Calcium sulfate whisker/epoxy resin composite filter material and preparation method thereof

A technology of calcium sulfate whisker and epoxy resin, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of complex filter structure, affecting filtration effect, diatomite cracks, etc., and achieve excellent treatment effect , the manufacturing process is simple, the effect of small aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

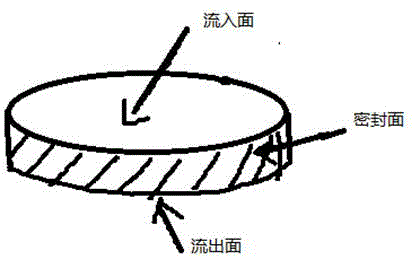

[0032] Example 1: Weigh 80g of bisphenol A epoxy resin (brand: E-51) in a container, add 640g of methanol therein, and stir until the epoxy resin is completely dissolved in methanol. Weigh 720g of calcium sulfate whiskers, slowly add it into the above solution, stir well to form a stable and uniform suspension. Add 20g of aliphatic polyamine-type curing agent ethylenediamine to the suspension, stir for 7 minutes, and then slowly cast it into a disc-shaped mold, then put it in a 68°C oven and bake it for 58 minutes, take it out, and then put it at room temperature Put it down for 24h to make a disc-shaped calcium sulfate whisker / epoxy resin composite filter material, such as figure 1 shown.

Embodiment 2

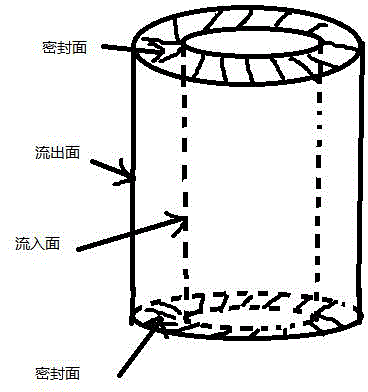

[0033] Example 2: Weigh 80g of bisphenol A epoxy resin (brand name: E-55) in a container, add 80g of ethanol therein, and stir until the epoxy resin is completely dissolved in ethanol. Weigh 53.3g of calcium sulfate whiskers, slowly add it into the above solution, and stir well to form a stable and uniform suspension. Then add 20g of aliphatic polyamine-type curing agent diethylenetriamine to the suspension, stir for 6 minutes, then slowly cast it into a hollow cylindrical mold, put it into a 70°C oven and bake it for 52 minutes, take it out, and then Place it at room temperature for 20 hours to make a hollow cylindrical calcium sulfate whisker / epoxy resin composite filter material, such as figure 2 shown.

Embodiment 3

[0034] Example 3: Weigh 80g of bisphenol F epoxy resin (grade: 170) into a container, add 160g of isopropanol therein, and stir until the epoxy resin is completely dissolved in isopropanol. Weigh 80g of calcium sulfate whiskers, slowly add it into the above solution, stir well to form a stable and uniform suspension. Then add 20g of aliphatic polyamine type curing agent trimethylhexamethylenediamine to the suspension, stir for 5 minutes, then slowly cast it into a disc-shaped mold, and then bake it in a 72°C oven for 42 minutes Then take it out, and then place it at room temperature for 10h to make a disc-shaped calcium sulfate whisker / epoxy resin composite filter material, such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com