Sewage filtering device for chemical industry

A filtration device and technology for sewage, which can be used in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., and can solve the problems of inefficient isolation and filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

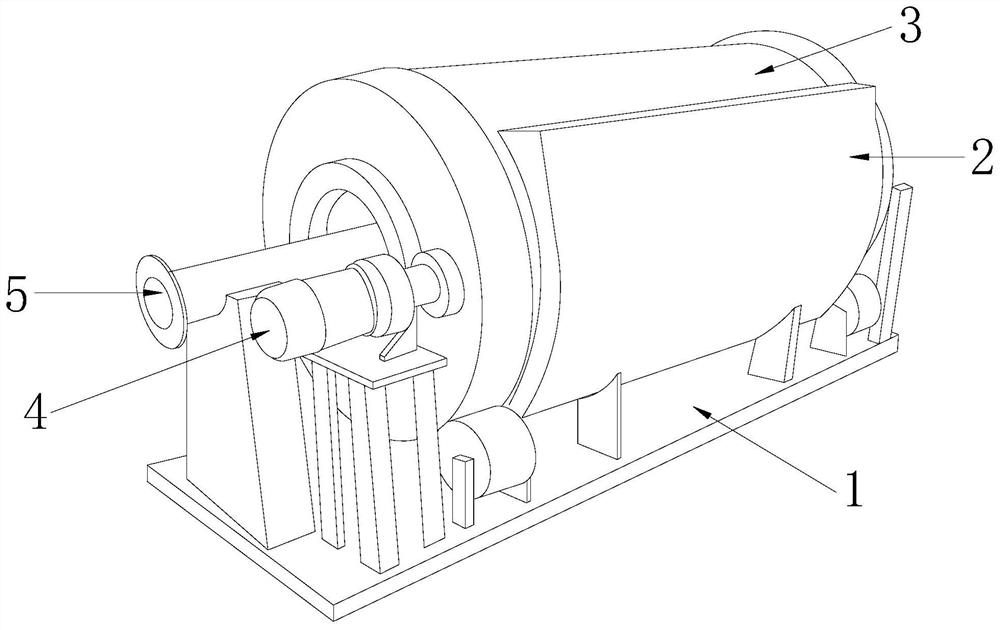

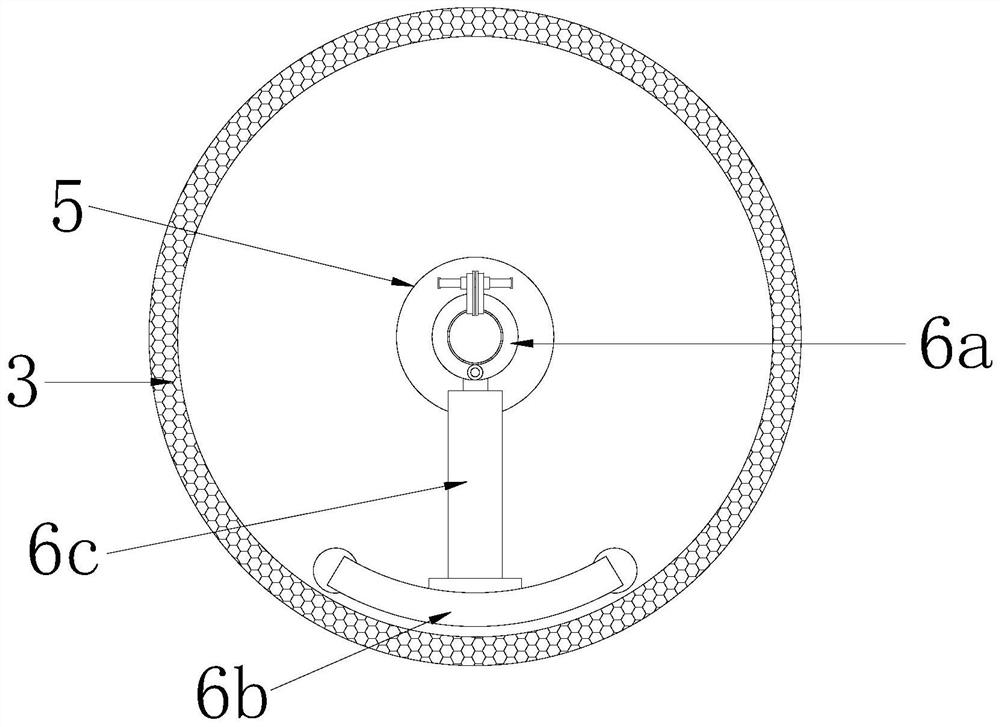

[0028]Such asFigure 1 - Figure 3 As shown, the present invention provides a technical solution for chemical sewage filtration devices:

[0029]Such asFigure 1 - Figure 2 As shown, a chemical sewage filtering device includes a mount 1, a sheath 2, a filter cartridge 3, a drive motor 4, a stirring 5, and an overboot system 6, and the sheath 2 is mounted to the mounting seat. 1 On the upper surface, the filter cartridge 3 is provided inside the sheath 2 and welded, the drive motor 4, which is disposed on the front surface of the filter cartridge 3, and the agitation 5 is provided inside the tube 3 and the outer end is exposed to the air. The outer end of the agitation 5 is mounted with the drive motor 4, the insulated epidemic system 6 is disposed in the middle of the agitation 5 and connected, and the insulated epitomy system 6 includes a lock structure 6a, a nna The plate 6b, the scraper mechanism 6c, the lock structure 6a, and the surface of the stiff 5, the spatula 6B is provided in t...

no. 2 example

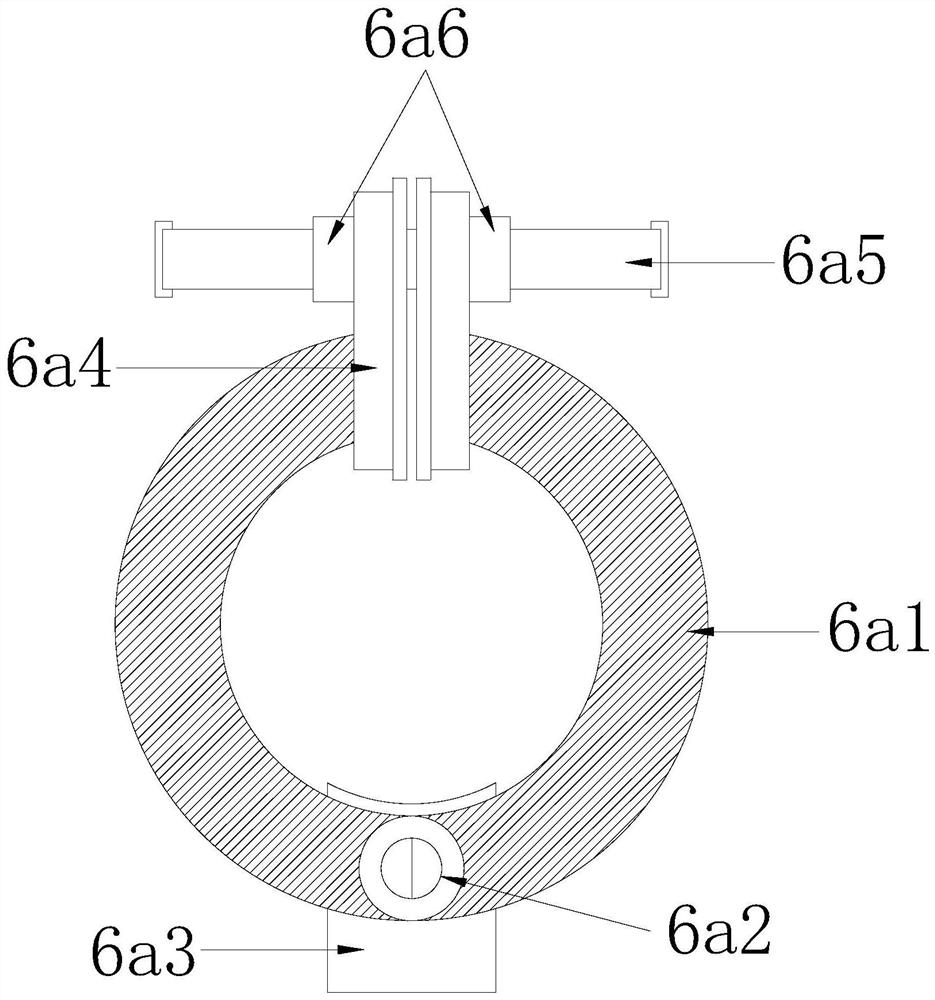

[0036]Such asFigure 4 - Figure 5As shown, the present invention provides a technical solution for chemical sewage filtration devices:

[0037]Such asFigure 4 As shown, a chemical sewage filtration device includes a structure including the spanker 6b1, a fastening groove 6b2, a scratch plate 6B3, a bonding tube 6b4, and the buckle 6b2 is mounted on the cavity plate 6b1. The surface is connected to the integrated structure, the buckle 6b2 is connected to the fastener plate 6a3, and the gripper 6b3 is provided with more than ten pieces and is present in the cavity panel 6b1, respectively, the tube holder 6B4. The lower surface of the chamber 6b1 is connected and connected, and the tube holder 6b4 is connected to the scraping mechanism 6c, which facilitates the achievement of absorption fitting after removing the fiber impurities.

[0038]Such asFigure 4 Design, an suction pump is provided inside the cavity plate 6b1, the cave plate 6B1 and the scraping mechanism 6c through the adapter tuber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com