Media, filter element using corrugated media sheet, corrugated sheet, and methods

a filter element and media sheet technology, applied in the field of filter elements, corrugated webs, corrugated webs, etc., can solve problems such as substantial damage to equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Some Principles Related to Filter Design

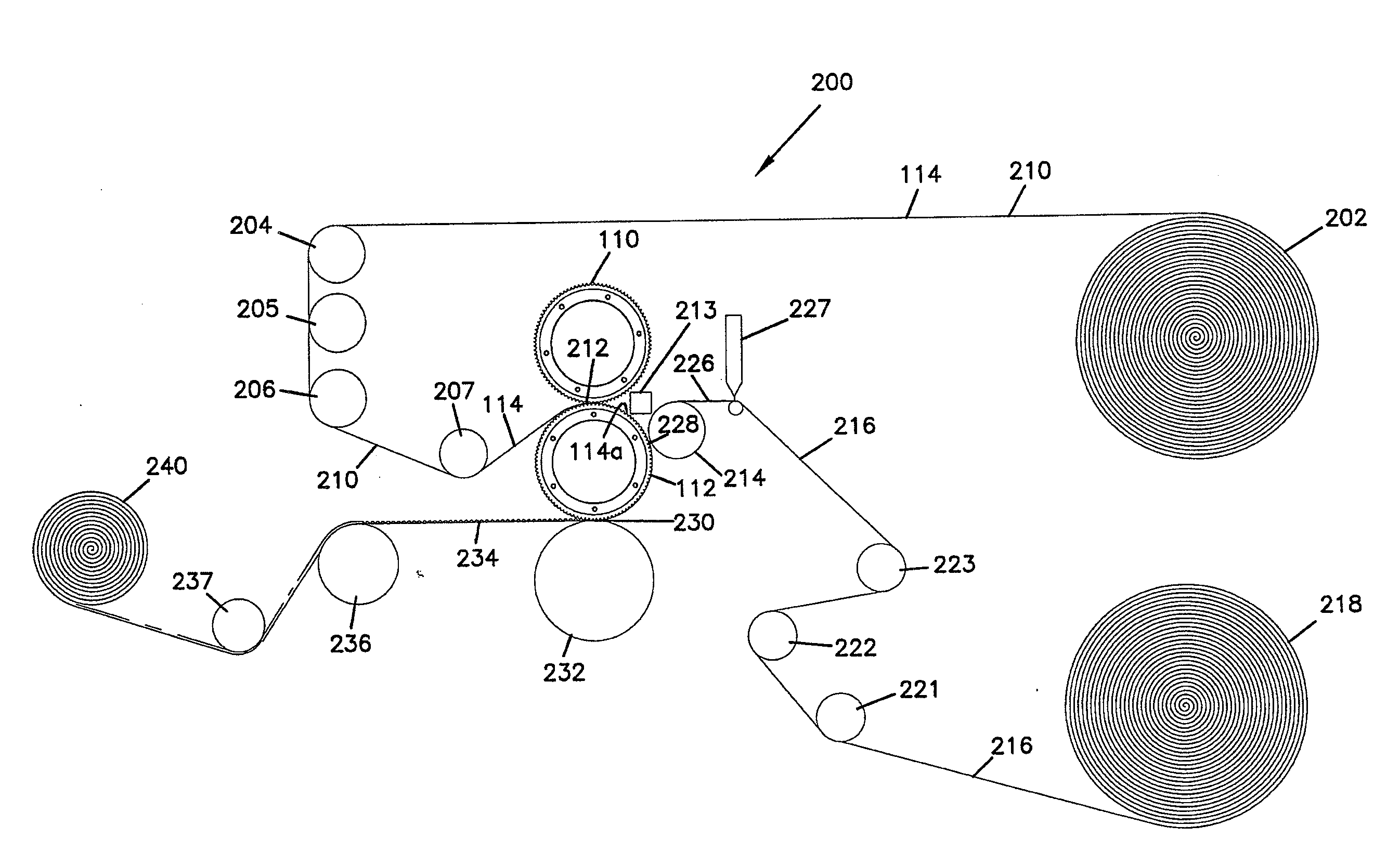

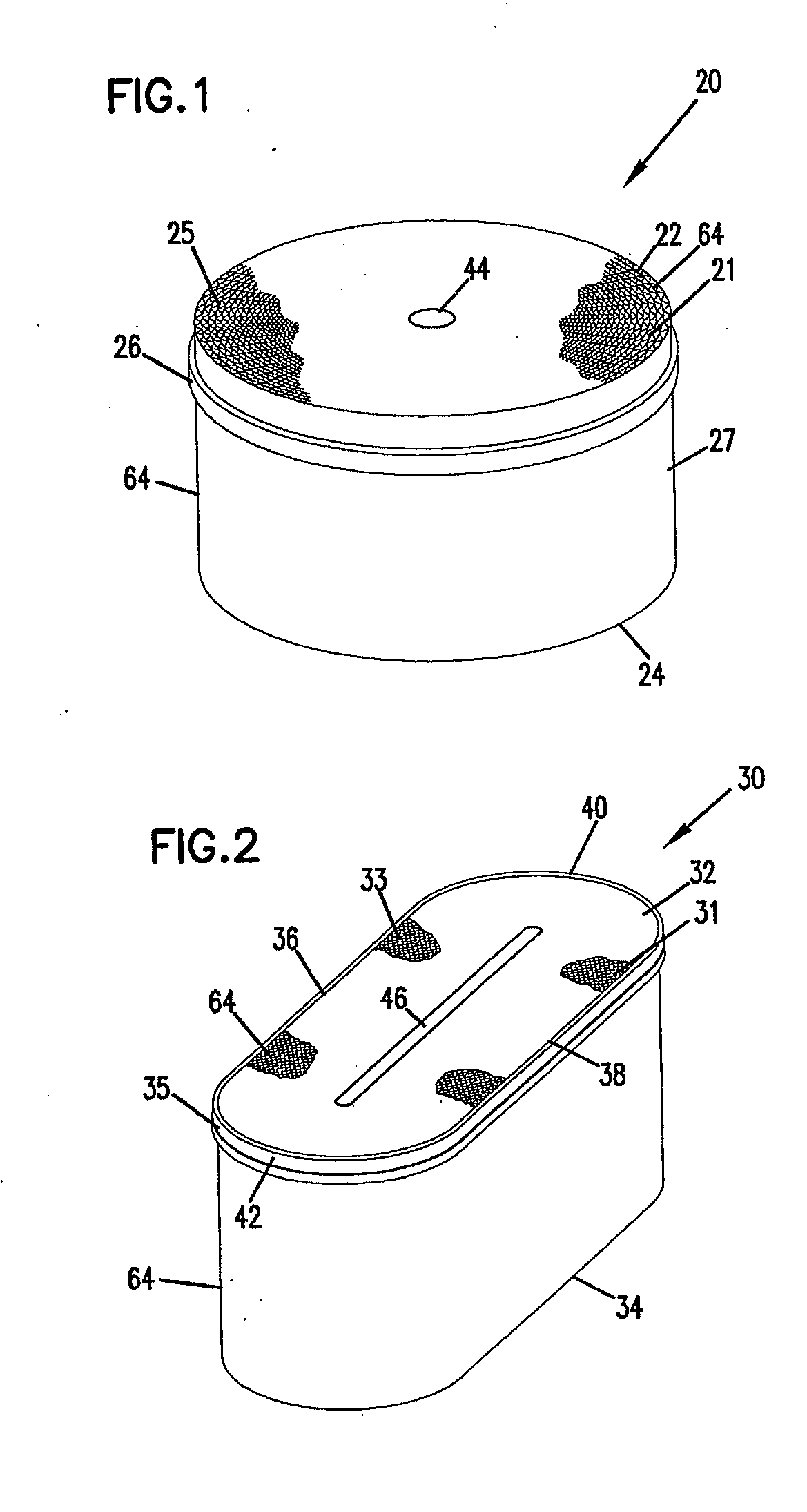

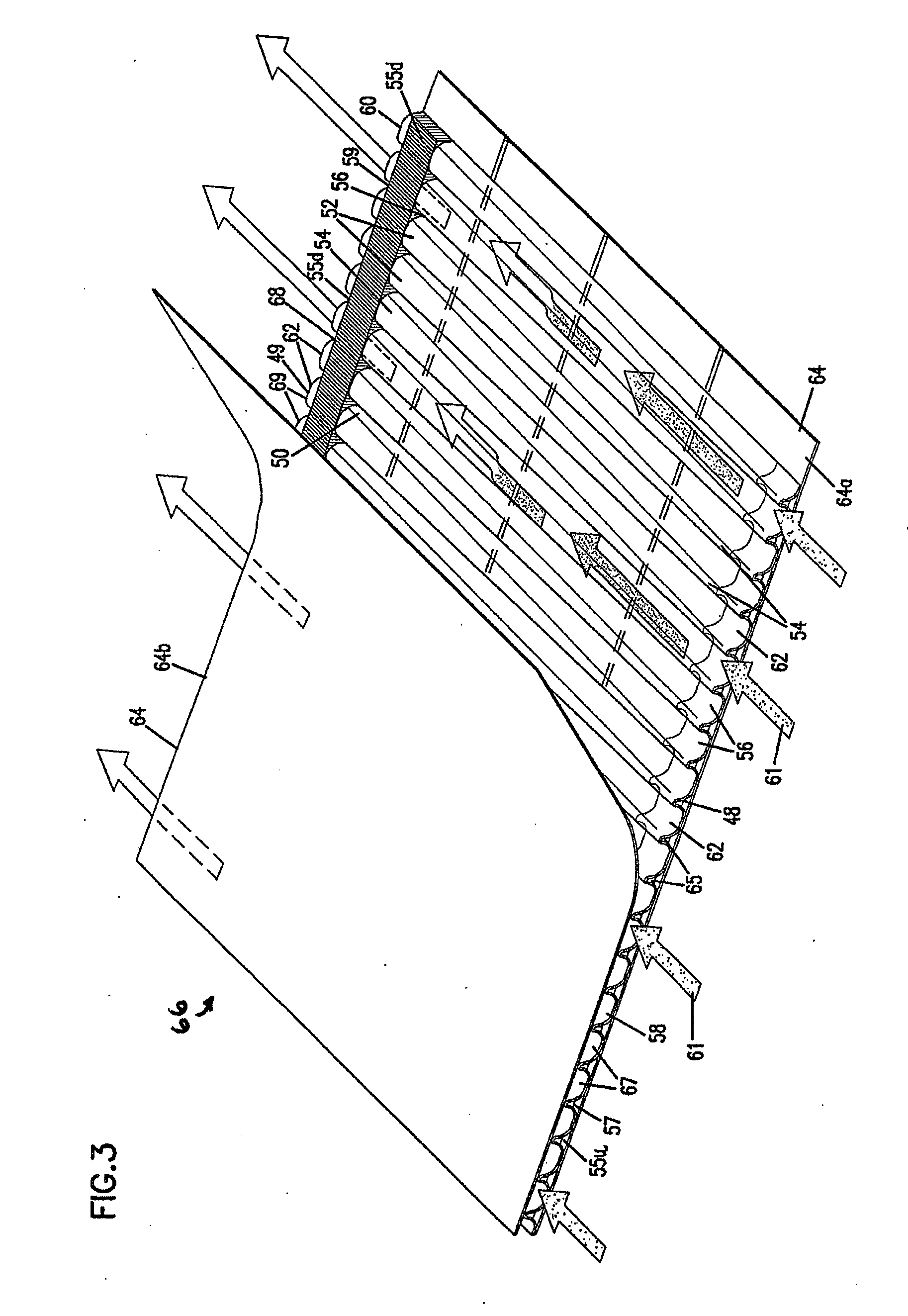

[0025]Filter elements utilizing fluted filter media, which accommodate straight through flow are known. Examples of some these type of filter elements are shown in U.S. Pat. Nos. 6,190,432; 5,820,646; and PCT Publication WO 97 / 40918, published on Nov. 6, 1997. Each of these patents and publication is incorporated by reference herein. In these types of filter elements, a corrugated sheet or web of filter media is attached to a flat sheet or web of material to result in a corrugated substrate. In many instances, the corrugated substrate is coiled or wound into a desired resulting element shape. Each individual corrugation, or flute, has one end open and the opposite end closed. Fluid to be filtered passes into open ends of selected ones of the flutes in the filter element. The fluid cannot proceed directly to exit out of the particular flute that it entered, because that particular flute is closed at the downstream end. In order to exit the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com