Tool for machining a hole

A hole processing and tool technology, applied in the direction of manufacturing tools, metal processing equipment, hole reaming devices, etc., can solve problems such as time and labor, achieve good dimensional accuracy and prevent vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

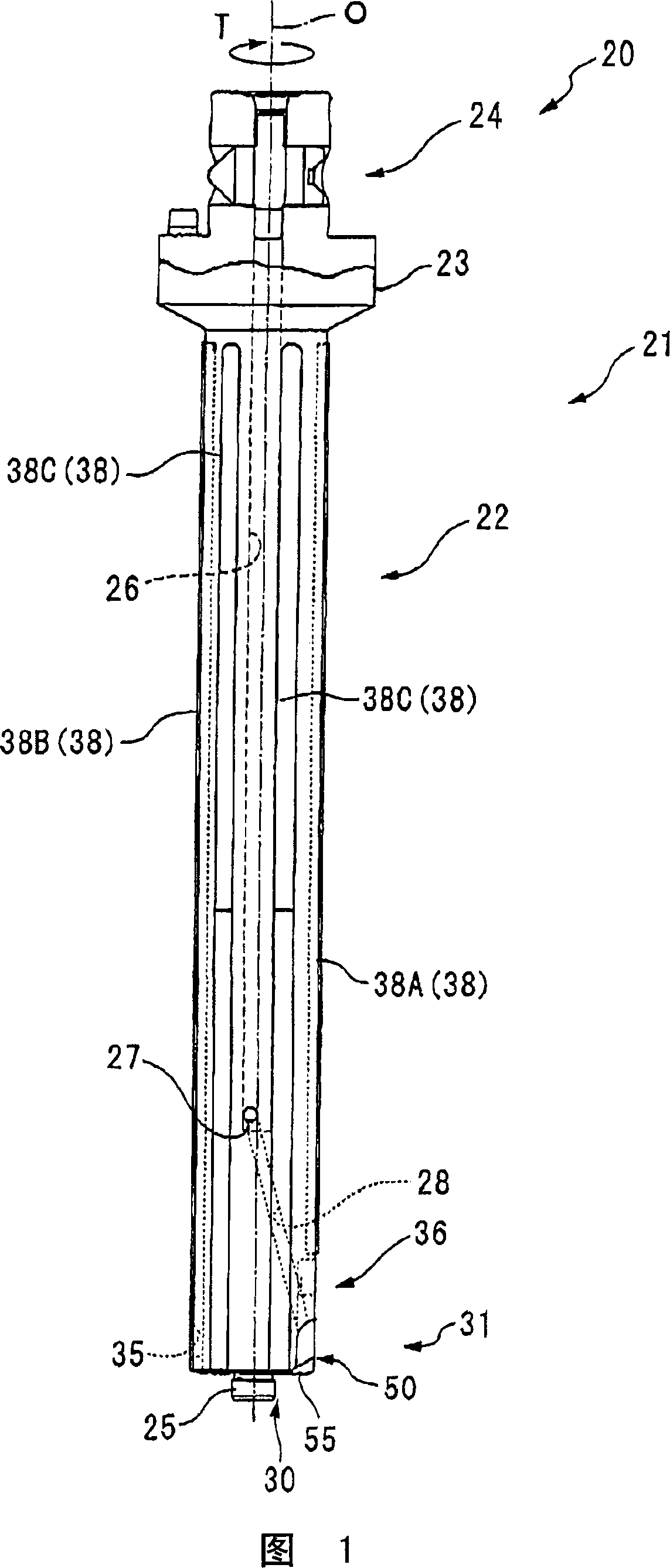

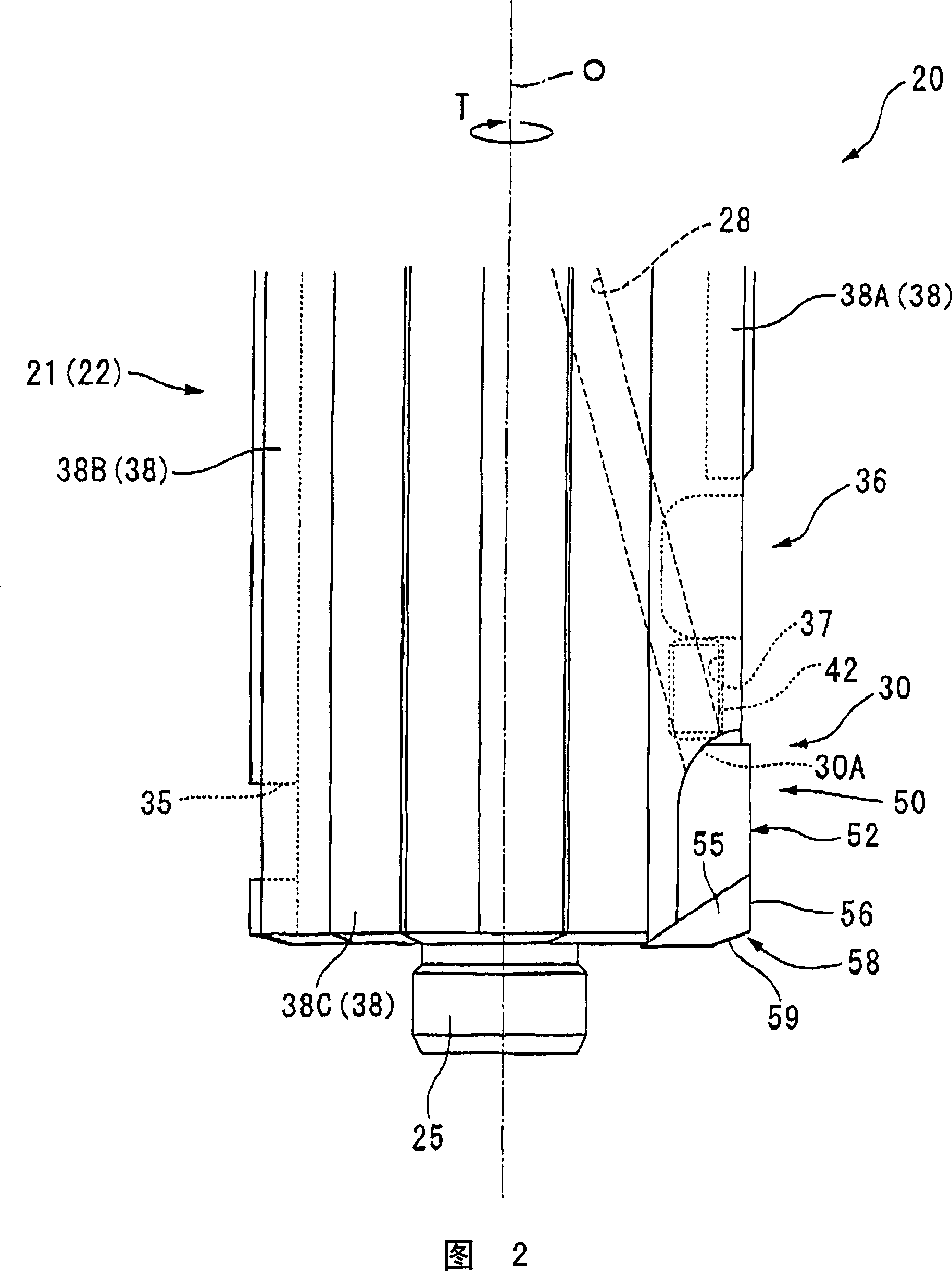

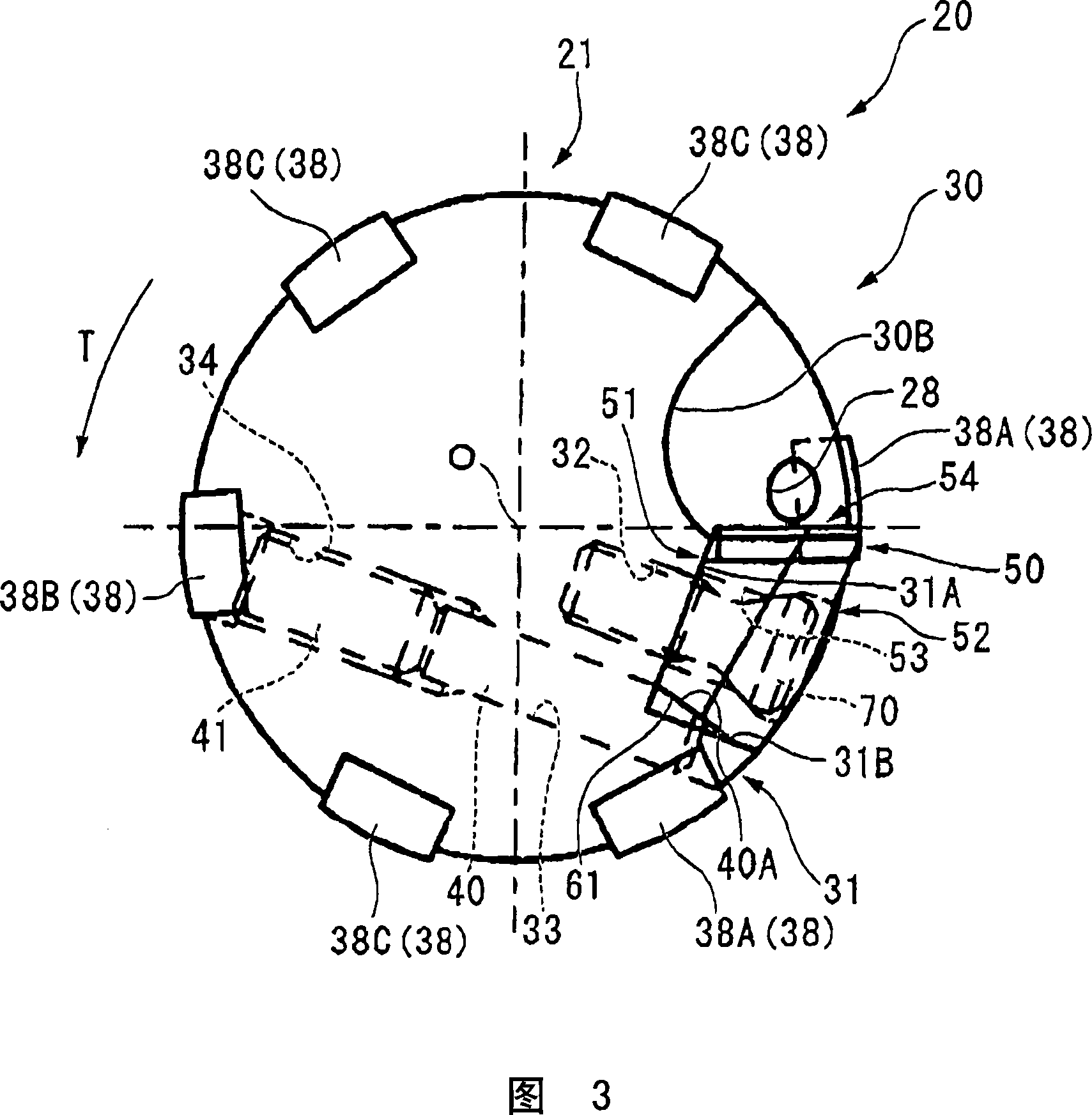

[0056] Next, a drilling tool as a first embodiment of the present invention will be described with reference to the drawings. FIG. 1 to FIG. 3 show a reamer as a drilling tool according to an embodiment of the present invention.

[0057] The reamer 20 according to this embodiment has a multi-stage cylindrical tool body 21 centered on the axis O. The front end side (lower side in FIG. 1 ) of the tool body 21 is a substantially cylindrical processed portion 22. On the rear end side (upper side in FIG. 1 ) of the tool main body 21, a flange portion 23 having a larger diameter than the processed portion 22 is formed. The reamer 20 is mounted on a mounting portion 24 of a tool holder (not shown) on a spindle end of a machine tool.

[0058] In addition, a guide rod 25 having a smaller diameter than the processed portion 22 is provided on the front end surface of the tool body 21 .

[0059] Furthermore, the tool main body 21 is pierced with a cooling part that is opened on the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com