Piezoelectric type ultrasonic rotary main shaft device

A rotating spindle and piezoelectric technology, applied in the field of material processing, can solve the problems of high processing cost, unsuitable size, complex structure, etc., and achieve the effect of compact structure, prolonging service life and ensuring wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

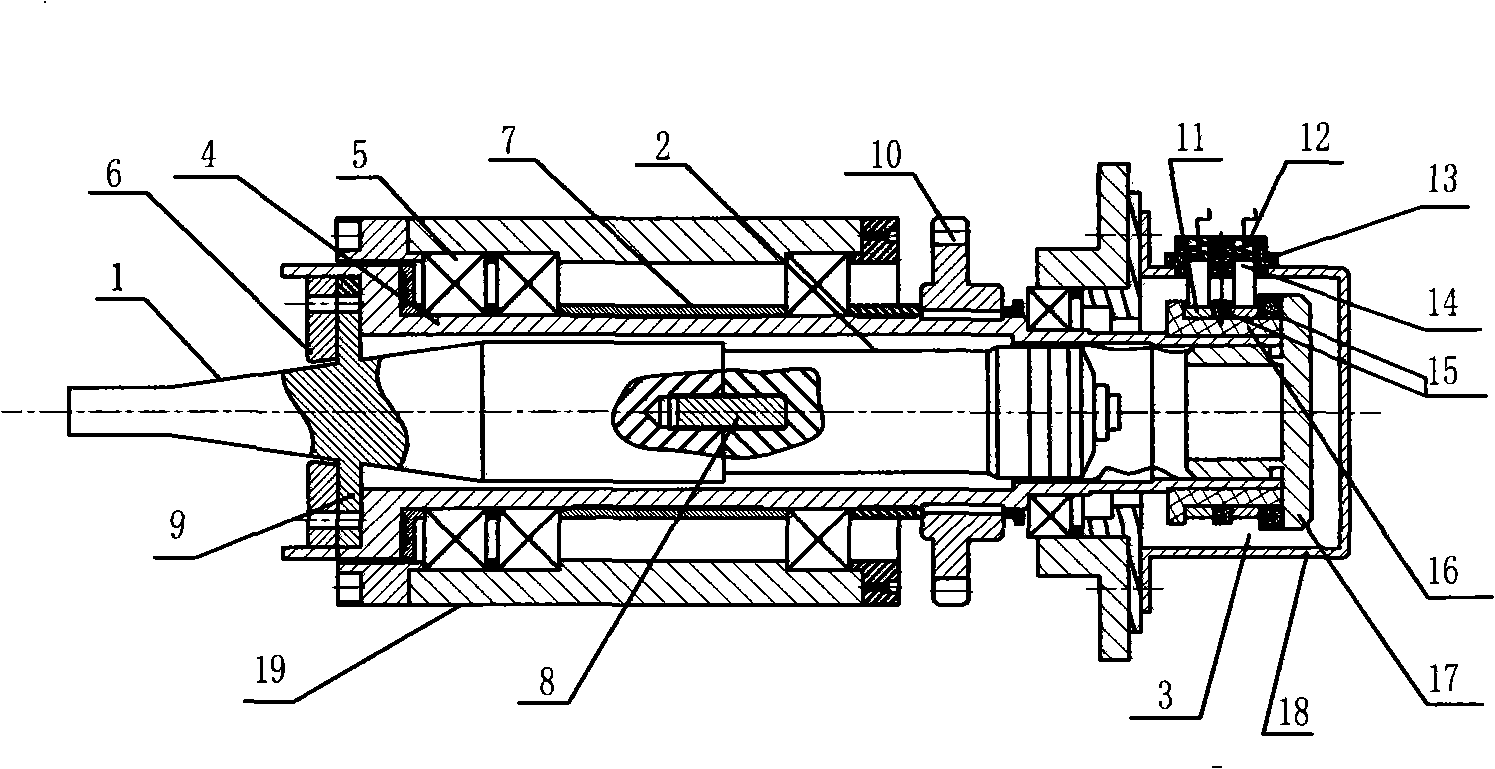

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] figure 1 As shown, the present invention is a piezoelectric ultrasonic rotating spindle device. It has a main shaft, a shaft sleeve 19, a horn 1, a transducer 2 and a current collecting device 3; The bearings are pressed and fixed between the outer shaft and the bushing 19 by the front and rear bearing flanges 6; positioning spacers and sleeves 7 are arranged between each bearing; the inner shaft is the horn Connect the horn and the transducer with a stud 8 and install it inside the outer shaft; the horn is provided with a flange part 9, and the flange part is connected by a flange and a screw Connected to the end of the outer shaft; only the flange at the wave node of the horn is connected to the outer shaft; a driving gear 10 is also installed in the middle of the outer shaft, and the rotating power is transmitted by the driving gear; The current collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com