Valve manifold serially mounted to distributed control system assembly

A distributed control and control system technology, applied in general control systems, control/regulation systems, program control, etc., can solve expensive and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

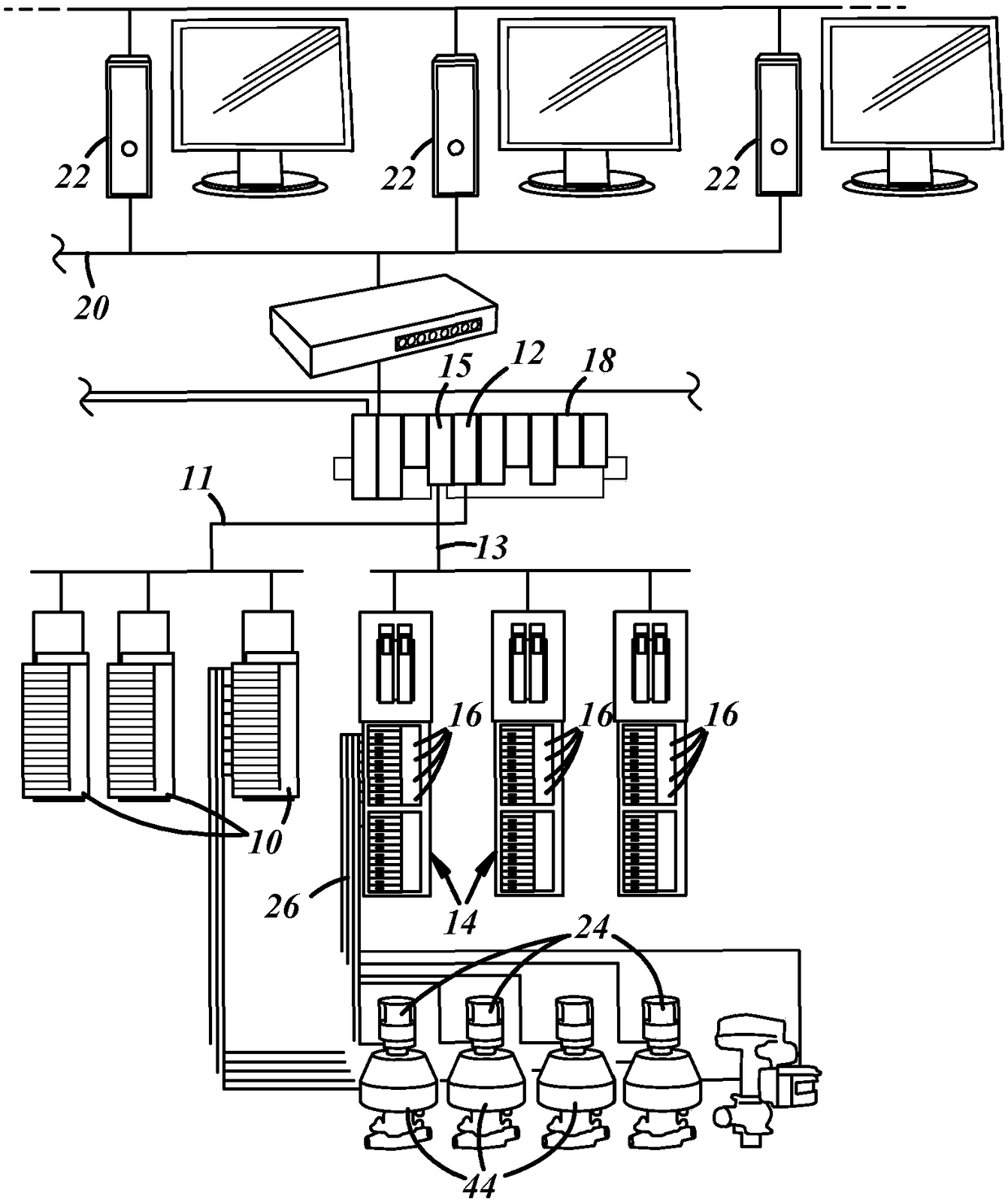

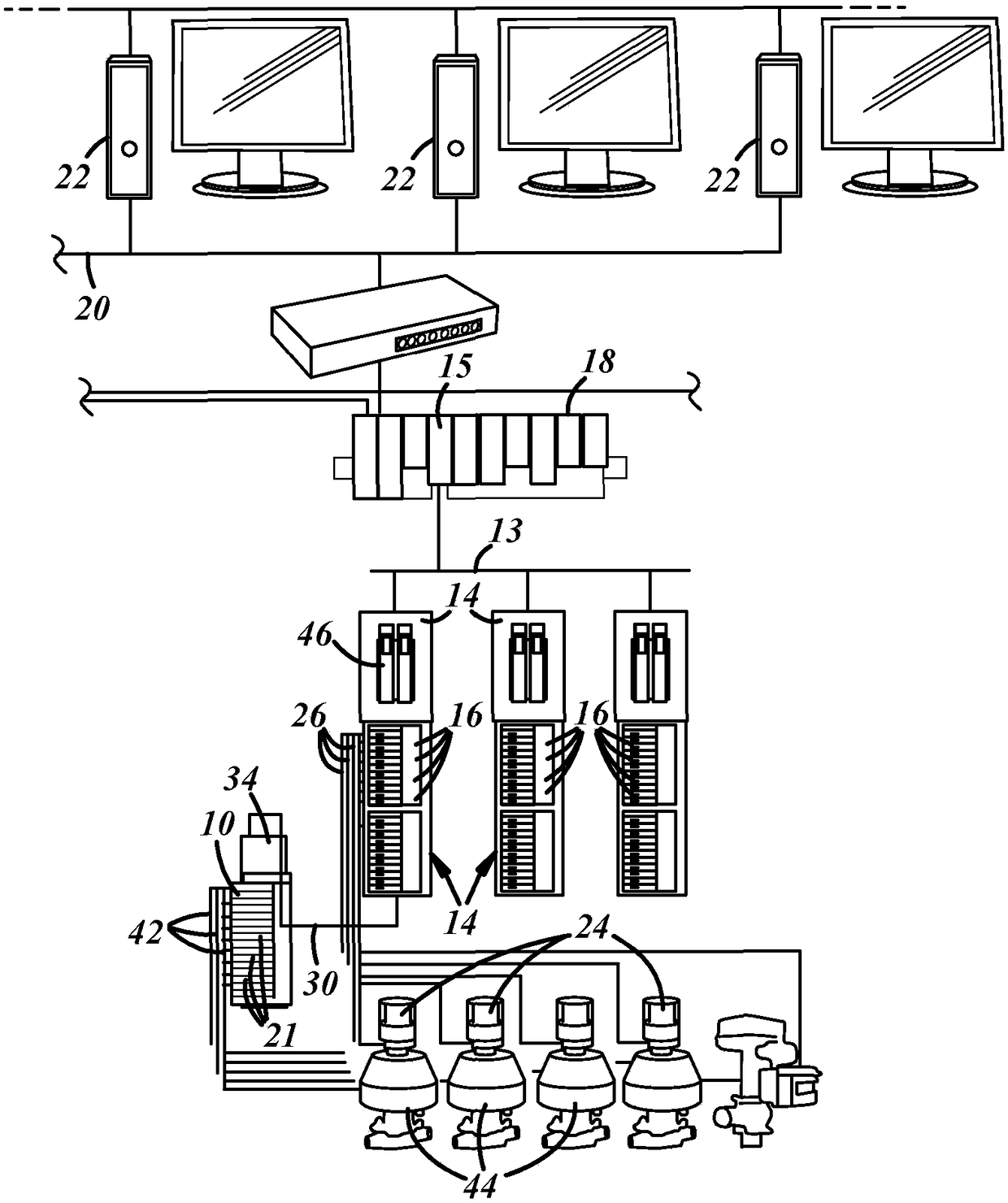

[0024] now refer to figure 2 , the control network 20 has a plurality of workstations 22 connected to the DCS 18 . The DCS may be the commercially available DELTAV from Emerson Process Management TM system. The DCS 18 is in turn connected through its network 13 to one or more I / O banks 14 comprising individual input / output modules 16 . A suitable I / O set may be the commercially available CHARM from Emerson Process Management TM I / O group. These I / O banks 14 may be located remotely from the DCS 18 .

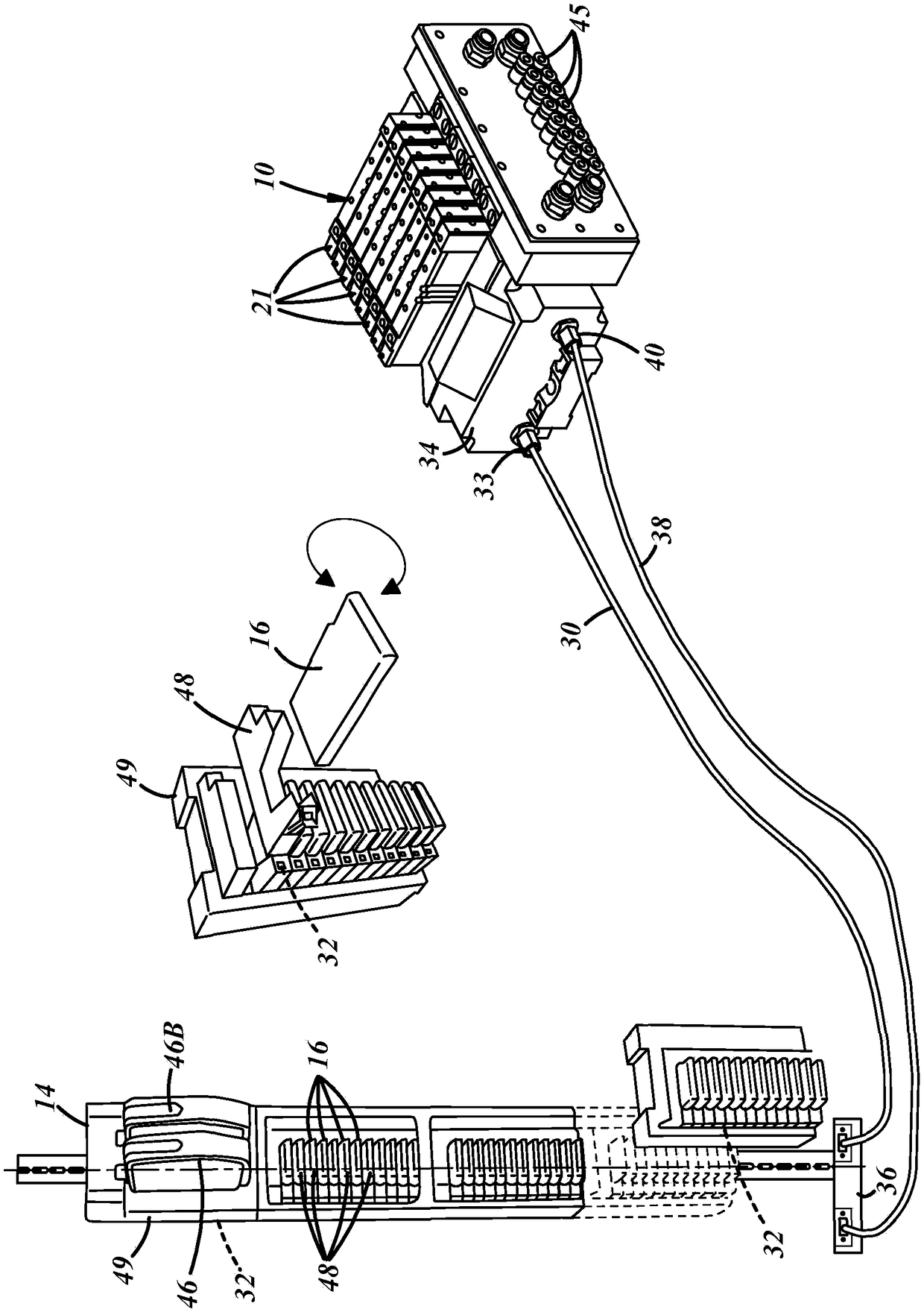

[0025] A number of individual I / O modules 16 in a group may be connected to field sensors 24 by cables 26 for receiving information from field sensors 24 . Additionally, valve manifold 10 may also be connected to I / O bank 14 . Preferably, as image 3 As shown, this connection is made by extending a cable 30 integrating both power and communication from a backplane 32 of the I / O pack 14 to a communication fitting 33 of a communication module 34 of the valve manifold 10 . M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com