Patents

Literature

36results about How to "Large dirt holding capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency purification energy-saving filter core

ActiveCN101780345AImprove qualityImprove the lubrication effectLoose filtering material filtersLubricant mounting/connectionCombustionVegetable oil

The invention relates to a high-efficiency purification energy-saving filter core which is manufactured by adopting the stems and the poles of various plants, pulverizing, screening, and bulking the stems and the poles, mixing the processed stems and the processed poles as filter materials (100 parts) with various chemical substances (6.43-11.56 parts), then adding special vegetable oil and a magnetic substance (15-25 parts) and finally packaging with an oil-resistant and high-temperature resistant fabric. The filter core of the invention is suitable for the lubricating oil purification of various internal-combustion engines or mechanical equipment, thereby not only leaching the impurities of more than 0.01mm in online engine oil, but also enhancing the lubricating efficacy, improving the quality and the use function of the engine oil, enabling lubricating oil not to deteriorate or age after long-term use, keeping the due physicochemical index thereof and really achieving the purposes of energy saving and emission reduction.

Owner:GANSU HENGTONG FILTER IND

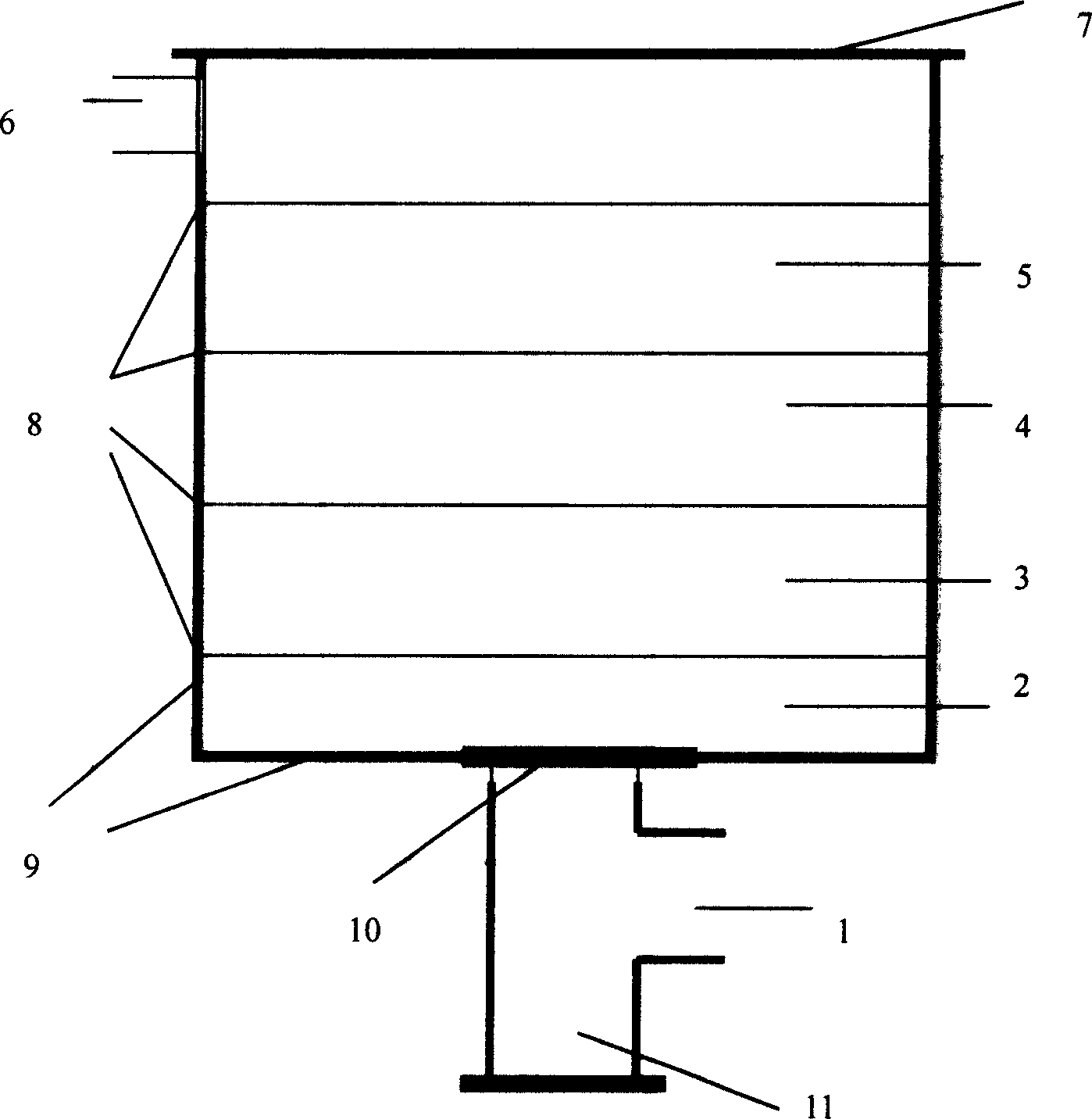

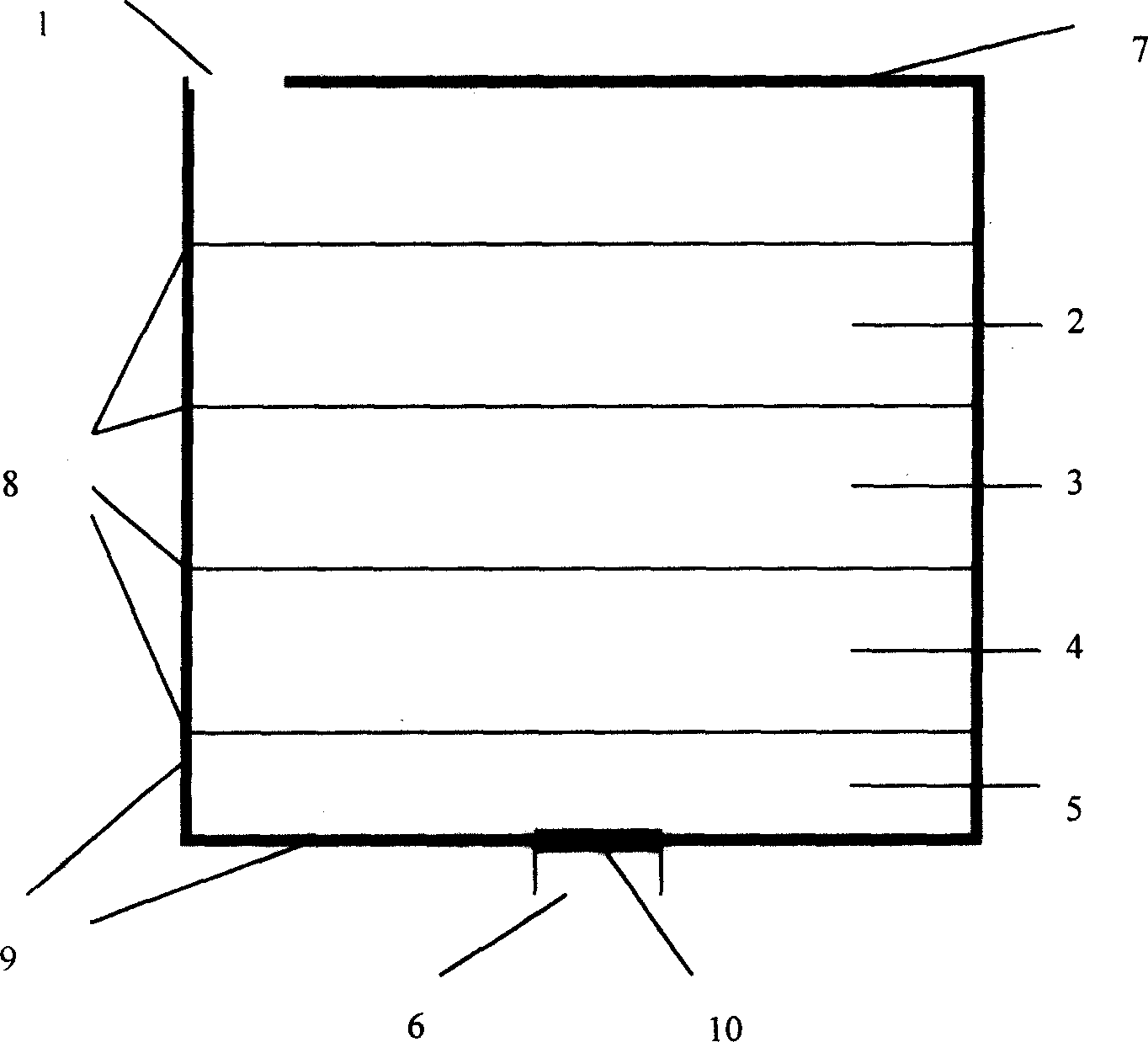

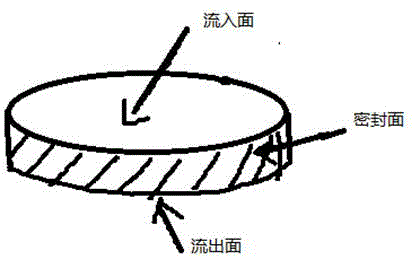

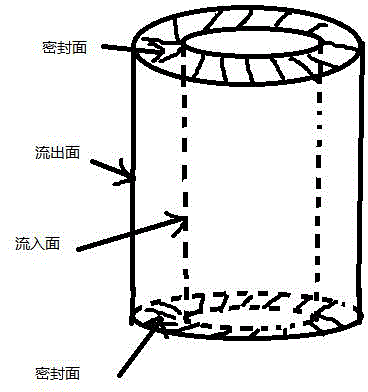

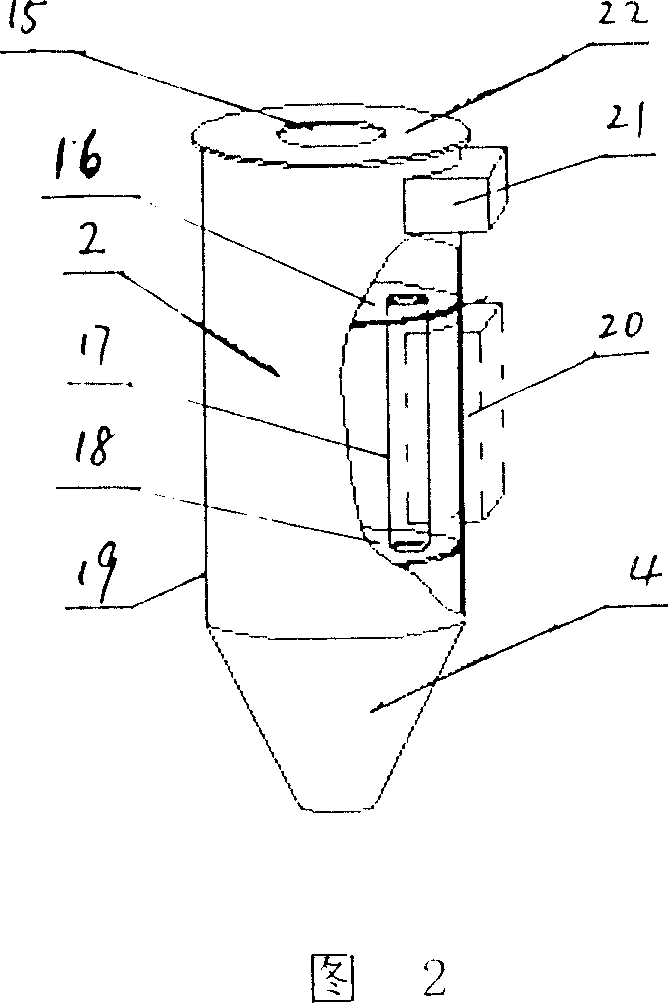

Deep sand filter

InactiveCN1528489ALarge dirt holding capacityAct as a coarse sand filterLoose filtering material filtersGravity filtersNormal filterEngineering

The invention is a depth-type sand filter, the size of sand gradually diminishing with the flow direction of the normal filtering fluid. It leads the fluid to the inlet of the sand filter through the pipeline, firstly holds back big suspension through big sand area, then holds back medium suspension through medium sand area, finally eliminates most fine suspension through fine sand area, and then makes the fluid flow out from the outlet. It is composed of wall body, filtering sand and ground leak; the wall body is set with inlet and outlet, the ground leak is set under the wall body, the filtering sand is spread in the liquid flow direction in turn according to the size. It can adopt upflow and downflow modes. It can stably and economically run in a wide range. It is applied to economical sand filtering field, especially the field where the sand filter is used infrequently or discontinuously.

Owner:安逢龙

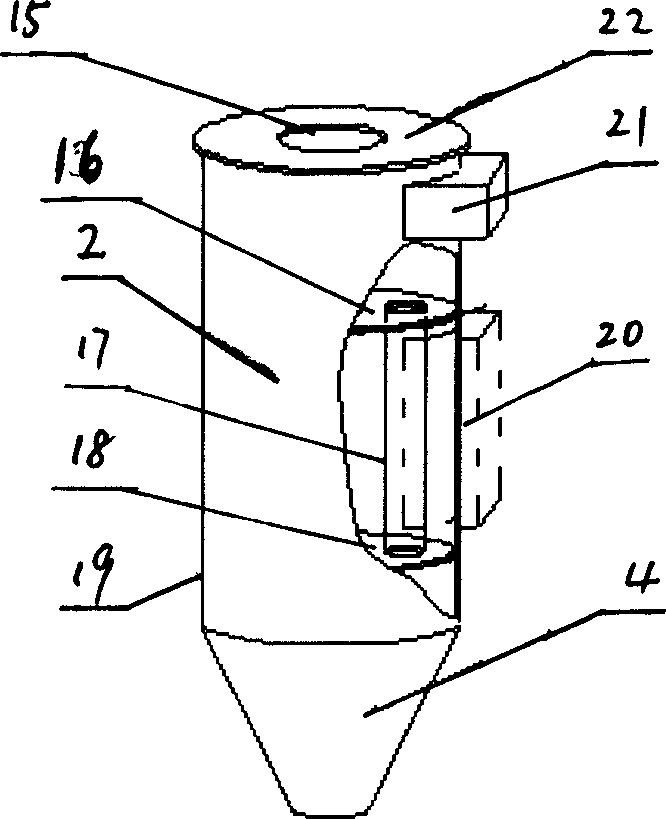

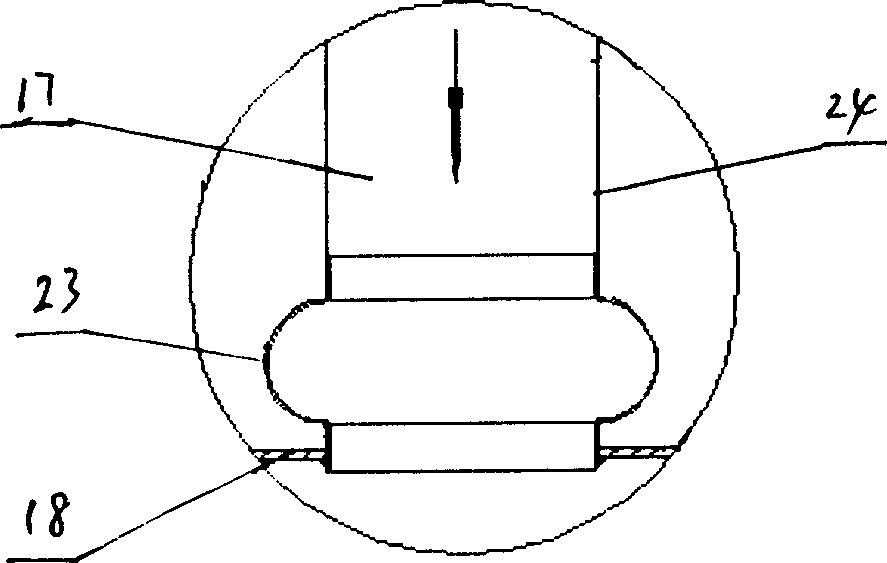

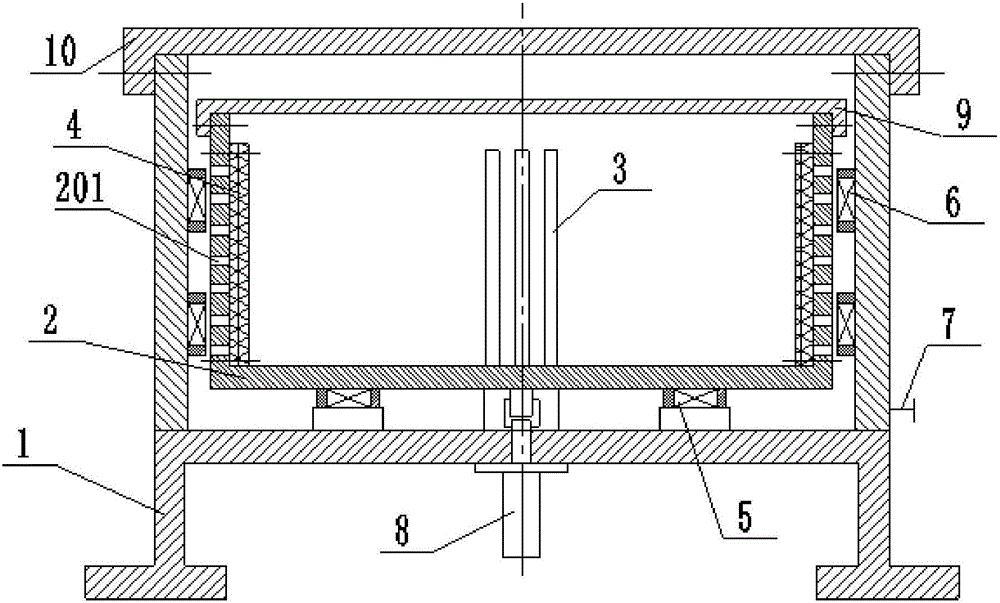

Magnetorheological fluid recovery device and method based on centrifugal separation effect

InactiveCN106082520AAvoid easy cloggingNot easy to settleWater/sewage treatment by centrifugal separationMagnetic liquidsDual effectDual action

The invention discloses a magnetorheological fluid recovery device and method based on a centrifugal separation effect, belonging to the field of magnetic waste liquid recovery equipment. The recovery device comprises an outer barrel, an inner barrel, an adsorption pipe and a filter net, wherein the inner barrel is installed in the outer barrel in a rotating manner by virtue of a bearing and is driven by a motor, and a filter hole communicating the inside and outside of the inner barrel is formed in the side wall of the inner barrel; the adsorption pipe is arranged in the middle of the inner barrel, and a coil is arranged in the adsorption pipe; the filter net is arranged on the inner side wall of the inner barrel and covers the filter hole; and the outer wall of the outer barrel is provided with a recovery check valve. The method utilizes the recovery device to allow carrier liquid and magnetic substances to make reverse motion under the dual effect of a centrifugal force and a magnetic field, so that the carrier liquid and the magnetic substances can be separated and recovered. By adopting the magnetorheological fluid recovery device and method, the magnetic substances of magnetorheological fluid can be separated and recovered from the carrier liquid. The magnetorheological fluid recovery device is simple in structure, easy to operate, high in recovery efficiency of the magnetic substances and also capable of reducing the subsequent treatment difficulty of the carrier liquid.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

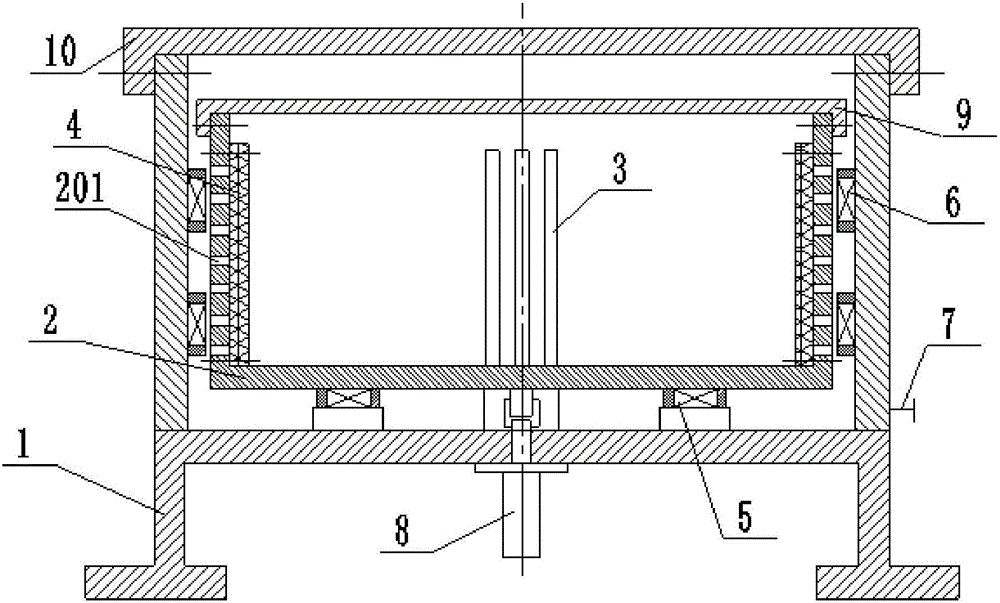

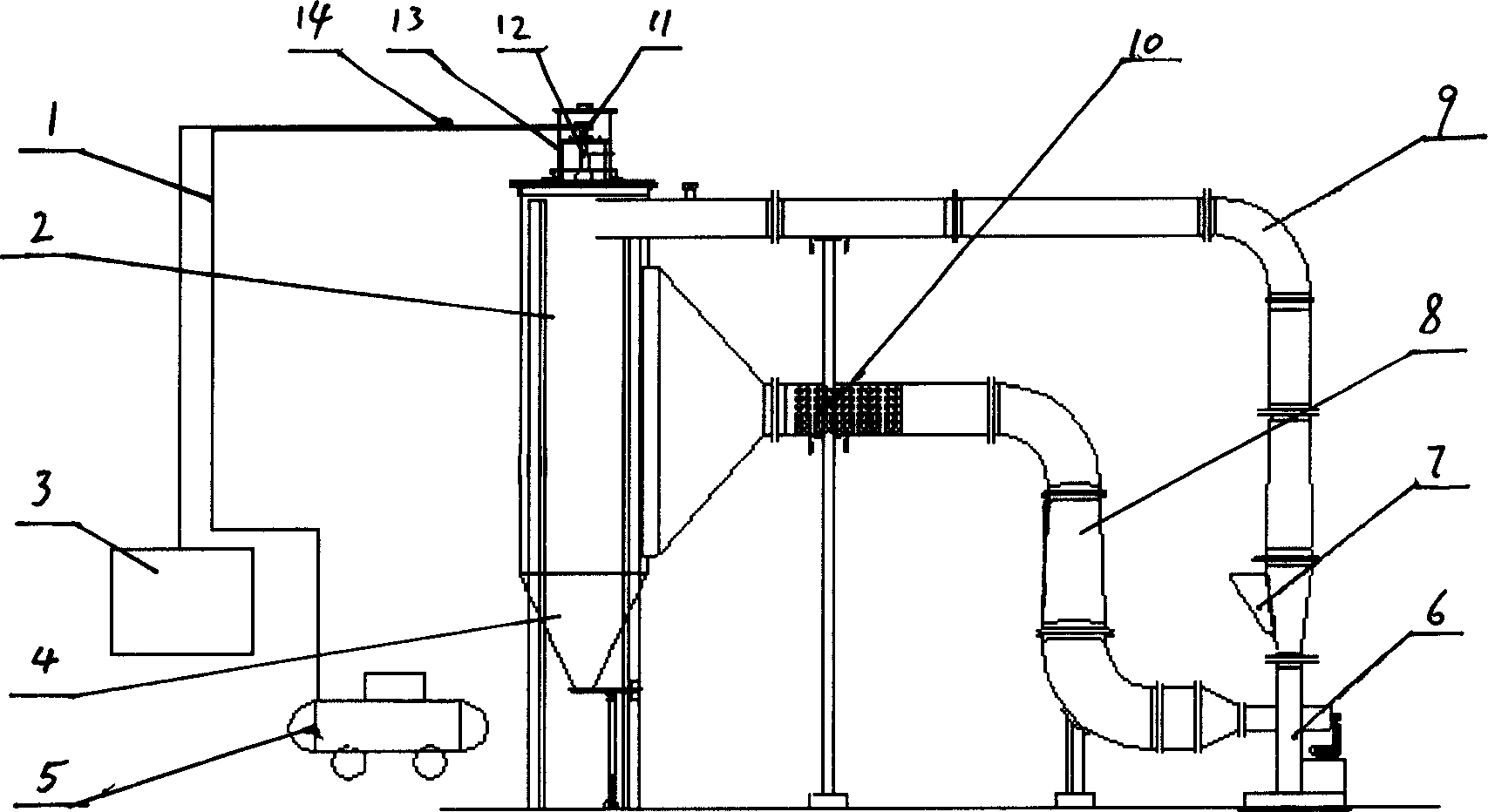

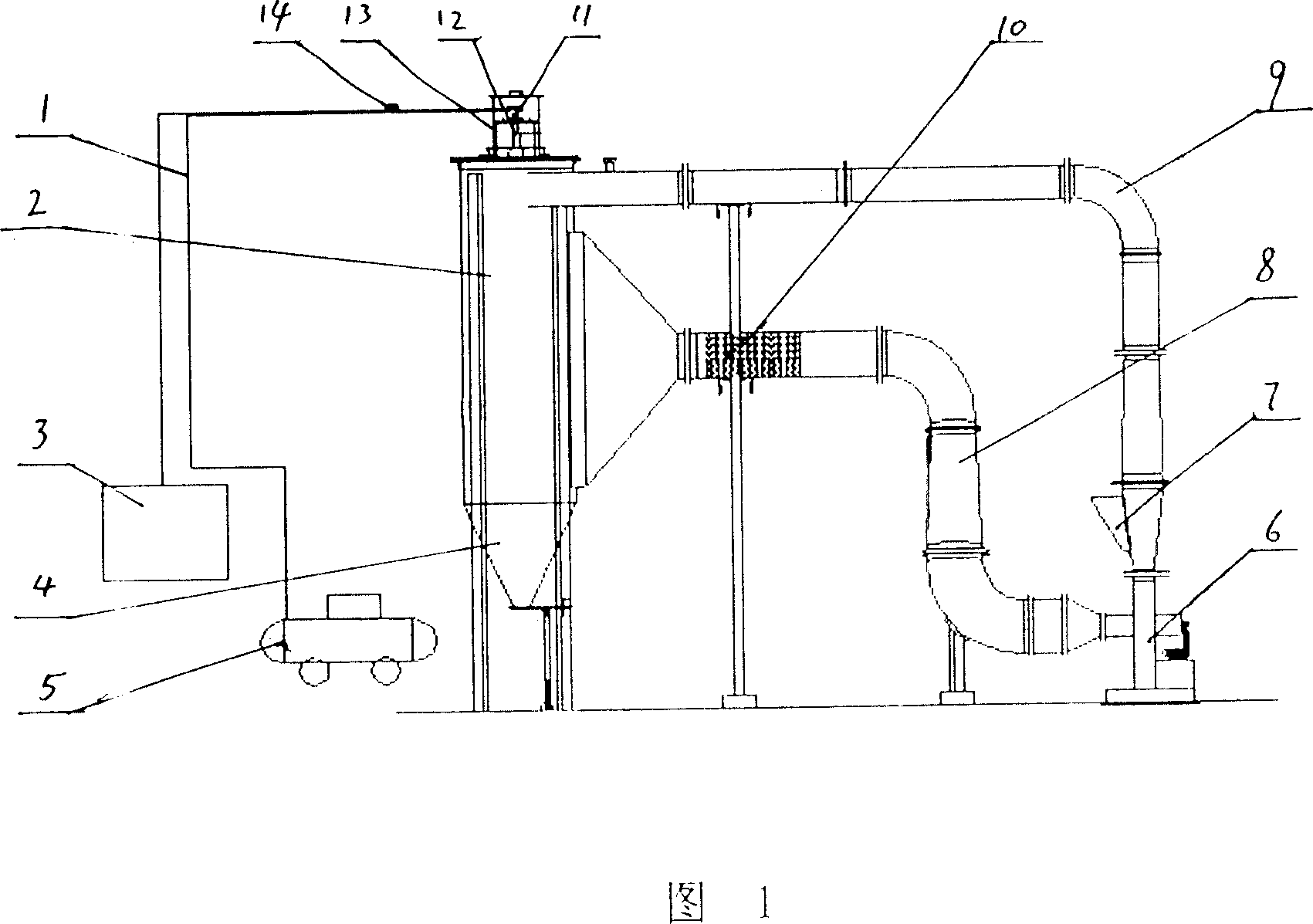

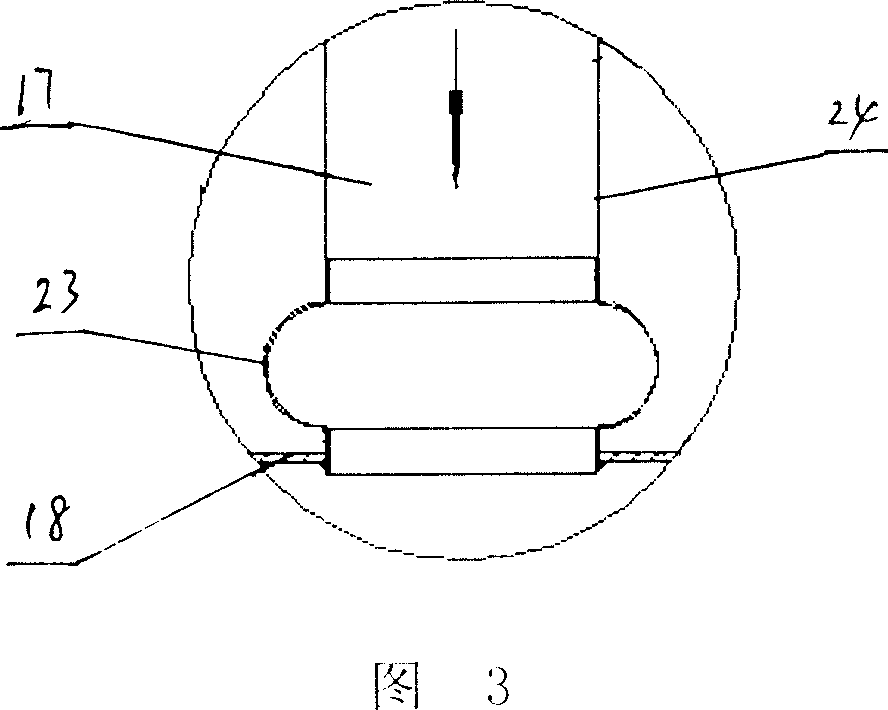

Experiment system for superhigh temperature bag duster

The experiment system for super high temperature bag duster includes super high temperature bag duster with fume inlet and fume outlet in the side wall, controller, compression air source and ash remover, as well as blower, simulating heater, air inlet pipeline, air outlet pipeline and ash adding unit on the side wall of the air inlet pipeline. The super high temperature bag duster consists of cover plate, cylindrical barrel, upper pattern board, lower pattern board and conic ash bucket, and one sound wave vibrating ash remover is installed over the cover plate. The present invention can simulate super high temperature fume filtering condition for directing the design of super high temperature bag duster.

Owner:JIANGXI JIANGLIAN PUKAI ELECTRIC POWER ENVIRONMENTAL PROTECTION ENG CO LTD

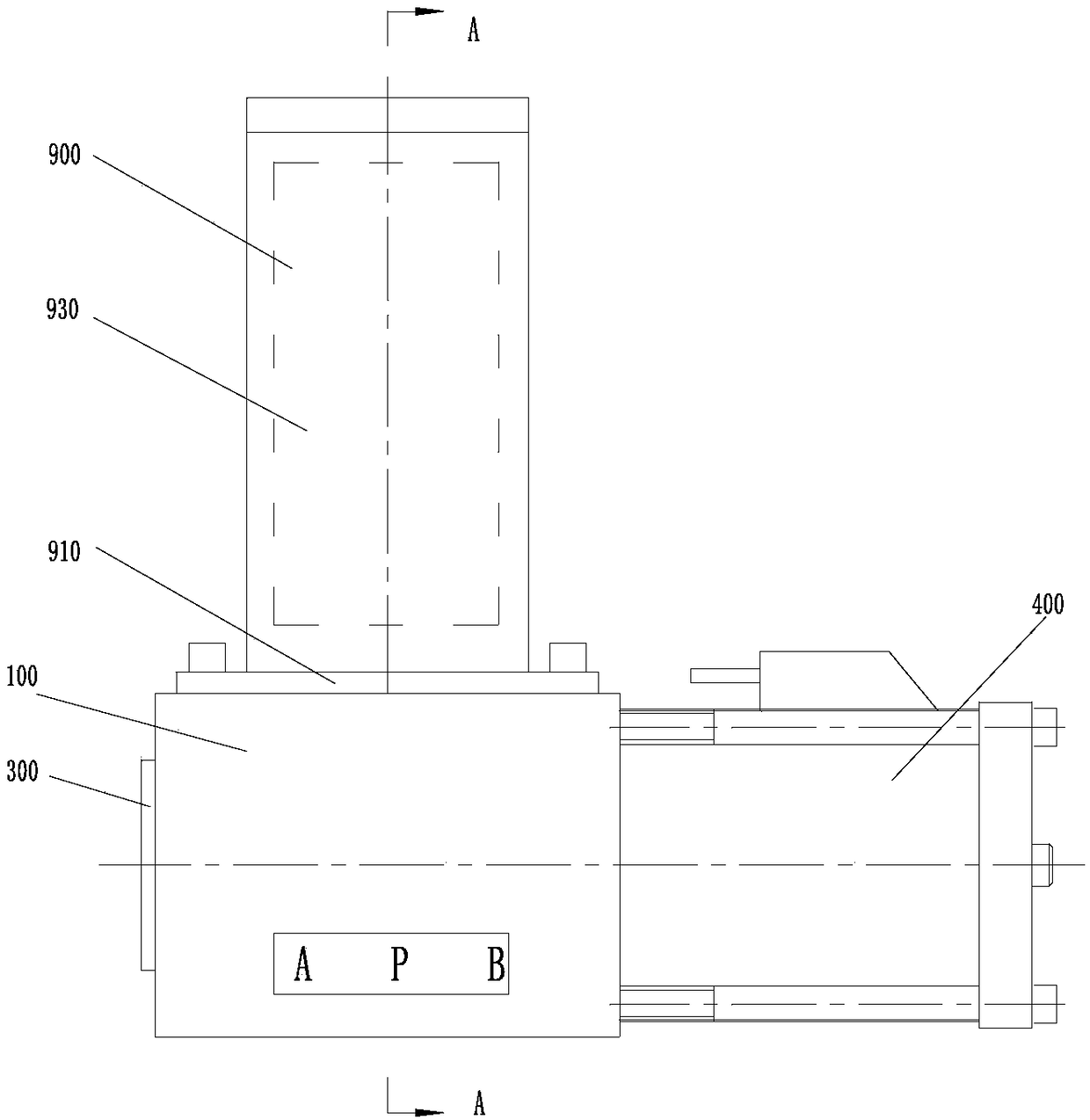

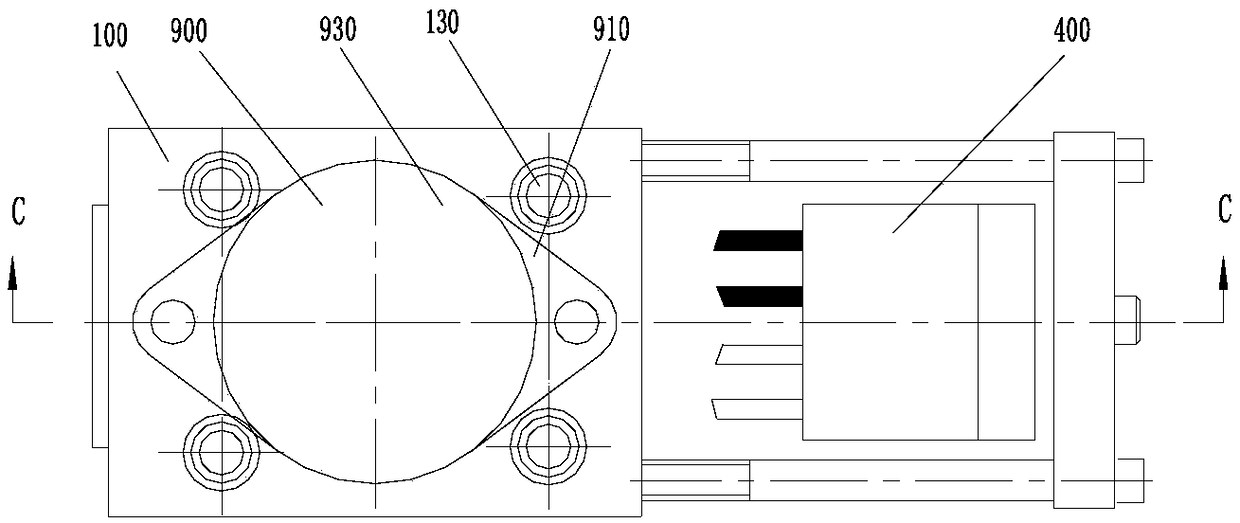

Electromagnetic reversing valve and valve body thereof

PendingCN108443561AEasy to installLarge dirt holding capacityOperating means/releasing devices for valvesMultiple way valvesBypass valveFilter element

The invention relates to an electromagnetic reversing valve and a valve body thereof. A filter oil outlet of the valve body and a filter oil inlet of the valve body as well as a filter oil output runner and a filter oil input runner are formed in the valve body, and a filter is fixedly connected to the valve body; the filter oil inlet of the valve body communicates to a second oil duct through a filter oil input runner; the filter oil outlet of the valve body communicates to the oil inlet through the filter oil output runner; a filter element is fixedly connected to an shell base, and an oil inlet of the filter and an oil outlet of the filter are formed in the shell base; the oil inlet of the filter is opposite to the filter oil outlet of the valve body; the lower part of a center hole ofthe filter element communicates to the oil inlet of the filter; and a bypass valve is arranged between the upper part of the center hole of the filter element and the inner wall of a top cover of theshell. According to the electromagnetic reversing valve, an oil filter is mounted on the valve body, so that the electromagnetic reversing valve is more conveniently cleaned; the dirt volume of the oil filter is greater; the maintenance interval time can be very long; as the oil filter is provided with the bypass valve, fetal failure is avoided when the quantity of pollutants is relatively great.

Owner:CHANGZHOU KANGSHIDA ELECTROMECHANICAL CO LTD

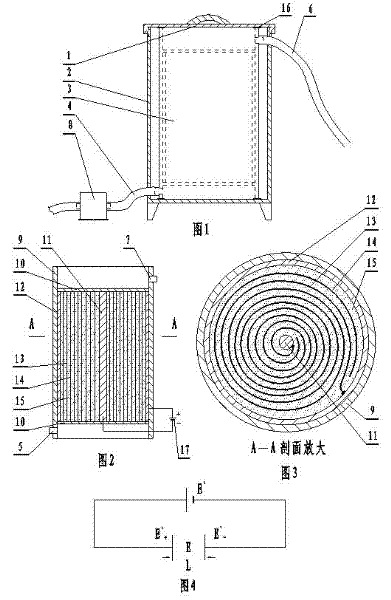

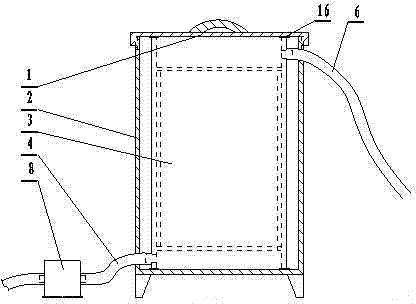

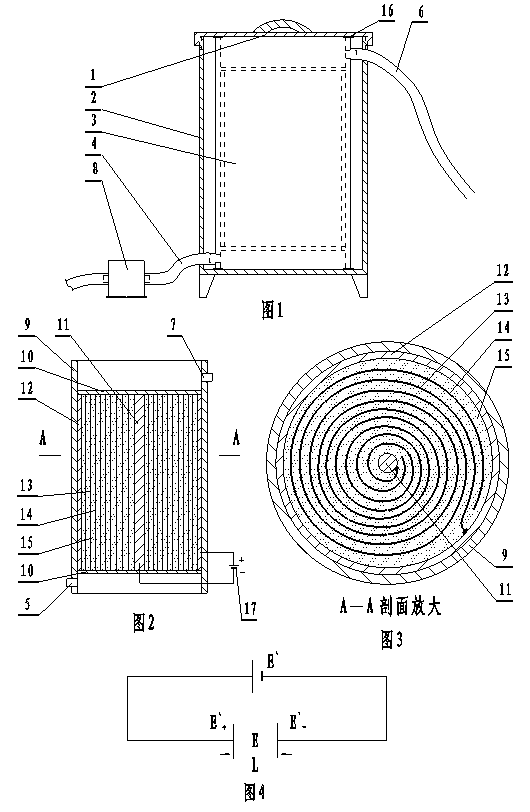

Electric oil purification method and device

ActiveCN102360748AImprove adsorption capacitySmall processing flowTransformers/inductances coolingEnergy based chemical/physical/physico-chemical processesPurification methodsFiltration

The invention discloses an electric oil purification method and an electric oil purification device and belongs to an electro-adsorption deionization technology. Under a constant direct current electric field, collection media and ions in oil liquid form a double electric layer to enrich the ions so that the oil is removed from the oil liquid. In the electric oil purification device, an oil tank is connected with the positive electrode of an external power supply; a core column is connected with the negative electrode of the external power supply; the negative electrode of a metal net is connected with the core column; the positive electrode of the metal net is connected with the oil tank; the collection media are filled in the oil tank; and an oil outlet pipe and an oil inlet pipe are connected with the upper part and the lower part of the oil tank respectively. A three-dimensional multi-layer type electric oil purification device for deep purification of transformer oil has the advantages of high filtration precision and high dirt holding capacity, so a problem of contradiction of the mechanical filtration precision and dirt holding capacity is solved and defects of selective adsorption of adsorbent, environmental pollution, low processing flow rate of the electrostatic oil purification method, low adsorption rate and poor adsorption effect are avoided; moreover, the invention has good adsorption and purification effect and is lower in cost, and favorable for protection of environment and working staff.

Owner:国网黑龙江省电力有限公司齐齐哈尔供电公司 +1

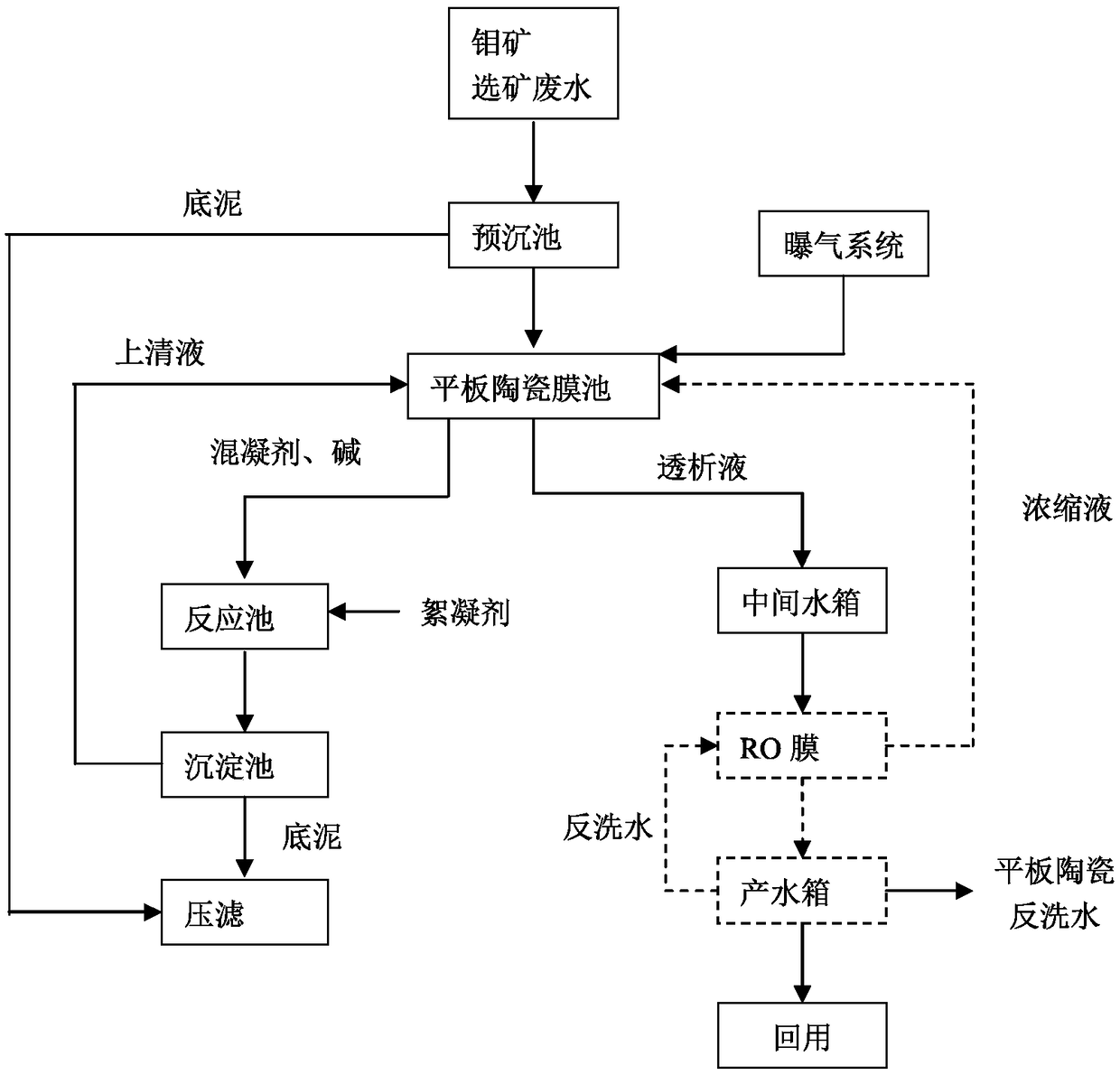

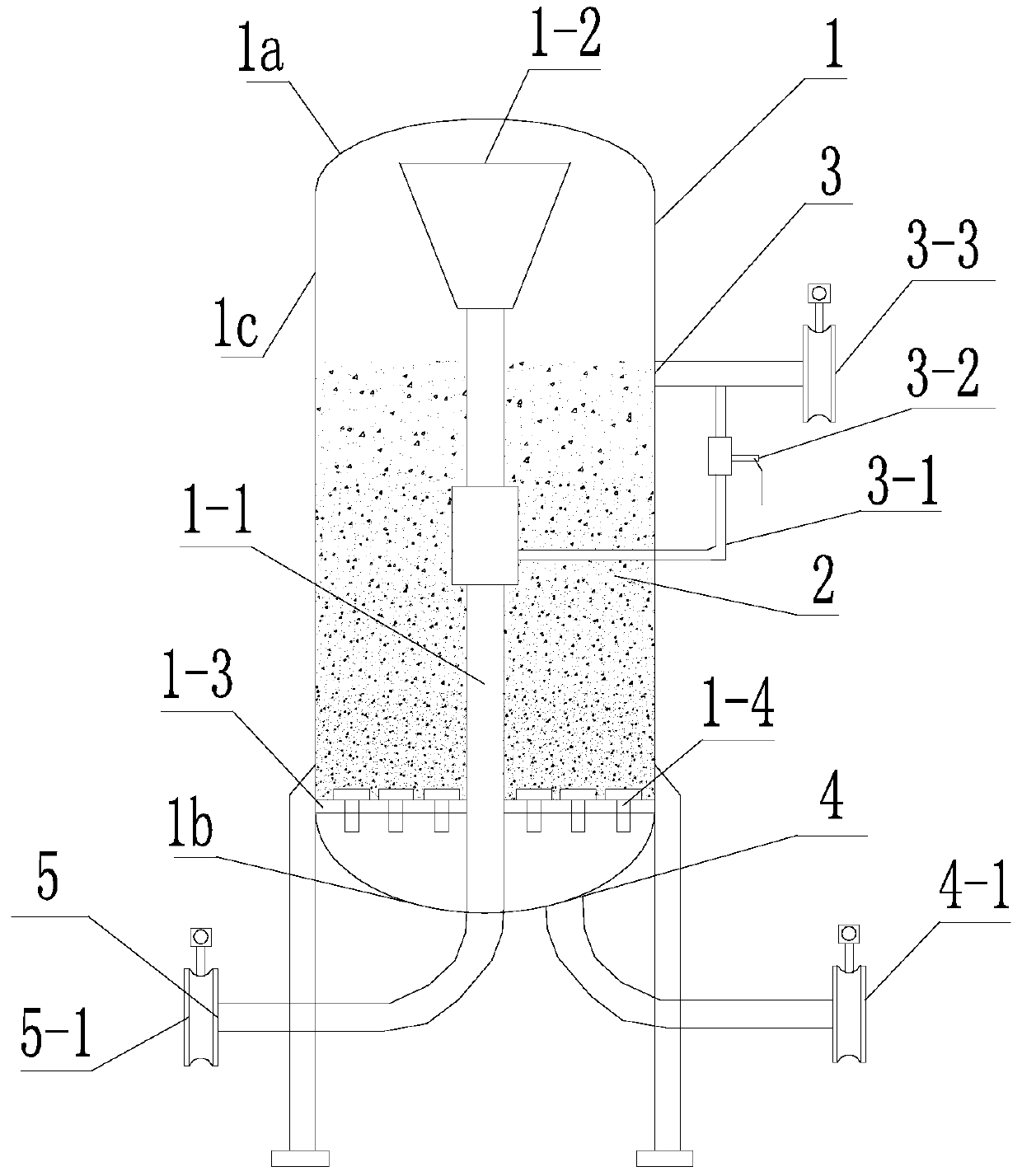

Processing method of molybdenum mineral dressing waste water

InactiveCN109179762AEfficient removalReduce problem sizeWater treatment parameter controlSludge treatmentParticulatesSludge

The invention discloses a processing method of molybdenum mineral dressing waste water. The processing method comprises following steps: 1, molybdenum mineral dressing waste water is introduced into apre-precipitation pool for precipitation so as to obtain pre-precipitation pool bottom sludge and a pre-precipitation pool supernatant; 2, the pre-precipitation pool supernatant is introduced into aflat ceramic membrane pool, and a flat ceramic membrane assembly is adopted for purifying to remove small particles and reduce the turbidity of produced water; 3, unfiltered waste water in the flat ceramic membrane pool is introduced into a reaction pool through a pipeline for reaction; and 4, waste water from the reaction pool is introduced into a precipitation pool for precipitation so as to obtain a precipitation supernatant and a precipitation pool bottom sludge. According to the processing method, the flat ceramic membrane is adopted for processing of molybdenum mineral dressing waste water, so that small particles can be removed with high efficiency, the turbidity of produced water is low, the technology is stable, waste water amount is reduced greatly, the adding amount of medicinesis low, operation cost is reduced greatly, precipitation pool equipment size and occupied land area are reduced at the same time, and investment cost is reduced.

Owner:SANDA FILM SCI & TECH XIAMEN

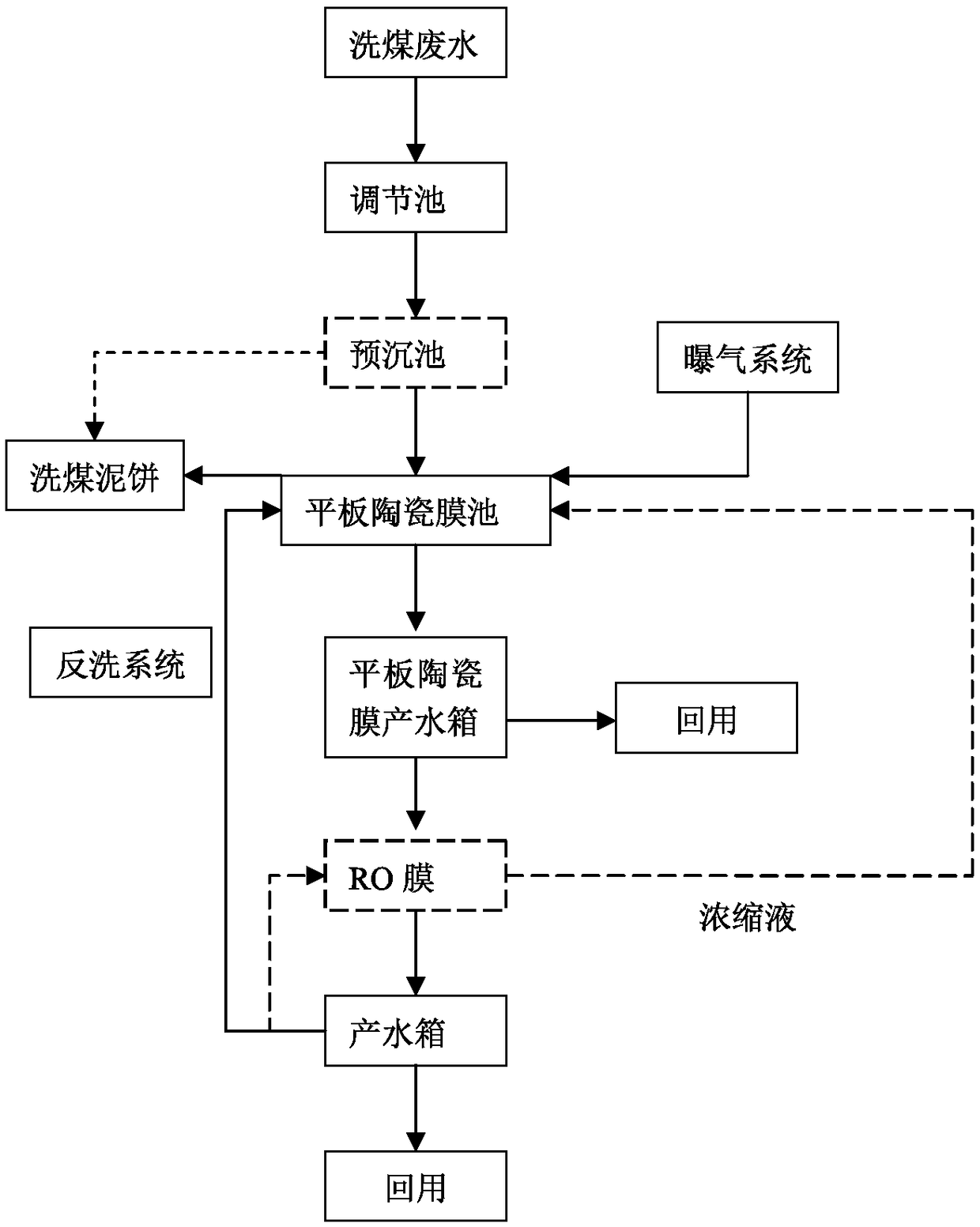

Processing method of coal mine water and/or coal washing waste water

InactiveCN109179578AEfficient removalHigh SS contentWater treatment parameter controlSpecific water treatment objectivesParticulatesResource utilization

The invention discloses a processing method of coal mine water and / or coal washing waste water. The processing method comprises following steps: 1, coal mine water and / or coal washing waste water is introduced into an adjusting pool to adjust water quality and water amount so as to obtain raw water; 2, the raw water is introduced into a flat ceramic membrane pool, a flat ceramic membrane assemblyis adopted for purification to remove small particles in the raw water and reduce the turbidity of produced water, wherein according to the operation mode of the flat ceramic membrane assembly, pumping, intermittent stopping, and backwash period are adopted alternatively; and 3, bottom sludge from the flat ceramic membrane pool is prepared into coal washing cakes which can be mixed with coal-air fuel, so that a fuel is prepared, and sludge resource utilization is realized, and produced water of the flat ceramic membrane assembly is subjected to deep treatment or is subjected to direct recycling as industrial recycled water. The processing method is capable of removing large particles, and small particles effectively; no medicine is added; the bottom sludge can be recycled as a fuel; the water quality of obtained water is stable, and recycling standards are reached.

Owner:SANDA FILM SCI & TECH XIAMEN

Ionization/centrifugation-based magnetorheological fluid recovery device and treatment method thereof

InactiveCN106007162AEvenly dispersedNot easy to settleWater/sewage treatment by centrifugal separationTreatment involving filtrationCentrifugationMagnetorheological fluid

The invention discloses a magnetorheological fluid recovery device and a treatment method based on ionization and centrifugation, and belongs to the technical field of magnetic waste liquid recovery and treatment. The device includes an outer barrel, an inner barrel, an adsorption tube, and a filter screen. The inner barrel is rotatably mounted in the outer barrel through a bearing and driven by a motor. The sidewall of the inner barrel is provided with filter holes that communicate with the inside and the outside, and the adsorption tube is arranged in the inner barrel. In the middle of the body, a coil is arranged in the adsorption tube, an electrode plate is arranged in the inner barrel, a filter screen is arranged on the inner side wall of the inner barrel and covers the filter hole, and a recovery stop valve is arranged on the outer wall of the outer barrel. The method of the invention realizes the separation and recovery treatment of the magnetorheological fluid through ionization treatment, centrifugal breaking treatment and centrifugal separation treatment. The present invention processes the magnetorheological fluid, separates and recovers the main dispersed particles and the carrier liquid, does not need any treatment agent for preliminary treatment in the early stage, and has high recovery efficiency, and the recovered carrier liquid can be used as a new carrier liquid after a little treatment.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

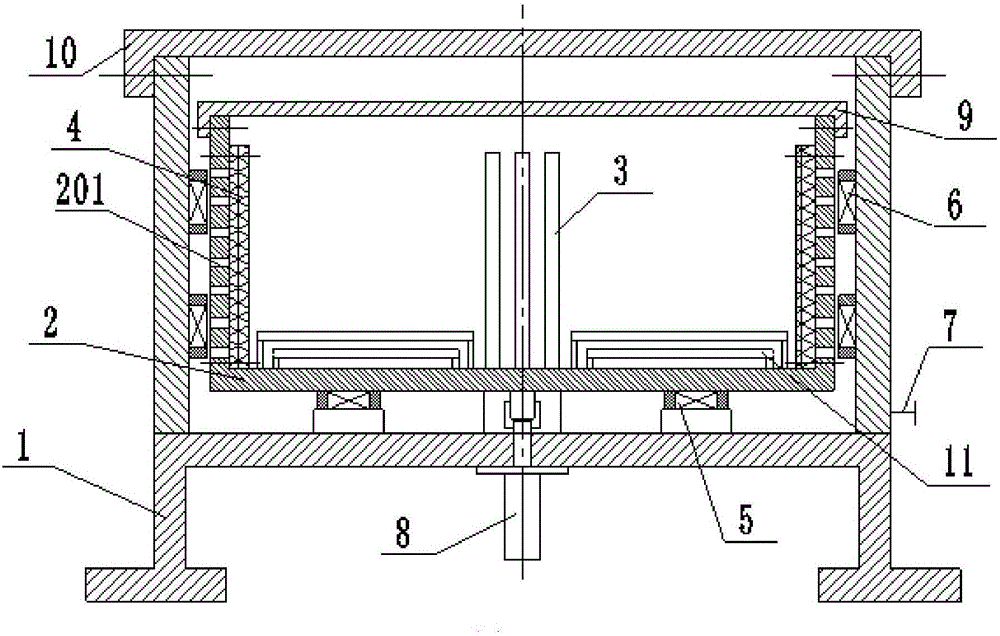

Adjustable composite dynamic filtering device

PendingCN110559702APrevent cloggingStable swirl stateSpecific water treatment objectivesTreatment involving filtrationPollutantEngineering

The invention discloses an adjustable composite dynamic filtering device. The device comprises a tank body, the middle part of the tank body is filled with a filter material layer, the upper part of the tank body is provided with a water inlet, the bottom of the tank body is provided with a water outlet, the filter material layer comprises a top fluidized bed layer and a lower fixed bed layer, andthe thickness and / or height of the fluidized bed layer is adjustable; a backwashing drain pipe is vertically mounted in the tank body, and a solid-liquid separator located in the tank body is mountedat the top of the backwashing drain pipe; a water inlet branch pipe is arranged at the water inlet, and the tail end of the water inlet branch pipe is connected to the middle part of the backwashingdrain pipe; and the water inlet corresponds to the fluidized bed layer, and is tangent to the tank body. According to the invention, large particles in inflow water can be adsorbed in the fluidized filter material layer, and fine particle pollutants in the inflow water can go deep into the lower filter bed, and in addition, the filter material with a large active catalyst medium specific surface area increases the dirt holding capacity of the filter material layer and prolongs the filtering period of the filter.

Owner:北京万诺生态科技有限公司

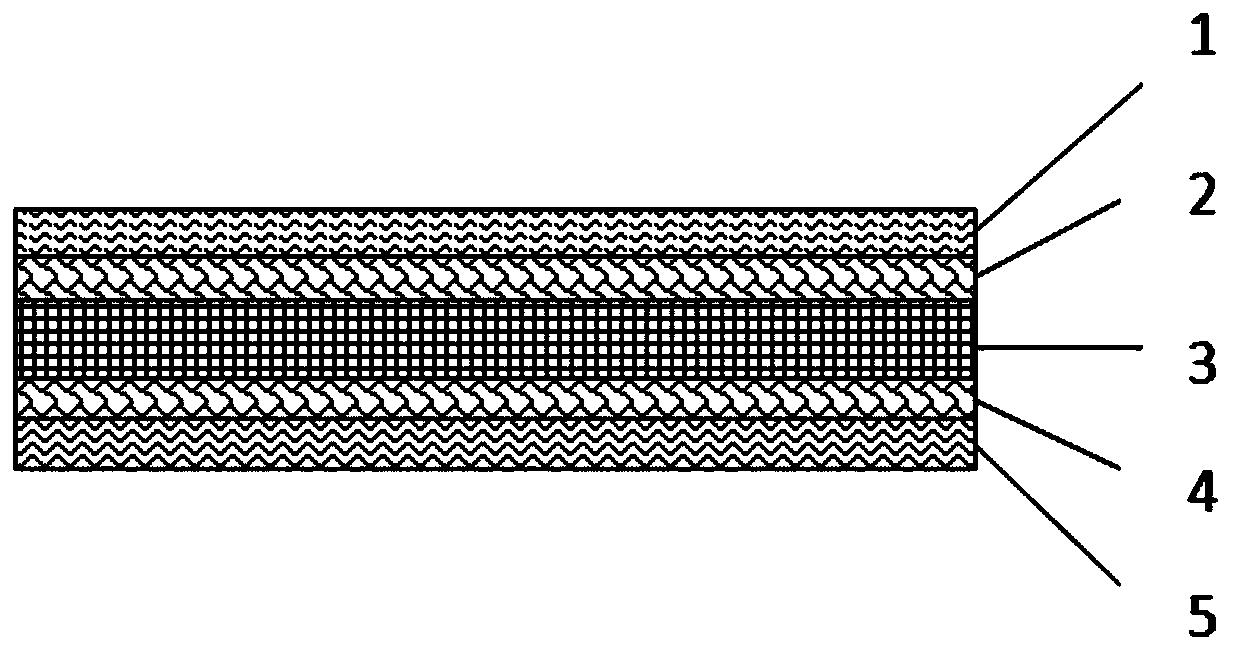

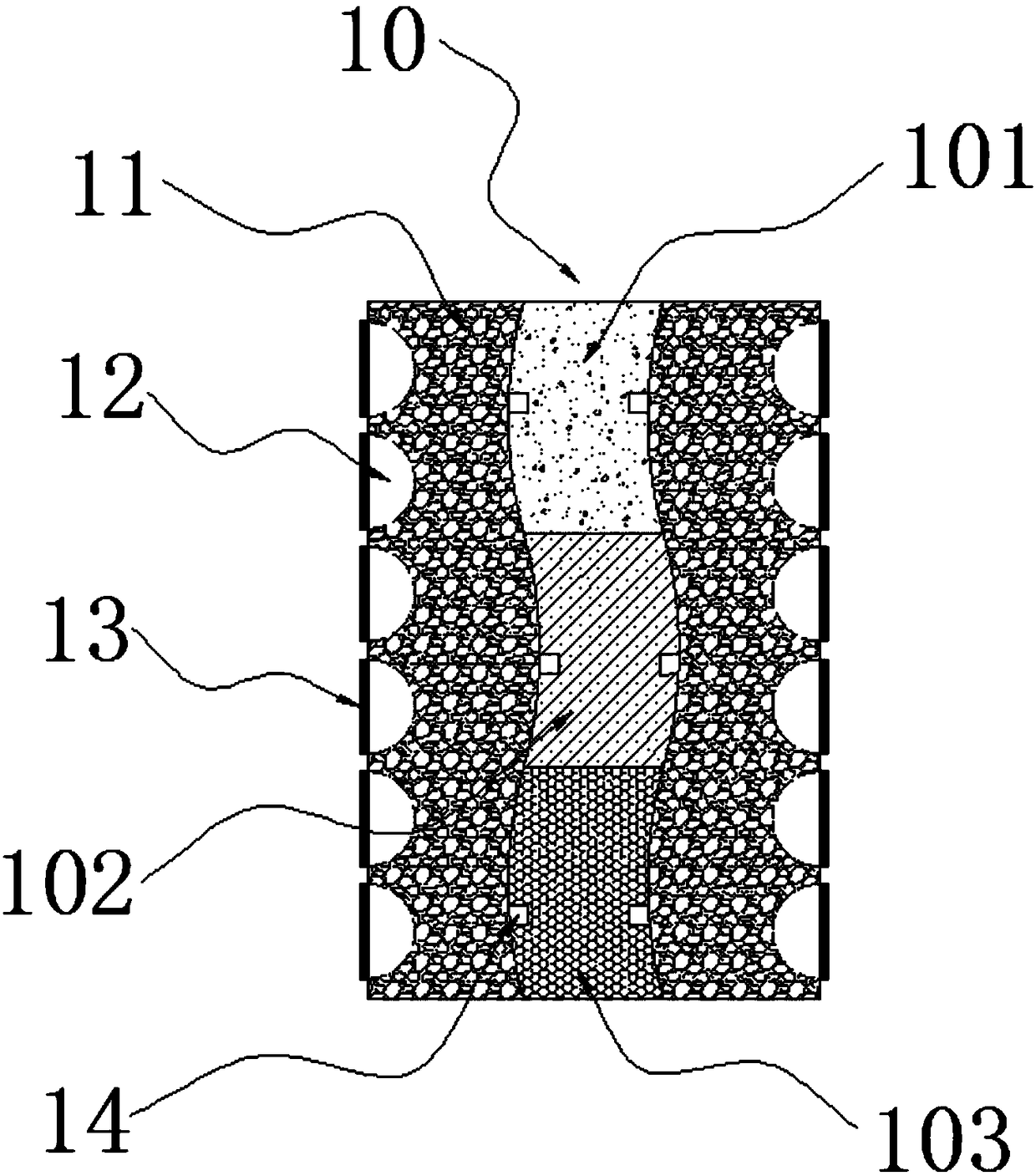

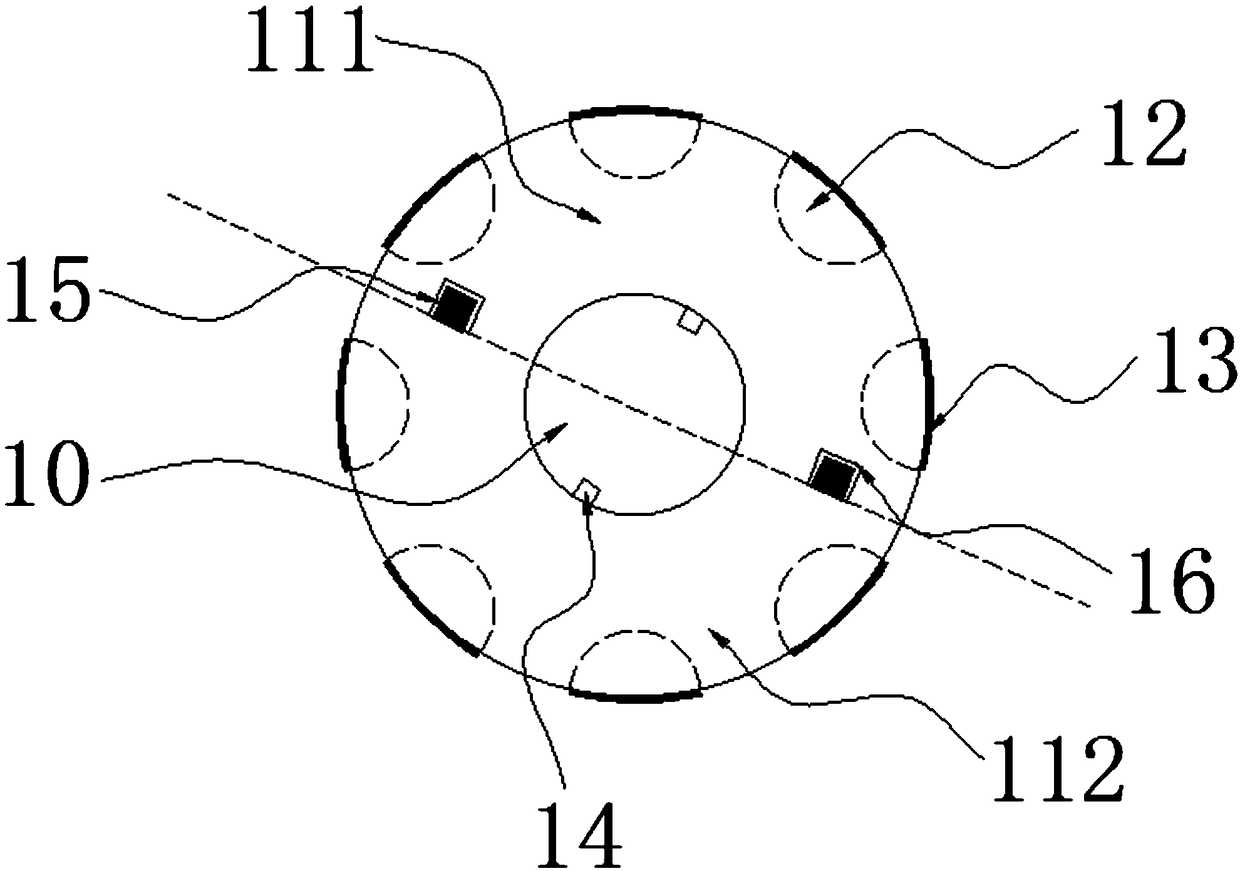

Pure metal fiber fabric filter composite material and preparation method thereof

InactiveCN110180262AImprove temperature resistanceIncreased durabilityFiltration separationMetal layered productsFiberMetallurgy

The invention discloses a pure metal fiber filter material used in the field of high-temperature dust removal. The filter material is formed by compounding of five layers including a woven fabric layer, knitted fabric layers and non-woven felt layers, and the filter material comprises a pure metal fiber felt dust facing layer, a first adhesion layer, a base cloth layer, a second adhesion layer anda bottom layer from the top to the bottom; and the surface of the dust facing layer is coated with corrosion-resistant coatings, and the layers of the composite filter material are connected by needling or sintering. The pure metal fiber composite filter material prepared by the invention has good high-temperature resistance and can be used for a long time at a high temperature of 500 DEG C or higher, the multi-layer composite structure has a stepwise-changed pore size, and the filtering effect is good; and the product dust facing layer is treated by the multi-layered acid-proof anti-corrosion coatings, so that the durability of the filter material is further improved.

Owner:HUIZHOU UNIV

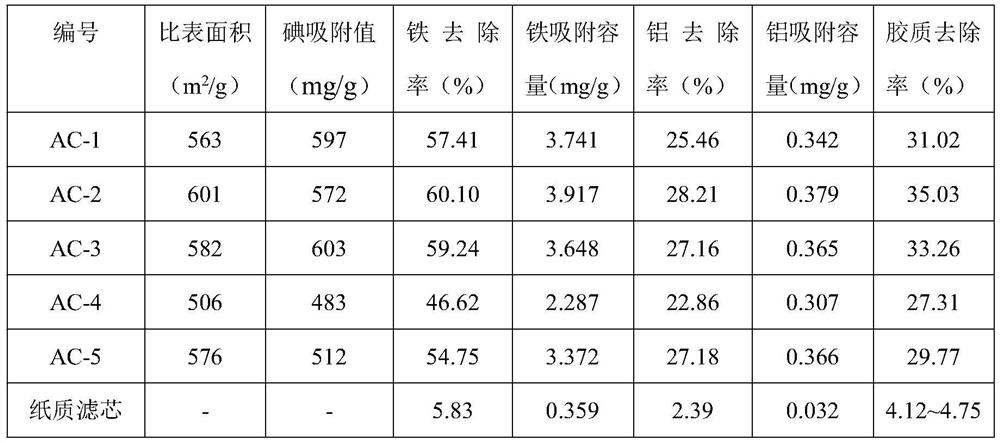

Preparation method of activated carbon filter element for engine oil purification

The invention discloses an activated carbon filter element for engine oil purification and a preparation method of the activated carbon filter element. The filter element is made into a cylinder by gluing, forming, curing and other processes through activated carbon and an adhesive, and the cylinder is placed in a filter to be used. The method comprises the following steps: uniformly mixing the activated carbon with the polyether polyurethane adhesive, quickly conducting stirring, adding an MDI curing agent, further conducting stirring, mixing and gluing, pouring the formed substance into a forming mold, achieving uniform filling, and conducting curing and molding. Impurities in engine oil can be adsorbed and filtered by utilizing the strong adsorption and filtration effects of the activated carbon, the dirt capacity is large, the filtration effect is good, the impurities in the engine oil are effectively reduced, engine abrasion is reduced, the service life of the engine oil is prolonged, and energy conservation and consumption reduction are achieved; and meanwhile, through gluing and mold molding, the filter element can be matched with various filters, the permeability is good, the pressure drop is small, the engine oil liquidity is good, the manufacturing process is simple, industrial, automatic and standardized production can be achieved conveniently, and the quality of the filter element can be controlled easily.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Bypass fine filtering device with high pollutant carrying capacity and working method of bypass fine filtering device

InactiveCN107875676AHigh precisionSimple structureLiquid separation auxillary apparatusFiltration separationCarrying capacityFiltration

The invention discloses a high-pollution-holding bypass fine filter device and its working method. The fine filter device includes a bracket, a filter and a filter pump. The filter is arranged above the bracket, and a filter pump is arranged on the right side of the filter. , One side of the filter is provided with an oil inlet pipe connected to the filter pump, and the bottom of the filter is provided with an oil outlet pipe. Simple structure, small flow rate, high precision, large dirt-holding capacity, convenient operation, low cost of use, and an independent oil circulation system that continuously captures pollutants and moisture in the oil to achieve the effect of cleaning the oil and ensure the oil system Cleanliness, water content and other indicators are maintained at ideal levels, prolonging the life of oil products and mechanical equipment, improving equipment reliability and reducing fuel consumption.

Owner:江苏高创风电设备有限公司

Calcium sulfate whisker/epoxy resin composite filter material and preparation method thereof

InactiveCN104559065ASmall apertureHigh filtration precisionFiltration separationEpoxyTherapeutic effect

The invention discloses a calcium sulfate whisker / epoxy resin composite filter material and a preparation method thereof. The composite filter material comprises calcium sulfate whisker and epoxy resin at the mass ratio of (9:1) to (4:6). The preparation method comprises the following steps: S1 weighing; S2 mixing, namely adding an organic solvent to the epoxy resin, adding the calcium sulfate whisker to form a turbid liquid, and adding a solidifying agent to the turbid liquid to obtain a pouring liquid; S3 removing a solvent, namely injecting the pouring liquid into a mold, and processing the mold at 60-80 DEG C for 30-60 minutes; and S4 solidifying, solidifying the mold for 7-26 hours. The calcium sulfate whisker / epoxy resin composite filter material disclosed by the invention is high in filtering accuracy, high in pollution receiving capacity, and low in material cost, and especially has an excellent treatment effect on metal ions such as lead ions in waste water. The preparation method disclosed by the invention has the advantages of being simple in manufacturing process, low in manufacturing cost, convenient to operate and suitable for industrial large-scale production.

Owner:SICHUAN MINGXIN JIAJIE NEW MATERIAL

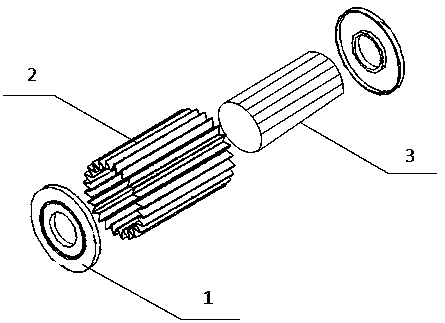

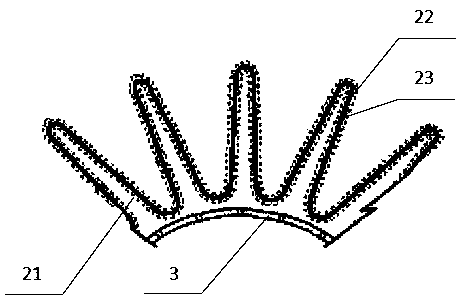

High-flux cartridge filter element

InactiveCN107694185ALarge dirt holding capacityExtended service lifeStationary filtering element filtersPolypropylenePollutant

The invention provides a high-flux cartridge filter element which can solve the problems that the service life of a filter element is short and use benefits of an inner filter element are low as an outer filter element is early blocked by pollutants. The high-flux cartridge filter element is characterized in that the filter element comprises an upper end cover, a lower end cover, an inner supporting framework, a filter medium middle layer, an outer fixing framework and an inner sleeve, the inner supporting framework, the filter medium middle layer and the outer fixing framework are closely combined in a sleeved manner, fitted on the inner sleeve and fixedly adhered at the upper end cover and the lower end cover in a hot melting manner, the filter medium middle layer is made of polypropylene and in a folded shape, the density of the filter medium middle layer is gradually increased from outside to inside, the porosity of the filter medium middle layer is gradually reduced from outside to inside, and the inner supporting framework and the outer fixing framework are stainless steel grids and matched with the folded shape of the filter medium middle layer.

Owner:DEQING GUONENG FILTER EQUIP CO LTD

Recycling and treatment method of waste magneto-rheological liquid

InactiveCN106116008AAvoid easy cloggingNot easy to settleWater/sewage treatment with mechanical oscillationsTreatment involving filtrationLiquid wasteEngineering

The invention discloses a recycling and treatment method of waste magneto-rheological liquid and belongs to the technical field of recycling and treatment of magnetic waste liquid. The method comprises the following steps: controlling a rotary speed of an inner barrel body to be 3600r / min-3650r / min; after running for 20min, electrifying a coil in an adsorption pipe to generate a magnetic field; controlling the intensity of the magnetic field to be 6.5T-6.7T, and keeping for 10min-12min; reducing the rotary speed of the inner barrel body to be 10r / min and keeping for 2min-3min; accelerating the inner barrel body to be 3800r / min-3850r / min; after stably running, adjusting the intensity of the magnetic field of the coil to be 7T-7.2T and keeping for 7min-9min; reducing the rotary speed of the inner barrel body to be 10r / min and keeping for 2min-3min; then adjusting the rotary speed of the inner barrel body to be 3900r / min-3920r / min; after stably running, adjusting the intensity of the magnetic field of the coil to be 8.3T-8.5T and keeping for 5min-6min; and reducing the rotary speed of the inner barrel body to be 10r / min and keeping for 2min-3min. The method utilizes a physical method to treat, a bonding effect of main dispersible particles and carrier liquid can be disconnected and the main dispersible particles and the carrier liquid are separated; new components are not introduced into the magneto-rheological liquid; and post-treatment is simple, the operation is simple and the separation rate is high.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

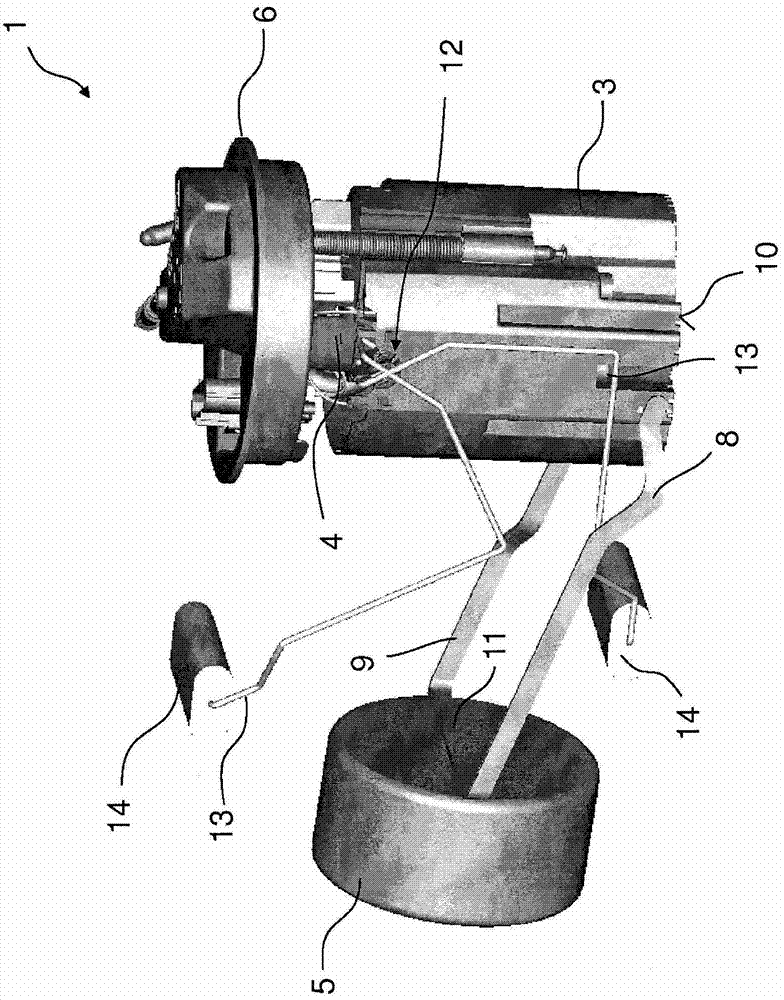

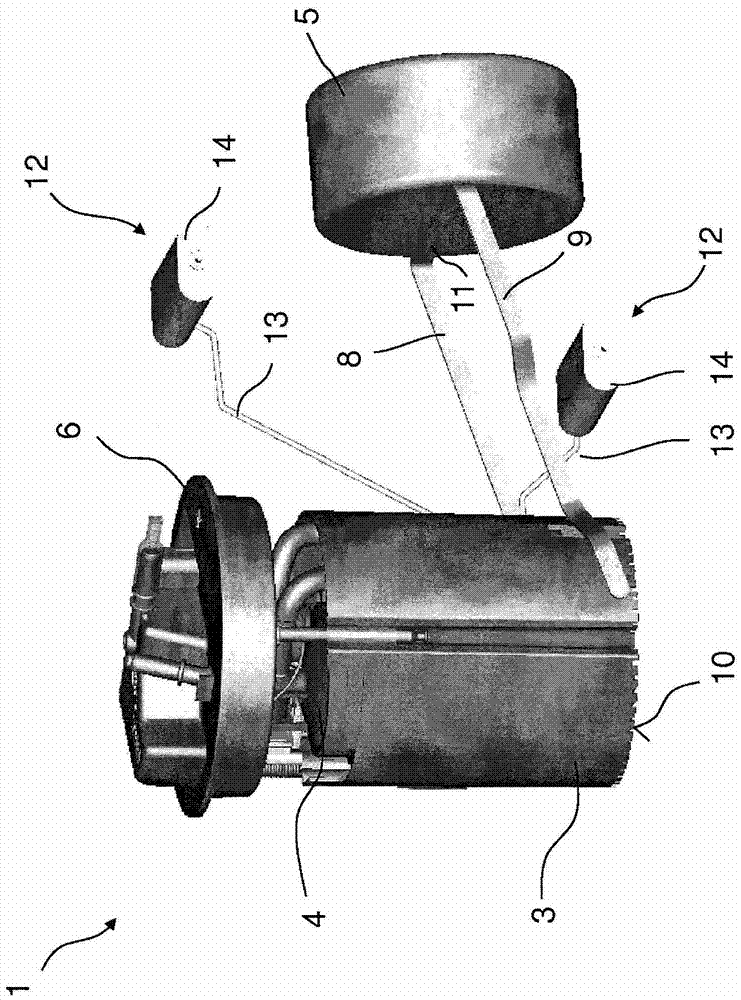

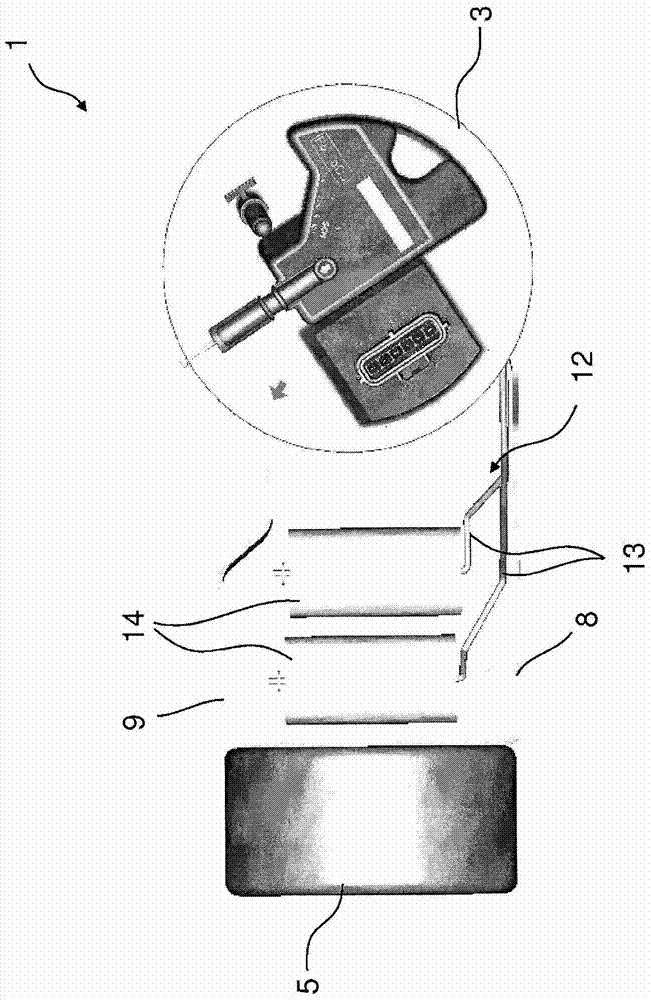

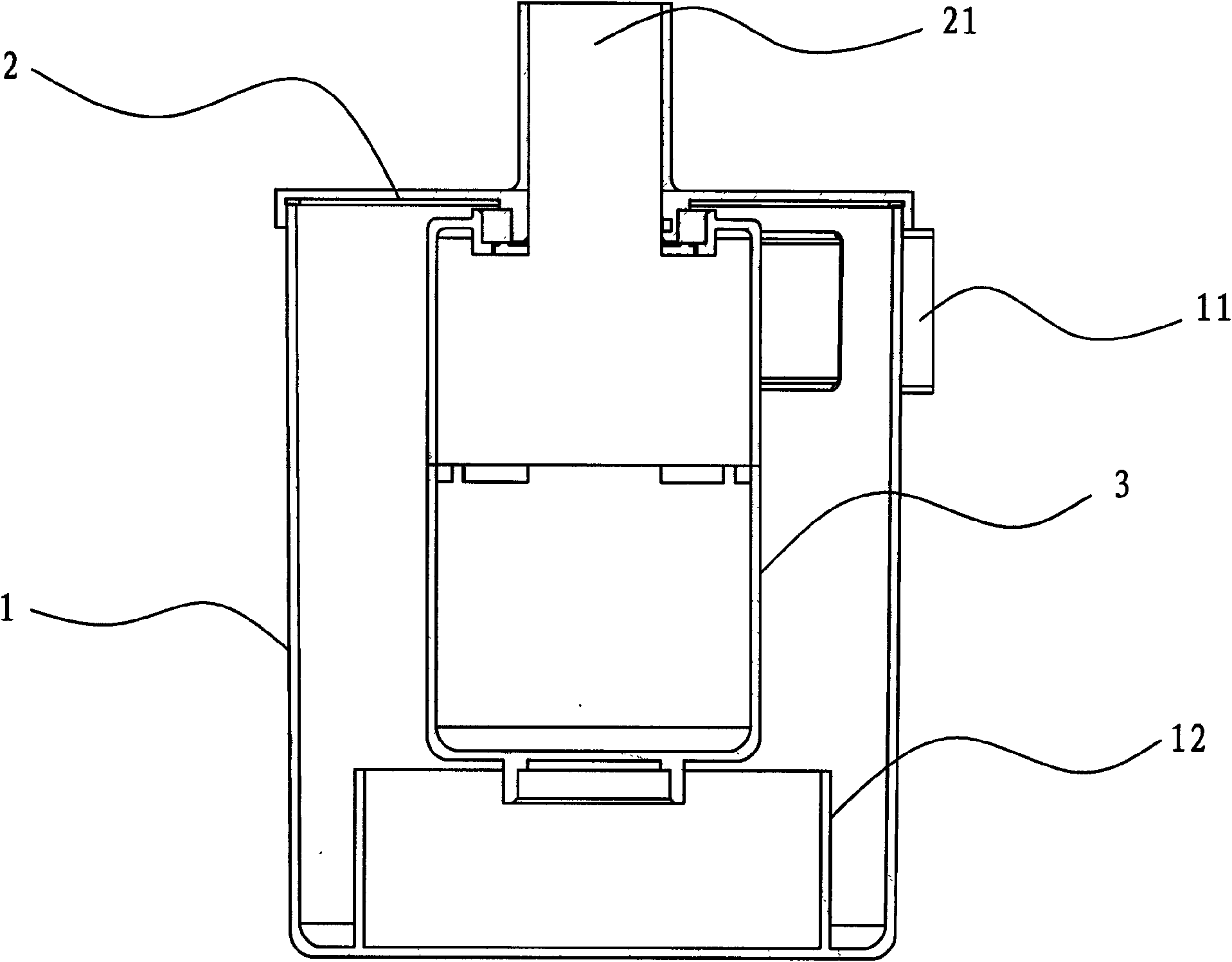

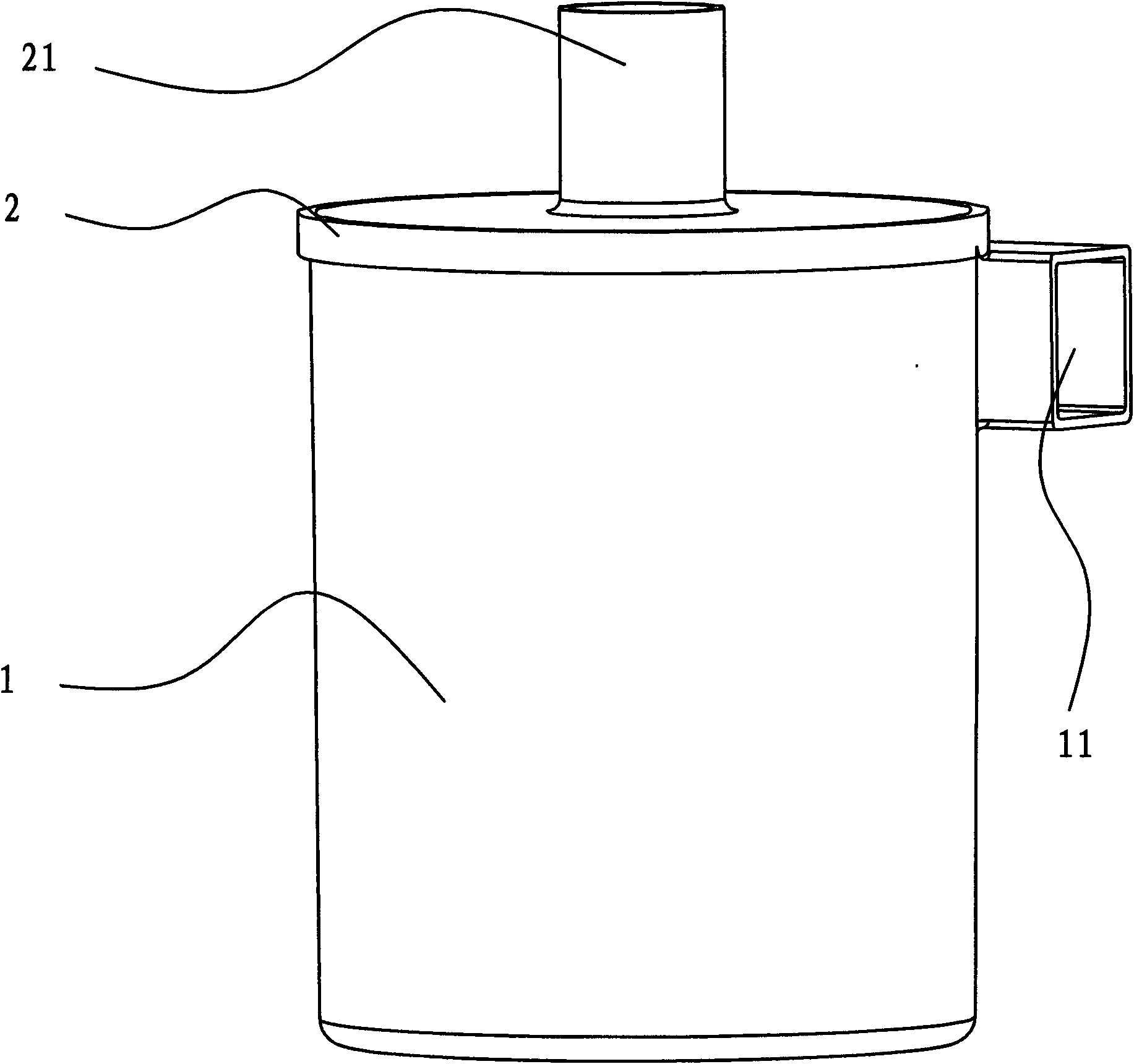

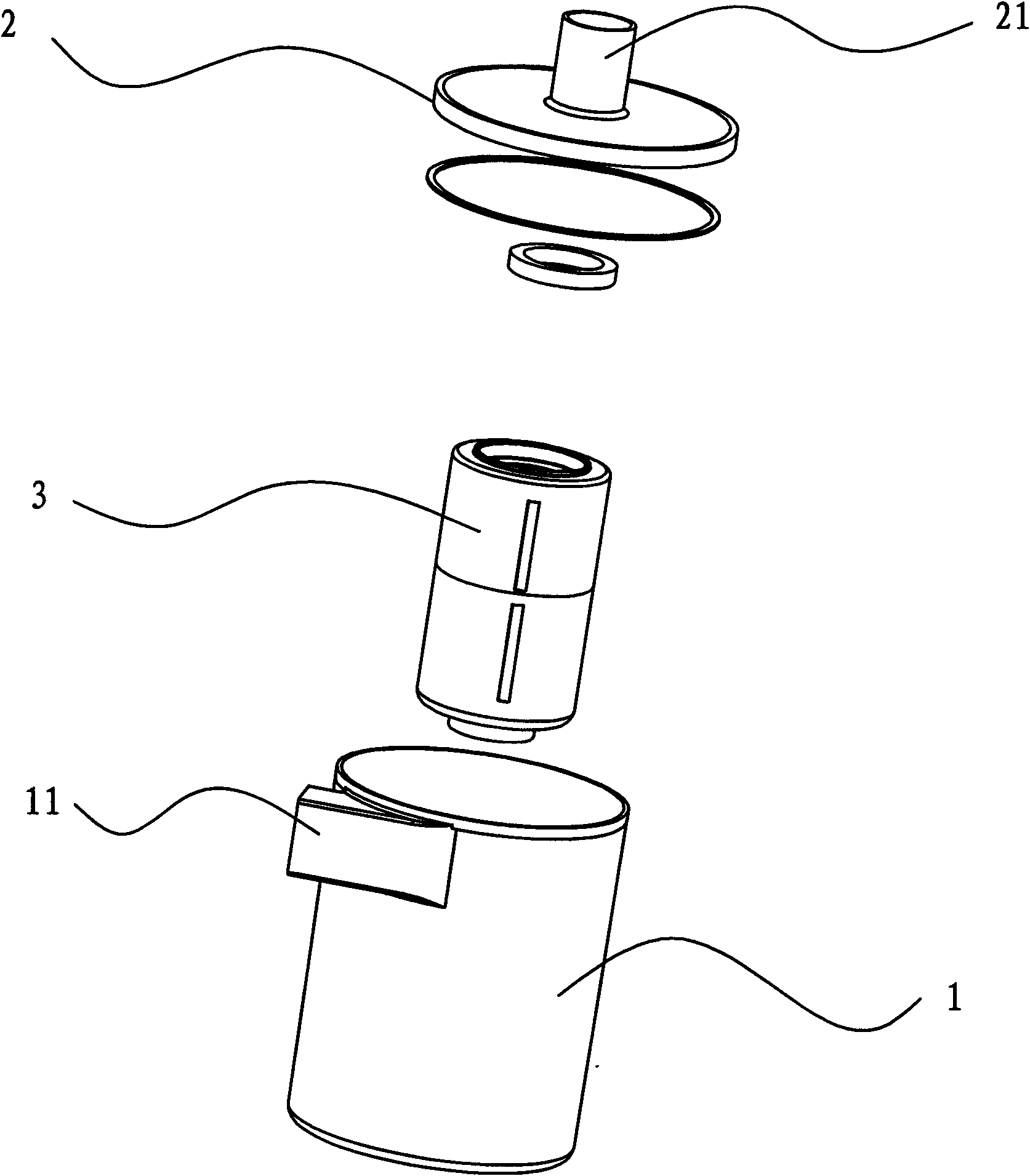

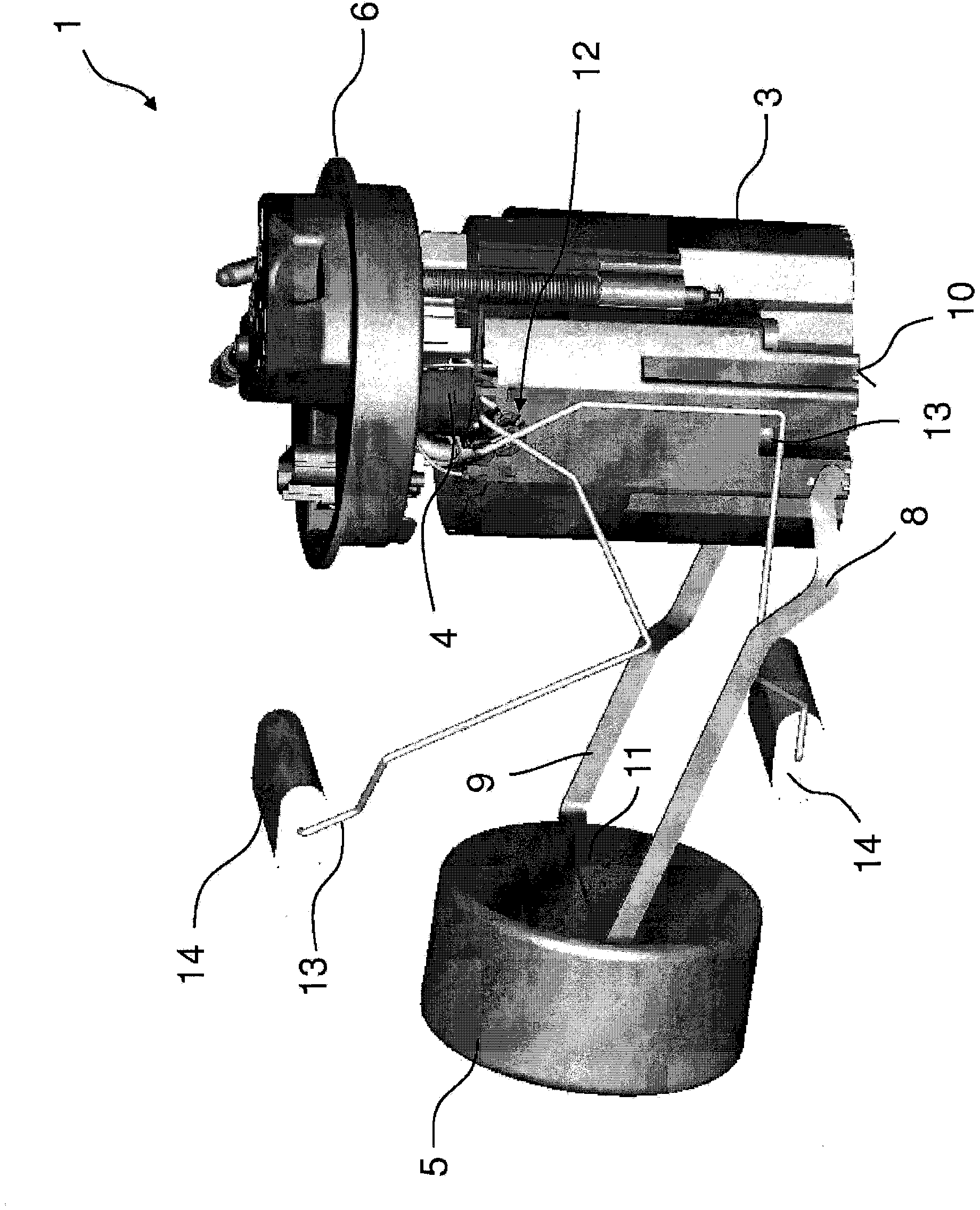

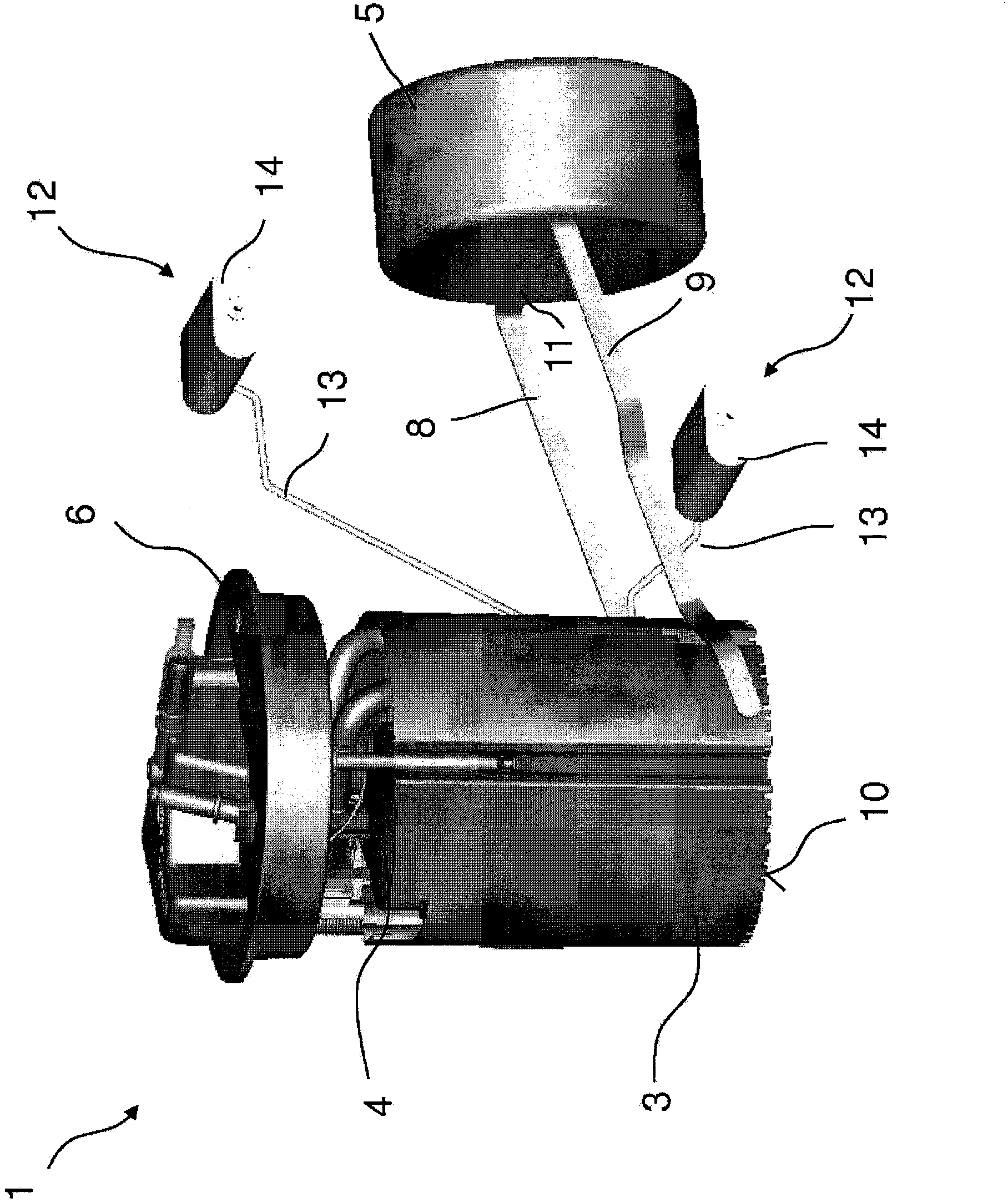

fuel delivery module with fuel filter

ActiveCN103375319BElimination of direct dependenciesIncrease in sizeNon-fuel substance addition to fuelMachines/enginesEngineeringFuel filter

The invention relates to a fuel delivery module for being arranged in a fuel container (2) of a vehicle, comprising a surge chamber (3) for storing fuel, a device for delivering fuel from the surge chamber (3) to a fuel consumer A fuel pump (4) and a fuel filter, the fuel delivered by the fuel pump (4) flows through the fuel filter. The fuel filter is received in a filter housing (5) arranged outside the surge chamber (3).

Owner:FORD GLOBAL TECH LLC

Experiment system for superhigh temperature bag duster

Owner:JIANGXI JIANGLIAN PUKAI ELECTRIC POWER ENVIRONMENTAL PROTECTION ENG CO LTD

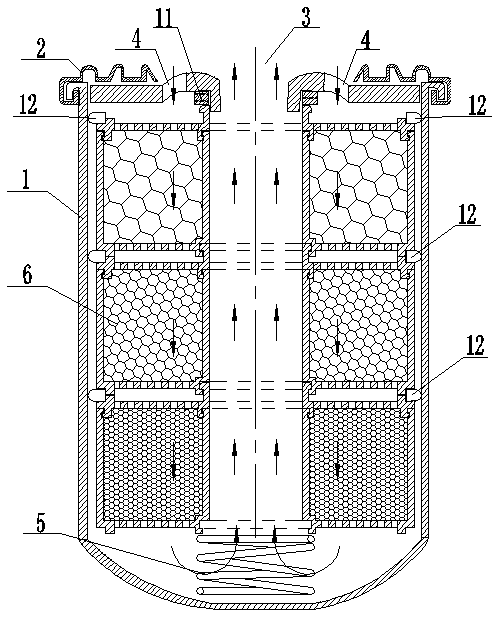

Efficient filter element for water purifier

InactiveCN108658317AHigh filtration precisionLarge dirt holding capacitySpecific water treatment objectivesTreatment involving filtrationWater filterEnvironmental engineering

The invention discloses an efficient filter element for a water purifier. The efficient filter element comprises outer filtering passages and an inner filtering passage, the outer filtering passages include a first outer filtering passage and a second outer filtering passage, an inner filtering passage is arranged in the middle of the outer filtering passage to form a cylindrical structure and equidistantly divided into three filtering sections, fixing blocks are symmetrically arranged on the inner sides of the three filtering sections, and a plurality of filtering grooves are uniformly formedin a circular section and a side face of the outer filtering passage. The inner filtering passage is arranged to be of a snake-shaped structure, so that water filtering efficiency is higher in a samefiltering section; the outer filtering passage is arranged to be of a detachable structure, so that convenience is brought to replacement of a KDF filter material, a PP melt-blown filter element andan ultrafiltration element.

Owner:浙江升元菲尔科技发展有限公司

Electric oil purification method and device

ActiveCN102360748BImprove adsorption capacitySmall processing flowTransformers/inductances coolingEnergy based chemical/physical/physico-chemical processesPurification methodsFiltration

The invention discloses an electric oil purification method and an electric oil purification device and belongs to an electro-adsorption deionization technology. Under a constant direct current electric field, collection media and ions in oil liquid form a double electric layer to enrich the ions so that the oil is removed from the oil liquid. In the electric oil purification device, an oil tank is connected with the positive electrode of an external power supply; a core column is connected with the negative electrode of the external power supply; the negative electrode of a metal net is connected with the core column; the positive electrode of the metal net is connected with the oil tank; the collection media are filled in the oil tank; and an oil outlet pipe and an oil inlet pipe are connected with the upper part and the lower part of the oil tank respectively. A three-dimensional multi-layer type electric oil purification device for deep purification of transformer oil has the advantages of high filtration precision and high dirt holding capacity, so a problem of contradiction of the mechanical filtration precision and dirt holding capacity is solved and defects of selective adsorption of adsorbent, environmental pollution, low processing flow rate of the electrostatic oil purification method, low adsorption rate and poor adsorption effect are avoided; moreover, the invention has good adsorption and purification effect and is lower in cost, and favorable for protection of environment and working staff.

Owner:国网黑龙江省电力有限公司齐齐哈尔供电公司 +1

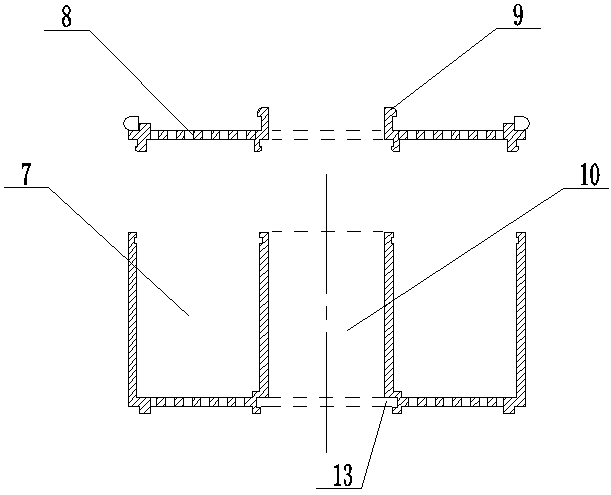

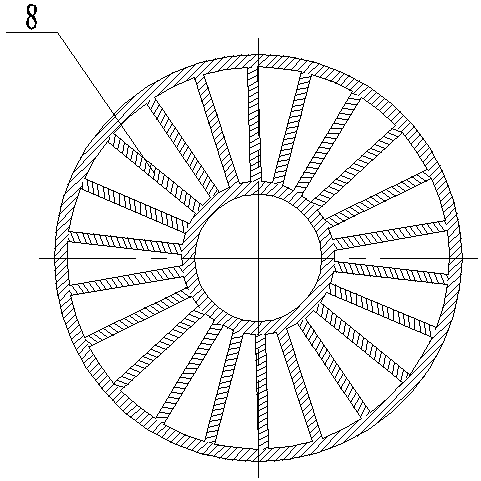

Dust suction filter

InactiveCN101617928ASimple structureLarge dirt holding capacitySuction filtersEngineeringFilter element

The invention discloses a dust suction filter, comprising a dust box and a sealing cover, wherein, the inside of the dust box is also hung with a filter core, an air inlet and an air outlet uprightly, the air inlet is arranged on the dust box, the air outlet is arranged on the sealing cover, the bottom of the inside of the dust box is provided with a skeleton position, and the skeleton position is positioned in a space between the filter core and the side wall of the dust box and is not higher than the bottom of the filter core. The device has very simple structure, greatly enhances the dust removal efficiency and also realizes the functions of smaller volume and bigger dirt storage capacity.

Owner:中山市龙的电器实业有限公司

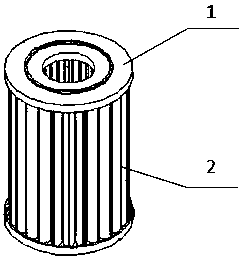

an oil filter

ActiveCN105464744BNovel structureNovel way of oil circuitLubricant mounting/connectionPressure lubricationButt jointFilter material

The invention discloses an oil filter which comprises a shell. A threaded cover plate is arranged at the upper end of the shell. An oil outlet hole is formed in the center of the threaded cover plate. Oil inlet holes are circumferentially formed in the position, on the outer side of the oil outlet hole, of the threaded cover plate. A supporting spring is arranged at the bottom in the shell, and a filter element formed by vertically assembling a plurality of filter element assemblies is arranged at the position, above the supporting spring, in the shell. Each filter element assembly comprises a filter box center pipe and a filter box located on the outer side of the filter box center pipe. The filter box center pipes are in butt joint to form a filter element center pipe communicated with the oil outlet hole. The filter boxes are filled with filter materials. Upper end covers are arranged at the top of the filter element, and a plurality of holes are formed in the bottoms of the upper end covers and the bottoms of the filter boxes. A check sealing ring is arranged between the threaded cover plate and the upper end cover of the top-layer filter element assembly, and a sealing ring is arranged between the shell and the filter element. Deep adsorption is achieved in the filter process of the oil filter, the structure is simple, the oil path manner is novel, and a filter material is convenient and flexible to replace; and good universality is achieved, the filter effect is good, and the oil filter can be applied to industrial production.

Owner:GANSU HENGTONG FILTER IND

Fuel delivery module with fuel filter

ActiveCN103375319AElimination of direct dependenciesIncrease in sizeNon-fuel substance addition to fuelMachines/enginesFuel filterFuel pump

The present invention relates to a fuel delivery module which is used for being arranged in an automotive fuel container (2) and comprises the following components: a surge chamber (3) configured to store fuel; a fuel pump (4) which is used for conveying fuel from the surge chamber (3) to a fuel consumption device; and a fuel filter, wherein the fuel which is conveyed by the fuel pump (4) flows through the fuel filter. The fuel filter is received in a filter housing (5) which is arranged outside the surge chamber (3).

Owner:FORD GLOBAL TECH LLC

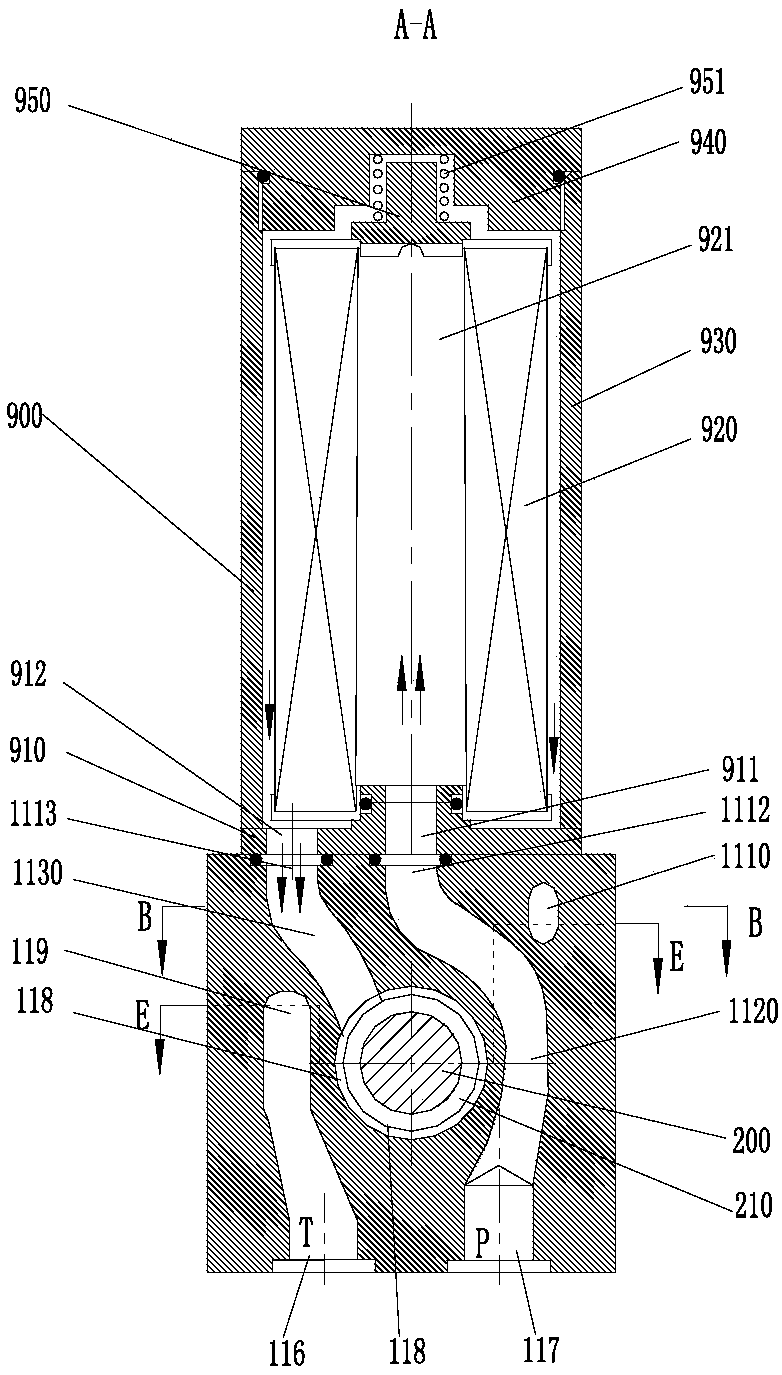

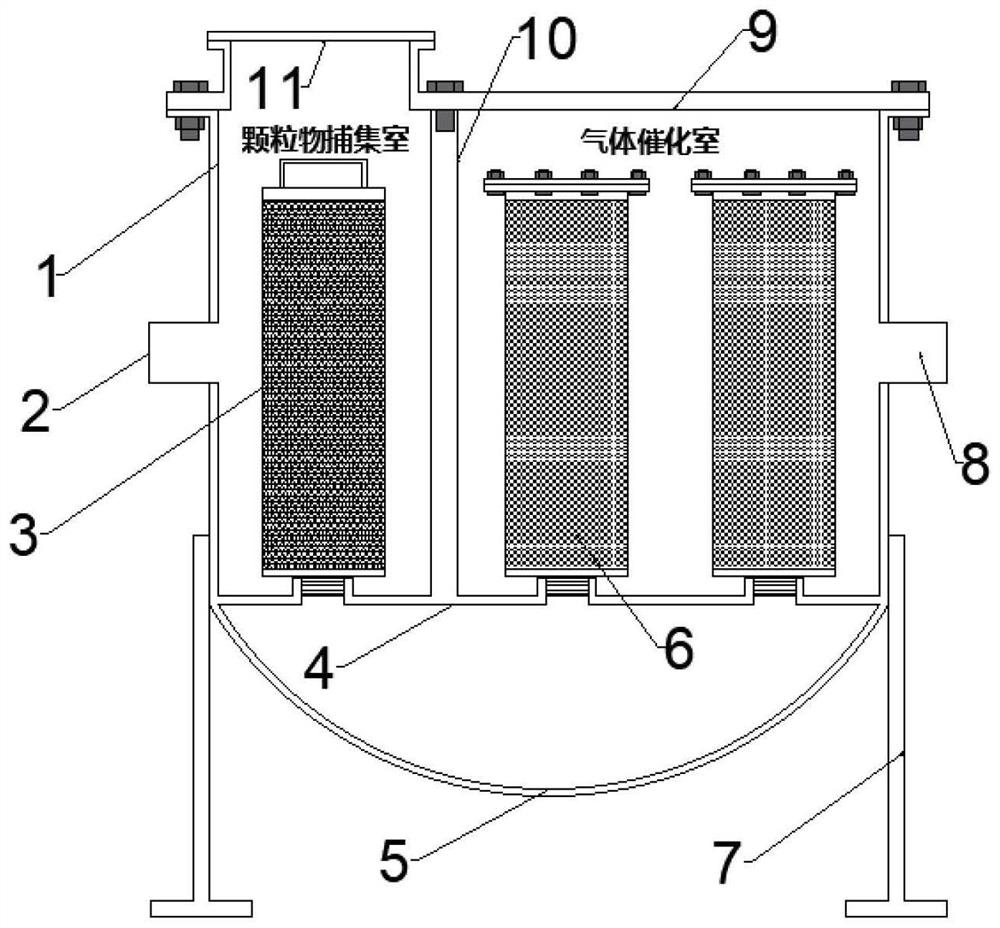

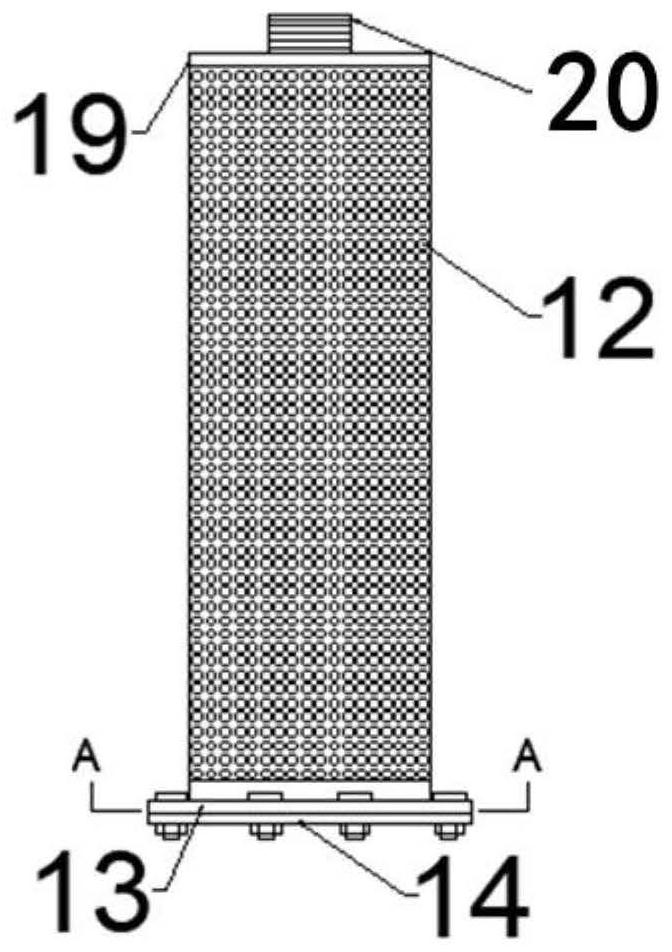

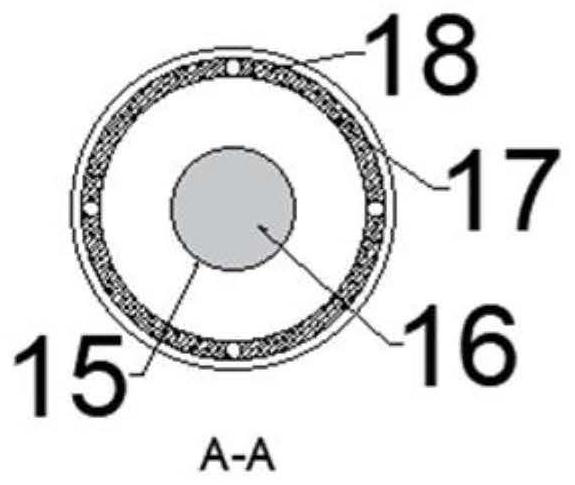

A mine explosion-proof diesel engine tail gas purification device and method

ActiveCN112081645BReduce corrosionReduced service lifeLiquid surface applicatorsHeterogenous catalyst chemical elementsParticulatesPtru catalyst

The invention discloses a mine explosion-proof diesel engine tail gas purification device and method. The device includes a purification chamber, a metal filter element, a spherical bottom cover, a purification cylinder and legs, and the purification chamber is provided with a particulate matter trapping chamber and a particle collection chamber. The metal baffle of the gas catalytic chamber, one side of the particulate matter trapping chamber is provided with an air inlet, the side of the gas catalytic chamber is provided with an air outlet, the metal filter element is disposed in the particulate matter trapping chamber, the purification cylinder is disposed in the gas catalytic chamber, and the purification chamber There is a high-temperature and high-pressure manhole on the body, which is used to take and place the metal filter element. The main advantages are as follows: 1) The metal filter element has large dirt holding capacity and low resistance; the surface is coated with PTFE coating, which is easy to clean and overcomes the shortcomings of traditional filter elements that are difficult to clean; 2) Utilizes the reducing and oxidizing hazards in the exhaust gas According to the characteristics of the coexistence of substances, transition metal oxide catalysts are prepared to eliminate "harms"; 3) avoiding the use of external reducing agents such as urea and electrical equipment, and simplifying the device structure.

Owner:CHINA UNIV OF MINING & TECH

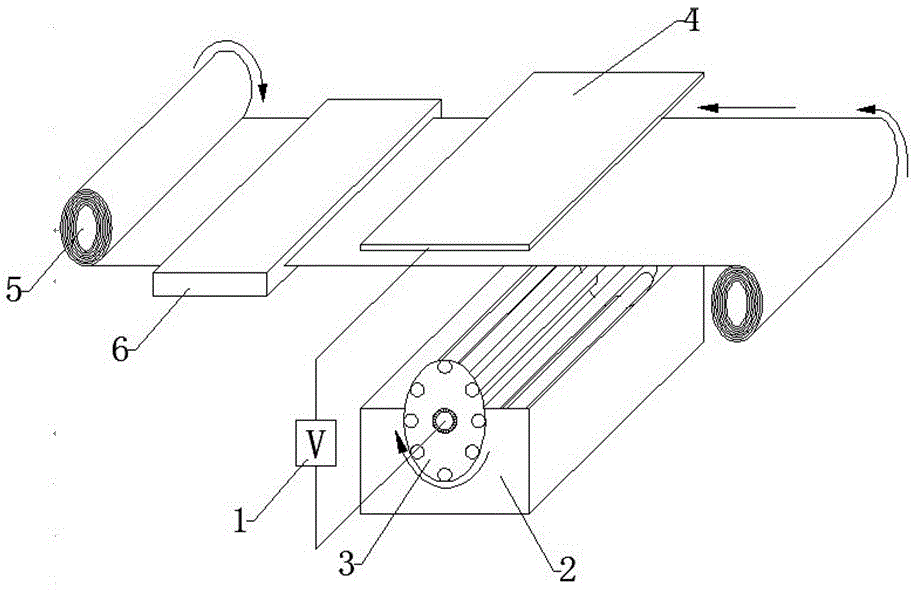

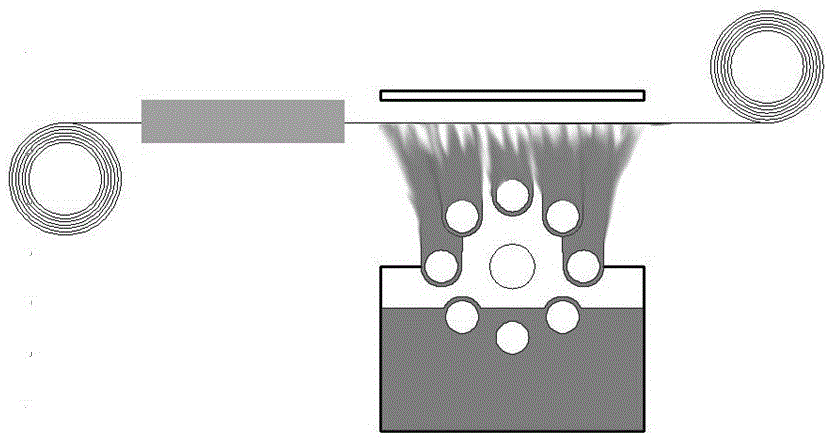

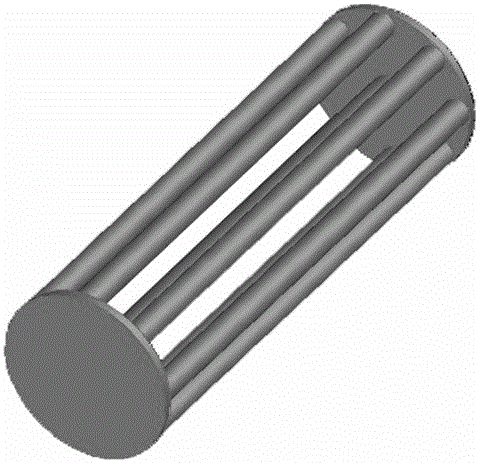

Composite filter paper manufacturing method and device capable of improving surface dust holding capacity

InactiveCN105833610AHigh filtration precisionReduce resistanceLayered product treatmentLaminationPaper manufacturingProcess engineering

The invention discloses a composite filter paper manufacturing method and device capable of improving surface dust holding capacity. The device mainly comprises a high-voltage electric field generator, a liquid storage slot, a drawing cylinder electrode, a collecting electrode plate, a substrate fabric reel, and an oven. The operating method comprises the following steps: dissolving fibers into a solvent to form an ultrafine fiber solution; forming a high-voltage electrostatic field between the drawing cylinder electrode and the collecting electrode plate through the high-voltage electric field generator; adhering the fiber solution to the substrate fabric in a filament form under the action of the strong electric field, thereby compounding an ultrafine fiber surface layer with a substrate fabric; and enabling the compounding product to pass through the oven to volatize the solvent of the ultrafine fiber solution, thereby obtaining the composite filer paper. The composite filter paper is high in filter efficiency, the surface dust holding capacity of the filter paper of is greatly improved, and the service life of the filter paper is prolonged; and the manufacturing method has the advantages of being reasonable in design, high in production efficiency and simple in process, guaranteeing uniform diameter and thickness of composite-layer fibers, and the like.

Owner:TONGJI UNIV

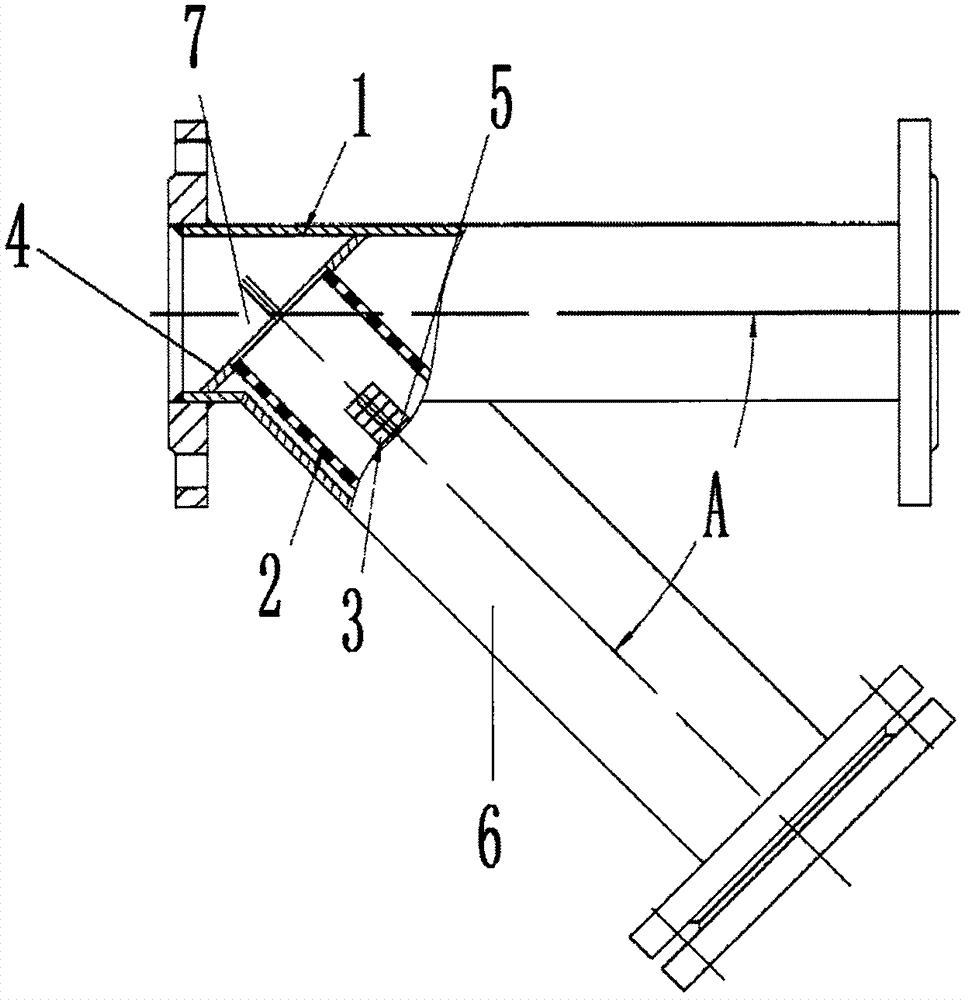

Nuclear power water feed pump mechanical seal magnetic filter

InactiveCN107159456AEasy to replaceEfficient removalMagnetic separationStationary filtering element filtersNuclear powerHigh intensity

The invention discloses a mechanically sealed magnetic filter for a nuclear power feedwater pump, which comprises an overflow cylinder body and a cylindrical filter fixed at the end of the overflow cylinder body and arranged in a Y shape with the overflow cylinder body; The inlet of the filter extends into the inside of the flow cylinder and is fixed by the connecting sleeve. The center point of the inlet of the cylindrical filter coincides with the central axis of the inner diameter of the flow cylinder; the inside of the cylindrical filter Install the ring-shaped filter cover, there is an installation gap between the filter cover and the inner wall of the cylindrical filter; the inner middle of the cylindrical filter is installed with a mounting rod that is axially consistent with the cylindrical filter, and the magnet ring is fixed at intervals on the mounting rod . The invention adopts a Y-shaped structure with an angle of 45 degrees, which is simple to manufacture and easy to replace the filter element; the Y-shaped structure is adopted, which is convenient for installation and has a large dirt holding capacity; the filter element adopts a cylindrical structure, and the flow rate is fast; the filter element is equipped with NdFeB high High-strength magnets can more effectively remove iron products in the filter.

Owner:QINGDAO TONGXING ENVIRONMENTAL PROTECTION EQUIP

Non-woven fabric engine oil filter element

InactiveCN107988793AHigh filtration precisionLarge dirt holding capacityFibre typesLiquid/gas/vapor removalWoven fabricFilter element

The invention discloses a non-woven fabric engine oil filter element and relates to the technical field of filter elements. A preparation method of the non-woven fabric engine oil filter element comprises the following steps: (1) preparing carbon powder; (2) preparing master batch; (3) preparing a primary fabric of the non-woven fabric; (4) obtaining a finished product. The non-woven fabric engineoil filter element prepared by the preparation method is high in filtering precision and large in dirt containing capacity and also has excellent strength and toughness.

Owner:安徽新立滤清器有限公司

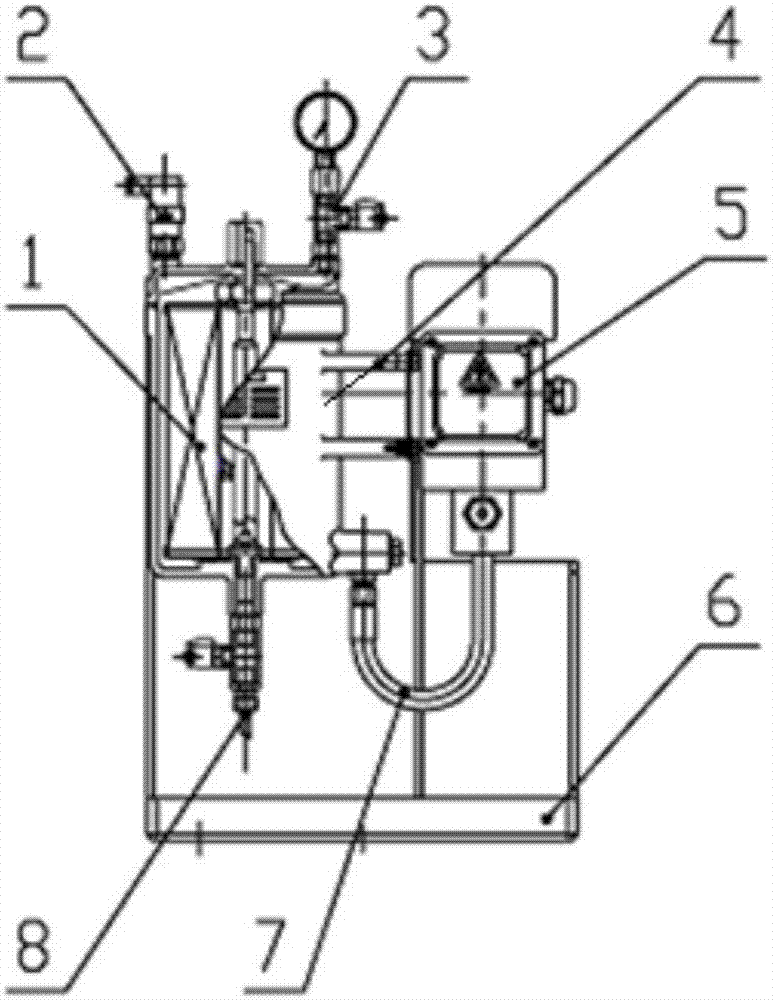

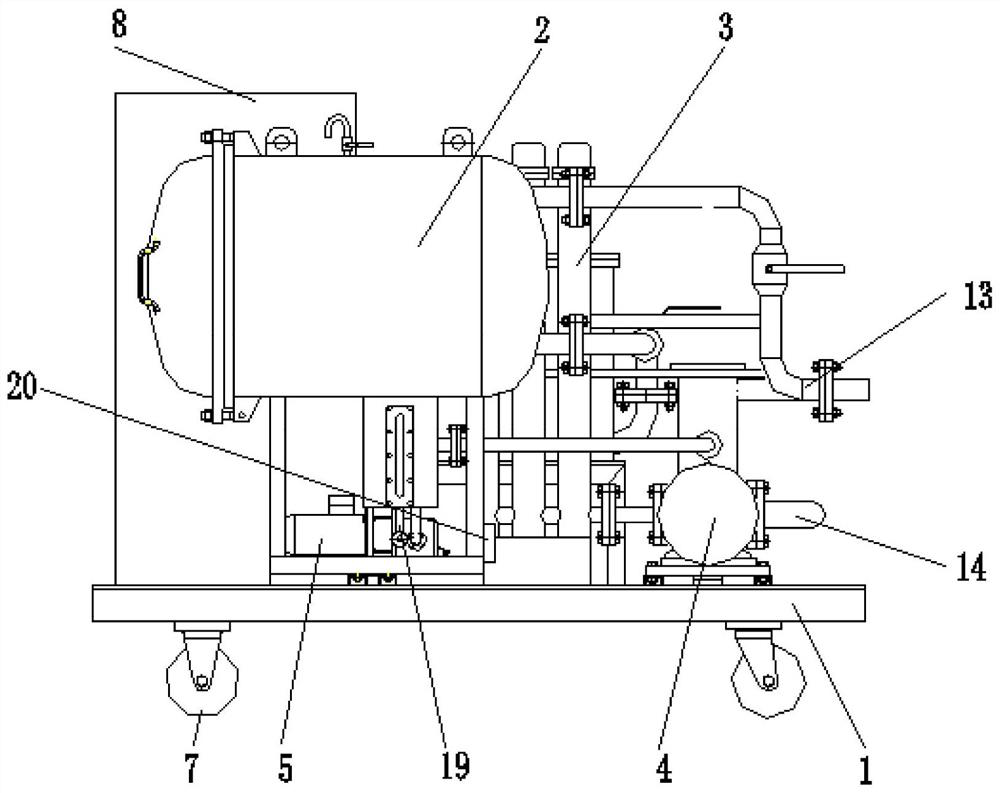

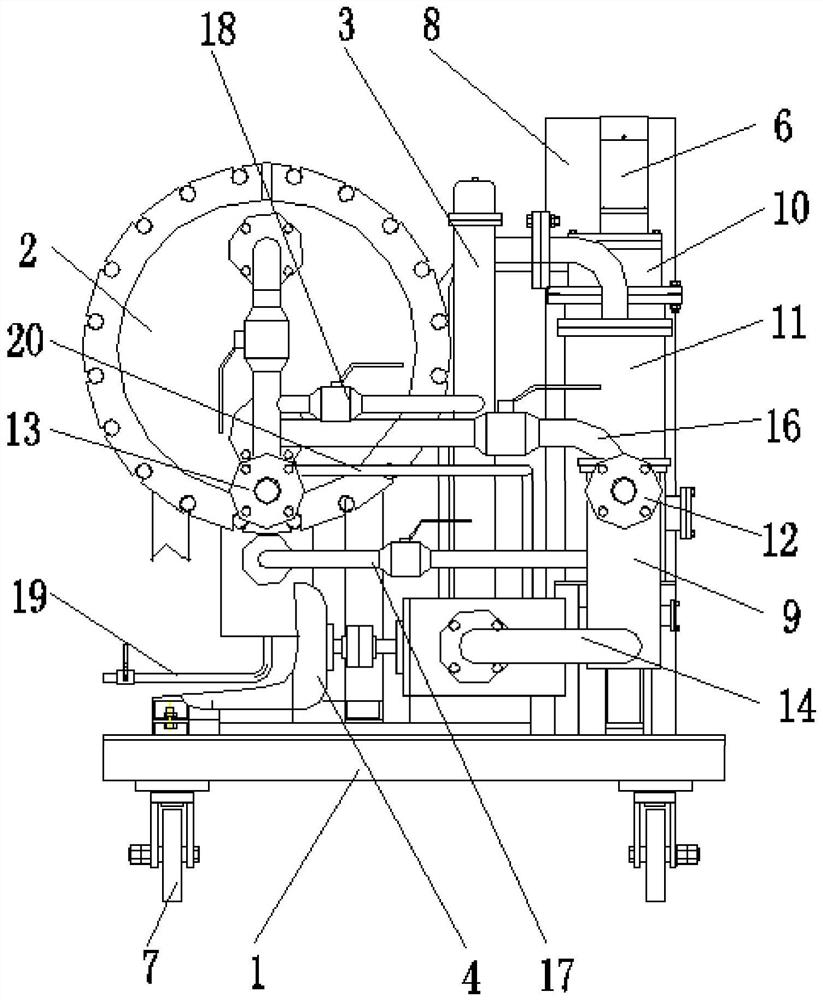

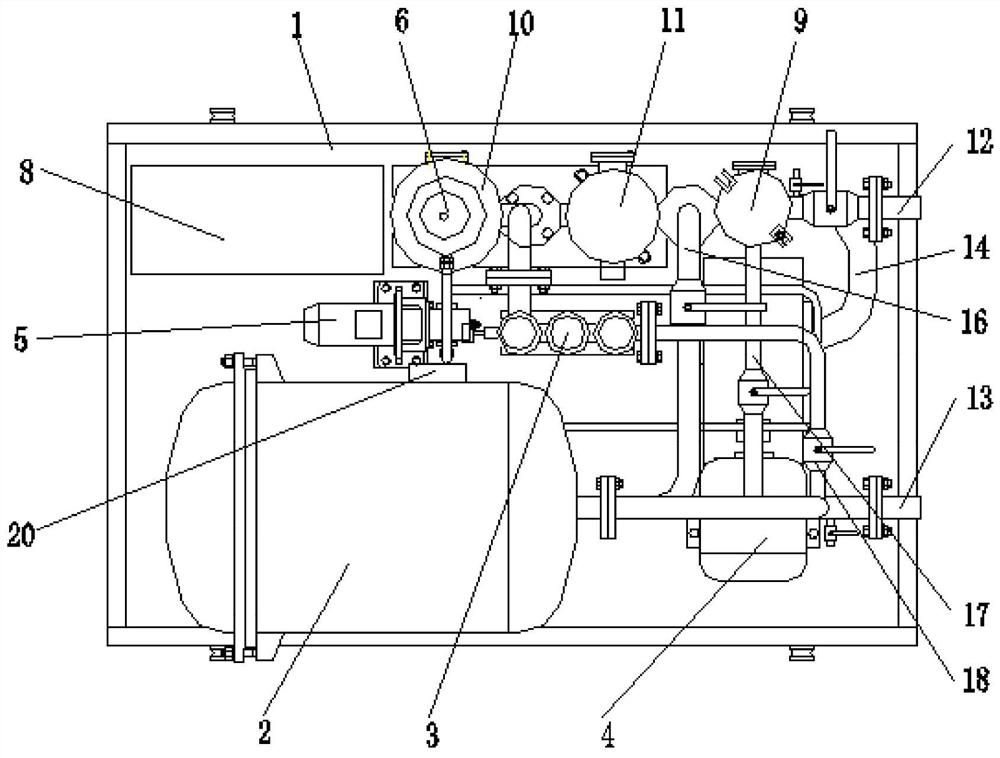

High-precision automatic backwashing oil-water separation device

PendingCN112107889AContinuous filterHigh filtration precisionLiquid suspension thickening by filtrationNon-miscible liquid separationProcess engineeringEnvironmental geology

The invention discloses a high-precision automatic backwashing oil-water separation device which comprises a base, a separator, a heater, a main oil pump, a backwashing pump, an electric appliance instrument box, a coarse filter, a fine filter, a high-precision filter oil pumping inlet pipe and an oil pumping outlet pipe; four universal wheels are installed at the lower end of the base; a separator, a heater, a main oil pump, a recoil pump, an electric appliance instrument box, a coarse filter, a fine filter and a high-precision filter are installed at the upper end of the base through supports, and an oil inlet pipe is installed at the upper end of the coarse filter. The high-precision automatic backwash oil-water separation device automatically and continuously backwashes sediments on the filter screen, effectively keeps the through-flow area of the filter screen basically constant to achieve the purpose of continuously and efficiently filtering dirt, has strong separation capability, can be suitable for high water content, large dirt holding capacity, high filtering precision, simplicity in operation and low maintenance workload. The filtering and coalescing separation element is long in service life and low in operation cost.

Owner:扬州中电电力设备有限公司

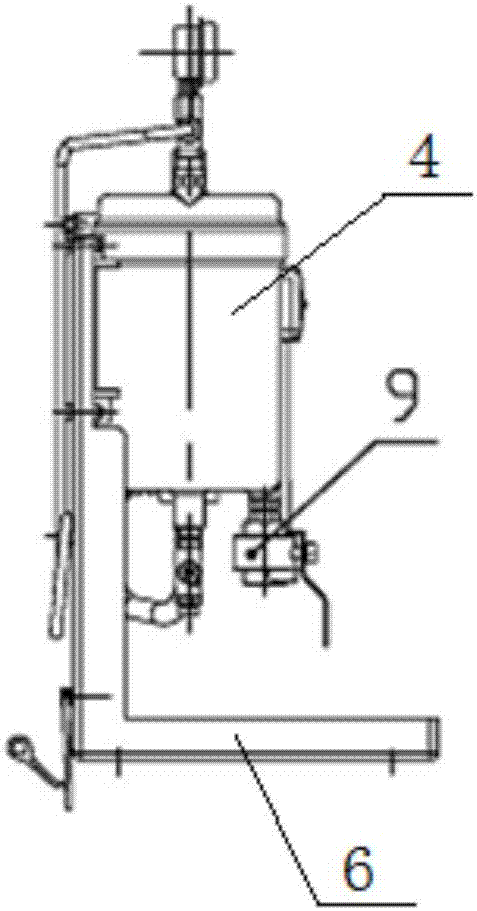

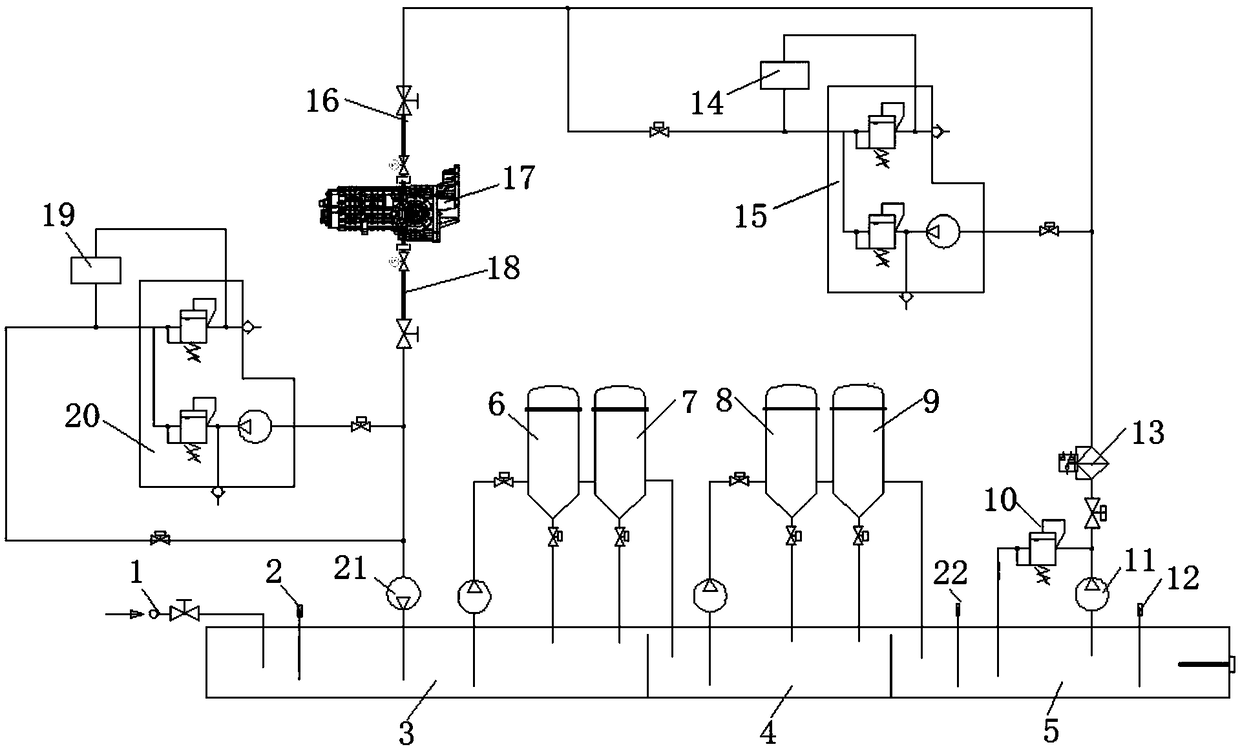

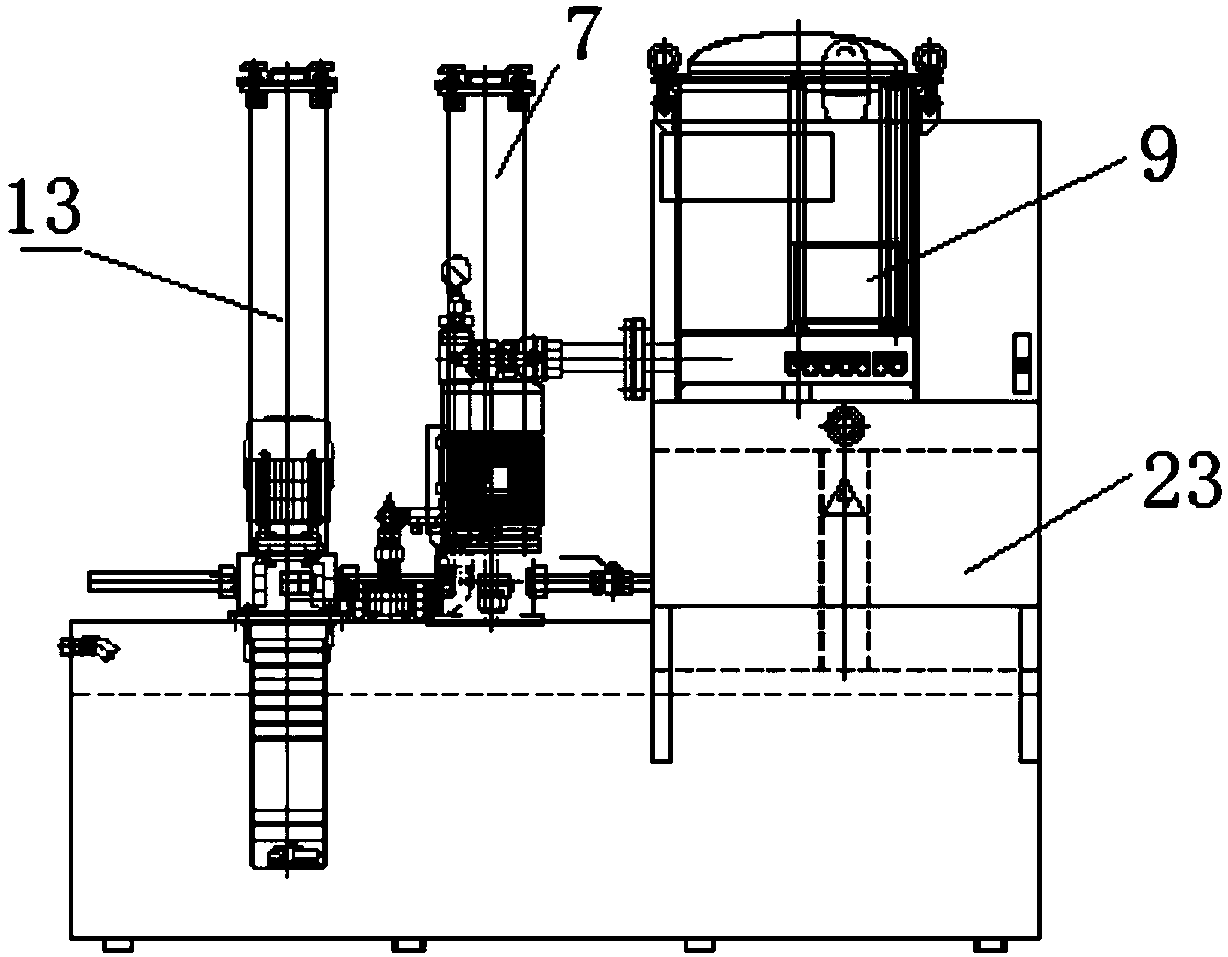

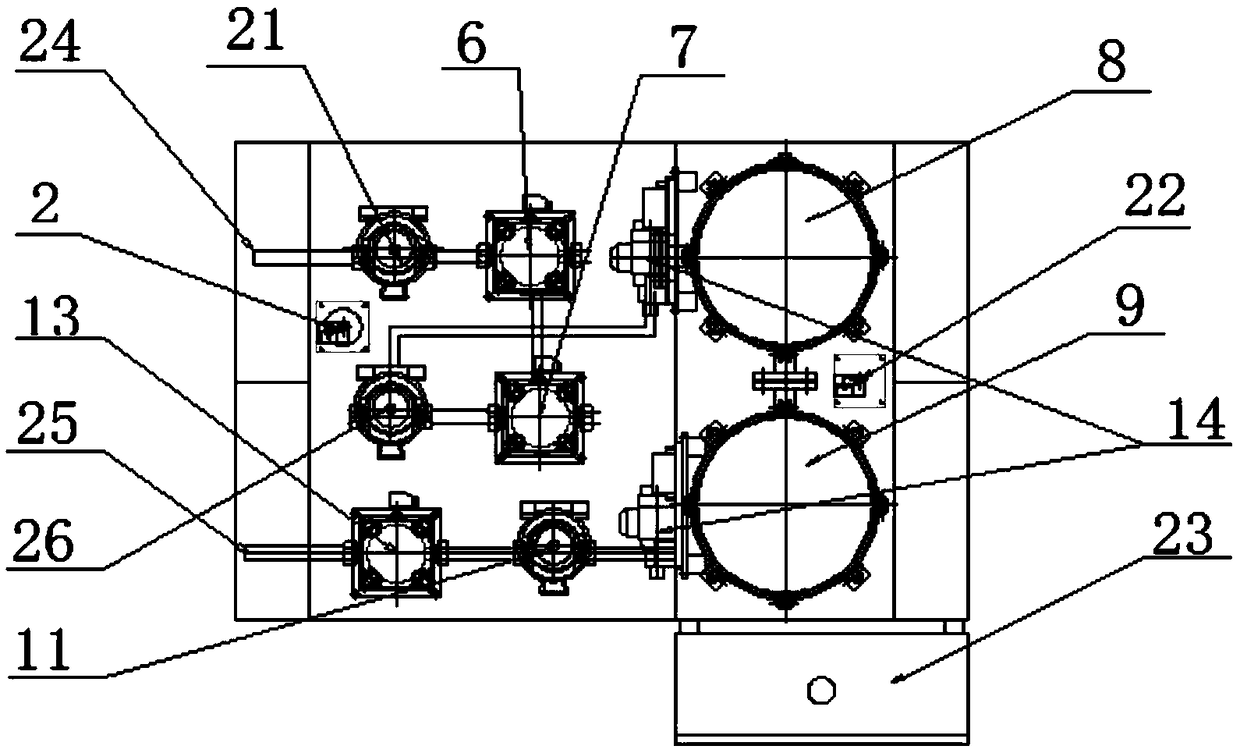

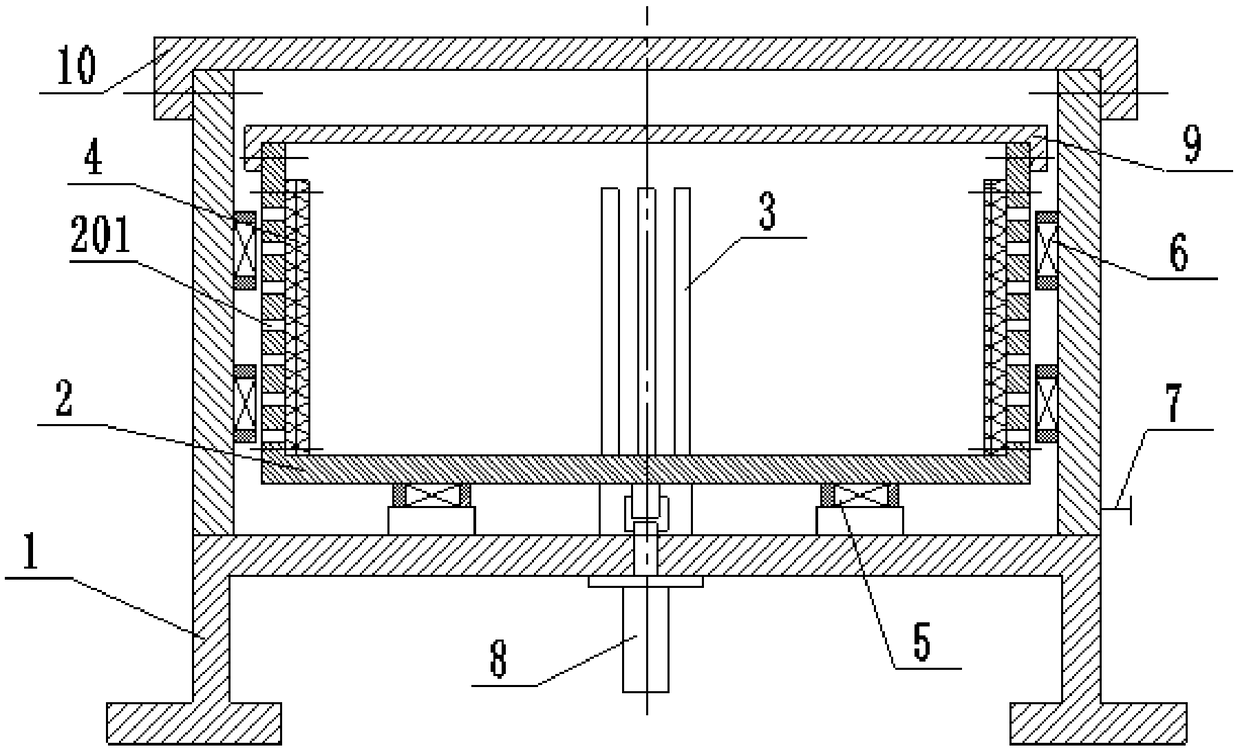

A transmission test oil circulation filter system, device and method

ActiveCN106955781BImprove controllabilityGuaranteed filtration accuracyMagnetic separationFiltrationLiquid storage tank

The invention discloses an oil circulating filtration system, device and method for a transmission test. The system comprises dirty oil tanks and a clean oil liquid storage tank. The dirty oil tanks communicate with the clean oil liquid storage tank through a multi-stage filtration device. The multi-stage filtration device is used for intercepting particles with the particle diameter being 5 micrometers or above in dirty oil. The clean oil liquid storage tank is connected with an oiling connector through an oiling pump. The oiling connector is used for being connected with an oiling fuse of a gearbox. The dirty oil tanks are connected with an oil drainage connector through an oil well pump. The oil drainage connector is used for being connected with an oil pumping hose of the gearbox. An oil outlet particle counter is connected to an oil pumping pipeline of the oil drainage connector in parallel. According to the oil circulating filtration system, device and method, oil product filtration precision and controllability of offline assembly cleanliness are guaranteed, and meanwhile, the technical requirements for use and maintenance convenience, low cost and the long period of filtration equipment are achieved.

Owner:SHAANXI FAST GEAR CO

A kind of waste magnetorheological fluid recovery treatment method

InactiveCN106116008BAvoid easy cloggingNot easy to settleWater/sewage treatment with mechanical oscillationsTreatment involving filtrationMagnetorheological fluidEngineering

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com