Plastic light guide fiber end face processing method

一种光导纤维、加工方法的技术,应用在光导、光波导的耦合、光学等方向,能够解决不能形成等问题,达到容易操作、简便端面加工、加工结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

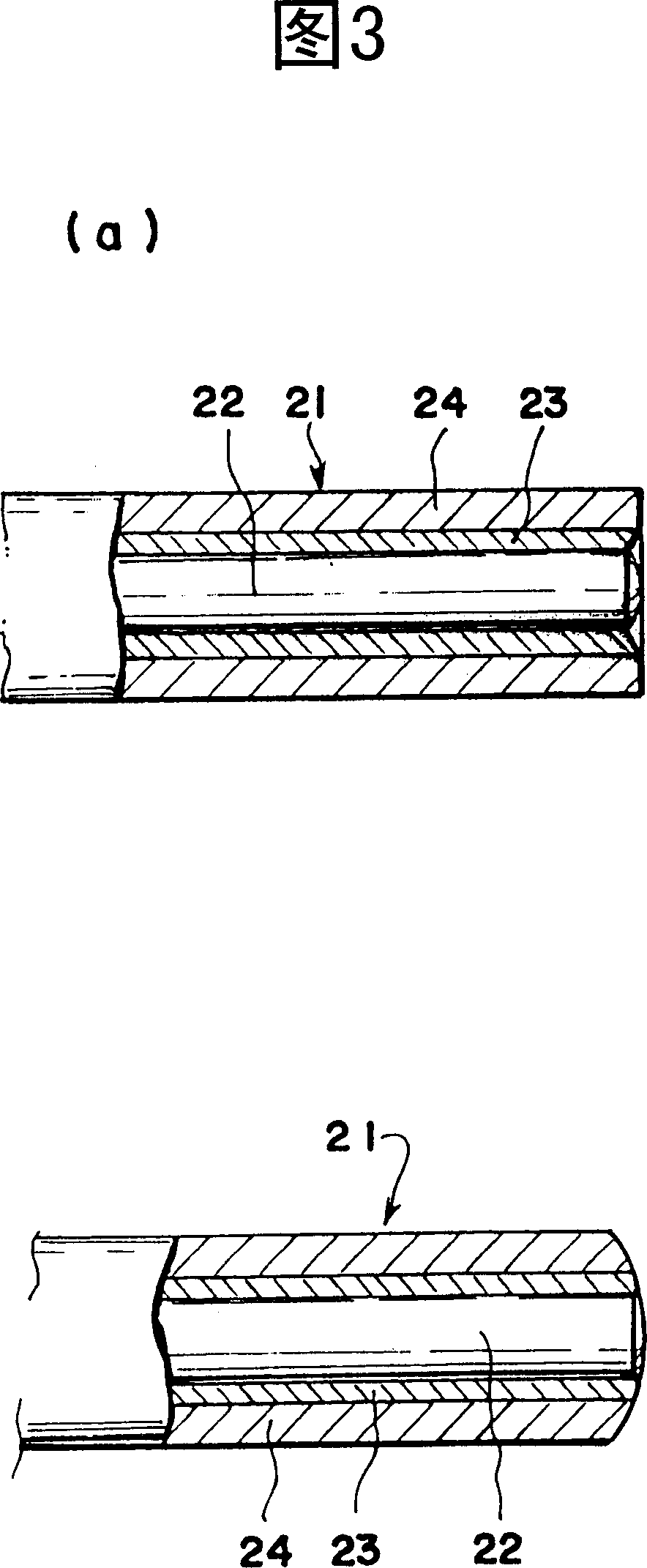

[0067] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The processing method of the plastic optical fiber end face of the present invention is to use a semicircular cutting blade to cut at least the core part of the plastic optical fiber end face into a hemispherical surface in the through hole of the jig, and the semicircular cutting blade is convex or concave. Shaped semicircular, the end face of the plastic optical fiber is machined into a convex or concave hemispherical surface.

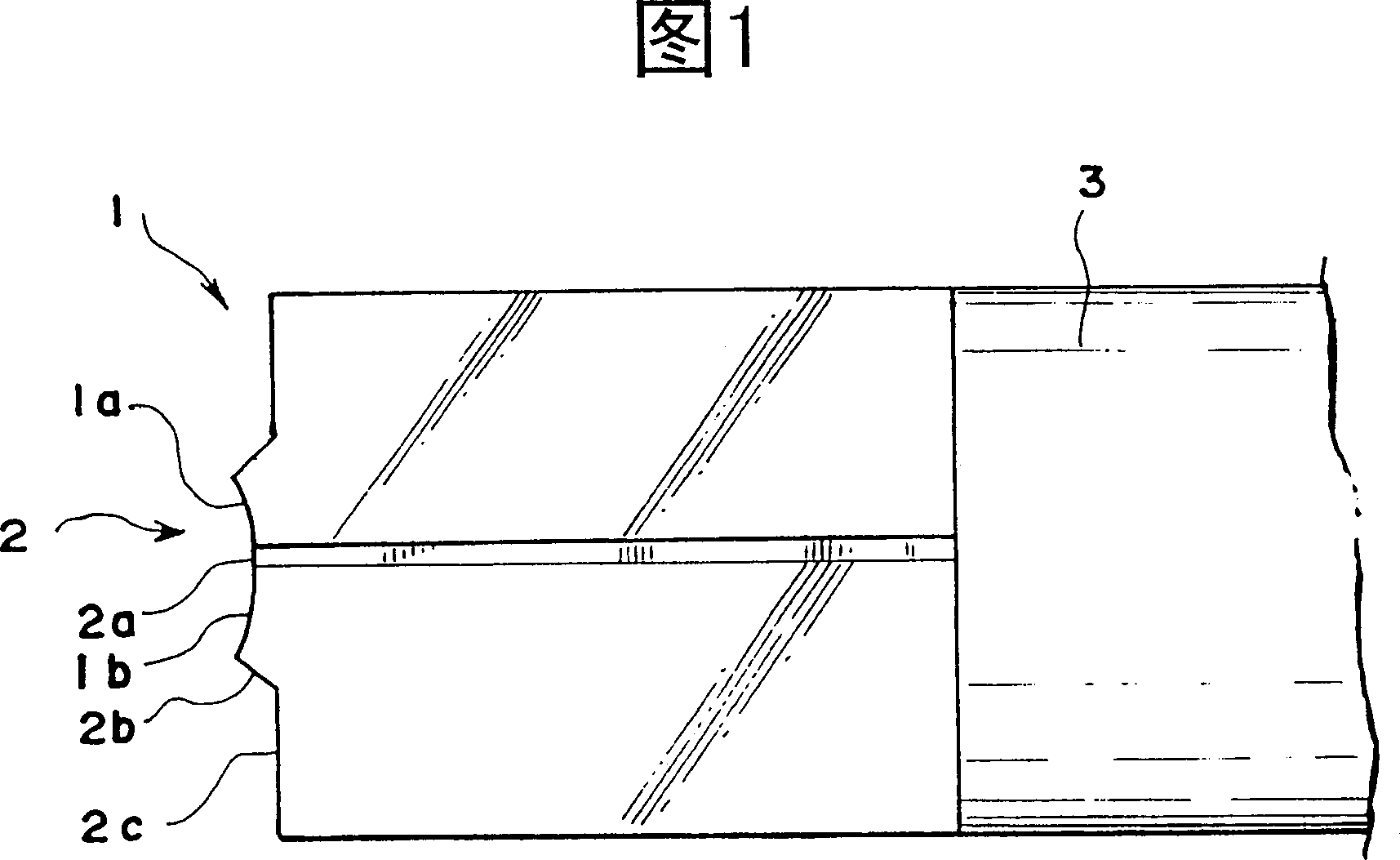

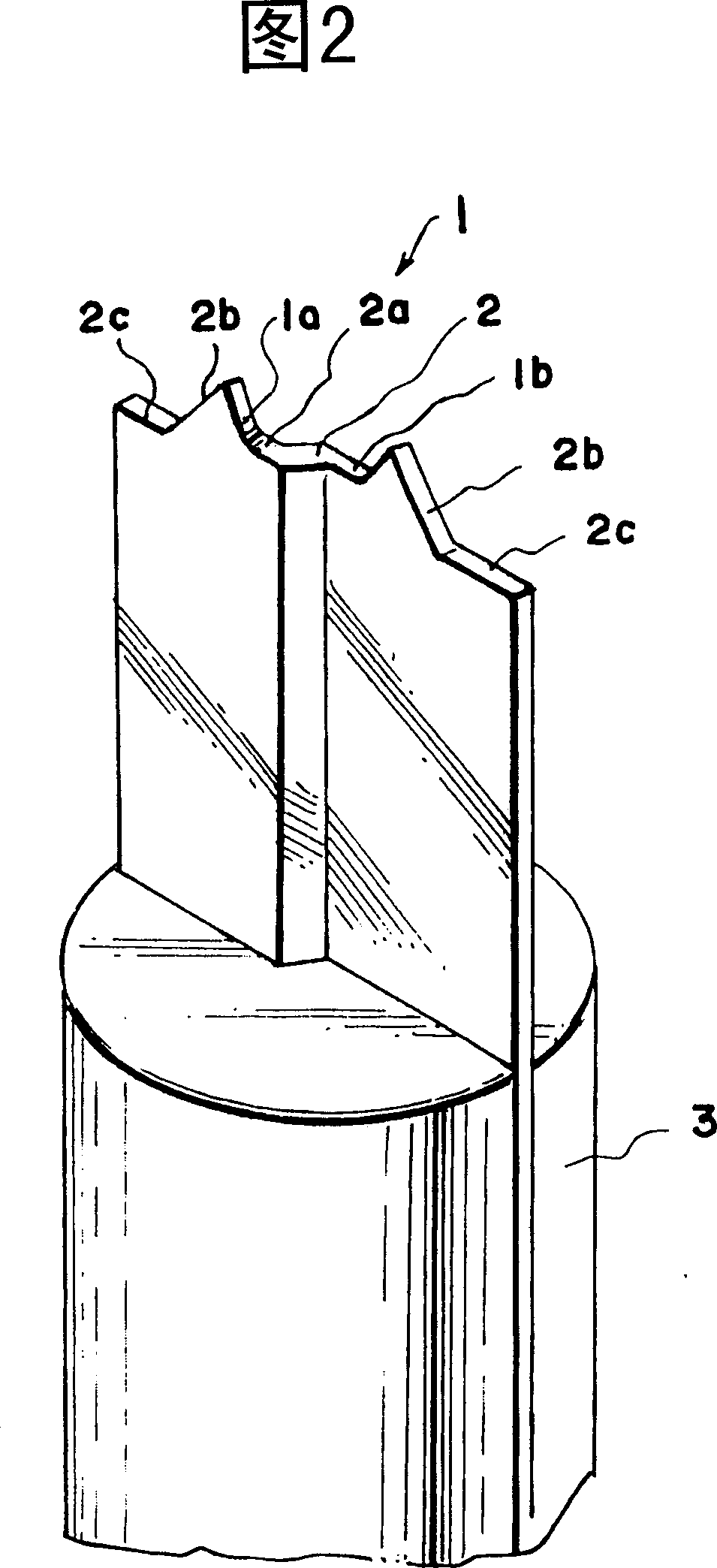

[0068] 1 and 2 are an enlarged front view and an enlarged perspective view of main parts showing an example of a semicircular cutting edge. In the above figure, the cutting edge 1 is provided at the tip of the shaft portion (cylindrical portion) 3. In this embodiment, the cutting edge 1 is formed into a convex semicircular shape by two cutting edges 1a, 1b. Specifically, as shown in FIGS. 1 and 2, the cutting edge 1 has a head 2 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com