Stabilization and regeneration method of aluminum and aluminum alloy chemical milling solution

An aluminum alloy and milling fluid technology, applied in the field of aluminum removal, can solve the problem of not forming a recycling method, and achieve the effects of reducing pollution, prolonging service life, and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Process the chemical milling fluid according to the following steps:

[0016] 1. Pretreatment:

[0017] (1) Take out part (accounting for about 10% of the volume of the chemical milling groove) of chemical milling fluid at 98°C from the chemical milling groove and place it in the storage tank;

[0018] (2) Filtration at 90°C to 98°C;

[0019] (3) When the aluminum ion concentration in the filtered solution is less than 55g / L, return to the chemical milling tank;

[0020] (4) when the aluminum ion concentration in the filtered solution is greater than 55g / L, import the reactor;

[0021] 2. Response:

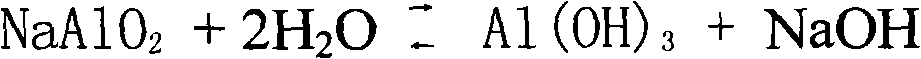

[0022] Add deionized water to the reactor to dilute the chemical milling solution. The amount of water added is 0.5 to 2 times the volume of the chemical milling solution. The temperature is controlled at 40°C to 60°C, and the concentration of sodium hydroxide is controlled at 60 to 110g / L.

[0023] 3. Crystallization - separation:

[0024] (1) Add aluminum hydroxide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com