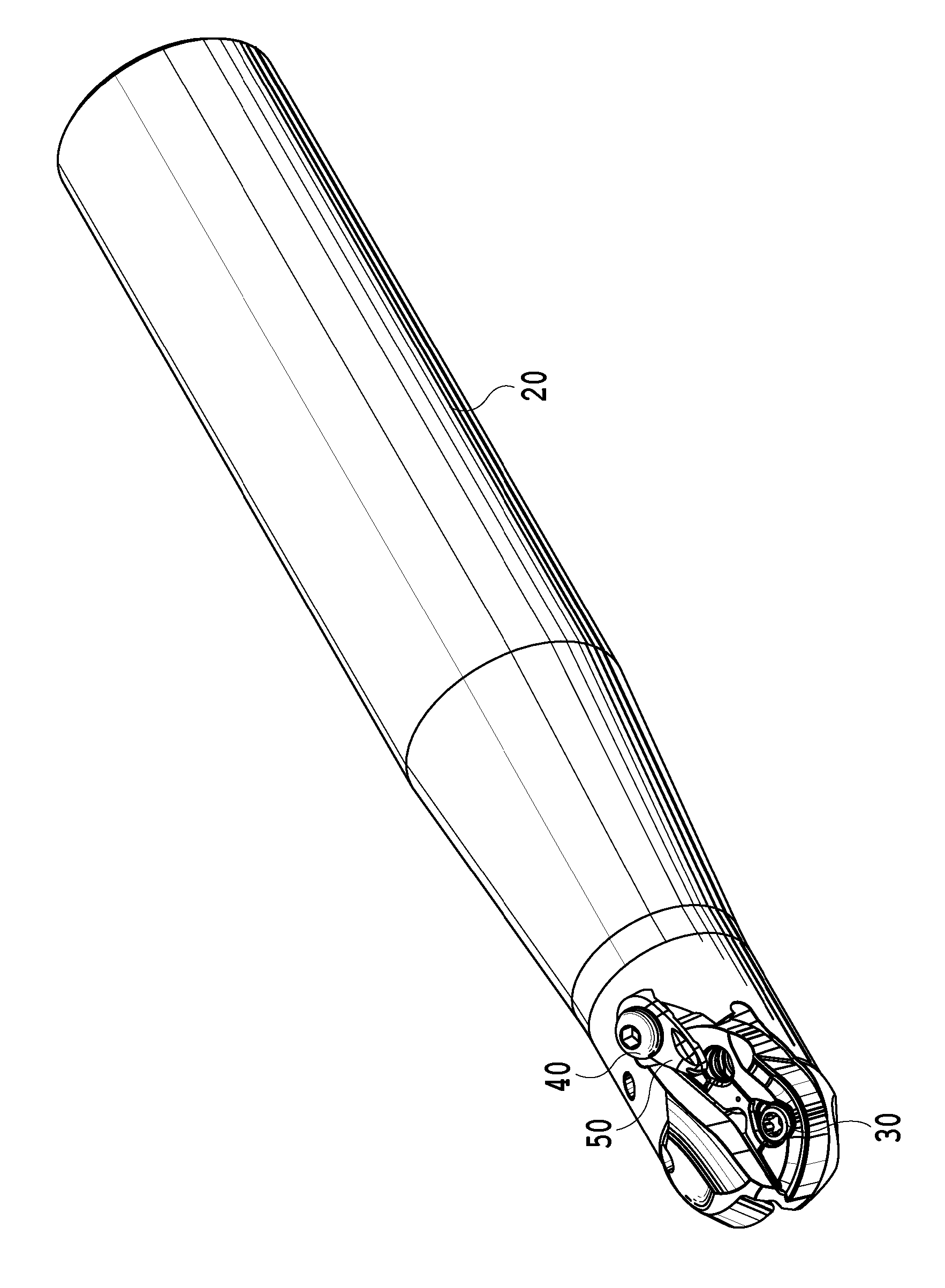

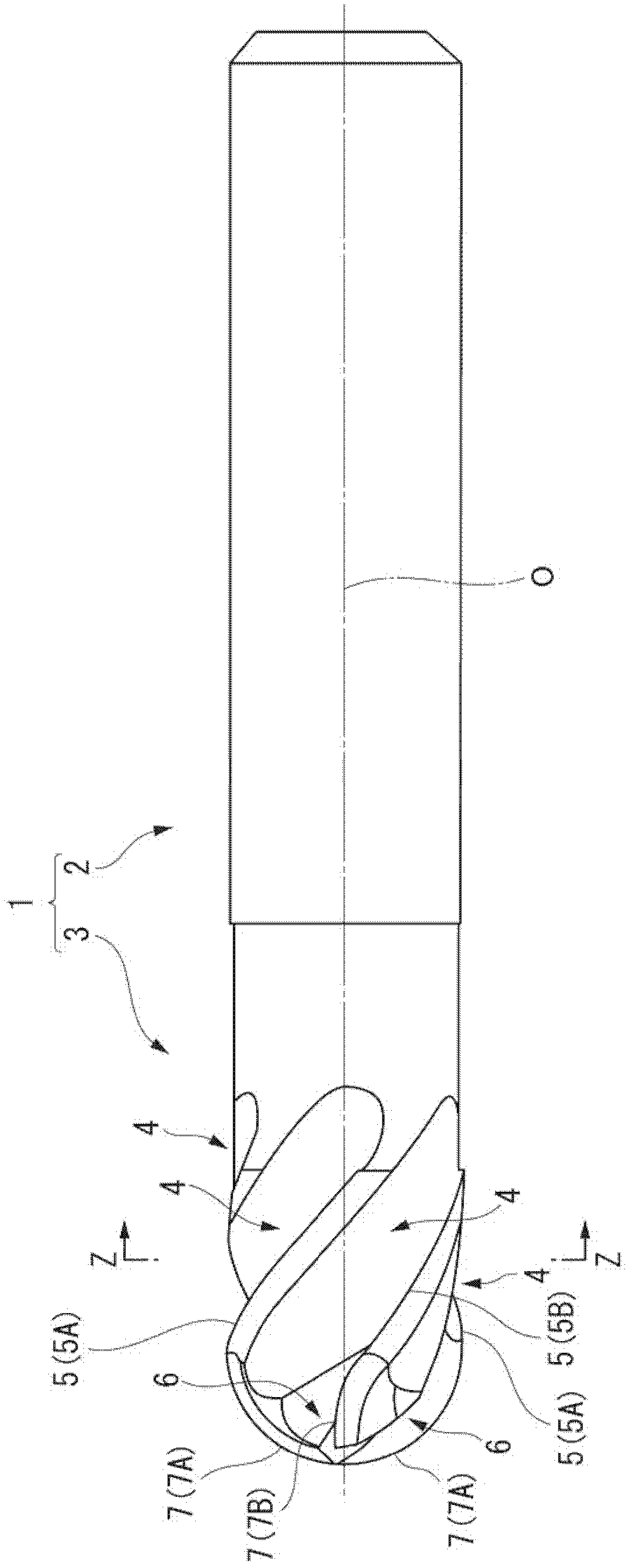

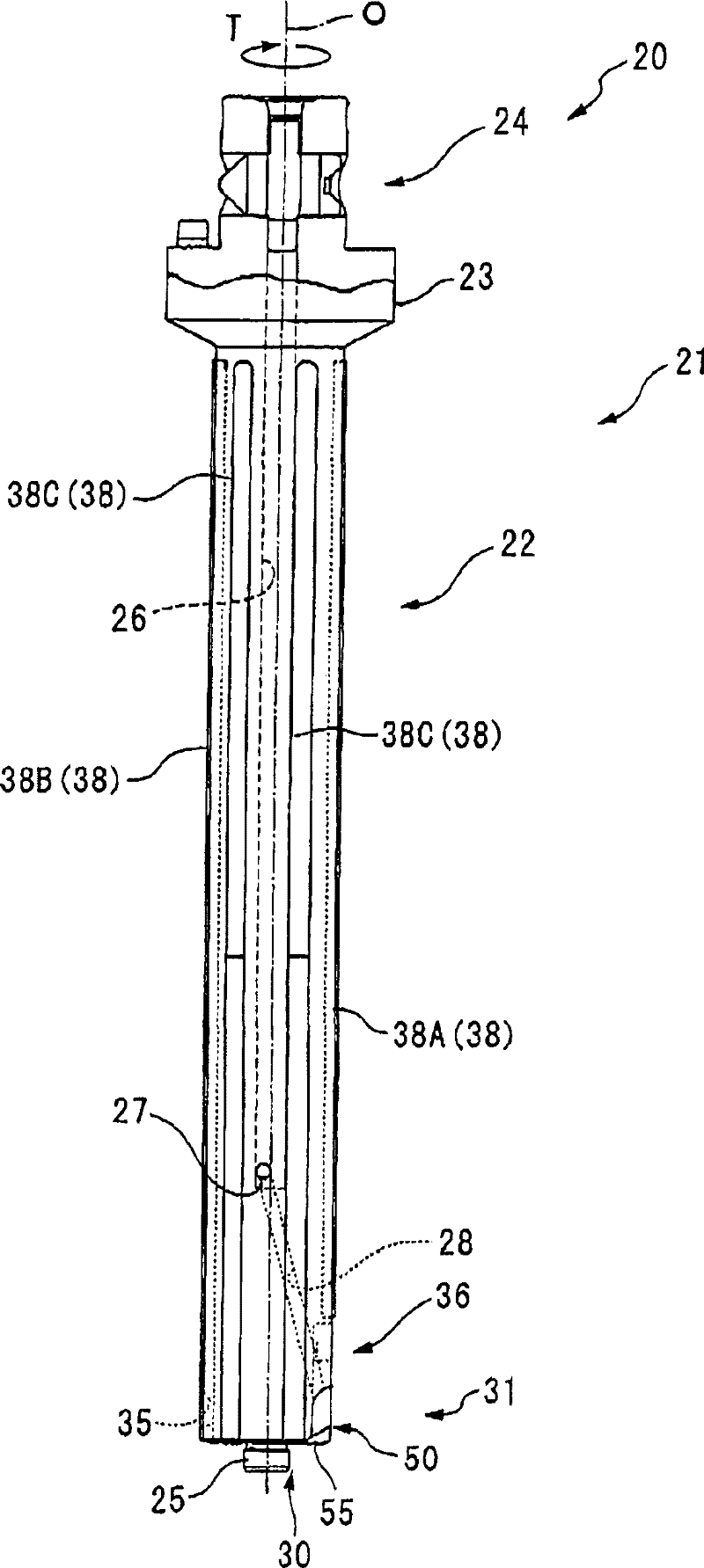

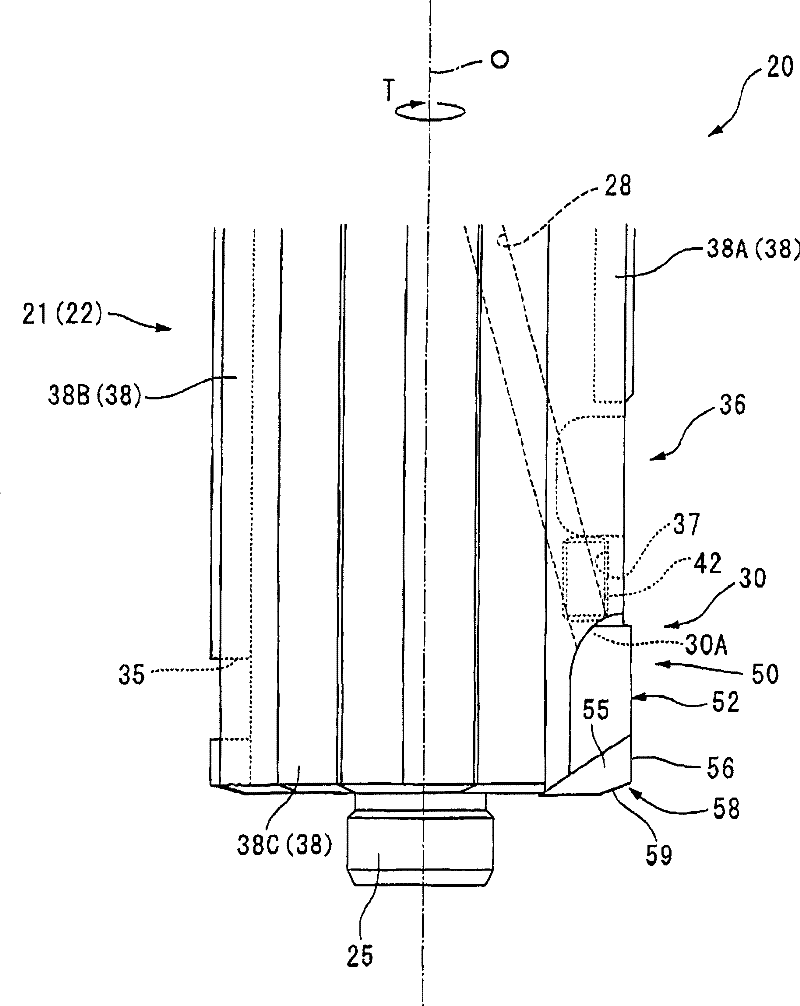

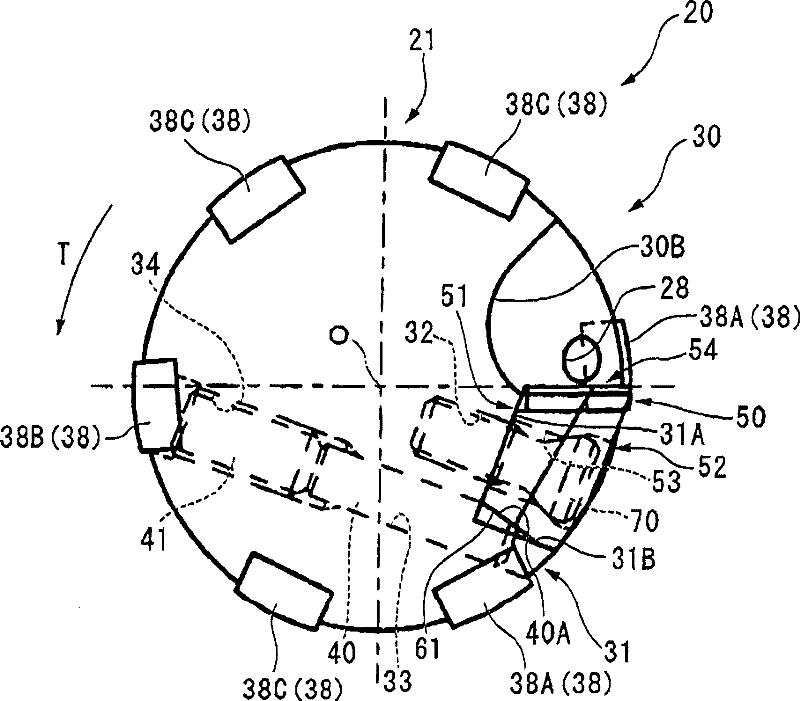

Tool for machining a hole

A hole machining tool is provided in which movement balance and rigidity of a tool body are enhanced and which can simply and precisely adjust a position of an insert to form a machined hole having a high circularity with high dimensional precision. A recessed portion and an attachment seat are formed in a front end portion of the tool body. A panel-shaped insert is attached to the attachment seat in a state where the thickness direction thereof is matched with the diameter direction of the tool body and a surface of the insert facing the rear side in a tool rotation direction becomes a pressed surface. A peripheral cutting edge is formed at a ridge portion of an inclined surface on the outside in the diameter direction of the tool body, a bevel edge is formed at a ridge portion on the front side of the tool body, and a back taper is attached to the peripheral cutting edge. A pressing member (40) for pressing the pressed surface (61) of the insert (50) to adjust a position of the peripheral cutting edge in the diameter direction of the tool body is disposed on the rear side (31B) of the attachment seat (31) in the tool rotation direction (T).

Owner:MITSUBISHI MATERIALS CORP

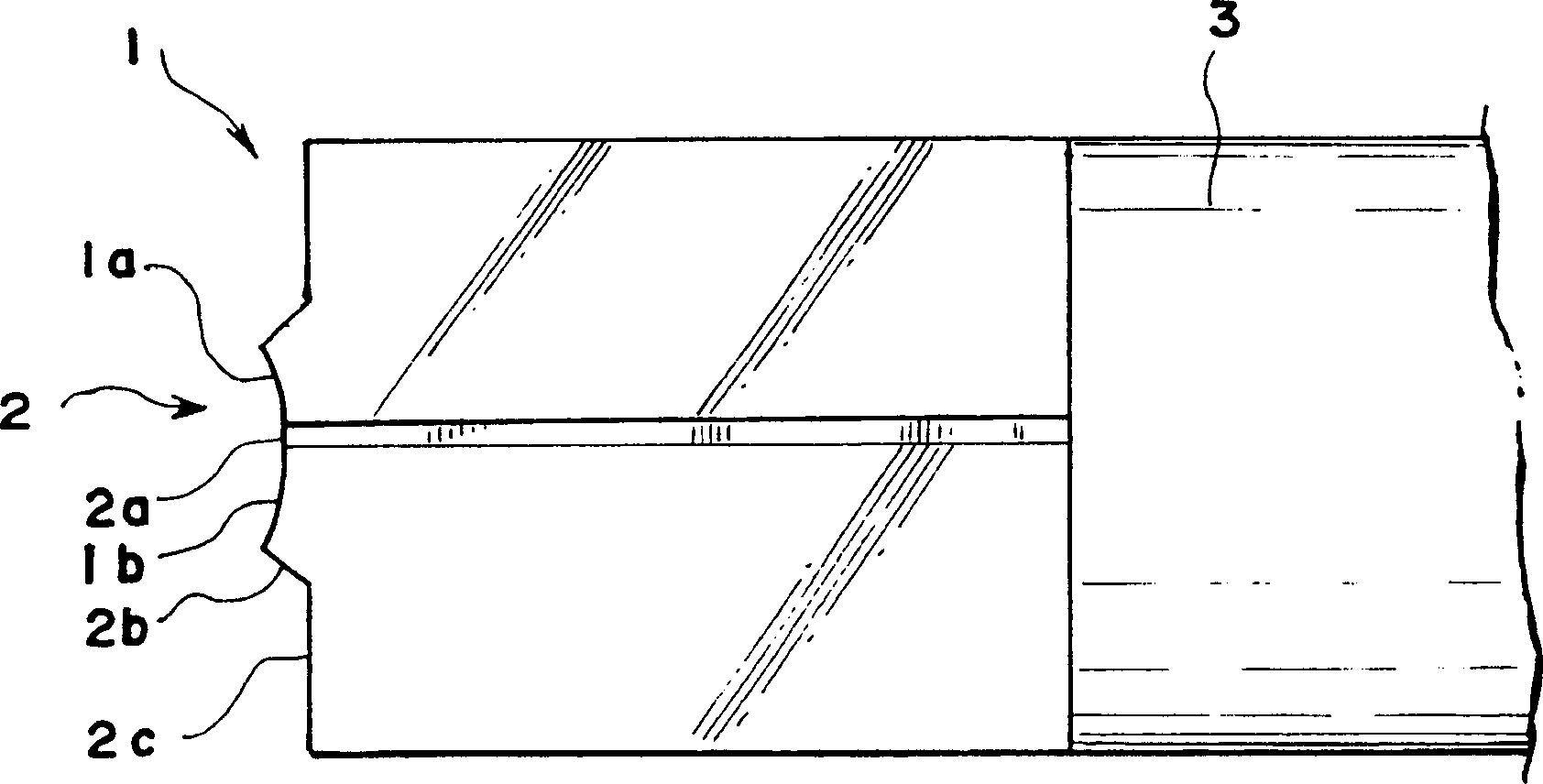

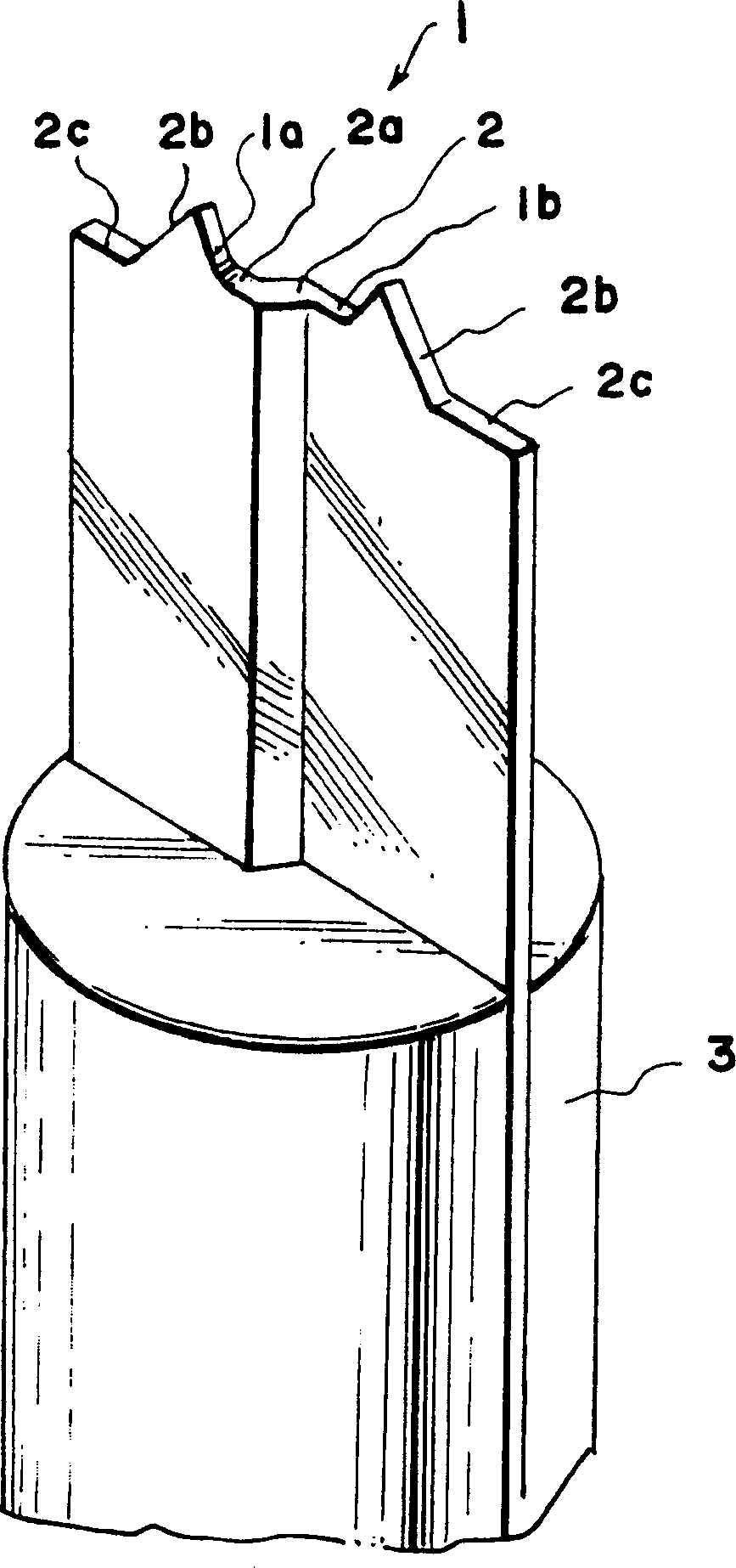

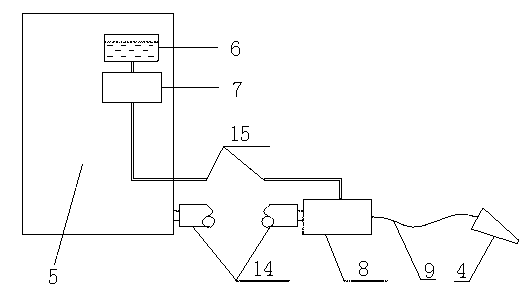

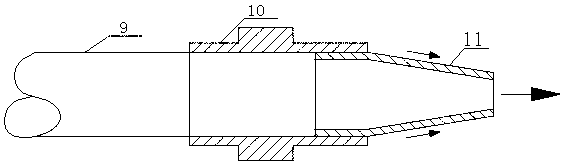

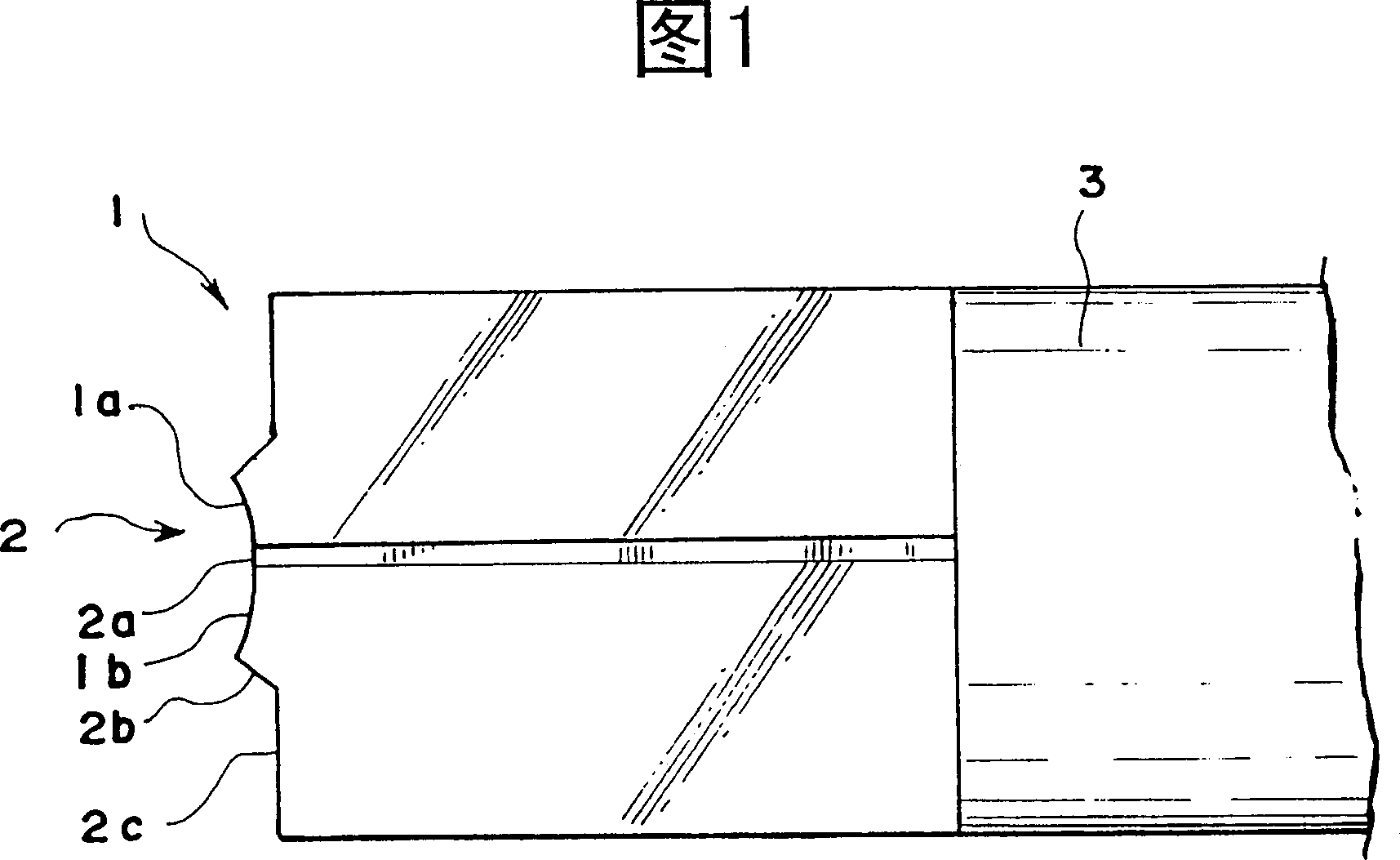

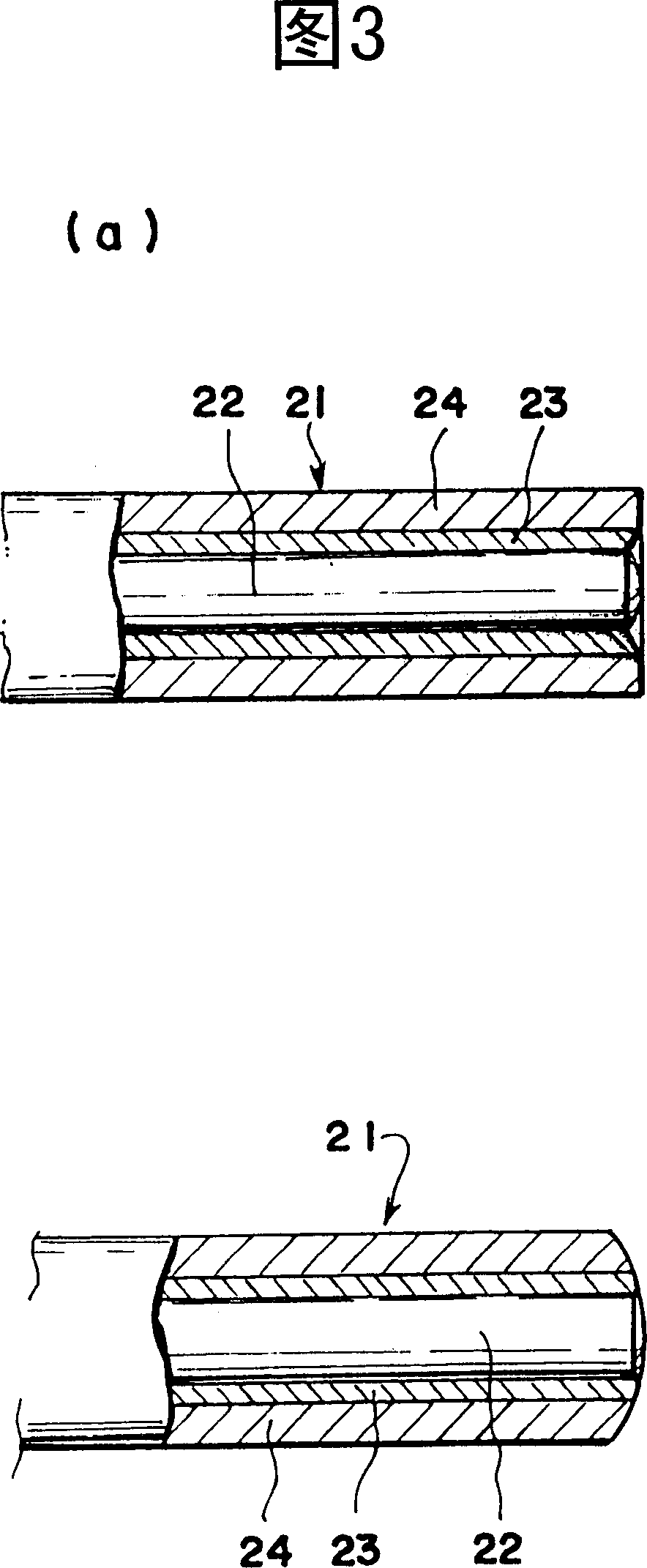

Plastic light guide fiber end face processing method, apparatus, cutting blade and connecting method

InactiveCN1403839AReduce the amount of lightChange the refractive indexCoupling light guidesFiberLight guide

A plastic optical fiber end surface processing method, a processing apparatus for the method, a cutter for use in the method, and a plastic optical fiber connecting method are provided. The processing method is that at least the core part of the end face of the plastic optical fiber is cut to be formed into a hemisphere face with a half circular cutting blade. The processing apparatus includes: a motor; a cutting blade connected with connecting component or directly to the driving shaft of the motor; a holder having a through hole for inserting the cutting blade into the middle portion of the through hole; a cutter inserted from one side into the through-hole of the holder for cutting at least the core part of the end face of the plastic optical fiber with rotating cutting blade. The invention is capable of processing the plastic optical fiber to be not only convex semi-spherical surface but also concave semi-spherical surface and arbitrary profile according to the change of the cutting blade shape.

Owner:NHK SALES

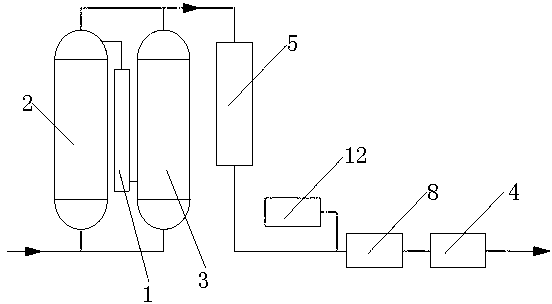

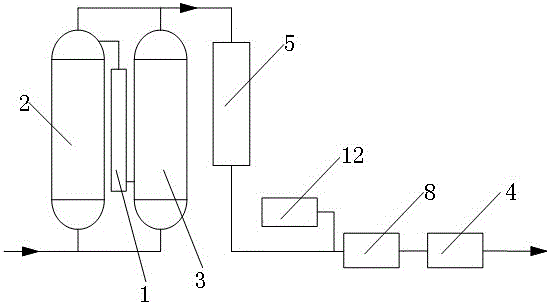

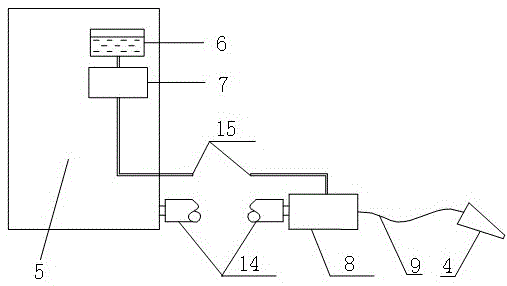

Low-temperature atomizing air cooler and achieving method thereof

ActiveCN103286630AReduce the temperatureSolve pollutionMaintainance and safety accessoriesControl systemSpray nozzle

The invention discloses a low-temperature atomizing air cooler and an achieving method thereof. The low-temperature atomizing air cooler solves the problems that a normal-temperature air microscale oil atomizing technique in the prior art is high in temperature and poor in cooling effect, and low-temperature air flow cooling processing in the prior art is low-temperature air flow dry type cutting processing so as to be insufficient in lubrication and quick in cutter abrasion. The low-temperature atomizing air cooler comprises a drying tower, a refrigerating system, a microscale oil supplying mechanism, a mixing block, a spray nozzle and a PLC control system, wherein the drying tower is used for drying and cleaning air from the outside of the low-temperature atomizing air cooler, the refrigerating system is communicated with the drying tower through a pipeline and used for cooling air dried by the drying tower to form low-temperature air flow, the microscale oil supplying mechanism can inject oil or fluid into the mixing block through an oil pipe, the mixing block is respectively communicated with the microscale oil supplying mechanism and the refrigerating system and used for primarily atomizing the oil or fluid injected into the mixing block and low-temperature air flow to form low-temperature air flow fluid fog, the spray nozzle is communicated with the mixing block and can secondarily atomize the low-temperature air flow fluid fog obtained from primary atomization to obtain low-temperature atomized air flow.

Owner:成都凯里恩科技有限公司

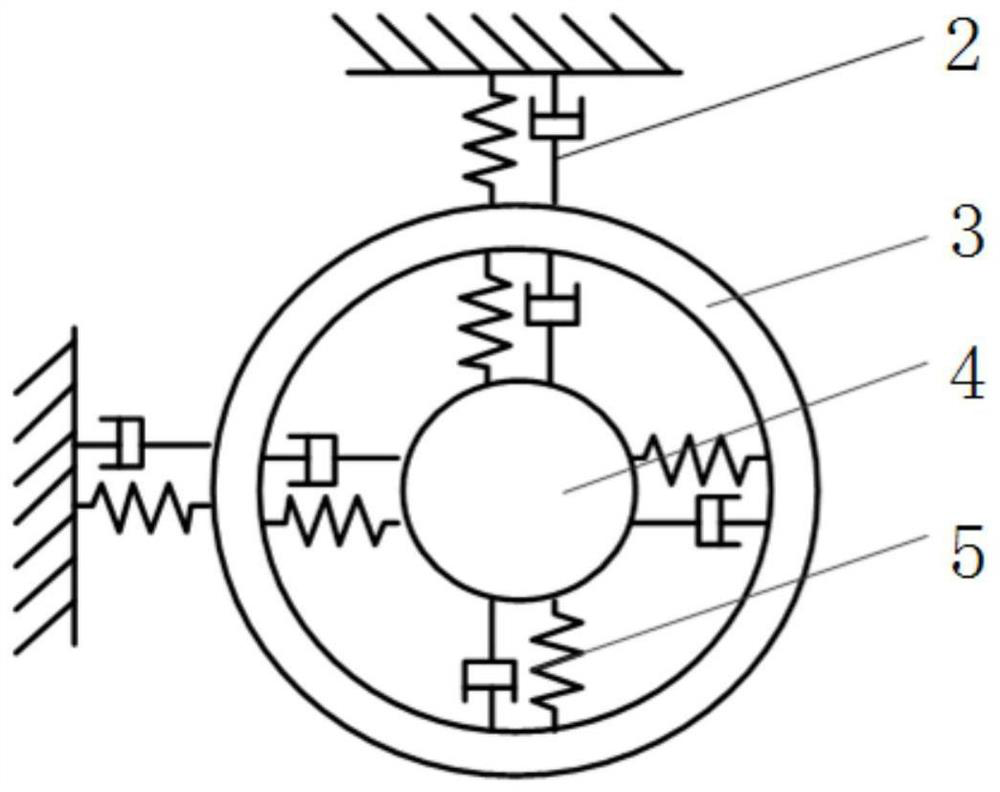

Online indirect measuring method for rotation precision of machine tool main shaft

InactiveCN112059721AAccurate measurementEasy to installMeasurement/indication equipmentsMechanical modelsControl engineering

The invention discloses an online indirect measuring method for rotation precision of a machine tool main shaft, and belongs to the technical field of machining. The method comprises the following steps: establishing a transmission mechanical model of vibration between a measuring point on a main shaft solid joint part and a main shaft to obtain a main shaft acceleration signal; deriving a main shaft displacement signal through an integration method, and drawing a radial axis trajectory chart and an axial axis trajectory chart of the main shaft; and performing precision assessment on a trajectory of the radial axis trajectory chart and the axial axis trajectory chart. The method for measuring the rotation precision of the machine tool main shaft under a measuring processing state providedcan obtain axial and radial absolute displacement of the main shaft, has the advantages of being accurate in measurement, wide in range of application, easy in mounting, and the like, and is of greatsignificance in predication on processing precision of the machine tool, assessment on dynamic performance of the machine tool, and online pre-warning of the machine tool.

Owner:TSINGHUA UNIV

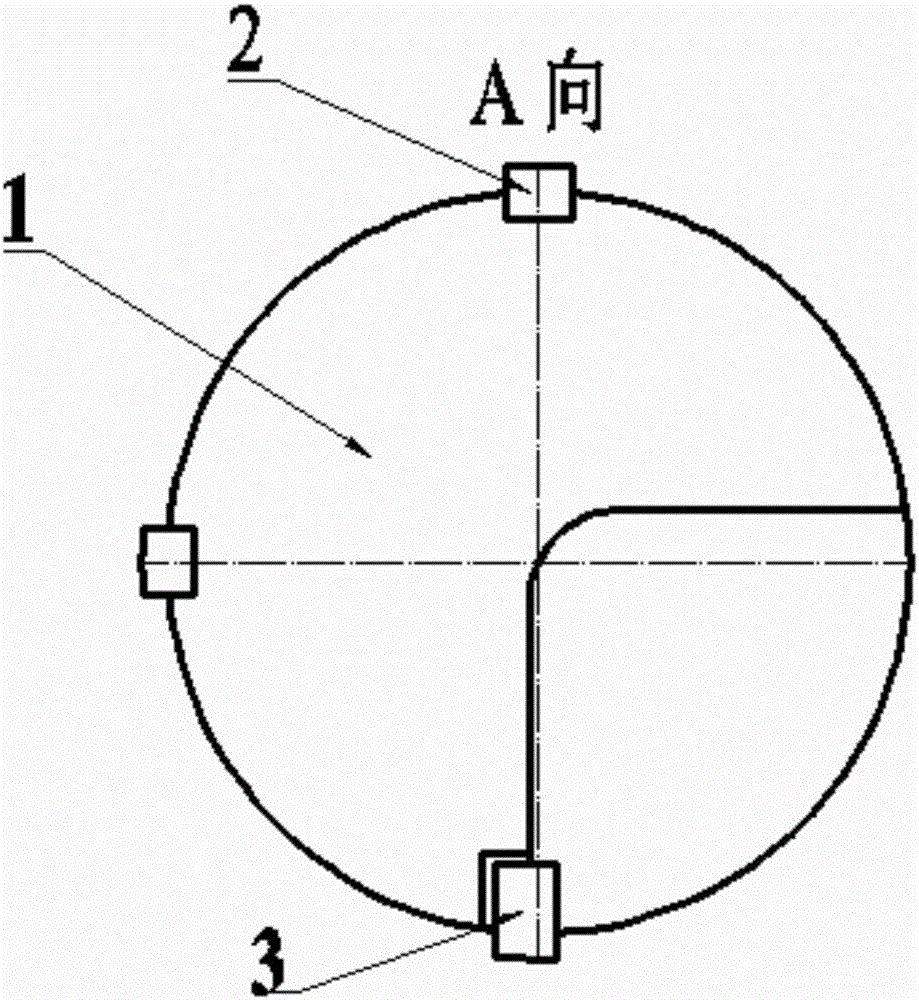

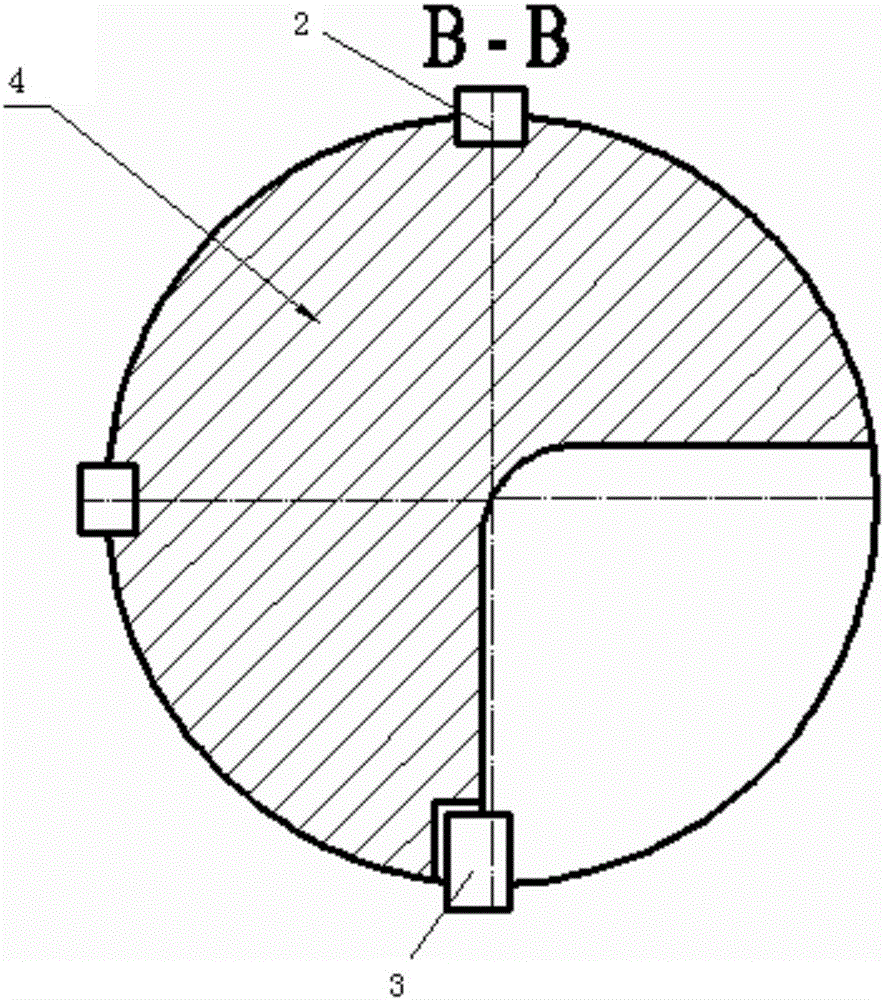

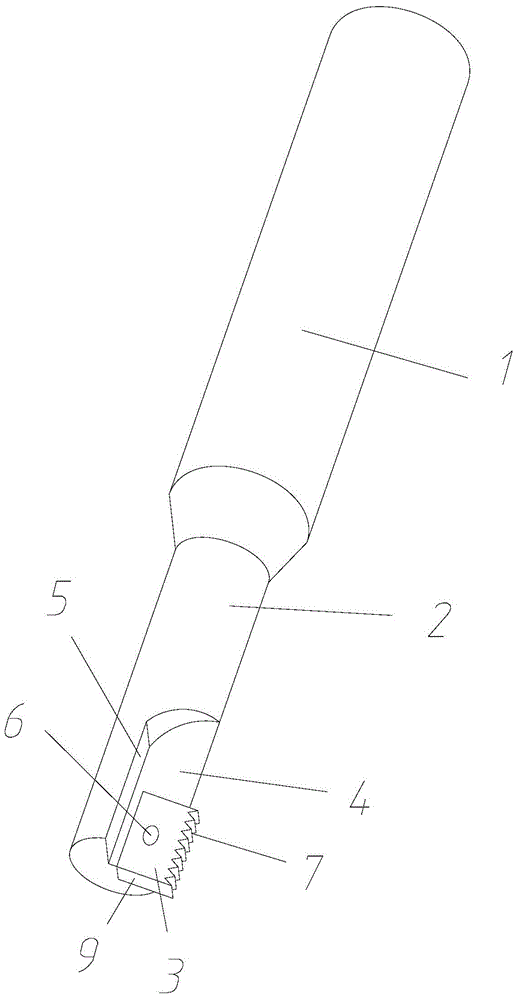

Deep-hole push-boring cutter device with two cutter bodies combined

InactiveCN106216718AGuaranteed service lifeGuaranteed a good service lifeTurning toolsEngineeringScrew thread

A deep-hole push-boring cutter device with two cutter bodies combined comprises the front cutter body, the rear cutter body, a mounting positioning face and a mounting thread, wherein the front cutter body, the rear cutter body, the mounting positioning face and the mounting thread are sequentially connected and are integrally formed. The outer circumference of the front cutter body and the outer circumference of the rear cutter body are each connected with a guiding block and a cutting blade. The cutting blades are manually edged. A drill rod stretches into a machined part, and after the push-boring cutter device with the two cutter bodies combined is assembled on the drill rod, push-boring cutting can be conducted. During push-boring cutting, the cutting blade at the front end and the cutting blade at the rear end are used for cutting the part at the same time. The deep-hole push-boring cutter device with the two cutter bodies combined has the characteristics of being simple in structure, convenient to use and practical.

Owner:XIAN MODERN DEEP HOLE TECH CO LTD

Drill

InactiveCN101195177ANo reduction in strength/rigidityIncrease supplyTransportation and packagingTwist drillsReference lineCutting oil

A plurality of cutting oil feed holes extend from the proximal side towards the distal side are provided in a drill body located on a reference line that extends towards a circumferential central portion of an outer circumferential surface of the drill body split by a chip discharge groove from an axis in a cross section orthogonal to the axis. A cutting oil feed hole that is located on the radial outermost side is used as a first cutting oil feed hole, and a cutting oil feed hole that is on the radial innermost side is used as a second cutting oil feed hole. Two or more openings of the cutting oil feed holes are provided in one cutting edge as the plurality of cutting oil feed holes are formed in the vicinity of the intersection ridgeline portion between the distal flank face and the second thinned face.

Owner:MITSUBISHI MATERIALS CORP

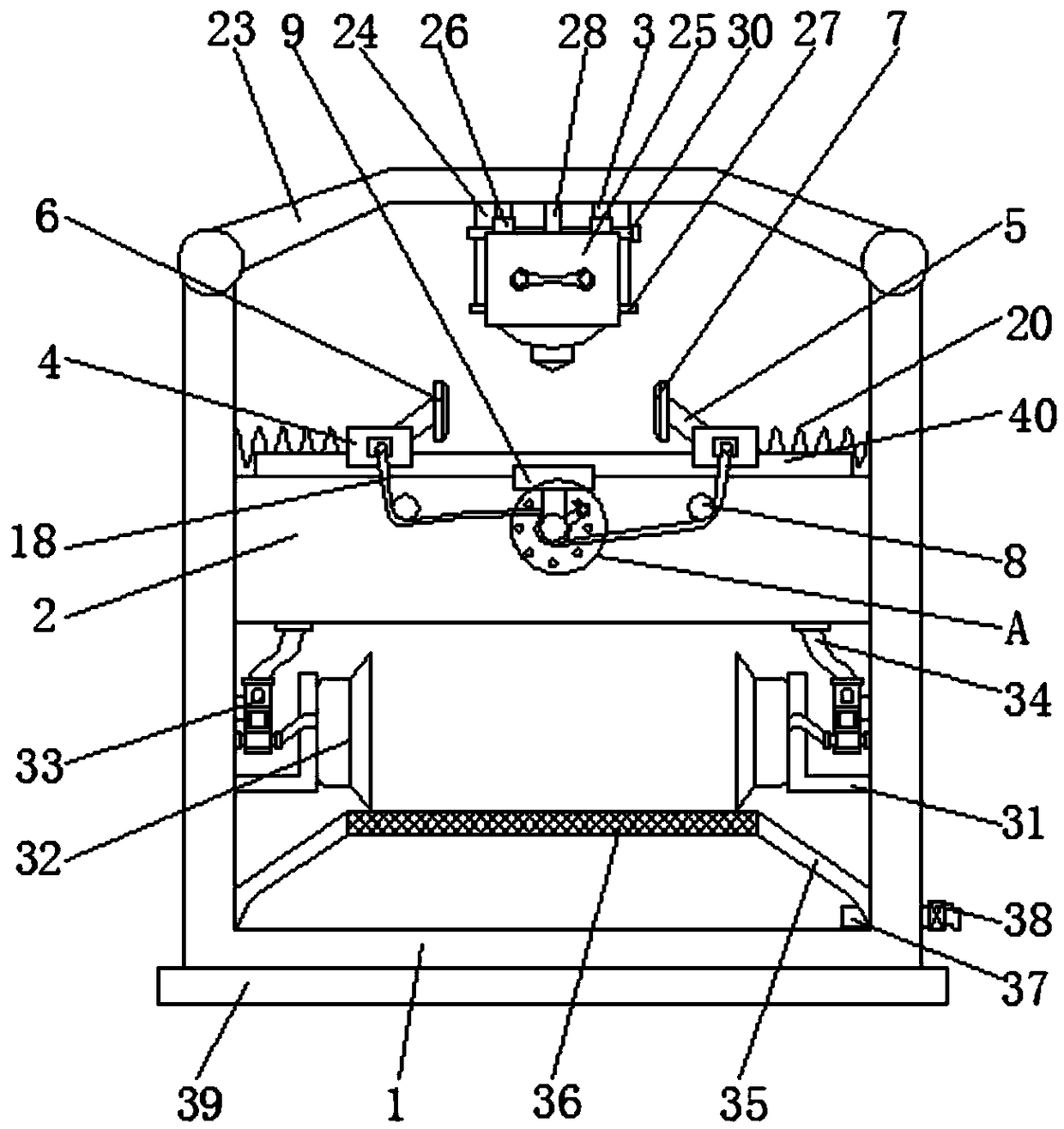

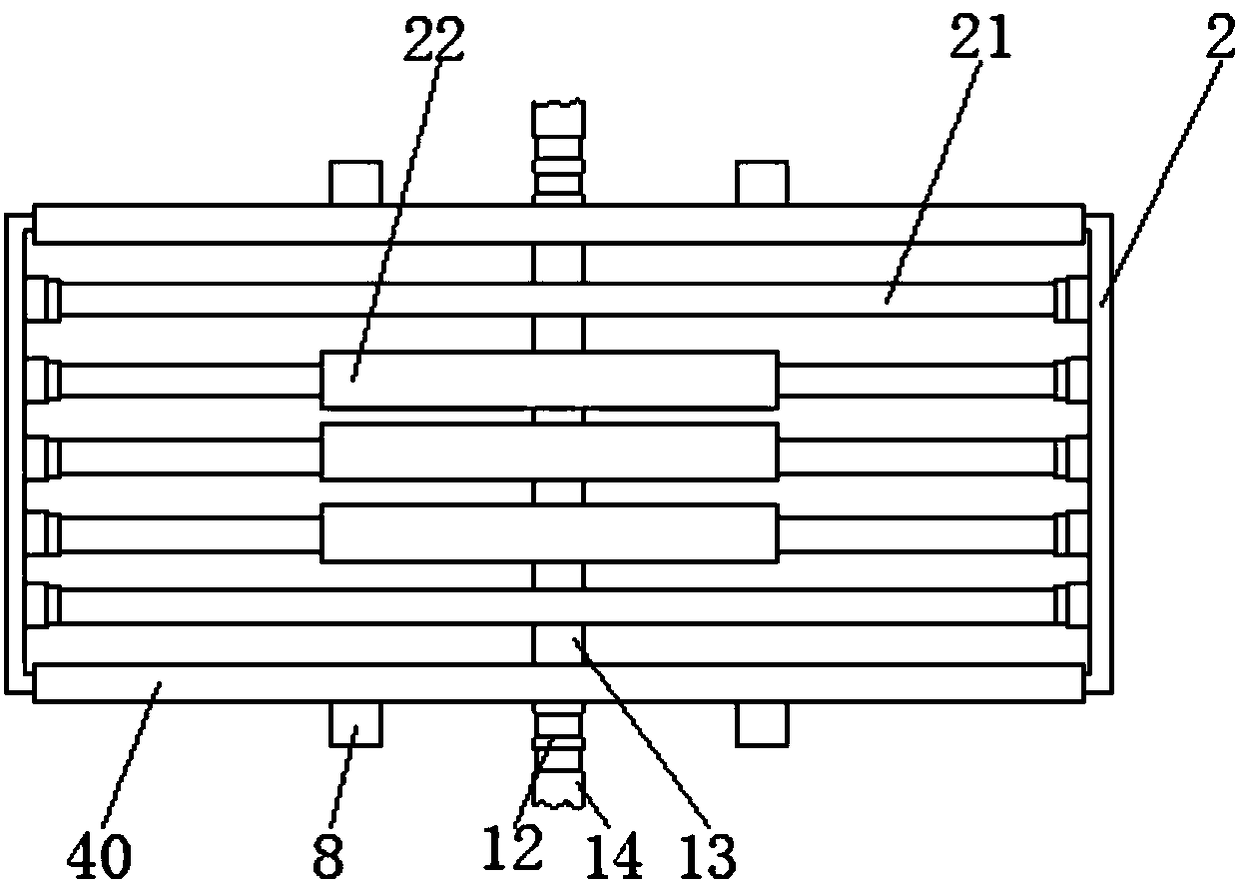

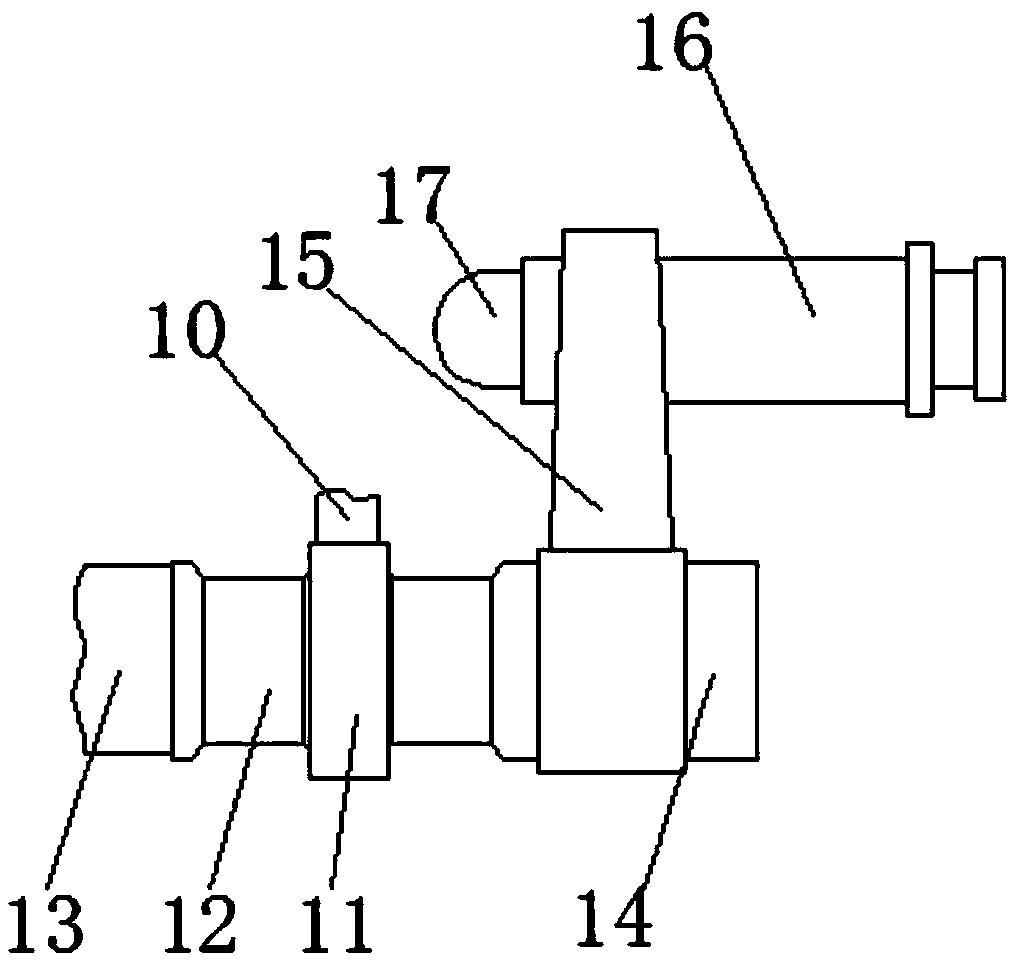

Efficient machining cooling device

InactiveCN108818147AEfficient MachiningRapid coolingMaintainance and safety accessoriesEngineeringSlide plate

The invention discloses an efficient machining cooling device which comprises a shell. The interior of the shell is fixedly connected with a cooling box. The front side and the rear side of the cooling box are fixedly connected with first sliding rails. The outer surfaces of the two first sliding rails are in sliding connection with sliding plates. The opposite sides of the two sliding plates arefixedly connected with supporting plates. The side, away from the corresponding sliding plate, of each supporting plate is fixedly connected with a clamp plate. One side of each clamp plate is fixedlyconnected with a buffer plate. The invention relates to the technical field of machines. According to the machining device for a machine, the cooling box is utilized for absorbing heat generated by machining when the machining device carries out machining, and the situation that the machining effect is influenced due to the fact that the machining environment is too high is avoided; and meanwhile, through cooperation of a wire winding column and a pull rope, the sliding plates can be driven to move on the first sliding rails, then the clamp plates are driven to clamp a machined mechanical tool, the machining device can machine the machined mechanical tool conveniently, the machined tool is prevented from offsetting, and machining is more precise.

Owner:熊飞燕

Method and machine tool for machining hypoid gear pair

The invention discloses a method and a machine tool for machining a hypoid gear pair and aims to solve the problem that the hypoid gear pair is difficultly machined in the prior art. The machining method comprises the following steps of: 1, machining a big gear surface, namely 1) machining the right gear surface of a big gear; and 2) machining the left gear surface of the big gear; and 2, machining a small gear surface, namely 1) machining the left gear surface of a small gear; and 2) machining the right gear surface of the small gear. The machining machine tool comprises a workpiece shaft, apower head, a tilting working table, a rotary working table, an XYZ working table and a body, wherein the workpiece shaft replaces an original power spindle head of the conventional machine tool; therotary working table is fixedly arranged on the XYZ working table and makes rotating axes of the rotary working table and the workpiece shaft coplanar; the tilting working table is fixedly arranged on the rotary working table; an inclined angle chi is formed between the upper surface of the tilting working table and the bottom surface of the tilting working table; and the power head is fixedly arranged on the tilting working table through a bolt, a guide rail and a guide rail groove.

Owner:JILIN UNIV

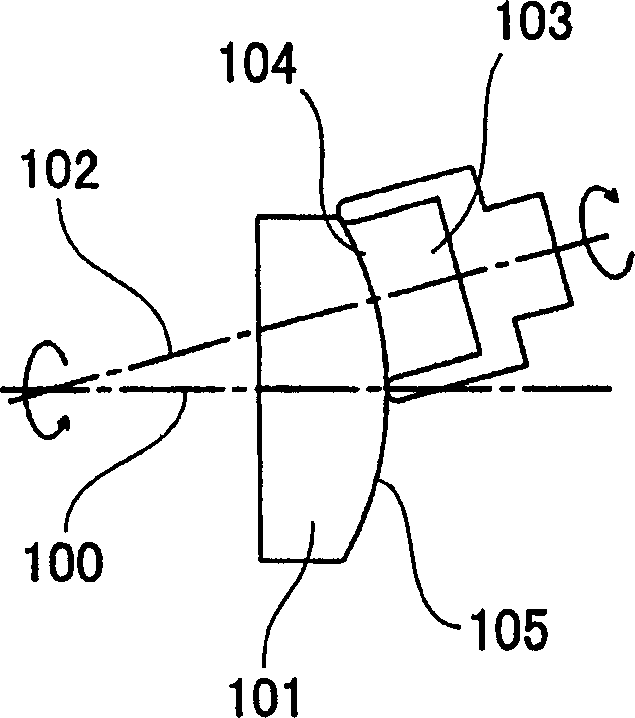

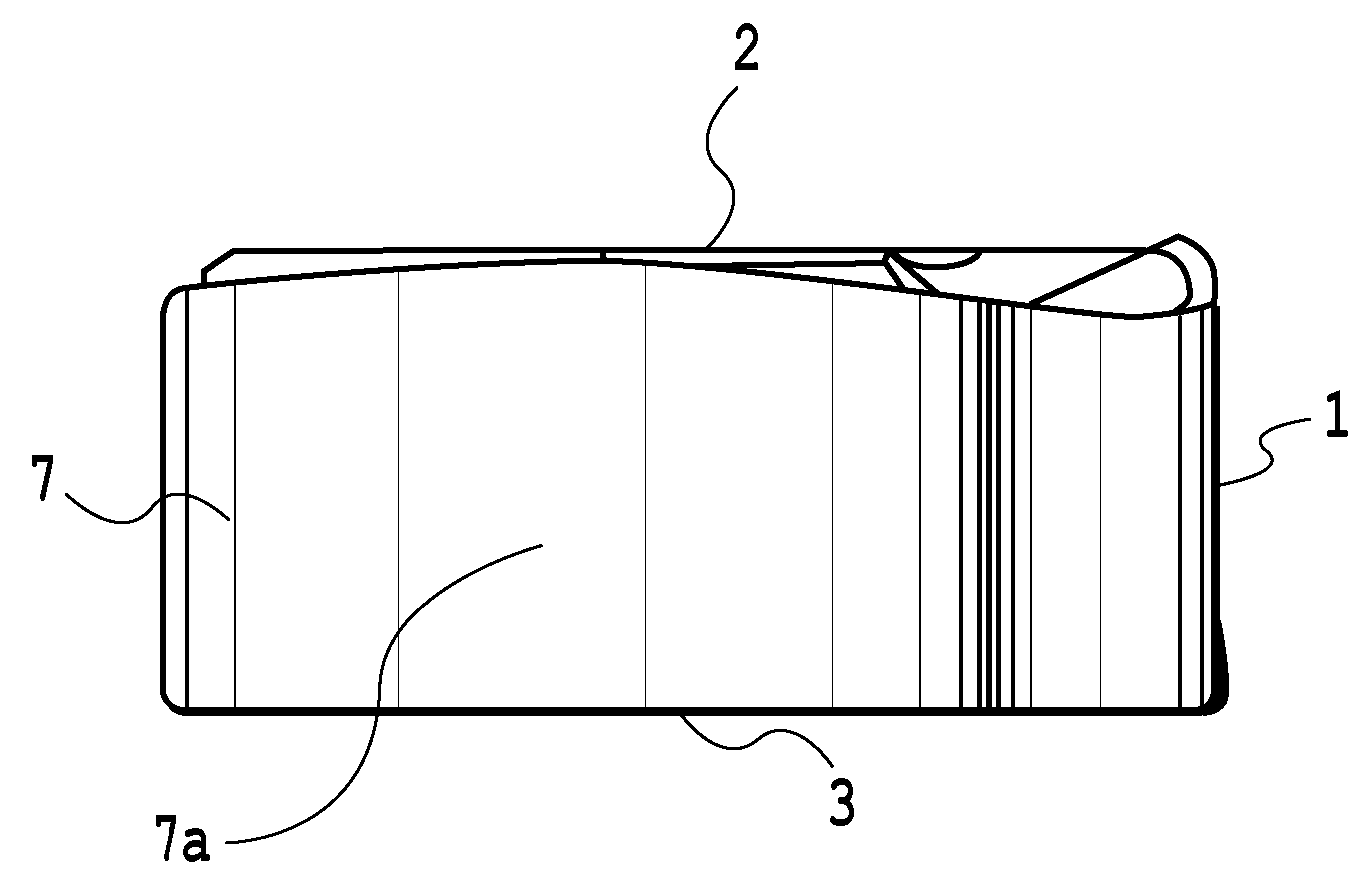

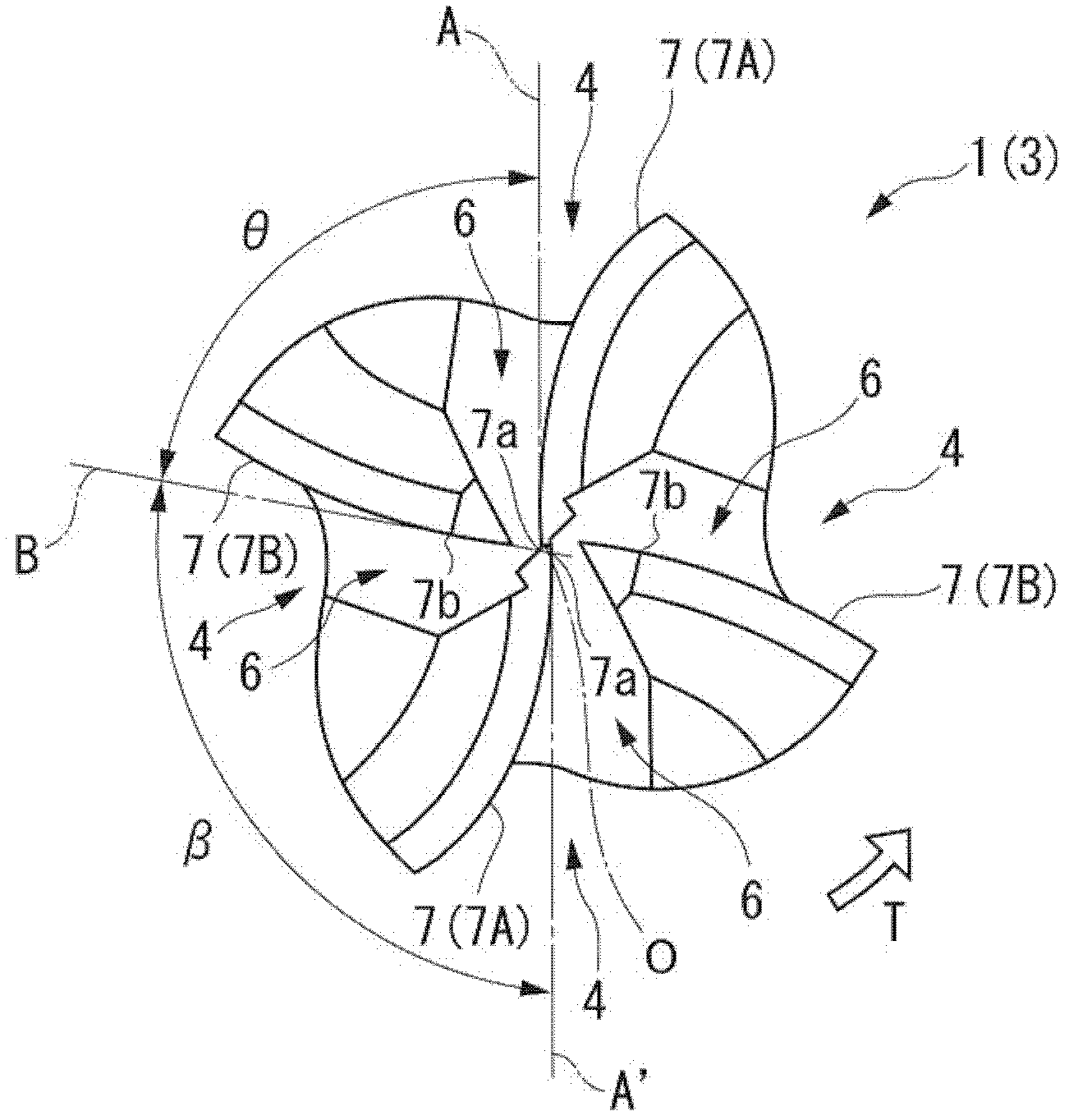

Cutting insert and cutting tool

ActiveCN103747904AReduce manufacturing costStrong Tool RigidityTransportation and packagingMilling cuttersStructural engineeringKnife blades

The invention provides a cutting insert and a cutting tool, which have very strong tool rigidity and are capable of highly efficient cutting, and the production cost per one cutting edge of which is low. For this purpose, a first rake face (4a) and a second seating surface (8a) are provided on the upper surface (2) of the cutting insert (1). A second rake face (4b) and a first seating surface (8b) are provided on the lower surface (3) of the cutting insert. The cutting edge is provided with: a first cutting edge portion (5a) formed at the ridge where the first rake face (4a) and a flank (7) intersect; and a second cutting edge portion (6a) formed at the ridge where the second rake face (4b) and the flank (7) intersect. The first cutting edge portion (5a) is provided at a position opposite the ridge where the first seating surface (8b) and the flank (7) intersect, and the second cutting edge portion (6a) is provided at a position opposite the ridge where the second seating surface (8a) and the flank (7) intersect.

Owner:TUNGALOY CORP

Lens grinding method and device

InactiveCN100491071CEfficient MachiningAvoid wastingOptical surface grinding machinesCircular coneEngineering

In the lens grinding apparatus of the present invention, while the grinding bowl-shaped tool with spherical grinding surface rotates around the rotary central line through the sphere center and the rotary central line performs sphere center swinging to describe one cone with the sphere center as vertex, the lens blank is fed in specified rate in the feeding direction through the sphere center and pushed towards the bowl-shaped tool for grinding, with the cutting speed being altered based on the lens blank feeding speed. The said lens grinding process can cut lens material in high efficiency and grind spherical lens with small curvature in high precision.

Owner:HARUCHIKA

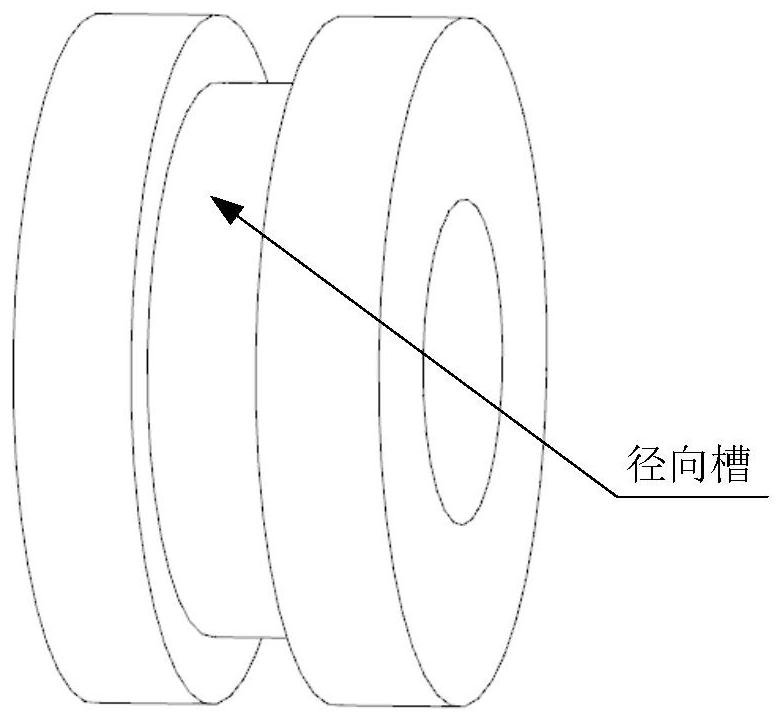

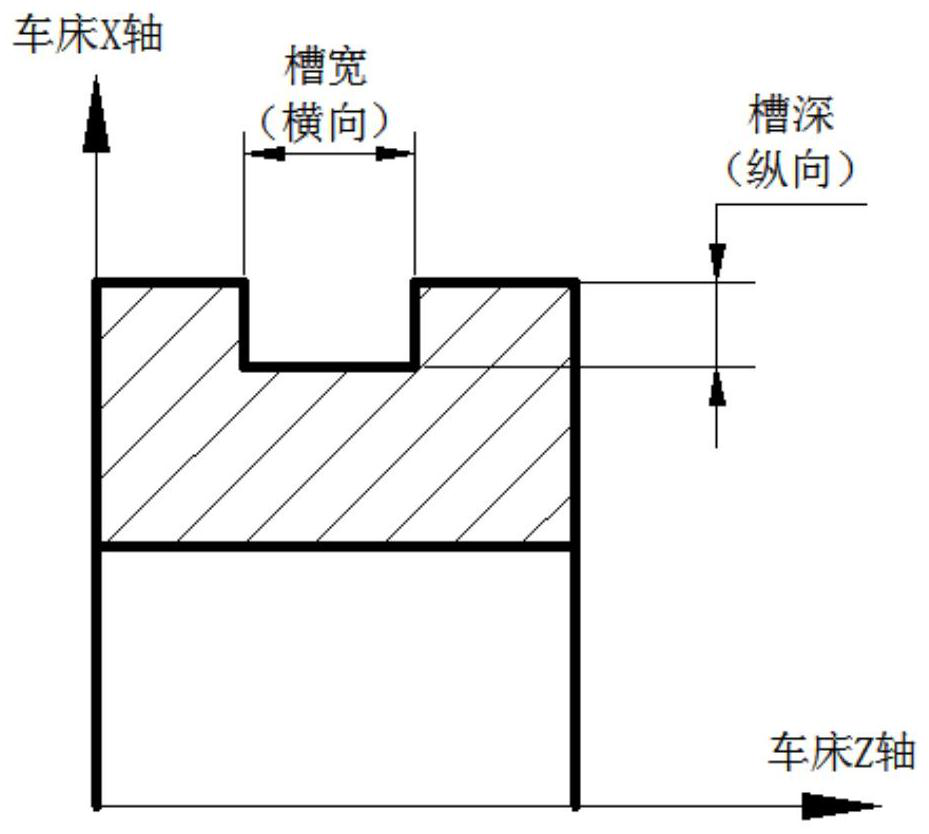

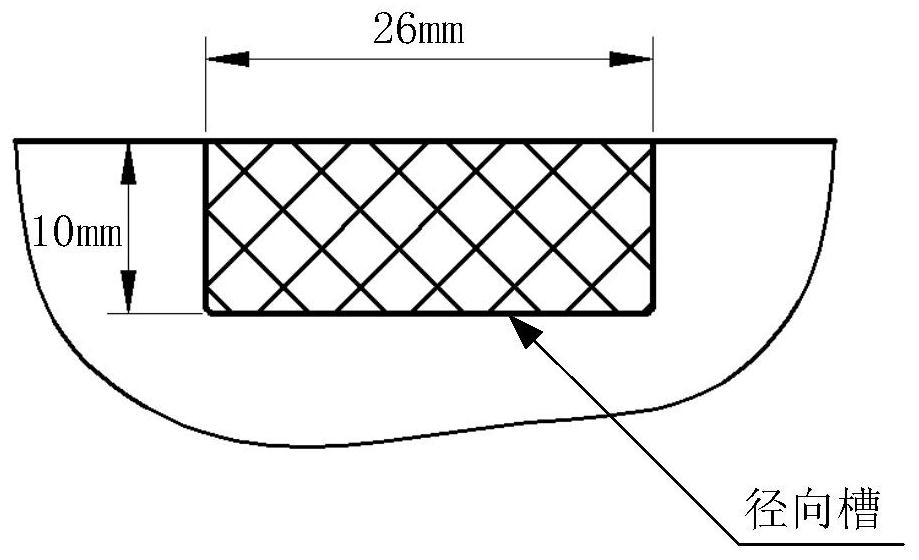

A high-efficiency grooving method applied to turning

ActiveCN112059207BHigh removal rateNC program shortAutomatic control devicesFeeding apparatusNumerical controlStructural engineering

A high-efficiency grooving processing method applied to turning belongs to the technical field of turning. The high-efficiency grooving processing method applied to turning includes the following steps: S1. Open a middle groove in the middle part to be grooved, the width of the middle groove is 1.5-1.8 times the width of the groove blade, and the middle groove passes through The groove blades are processed in the way of vertical and progressive feeding along the two sets of tool tracks; S2. After the middle groove is processed, the left and right alternate processing methods are used to process the left and right sides of the middle groove respectively to process a complete groove. When feeding each time, the width of the groove blade traveling in the transverse direction is 0.5-0.8 times of the width of the groove blade. The high-efficiency grooving processing method applied to turning has short numerical control programs, few idle tool passes, and high metal removal rate, and realizes efficient and high-quality numerical control turning grooving processing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

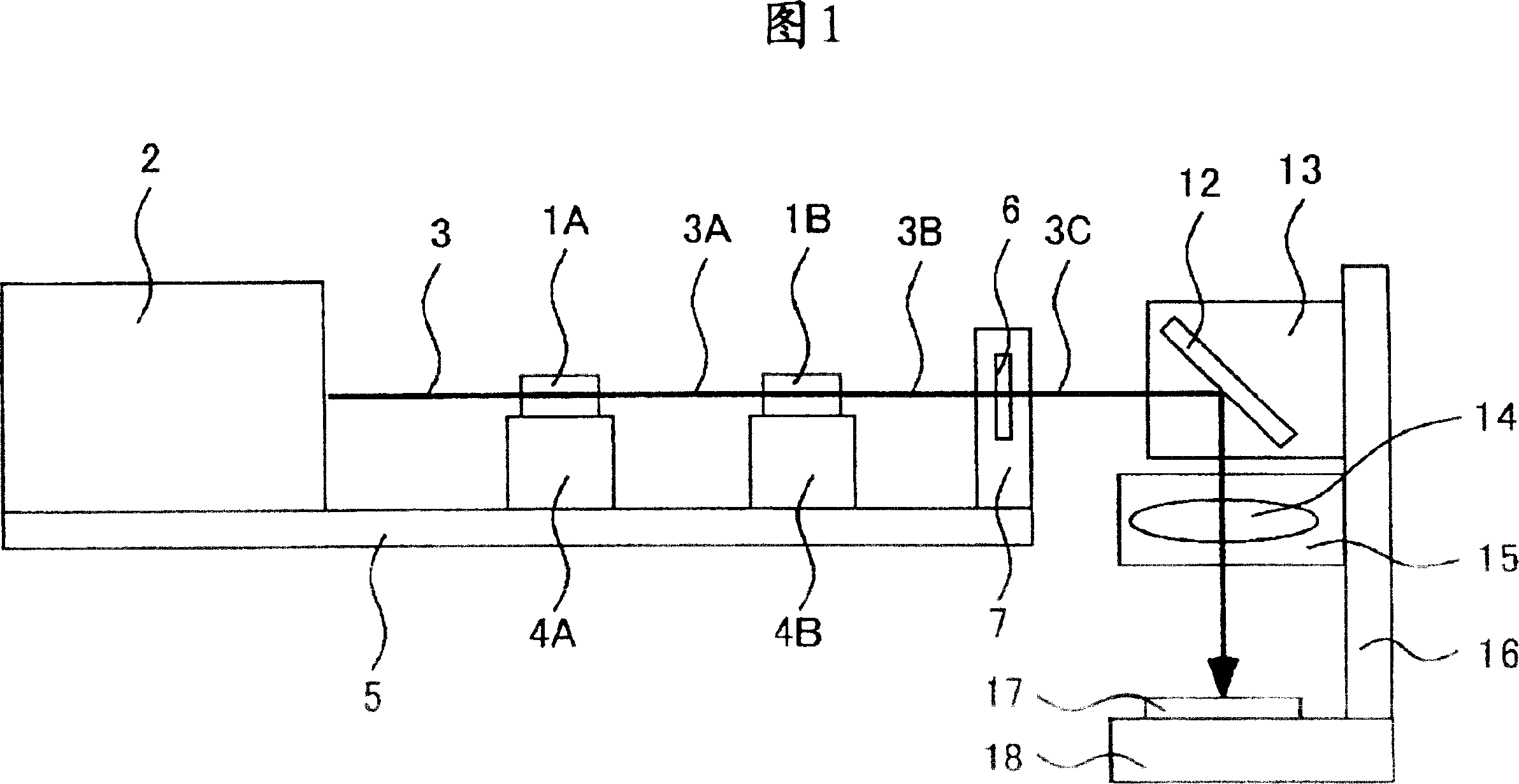

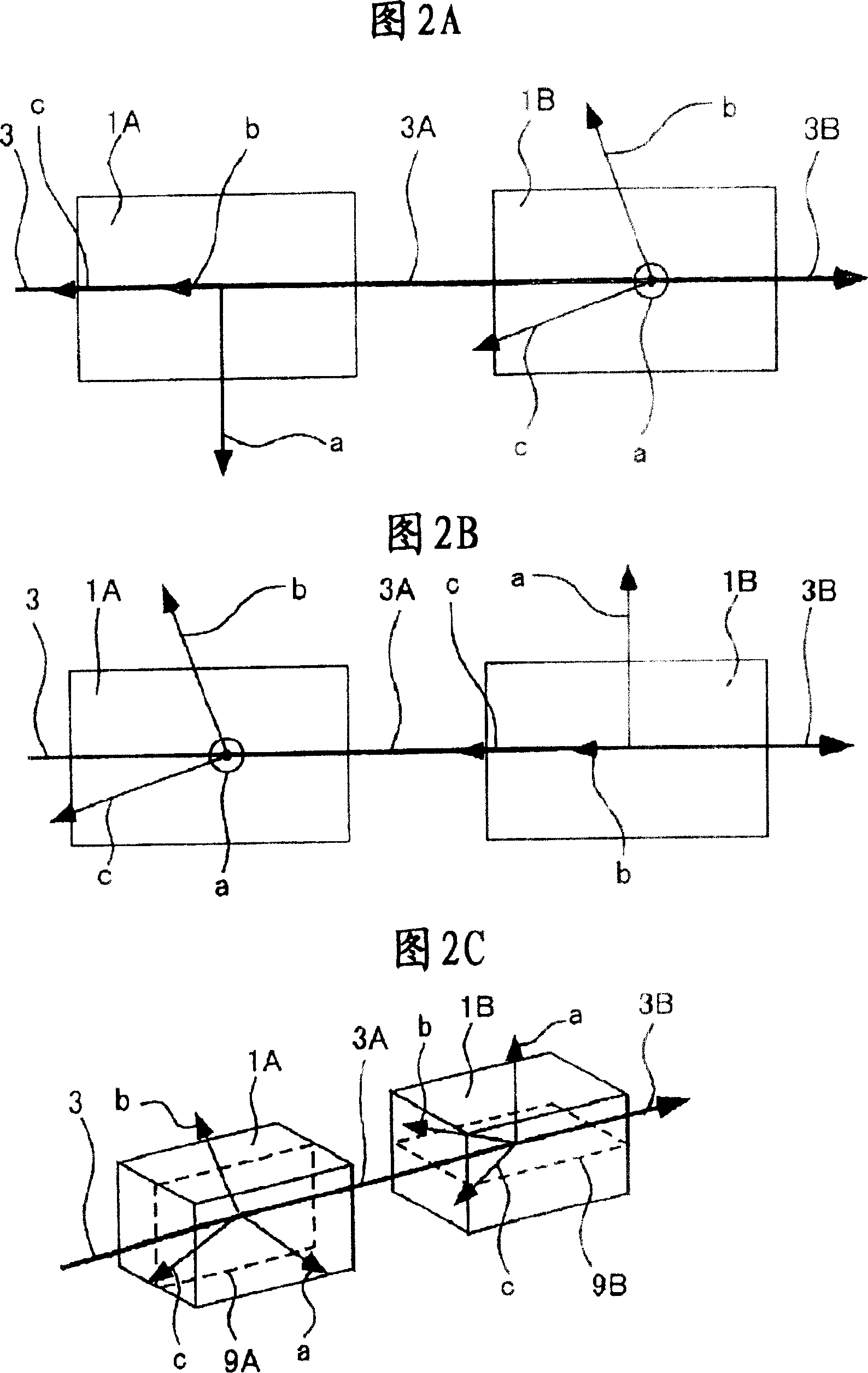

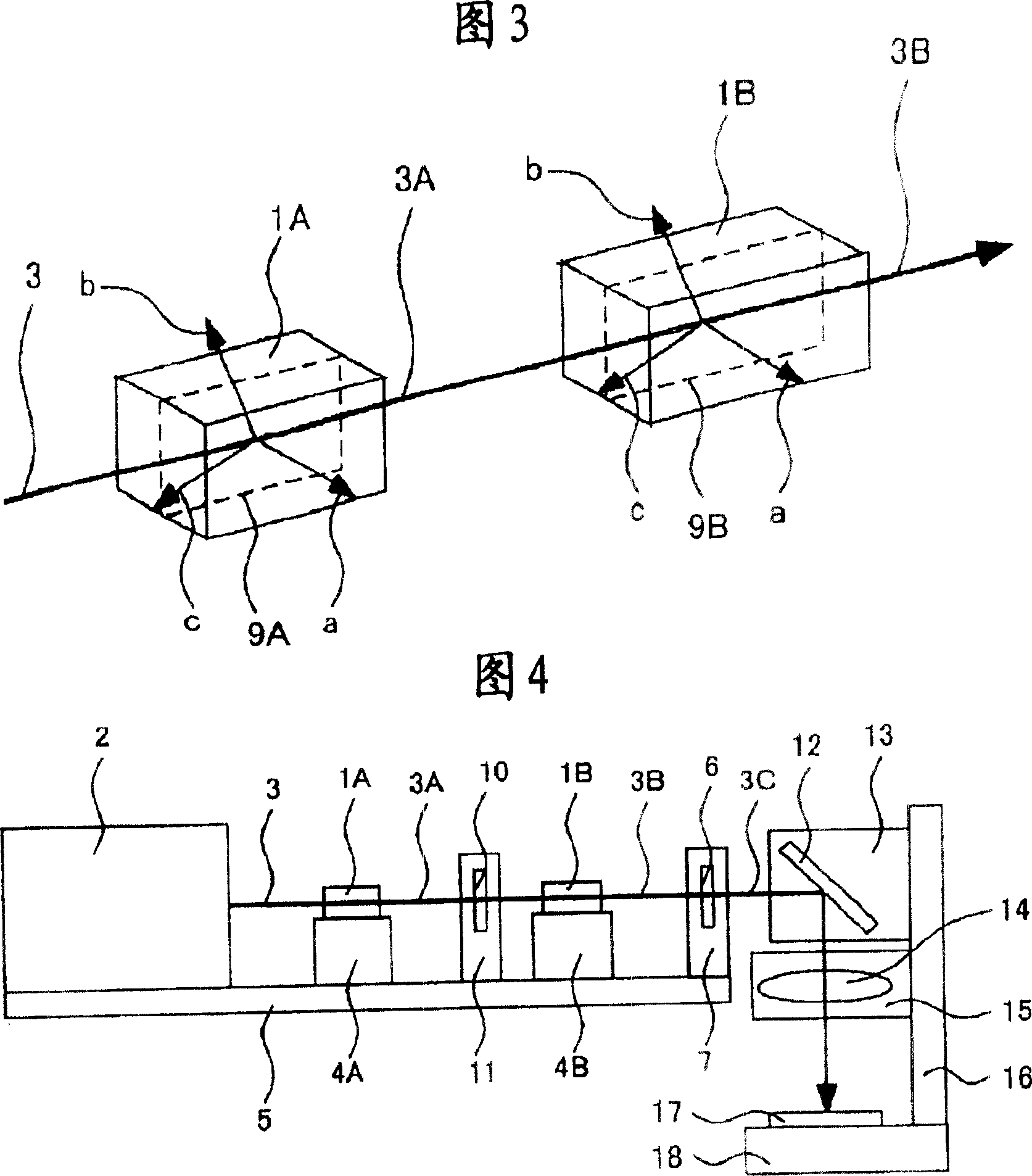

Wavelength conversion method, wavelength conversion laser, and laser beam machining apparatus

InactiveCN1332262CStable executionEnsure correct executionLaser detailsNon-linear opticsNonlinear optical crystalOptical axis

A fundamental laser beam to is wavelength converted through nonlinear optical crystals by traveling in one direction, sequentially through two nonlinear optical crystals arranged in series. A wavelength-converted laser beam is generated and includes wavelength-converted laser beams having polarized directions differing from each other by angles in a range from 45 DEG to 90 DEG . The two nonlinear optical crystals have crystal orientation axes differing by 45 DEG to 90 DEG when viewed along the optical axis of the laser beam.

Owner:MITSUBISHI ELECTRIC CORP

Plastic light guide fiber end face processing method

InactiveCN1307446CReduce the amount of lightChange the refractive indexCoupling light guidesFiberDrive shaft

Owner:NHK SALES

A steel belt drive swing head structure

ActiveCN111098172BSimple structureReduce weightMechanical energy handlingMetal working apparatusDrive wheelPull force

The invention discloses a steel belt transmission swing head structure, which adopts the combination of the A pendulum structure and the B pendulum structure, adopts the direct drive of the torque motor as the driving mode, adopts the combination of the pulley and the guide belt as the transmission mode, and adopts the arc guide rail and the rotating shaft Supporting and guiding the weight of the swing head is greatly reduced, and the speed and acceleration of the swing head are increased, which in turn can achieve more efficient cutting than the traditional mechanical AB swing head. By adjusting the tension of the two guide belts, the guide can be With two-way tensile pretension, the swing movement of the guide belt around the swing center O is completed, the swing head swings clockwise or counterclockwise, and the two guide belts are in a tight state, restraining the fan-shaped plates connected by the steel belt, eliminating The reverse clearance of the entire swing head; the two drive wheels of the entire swing head structure are directly driven by torque motors, and the rotor of the motor is rigidly coupled with the drive wheels, forming a transmission mechanism with no backlash, which simplifies the structure of the swing head and greatly reduces The weight of the swinging head.

Owner:XI AN JIAOTONG UNIV

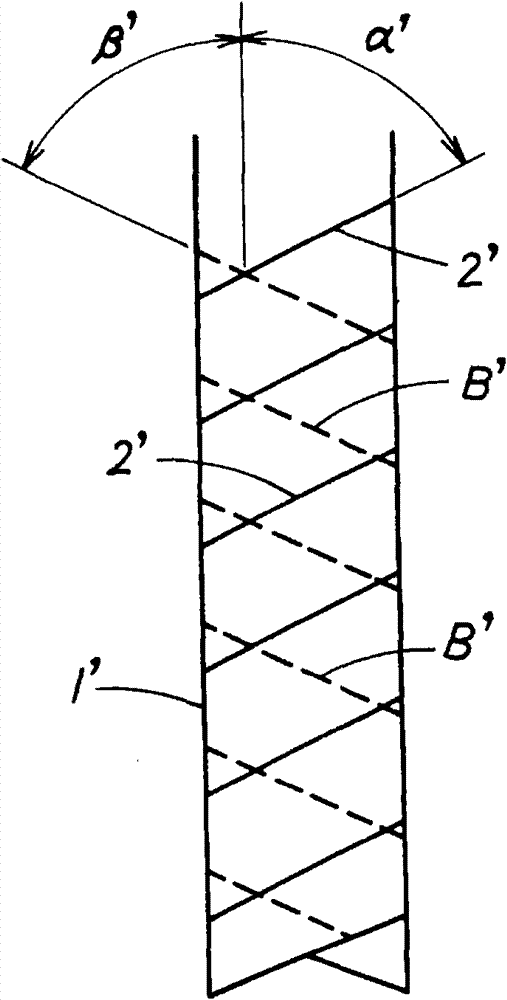

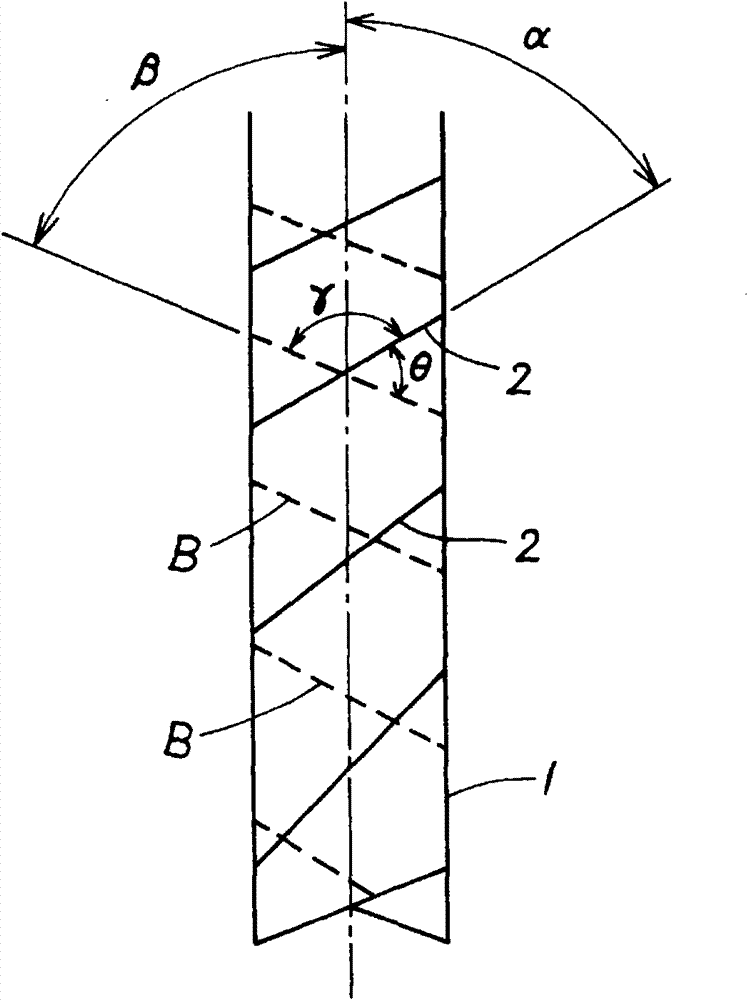

Rotary cutting tool

ActiveCN102000863BEfficient MachiningPracticalMilling cuttersDrilling toolsEngineeringMechanical engineering

The invention provides a rotary cutting tool. Compared with a conventional rotary cutting tool with a constant helical angle cuttings chute, the rotary cutting tool keeps good cutting machining for a long distance and has very excellent practicability. A plurality of spiral cuttings chutes (3) towards the proximal end side from the end of the tool are formed on the cirumference of the tool main body (1) and after the front tool surface of the cuttings chute (3) is crossed with the cirumferential surface of the tool main body (1) or the front tool surface of the cuttings chute (3) is crossed with the cirumferential back tool surface formed at the cirumference of the tool main body (1), a cirumferential cutting edge is formed at the crosses edge part and the helical angle (alpha) of the cirumferential cutting edge gradually increases from the end of the tool towards the proximal end side.

Owner:UNION TOOL

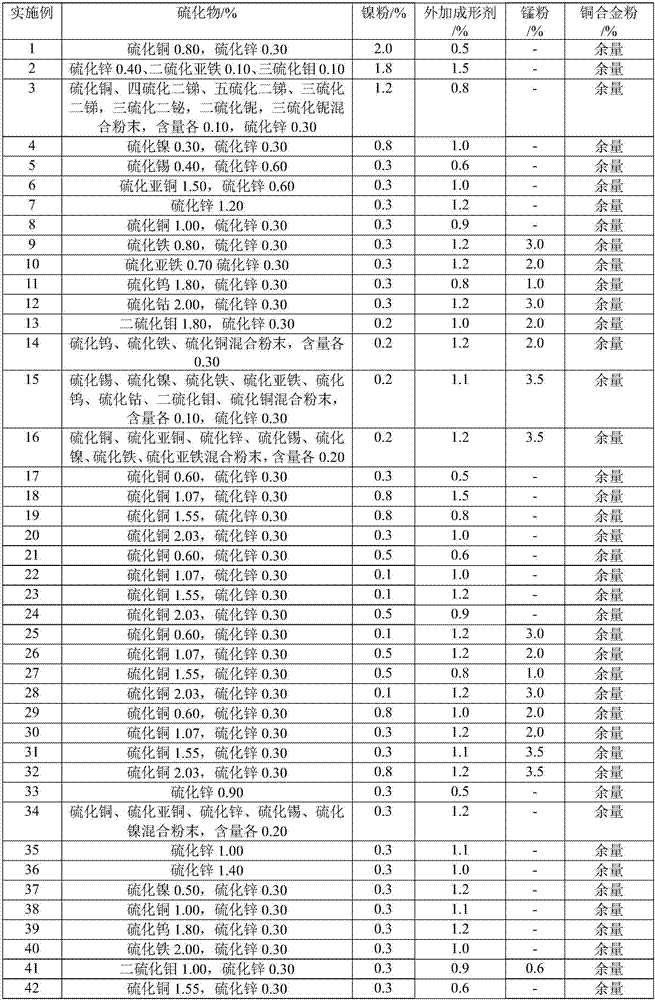

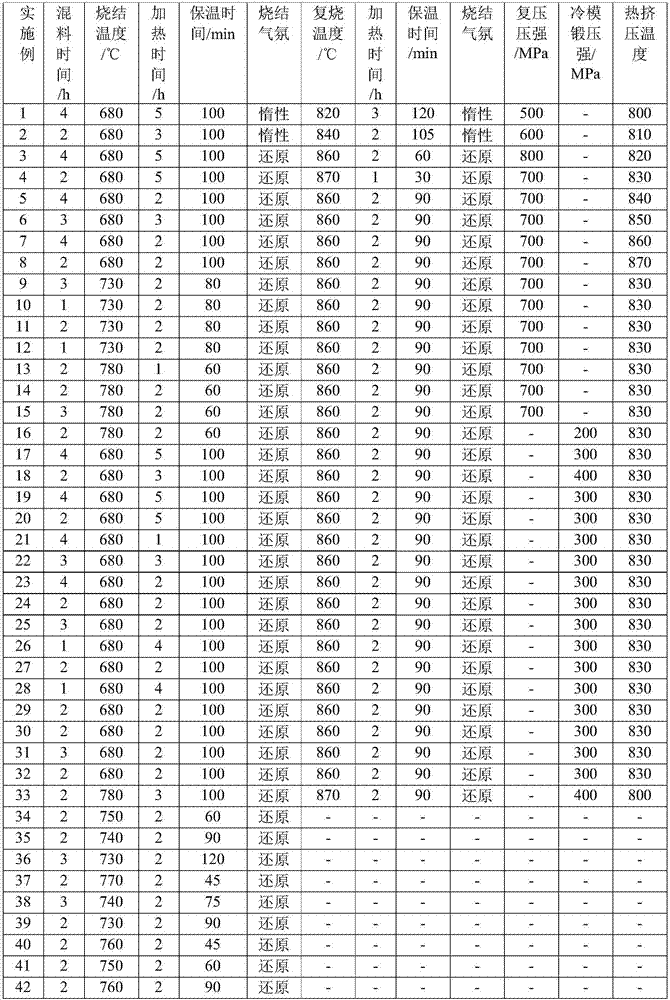

A lead-free free-cutting high-sulfur manganese-containing copper alloy and its manufacturing method

A lead-free free-cutting high-sulfur manganese-containing copper alloy and a manufacturing method thereof. The alloy composition is calculated by mass percentage: copper 52.0%‑95.0%, phosphorus 0.01%‑0.20%, tin 0.01%‑20%, manganese 0.55%‑7.0%, sulfur 0.191%‑1.0%, affinity with sulfur except zinc One or more metals with an affinity lower than the affinity between manganese and sulfur, the sum of their contents ≤ 2.0%, the balance being zinc and unavoidable impurities, among which the metals with an affinity lower than the affinity between manganese and sulfur are nickel and iron except for zinc , tungsten, cobalt, molybdenum, antimony, bismuth and niobium. The copper alloy is manufactured by powder metallurgy. After uniformly mixing alloy powder, sulfide powder and nickel powder, it is pressed and formed, sintered, re-pressed and re-fired to obtain the copper alloy and subjected to thermal processing.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

Ball end mill

ActiveCN102497950BIncrease resistanceEasy loadingMilling cuttersShaping cuttersEnd millMechanical engineering

At the front end portion of the end mill body that rotates around the axis, a plurality of bottom cutting edges are formed extending from the inner side of the front end to the outer side of the rear end of the front end portion. On the outer peripheral portion of the end mill main body, a plurality of outer peripheral cutting edges connected to the outer end of the bottom cutting edge and extending toward the rear end are formed. Some of the plurality of bottom edges are long bottom edges extending from the vicinity of the axis at the front end portion of the end mill body. A straight line connecting the outer peripheral edge connected to the long bottom edge and the axis on any cross section perpendicular to the axis and a bottom edge positioned forward in the direction of rotation of the end mill compared with the long bottom edge The angle formed by the outer peripheral cutting edge and the straight line of the axis is greater than the tangent line on the inner end of the long bottom edge when viewed from the front end in the direction of the axis and the bottom of the long bottom edge located in front of the rotation direction of the end mill compared with the long bottom edge The angle formed by the tangent on the inner end of the edge.

Owner:MITSUBISHI MATERIALS CORP

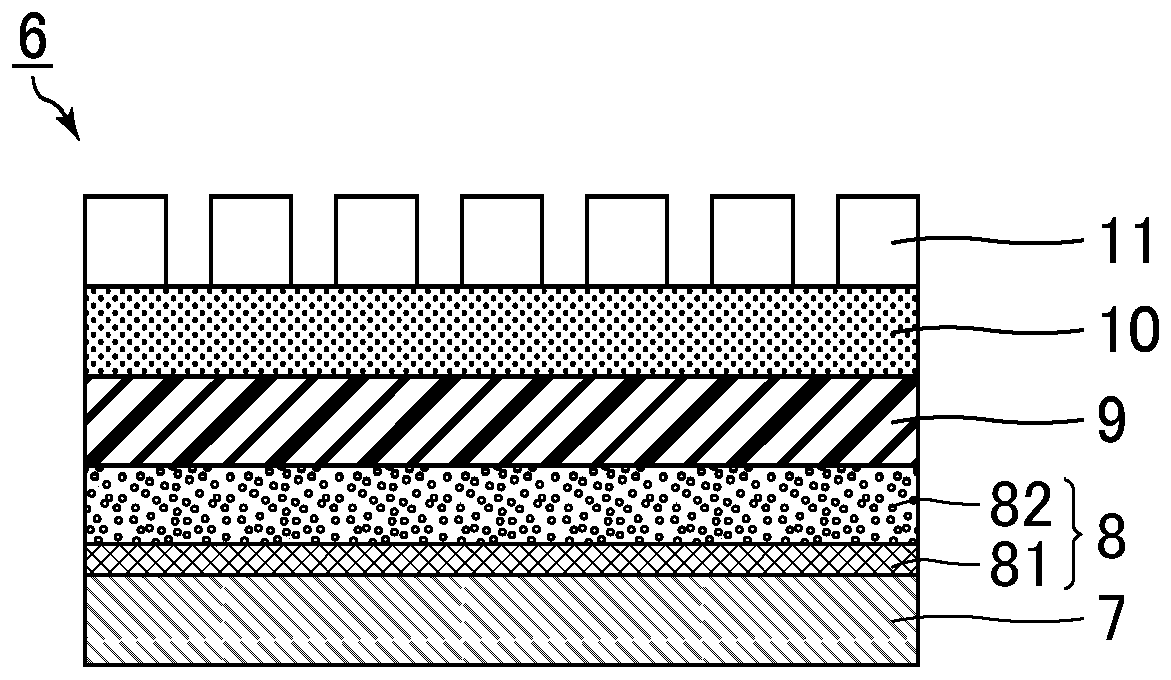

Solar cell and method for manufacturing solar cell

PendingCN110268537AEfficient MachiningImprove photoelectric conversion efficiencyFinal product manufactureSolid-state devicesElectrical batteryTitanium zirconium

A first purpose of the present invention is to provide a solar cell which has exceptional photoelectric conversion efficiency and for which machining during manufacturing (e.g., mechanical patterning) can be performed well, and a method for manufacturing said solar cell. The first invention is a solar cell which has, on flexible bases (1, 2), an electrode (4), a transparent electrode, and a photoelectric conversion layer disposed between the electrode (4) and the transparent electrode, wherein: the solar cell furthermore has a hard film (3) disposed between the flexible bases (1, 2) and the electrode (4); and the hard film (3) contains a nitride, a carbide, or a boride containing at least one element selected from the group consisting of titanium, zirconium, aluminum, silicon, magnesium, vanadium, chromium, molybdenum, tantalum, and tungsten.

Owner:SEKISUI CHEM CO LTD

Design method of hypoid gear pair

InactiveCN101982673BSimplify the design processImprove tooth surface accuracyToothed gearingsPortable liftingGear toothDesign methods

The invention discloses a design method of a hypoid gear pair, aiming at solving the problem of difficulty in designing the hypoid gear pair by using the prior art. The design method of the hypoid gear pair comprises the following steps: 1, taking a plane as a hypoid gear pair transmission forming principle for a big gear tooth surface; 2, determining the geometric technical parameters of a big gear tooth surface shape; 3, determining the geometric technical parameters of a small gear tooth surface shape; and 4, since the gear parameters refers to right-handed rotation of a big gear and left-handed rotation of a small gear, when the big gear is in right-handed rotation and the small gear is in left-handed rotation, dereferencing opposite numbers for the parameters related to the y axle inthe parameters. The determination of the geometric technology parameters of the big gear tooth surface shape comprises the following steps: definition of representing the geometric parameters of the big gear tooth surface shape, determination of the coordinates of an M point, determination of the component expression formula of a vector shown in the specification, solution of a tooth-shaped unit vector shown in the specification, solution of another tooth-shaped unit vector shown in the specification, solution of the normal vector shown in the specification one side tooth surface sigma2, determination of the equation of the one side tooth surface sigma2, determination of the equation of the other side tooth surface sigma1, determination of the equation of a tooth surface sigma1theta and formation of the gear teeth of the gear in array.

Owner:JILIN UNIV

Tooth groove machining cutter

InactiveCN104439541AEfficient MachiningImprove machining accuracyGear teeth manufacturing toolsGear teethEngineeringBlind hole

The invention relates to a tooth groove machining cutter. The tooth groove machining cutter comprises a holder, a cutting head and a blade body, wherein the holder and the cutting head are machined with chamfering transition; a straight groove is formed in the cutting head and comprises two mutually perpendicular groove walls; the first groove wall is a plane, and the second groove wall comprises a plane and a cambered surface; a sunken part is arranged at the front end of the first groove wall; a threaded blind hole perpendicular to the first groove wall is formed in the center of the sunken part; the blade body is placed in the sunken part and in threaded connection with the sunken part through a bolt; the blade body is a regular hexahedron; a plurality of straight teeth, which are in parallel, are arranged on the surface, far away from the second groove wall and parallel to the second groove wall, of the blade body; cutting edges are arranged on the straight teeth; furthermore, the straight teeth are perpendicular to the first groove wall. With application of the scheme, the straight teeth of the blade body are matched with the tooth grooves of the workpiece under machining; the workpiece can be quickly and efficiently cut and machined through the blade body, so that the machining precision and the machining efficiency can be greatly improved.

Owner:CHANGZHOU ZHUJIANG TOOL

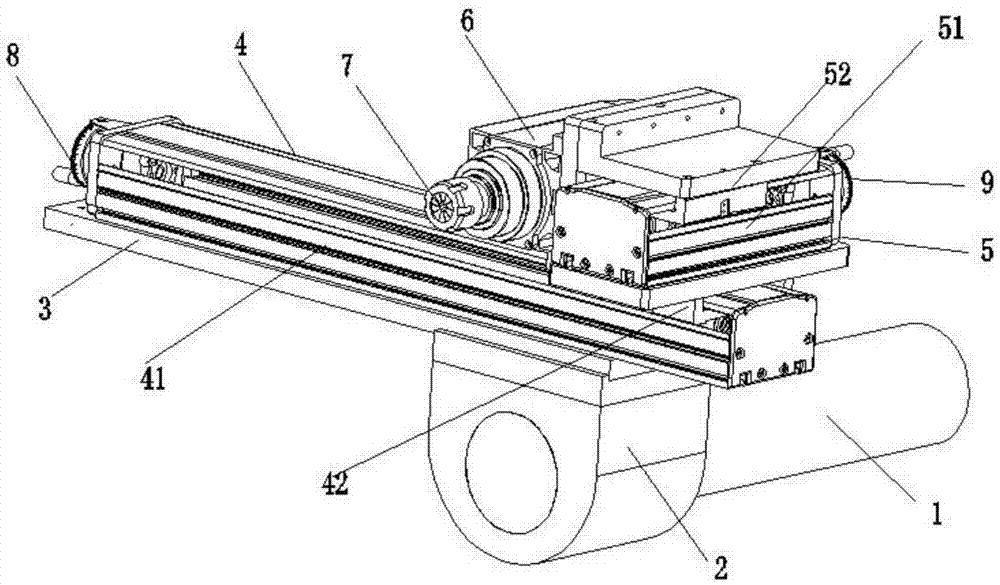

Mechanical arm used for machining installing face of aluminum alloy ship spray pump

PendingCN107336031AEfficient MachiningEasy to processLarge fixed membersMilling equipment detailsMarine engineeringMilling cutter

The invention discloses a mechanical arm used for machining the installing face of an aluminum alloy ship spray pump. The mechanical arm comprises a boring rod shaft, a fixing sleeve, a guide rail base, an X-axis direction guide rail assembly, a Y-axis direction guide rail assembly, a main shaft motor and a milling cutter disc. The fixing sleeve is fixedly arranged at one end of the boring rod shaft in a sleeving manner, a drive mechanism is arranged at the other end of the boring rod shaft, and the fixing sleeve is fixed to the lower end of the guide rail base. The X-axis direction guide rail assembly comprises an X-axis direction guide rail base, an X-axis direction lead screw and a first sliding block driven by the X-axis direction lead screw, and the guide rail base is fixedly arranged below the X-axis direction guide rail base. The Y-axis direction guide rail assembly comprises a Y-axis direction guide rail base, a Y-axis direction lead screw and a second sliding block driven by the Y-axis direction lead screw. The bottom face of the Y-axis direction guide rail is fixedly arranged on the upper face of the first sliding block, and the main shaft motor is fixedly arranged on one side of the second sliding block. The mechanical arm can efficiently, conveniently and rapidly machine the installing face of the spray pump with high precision, and the plane can achieve smooth finish of 1.6 microns and precision of 0.2 mm.

Owner:澳龙船艇科技有限公司

Tool for machining a hole

A hole machining tool is provided in which a dynamic balance and rigidity of a tool body are enhanced, positional adjustment of an insert can be easily and accurately performed, and a machining hole having a higher circular degree with excellent dimensional precision is formed. The invention is characterized in that a recessed portion (30) and a mounting seat (31) are formed at the front end of a tool body (21), on the mounting seat (31), the flat-shaped insert (50) is mounted to enable the thickness direction to face the tool body (21) radial direction, a surface directed in the rear side in the rotation direction T of the insert (50) is set as a pressed surface (61), a peripheral cutting edge is formed at a ridge portion on the outside of the tool body (21) radial direction of a rake face, and a cutting edge is formed at the ridge portion on the front side of the tool body (21), a back taper is attached to the peripheral cutting edge, and a pressing member (40) for pressing the pressed surface (61) of the insert (50) and adjusting a radial position of the peripheral cutting edge of the tool body (21) at the rear side in the tool rotation direction T of the mounting seat (31).

Owner:MITSUBISHI MATERIALS CORP

Low-temperature atomizing air cooler and its realization method

ActiveCN103286630BReduce the temperatureSolve pollutionMaintainance and safety accessoriesControl systemSpray nozzle

The invention discloses a low-temperature atomizing air cooler and an achieving method thereof. The low-temperature atomizing air cooler solves the problems that a normal-temperature air microscale oil atomizing technique in the prior art is high in temperature and poor in cooling effect, and low-temperature air flow cooling processing in the prior art is low-temperature air flow dry type cutting processing so as to be insufficient in lubrication and quick in cutter abrasion. The low-temperature atomizing air cooler comprises a drying tower, a refrigerating system, a microscale oil supplying mechanism, a mixing block, a spray nozzle and a PLC control system, wherein the drying tower is used for drying and cleaning air from the outside of the low-temperature atomizing air cooler, the refrigerating system is communicated with the drying tower through a pipeline and used for cooling air dried by the drying tower to form low-temperature air flow, the microscale oil supplying mechanism can inject oil or fluid into the mixing block through an oil pipe, the mixing block is respectively communicated with the microscale oil supplying mechanism and the refrigerating system and used for primarily atomizing the oil or fluid injected into the mixing block and low-temperature air flow to form low-temperature air flow fluid fog, the spray nozzle is communicated with the mixing block and can secondarily atomize the low-temperature air flow fluid fog obtained from primary atomization to obtain low-temperature atomized air flow.

Owner:成都凯里恩科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com