Vertical leaf filter filtering device and filter method and application thereof

The technology of a filter device and a leaf filter is applied in the field of a vertical leaf filter filter device and its filtration of sodium aluminate solution, which can solve the problems of long time for replacing filter cloth, long production cycle, and high labor intensity, etc., so as to improve the effective Filtration time, slow rate of decline in production capacity, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

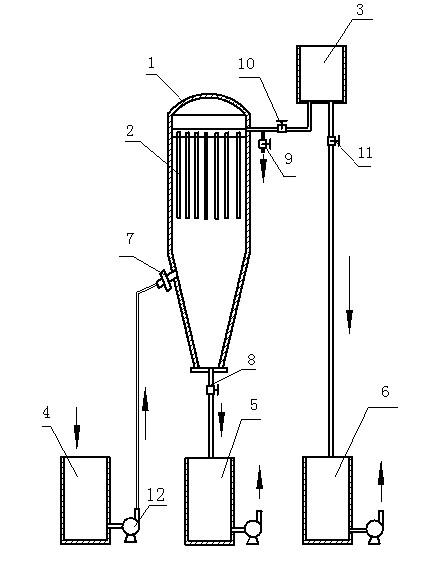

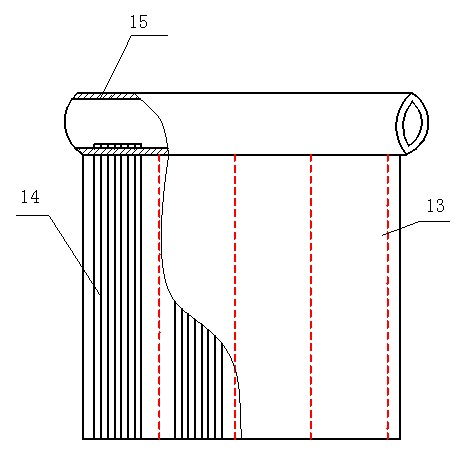

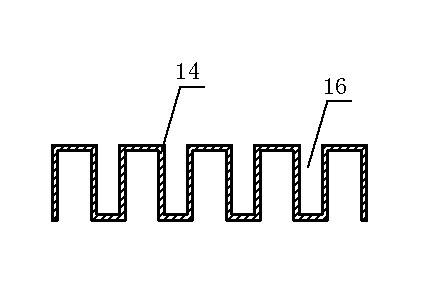

[0032] Embodiment 1: A filter device for a vertical leaf filter, comprising a vertical leaf filter housing (pressure vessel) 1, a filter plate 2, an elevated tank 3, a crude liquid tank 4, a filter cake tank 5, a semen tank 6 and The pressure pump 12 is composed of the filter plate 2, which is composed of a strip bracket 14 and a stainless steel wire filter cloth 13. The strip bracket 14 is installed between two layers of filter cloth. The groove 16 and the liquid collecting pipe 15 are provided with transverse grooves, the strip support 14 communicates with the liquid collecting pipe 15 through the transverse grooves, and the stainless steel wire filter cloth 13 is wrapped on the liquid collecting pipe 15 .

[0033] In addition, a pneumatic valve and a control system are provided, and the automatic control of the valve is realized through the control system. The pneumatic valve includes a feed valve 7 , a mud discharge valve 8 , a return valve 9 , a semen feed valve 10 and a s...

Embodiment 2

[0046] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0047] The filter cloth of the filter device of the vertical leaf filter is stainless steel wire filter cloth, the diameter of the stainless steel wire in the filter cloth is 0.1mm, the mesh number of the filter cloth is 1600 mesh, and the filter cloth is twill weave.

[0048] The method of filtering the sodium aluminate solution, the filtration cycle is 50min. The first stage, feeding mud hanging stage, time is 6min; the second stage, normal filtration stage, time is 42min, the pressure during filtration is 0.3-0.4Mpa; the third stage, decompression cake unloading and recovery stage, time is 2min.

Embodiment 3

[0049] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0050] The filter cloth of the filter device of the vertical leaf filter is stainless steel wire filter cloth, the diameter of the stainless steel wire in the filter cloth is 0.08mm, the mesh number of the filter cloth is 1800 mesh, and the filter cloth is forged weave.

[0051] The method of filtering sodium aluminate solution, the filtration period is 46min, the first stage, the feeding sludge stage, the time is 5min; the second stage, the normal filtration stage, the time is 40min, and the pressure during filtration is 0.4-0.5MPa; Three stages, decompression cake unloading and recovery stage, the time is 1min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com