High-efficiency fine defoaming and desanding separator for natural gas

A separator and natural gas technology, applied in separation methods, dispersed particle separation, gas fuel, etc., to achieve the effect of reducing the rising speed, increasing the resistance formation time, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The high-efficiency fine foam and sand removal separator for natural gas of the present invention will be further described in detail with reference to the accompanying drawings. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

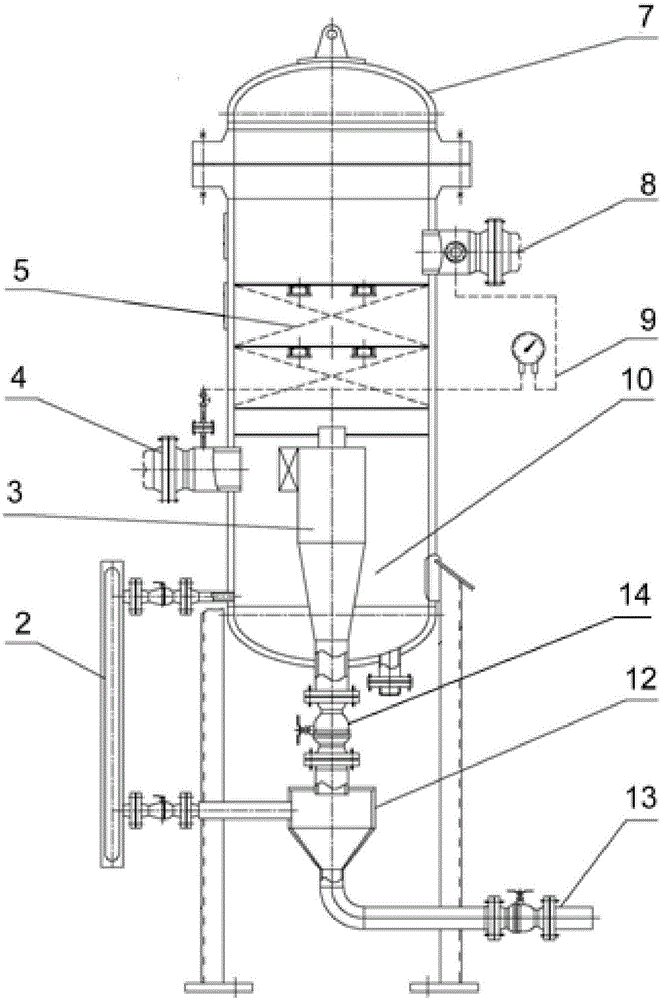

[0019] Such as figure 1 As shown, the natural gas high-efficiency and fine defoaming and sand removal separator of the present invention comprises a tank body 7, the bottom of the tank body 7 is a gravity settling chamber 10, and the center of the gravity settling chamber 10 is provided with a cyclone separator 3, and the cyclone separator 3 is provided with a gas defoaming and desanding filter 5 above the outlet, and the air inlet 4 of the natural gas high-efficiency and fine defoaming and desanding separator is arranged at the lower part of the tank body 7, leading directly to the gravity settling chamber 10, and the exhaust port 8 is It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com