Lens grinding method and device

A lens and grinding technology, used in grinding/polishing equipment, grinders, optical surface grinders, etc., can solve the problems of no consideration, processing time loss, etc., and achieve the effect of reducing resistance, avoiding waste, and inhibiting wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

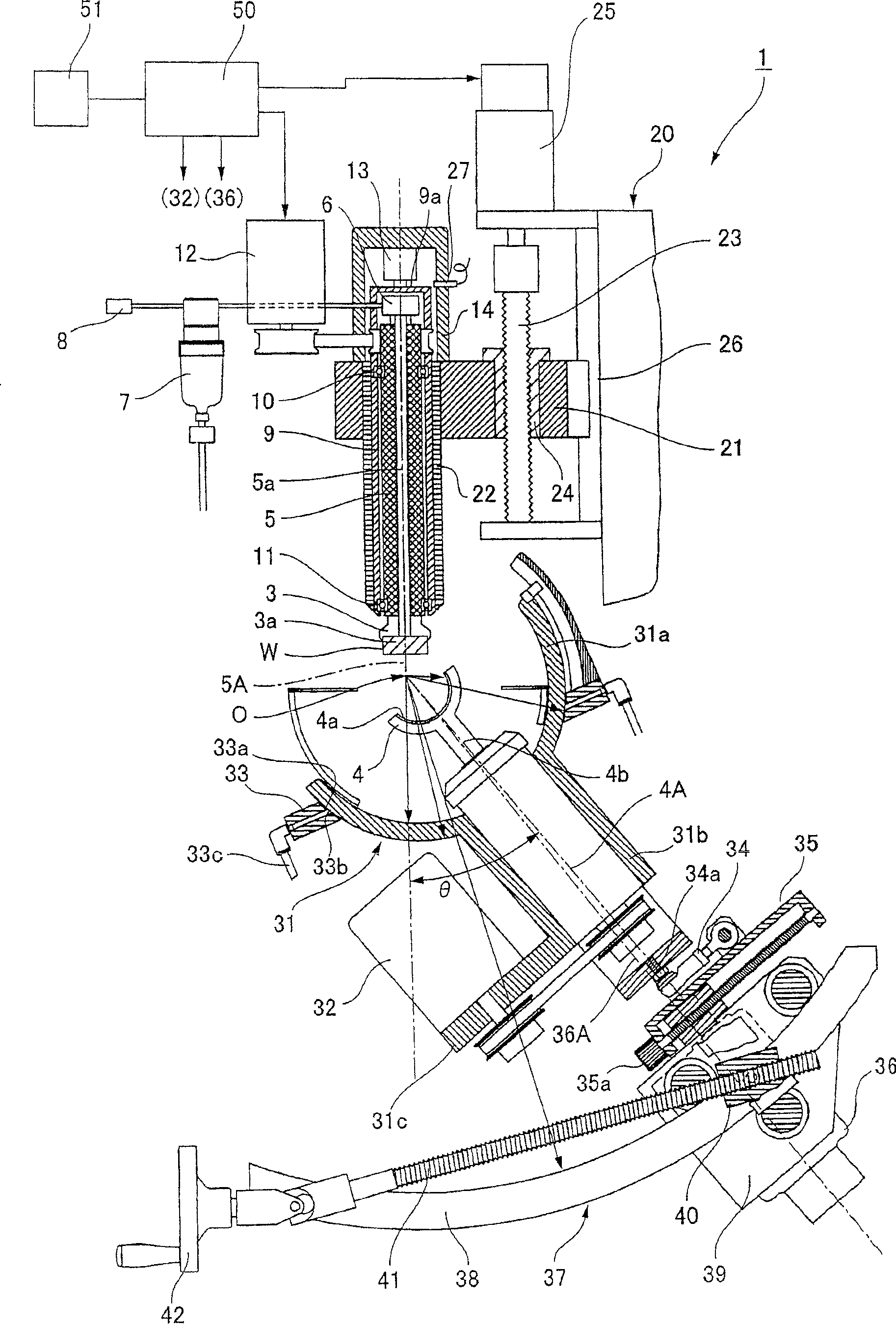

[0036] Hereinafter, an embodiment of a grinding apparatus for an optical spherical lens to which the present invention is applied will be described with reference to the drawings.

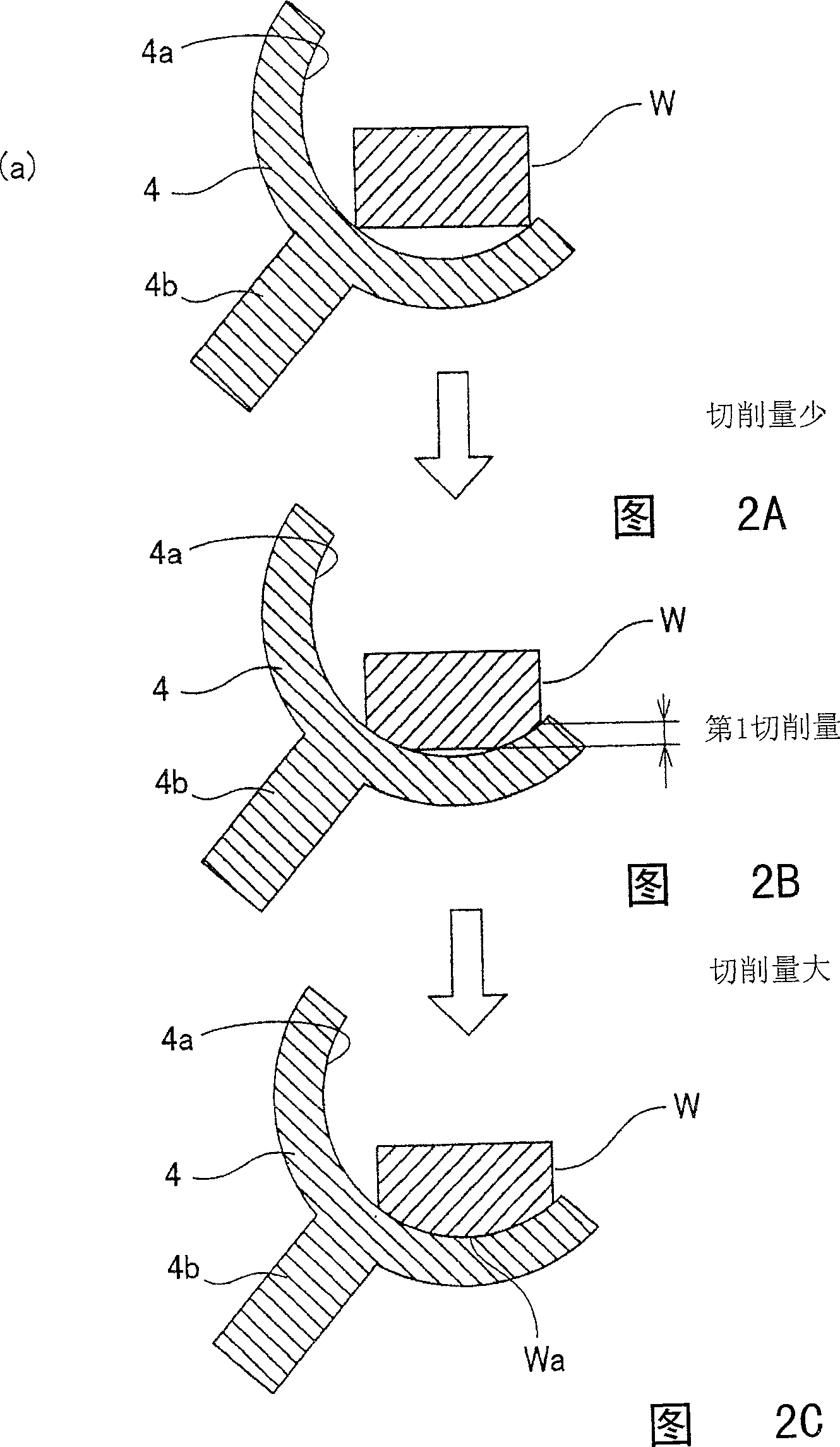

[0037] figure 1 It is a schematic configuration diagram showing a main part of the grinding apparatus for an optical spherical lens according to the present embodiment. Described with reference to this figure, the grinding device 1 has: a lens holder 3 for holding a lens blank W to be processed; and a spherical grinding surface 4a for grinding the lens blank W held on the lens holder 3 The bowl tool 4.

[0038]The lens holder 3 is fixed to the lower end of the vertical lens main shaft 5 with its holding surface 3 a held horizontally downward. At the center of the lens main shaft 5, a suction passage 5a extending toward its axis is formed, its lower end opens to the center of the holding surface 3a of the lens holder 3, and its upper end passes through the connection between the rotary joint 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com