Low-temperature atomizing air cooler and achieving method thereof

A realization method, the technology of air cooler, applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of high cost input, large temperature loss, high processing cost, etc., and achieve energy-saving and clean processing, high efficiency Cutting process, the effect of improving cutting parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

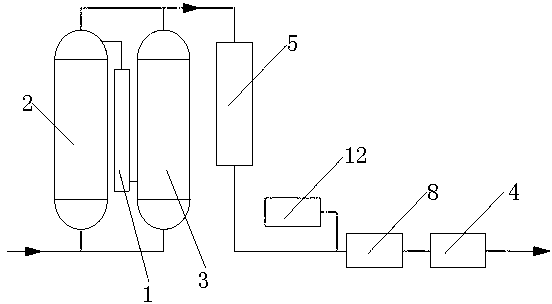

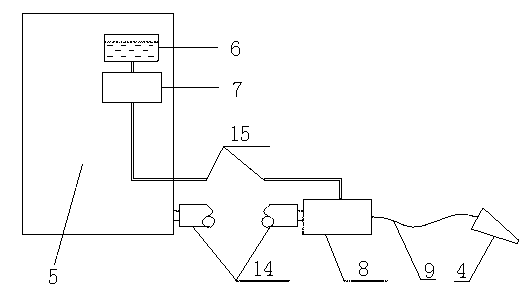

[0040] In the cutting process of existing machine tools, the cooling of workpieces and tools is mainly divided into three types: traditional coolant spray cooling and lubrication; micro oil atomization of normal temperature air with lubrication but poor cooling effect; low temperature air without lubrication flow cooling. In order to overcome the above defects, this embodiment provides a low-temperature atomizing air cooler, such as figure 1 As shown, the low-temperature atomizing air cooler has changed the traditional cutting method of cooling with oil and coolant, and at the same time organically combined the micro-oil atomization of normal temperature air and the cooling technology of low-temperature air flow into one, and the machine under a certain pressure After the normal temperature air is dried and purified, the airflow is cooled by the refrigeration system to form a low-temperature airflow, and then the liquid or oil is atomized twice to atomize a small amount of oil...

Embodiment 2

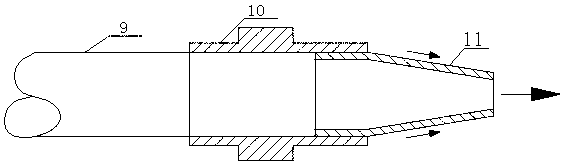

[0056] The difference between this embodiment and Embodiment 1 is that the structure of the nozzle is different, such as Figure 4 As shown, the nozzle in this embodiment is composed of a nozzle body 10, a nozzle opening 11 and a valve core 13 arranged between the two. The adjustable pipe is connected to the nozzle body, the mixing block and the nozzle are connected to the nozzle through an adjustable hose 9, the liquid is sprayed from the hole diameter (1mm in diameter) in the center of the valve core, and the low-temperature air flow is from the center hole of the valve core and the nozzle body and the nozzle mouth The gap is sprayed to achieve the second atomization, and the arrow in the figure indicates the direction of the mist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com