A kind of intake and exhaust valve for sewage with many impurities and large gas volume

A technology for intake and exhaust valves and sewage, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of impurities easily blocking the air outlet, small air output, complex structure, etc., to ensure long-term operation , reduce clogging, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

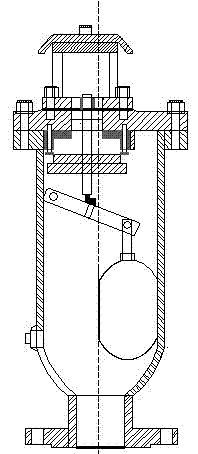

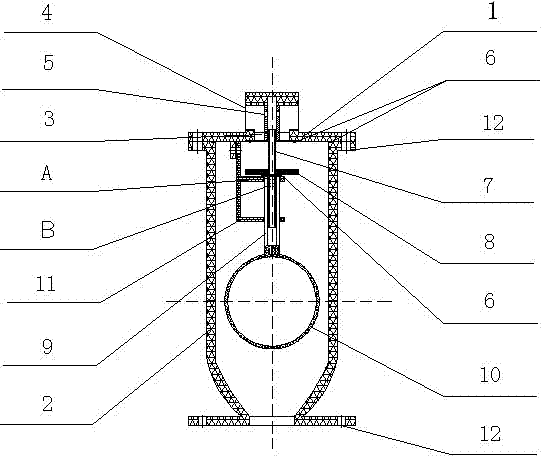

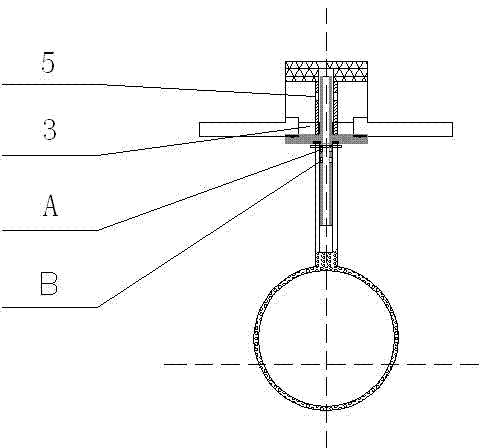

[0017] Such as figure 2 As shown, a sewage inlet and exhaust valve includes a valve body 2, a valve cover 1, a floating ball 10, a moving sealing rod 7, an air outlet 3, an air outlet 5 and a hanger 11. The valve cover 1 is fixedly mounted on the upper end of the valve body 2, and the valve cover 1 is provided with an air outlet 3; The lower end of the air outlet is equipped with an annular sealing gasket 6, and a movable sealing rod 7 that can move up and down is installed at the air outlet, and a top plate 8 is fixedly installed in the middle of the moving sealing rod, and the top plate 8 is fixed on the moving sealing rod. Ventilation holes A and B are arranged in sequence from top to bottom under the plate, and the gas in the valve can be discharged from the air outlet through A and B; the lower end of the valve cover and the lower end of the top plate are equipped with an annular gasket 6; The moving seal rod is hollow tubular, and the middle and lower ends are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com