A lead-free free-cutting high-sulfur manganese-containing copper alloy and its manufacturing method

一种锰铜合金、易切削的技术,应用在无铅易切削铜合金及其制造领域,能够解决石墨含油自润滑轴承强度有限、界面强度低、不能满足重载高速的使用环境等问题,达到优异工艺性能、切削性能好、热锻高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The mass fractions of each element in the manganese-containing copper alloy powder are: copper 54.0%, phosphorus 0.11%, tin 0.011%, manganese 0.6%, and the balance is zinc and unavoidable impurities. The mass fractions of various powders are as follows: the sulfide powder is a mixture of copper sulfide powder and zinc sulfide powder, the content of which is 0.8% and 0.30% respectively; the content of nickel powder is 2.0%; ; The balance is the above-mentioned manganese-containing copper alloy powder. The powder mixing time is 4.0h. After the mixing is completed, it is pressed. After the pressing, it is put into the sintering furnace for sintering. The sintering process is: heating from room temperature to the sintering temperature, heating time 5.0h, fully removing the forming agent, and sintering temperature 680 ℃, the holding time is 100min, the sintering atmosphere is an inert atmosphere, and after sintering, pass water to cool to room temperature. The sintered bras...

Embodiment 2- Embodiment 33

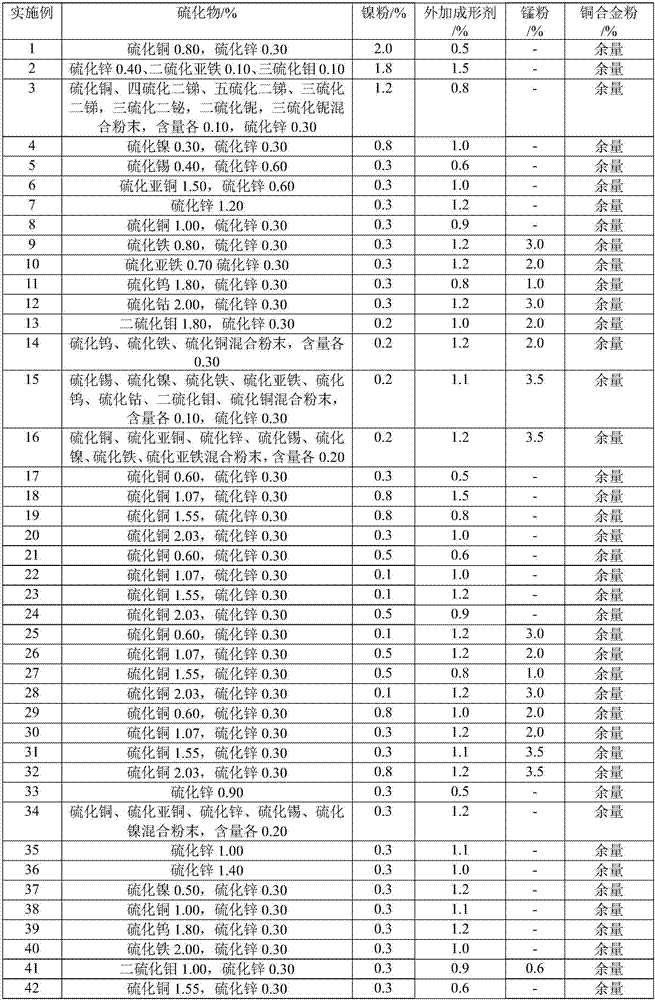

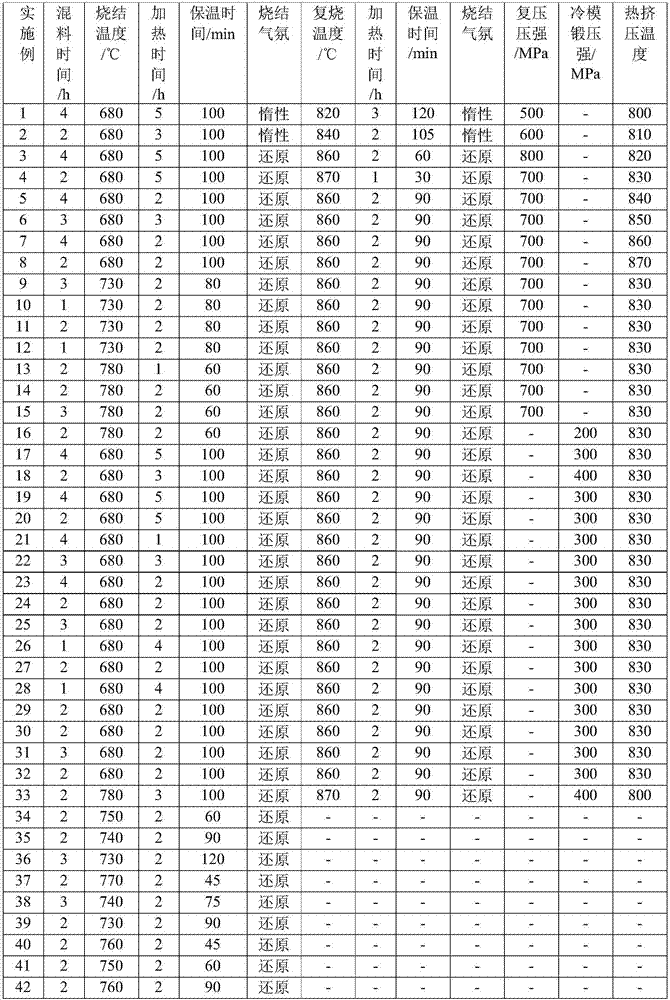

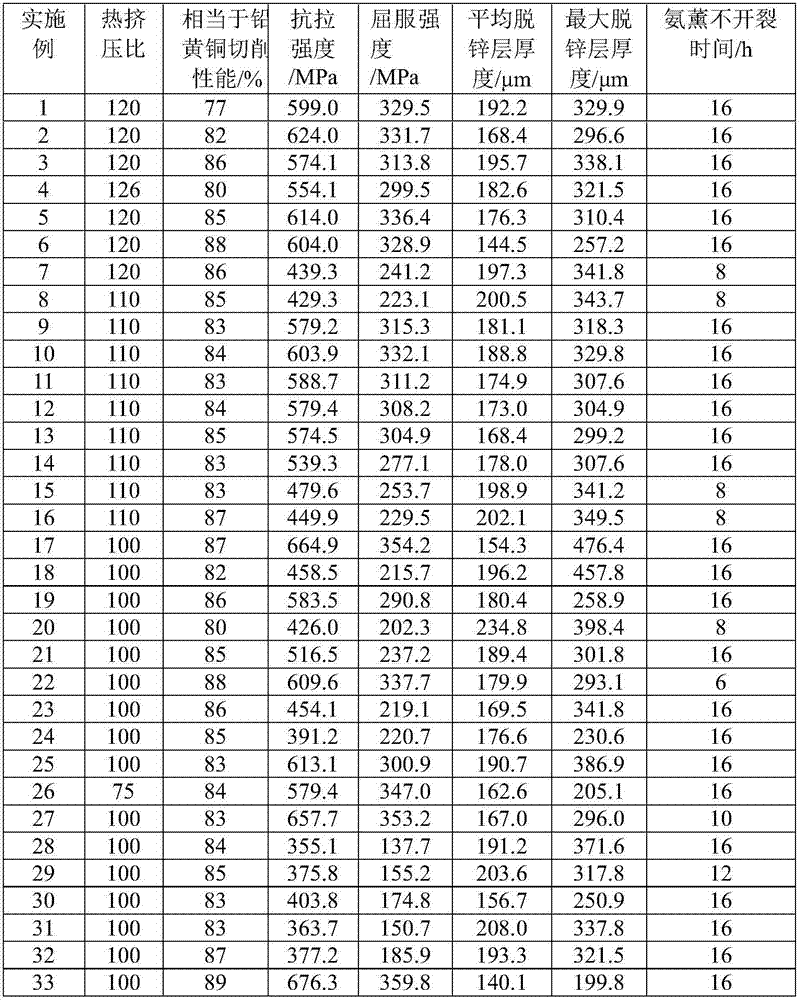

[0038] Embodiment 2-Example 33: See Table 1 for the chemical composition of the copper alloy powder in all examples of Example 2-33, see Table 2 for the mass percentages of various powders, and see Table 2 for the copper alloy manufacturing process parameters in the corresponding examples. Table 3, the properties of copper alloys in Examples 2-33 are shown in Table 4.

Embodiment 34

[0039] Example 34: The mass fractions of each element in the manganese-containing copper alloy powder are: copper 88%, tin 10.0%, manganese 1.5%, and the balance is zinc and unavoidable impurities. The mass fractions of various powders are as follows: a mixture of copper sulfide, cuprous sulfide, zinc sulfide, tin sulfide, nickel sulfide and other powders, the content of each sulfide is 0.2%; the content of nickel powder is 0.3%; The content of paraffin powder as an external forming agent is 1.2%; the balance is the above-mentioned copper alloy powder containing manganese. The powder mixing time is 2 hours. After the mixing is completed, it is pressed. After the pressing, it is put into a sintering furnace for sintering. The sintering process is: heating from room temperature to the sintering temperature, heating time 2 hours, fully removing the forming agent, and the sintering temperature is 750 ° C. The holding time is 60 minutes, and the sintering atmosphere is a reducing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com