Electric oil purification method and device

An electric purification and oil technology, which is applied in the field of purifying and purifying oil and electric purification of waste transformer oil, can solve the problems of small processing flow and low adsorption efficiency, and achieve good adsorption purification effect, low adsorption efficiency and effect. , The effect of large dirt holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

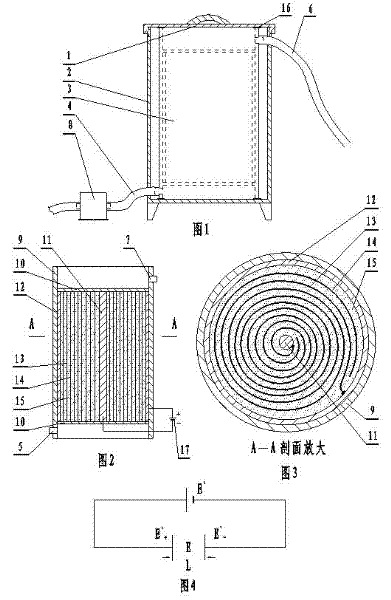

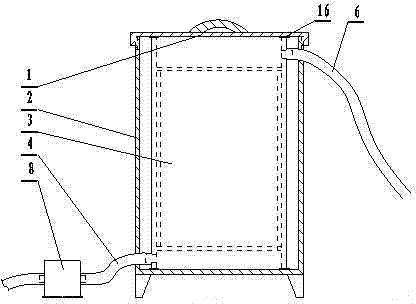

[0025] see Figure 1 to Figure 3 , the method and device of electric purification and oil purification, under the external constant direct current electric field, make the trapping medium in the electric field and the ions in the oil liquid to form an electric double layer to enrich the ions, and deionize the oil liquid flow out. In the electric double layer, under the action of an external electric field, the trapping medium in the electric field is polarized to generate surface bound charges, while the electrolyte in the liquid is ionized under the action of the electric field to become charged ions, which move downward under the action of the electric field force. The counter ions move in the direction and are adsorbed by the bound charges, forming an electric double layer at the solid-liquid interface. As the thickness of the electric double layer increases, the ion content in the liquid gradually decreases, achieving the purpose of adsorption and purification. The ions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com