Bypass fine filtering device with high pollutant carrying capacity and working method of bypass fine filtering device

A technology of dirt holding and fine filtration, applied in the field of filtration, can solve the problems of not fully satisfying the cleanliness of lubricating oil, not having the ability to remove moisture and oxides, filter restrictions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the above technical solutions will be further described below in conjunction with the illustrations.

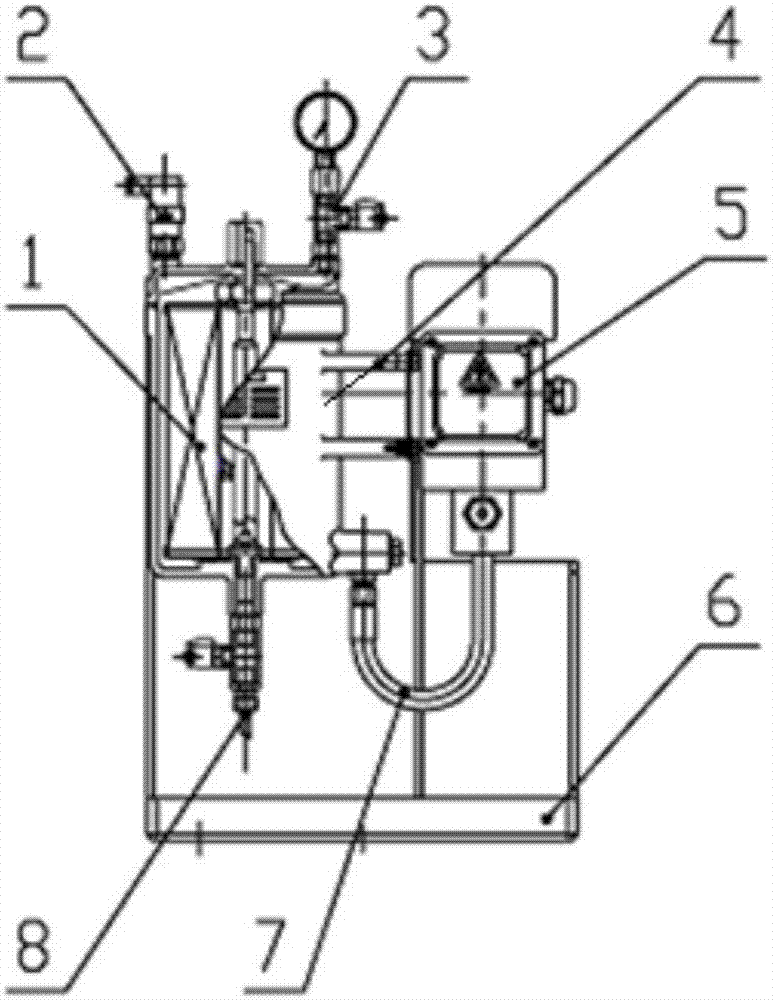

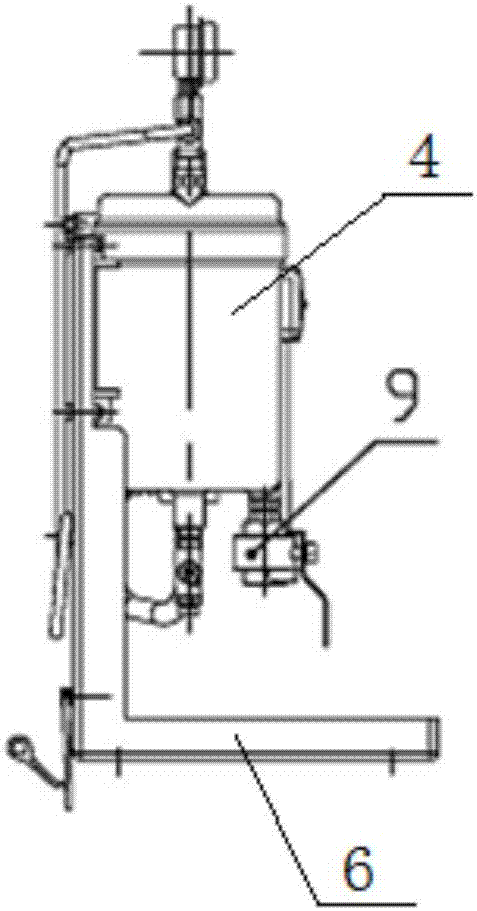

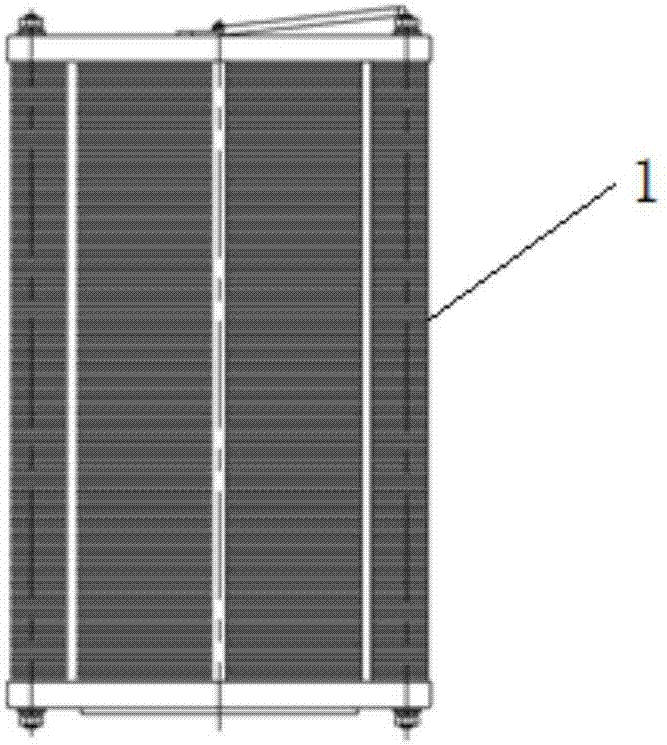

[0030] Such as Figure 1-6 The high dirt-holding bypass fine filtration device includes a bracket 6, a filter 4 and a filter pump 5, the filter 4 is arranged above the bracket 6, and the right side of the filter 4 is provided with a filter pump 5, so An oil inlet pipe 7 connected to the filter pump 5 is arranged on one side of the filter 4 , and an oil outlet pipe 8 is arranged at the bottom of the filter 4 . The filter 4 includes a housing, and a filter element 1 is arranged in the housing, and the filter element 1 is formed by stacking and compacting a plurality of filter paper sheets 10 neatly, and the oil outlet pipe 8 is arranged at the bottom of the housing. The filter paper sheet 10 is a circular sheet, the center of the circular shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com