Adjustable composite dynamic filtering device

A dynamic filtration and composite technology, which is applied in the direction of filtration separation, filtration treatment, gravity filter, etc., can solve the problems of filter bed breakdown, deterioration of effluent quality, large filter bed depth, etc., achieve stable swirling state, and improve flexibility High performance and high charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

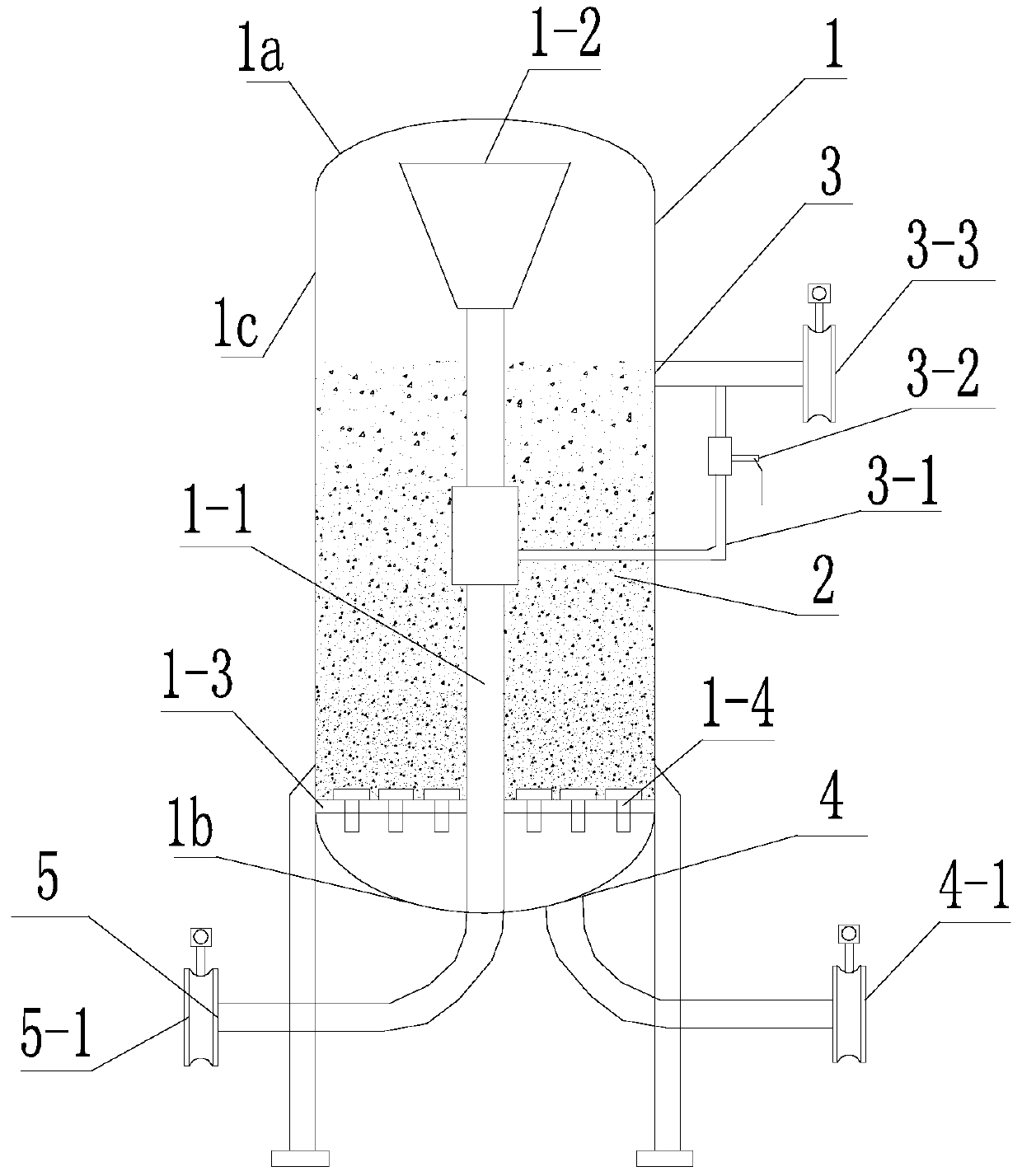

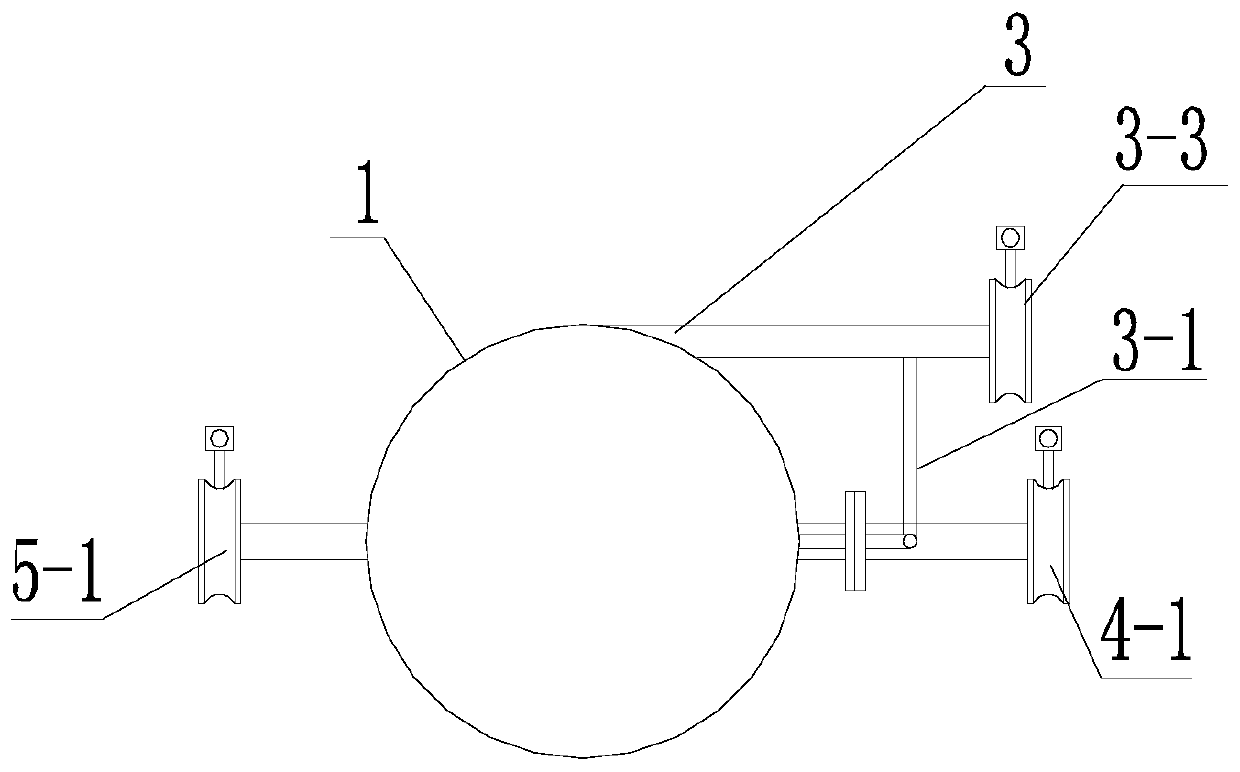

[0032] see Figure 1-Figure 2 , the adjustable composite dynamic filter device in this embodiment includes a tank body 1, the middle part of the tank body 1 is filled with a filter material layer 2, there is no gap between the filter material layer 2 and the tank wall, and the entire horizontal direction of the tank body 1 is filled. section. The top of the tank body 1 is provided with a water inlet 3, and the bottom of the tank body 1 is provided with a water outlet 4; a backwash drain pipe 1-1 is vertically installed inside the tank body 1, and a backwash drain pipe 1-1 is installed on the top of the tank body 1. The solid-liquid separator 1-2 in the tank body 1; the water inlet 3 is provided with a water inlet branch pipe 3-1, and the end of the water inlet branch pipe 3-1 is connected with the middle part of the backwash drain pipe 1-1; the water inlet 3 The corresponding height is set on the top of the filter material layer 2, and the water inlet 3 is arranged tangential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com