Preparation method of activated carbon filter element for engine oil purification

An activated carbon filter element and activated carbon technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of small filtration fineness, small dirt holding capacity, and poor filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

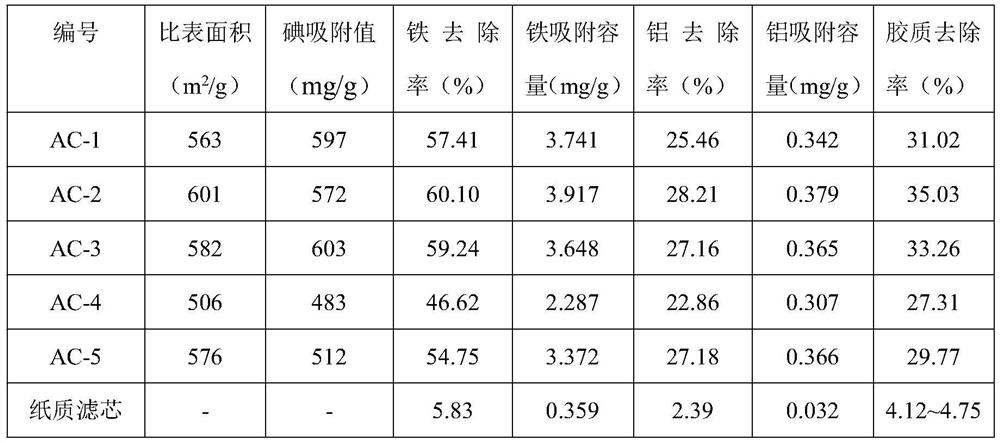

Examples

preparation example Construction

[0018] A preparation method of an activated carbon filter element for engine oil purification: quickly stir and evenly mix activated carbon with polyether polyurethane glue (main glue, Jiangsu Chemical Industry Research Institute Co., Ltd.) according to a certain mass ratio, and then add MDI (diphenylmethane di Isocyanate) curing agent is further mixed, stirred and glued, and then poured into the forming mold to make it evenly filled, and matured and formed at a certain temperature.

[0019] Further, the activated carbon is spherical activated carbon with a particle size of 1-3mm;

[0020] Further, the adhesive is polyether polyurethane glue (main glue) and MDI curing agent, the mass ratio of the two is 1:(0.8~1);

[0021] Further, the mass ratio of the activated carbon to the adhesive (polyether polyurethane glue and MDI curing agent) is (3~6):1;

[0022] Further, the aging temperature is 60-140°C;

[0023] Further, the aging time is 1-3 hours.

Embodiment 1

[0025] Spherical activated carbon with a particle size of 1 mm was acid-washed and washed with water, and then dried at 110°C for use; 5 g of polyether polyurethane glue (main glue, Jiangsu Provincial Chemical Research Institute Co., Ltd.) was added to 40 g of spherical activated carbon, and then stirred quickly and uniformly. Mixing; after that, add 5g of MDI curing agent for further stirring, mixing, and gluing; after gluing, pour the mixture into the molding mold at room temperature to make it evenly filled; then place it in a temperature-controlled oven at 80°C After aging for 2 hours, the mold was removed to obtain an activated carbon filter element, which was coded as AC-1.

Embodiment 2

[0027] Spherical activated carbon with a particle size of 2 mm was acid-washed and washed with water, and then dried at 110°C for use; 5 g of polyether polyurethane glue (main rubber, Jiangsu Provincial Chemical Research Institute Co., Ltd.) was added to 40 g of spherical activated carbon, and then stirred quickly and evenly Mixing; after that, add 5g of MDI curing agent for further stirring, mixing, and gluing; after gluing, pour the mixture into the molding mold at room temperature to make it evenly filled; then place it in a temperature-controlled oven at 120°C After aging for 2.5 hours, the mold was removed to obtain an activated carbon filter element, which was coded as AC-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com