Patents

Literature

40results about How to "Improve flash point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

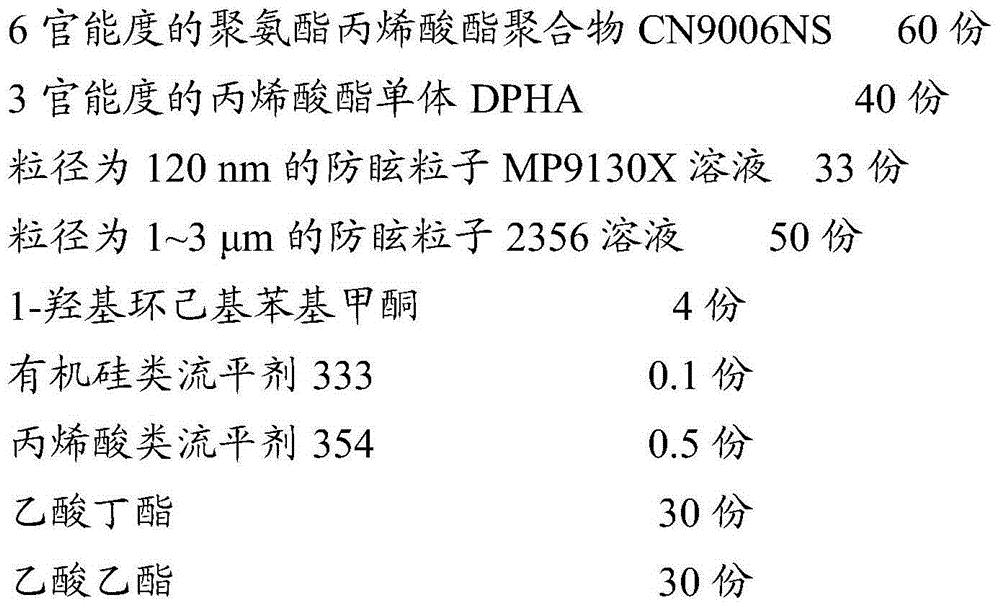

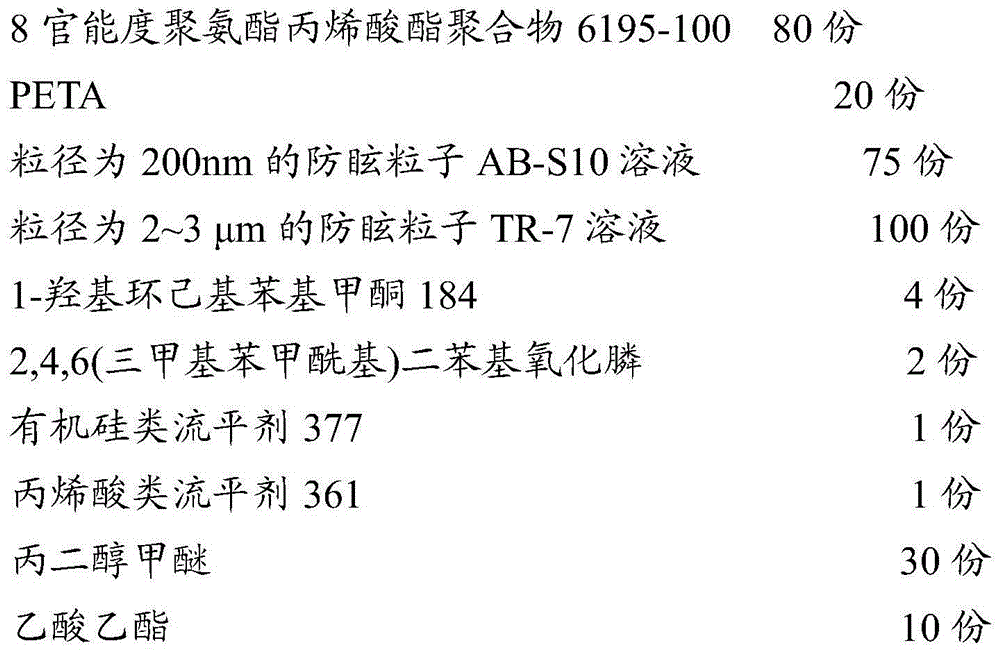

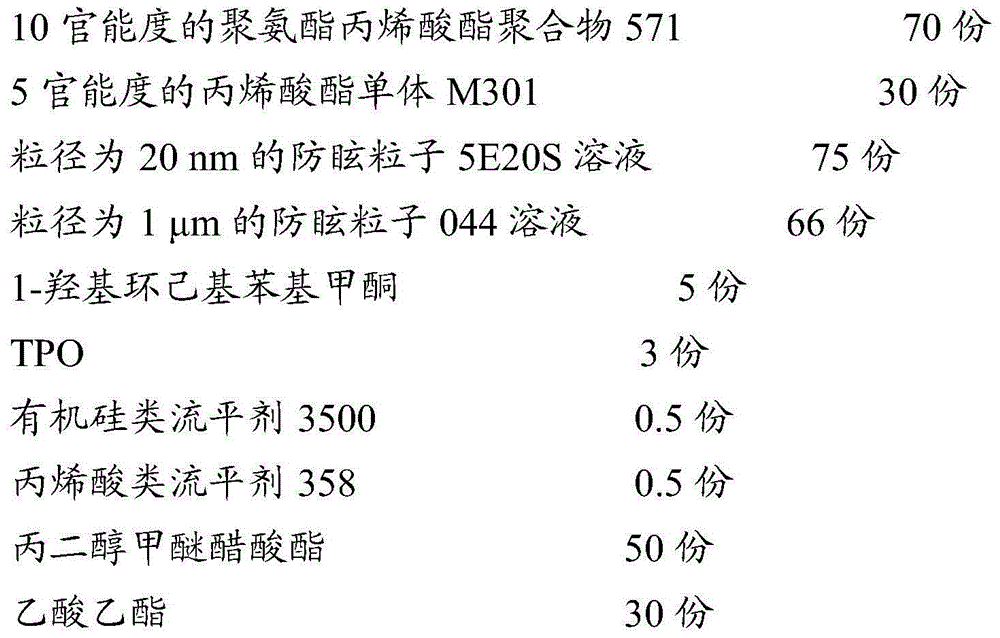

Anti-dazzle coating and anti-dazzle hardening film

ActiveCN104817951AImprove flash pointLow flash pointPolyurea/polyurethane coatingsOptical elementsOrganic solventUrethane acrylate

The invention provides an anti-dazzle coating and an anti-dazzle hardening film. The anti-dazzle coating comprises the following components in parts by weight: 60-80 parts of polyurethane acrylate polymer with six degrees of functionality or above, 20-40 parts of acrylate monomer with six degrees of functionality or above, 10-15 parts of anti-dazzle particles with particle size of less than or equal to 500nm, 5-10 parts of anti-dazzle particles with particle size of 1-3mu m, 4-8 parts of a photoinitiator, 0.1-1 part of an organosilicone levelling agent, 0.5-1 part of an acrylic acid levelling agent and 40-80 parts of an organic solvent. The anti-dazzle coating provided by the invention is used for preparing an anti-dazzle hard coating film; two types of anti-dazzle particles different in particle size are used together so that the prepared anti-dazzle hard coating film has excellent properties of low flash point and high definition; in addition, the anti-dazzle hard coating film further has excellent levelling property so that the flash point of the anti-dazzle hardening film can be lowered further.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

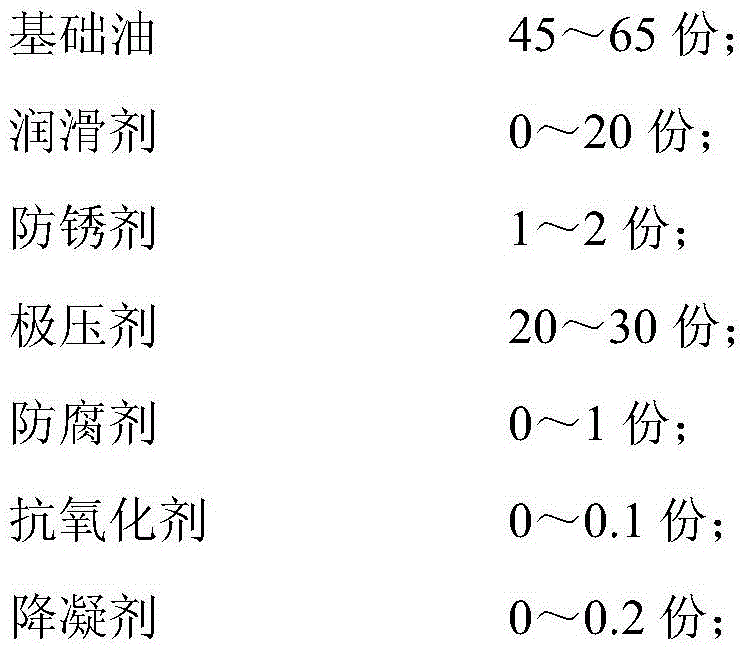

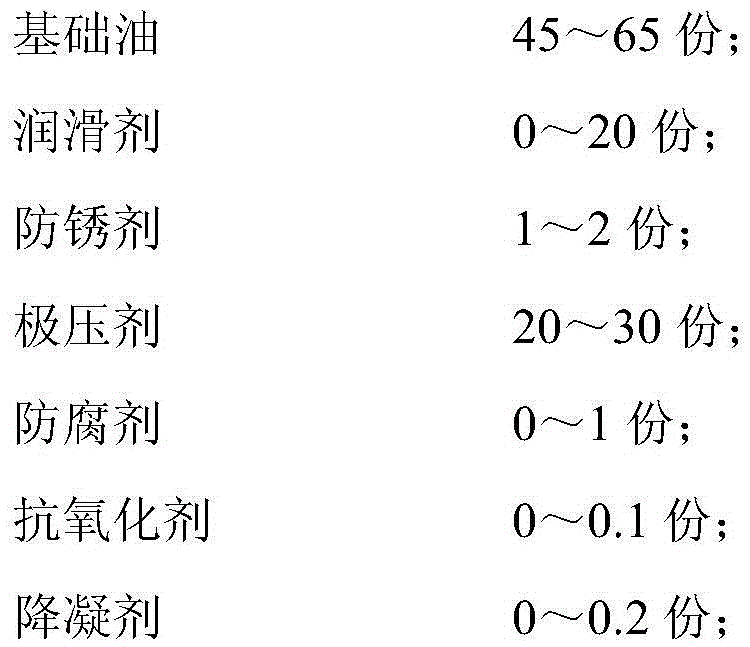

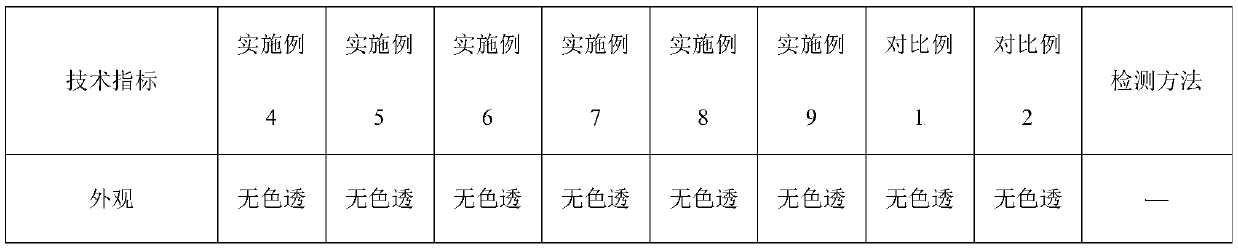

Environmentally-friendly cold heading oil with epoxidized vegetable oil as base oil, and preparation method thereof

ActiveCN105482873AHigh viscosity indexImprove the lubrication effectAdditivesBase-materialsVegetable oilRenewable resource

The invention discloses an environmentally-friendly cold heading oil with epoxidized vegetable oil as base oil, and a preparation method thereof. The environmentally-friendly cold heading oil is prepared through adding a lubricant, an antirust agent, an extreme pressure agent, an antiseptic, an antioxidant and pour-point depressant to the epoxidized vegetable oil used as the base oil. The epoxidized vegetable oil is used as the base oil to substitute traditional non-renewable mineral oil, so consumption of non-renewable resources is avoided, and pollution to environment is greatly reduced. The environmentally-friendly cold heading oil is suitable for various machining, such as carbon steel cold heading, molding processing hot headed nuts, high-strength bolt sleeves and hollow and semi-hollow rivets, and molding processing of rivets; and the preparation method is simple and has low requirements about devices.

Owner:NEUFTECH BIOTECH HEFEI

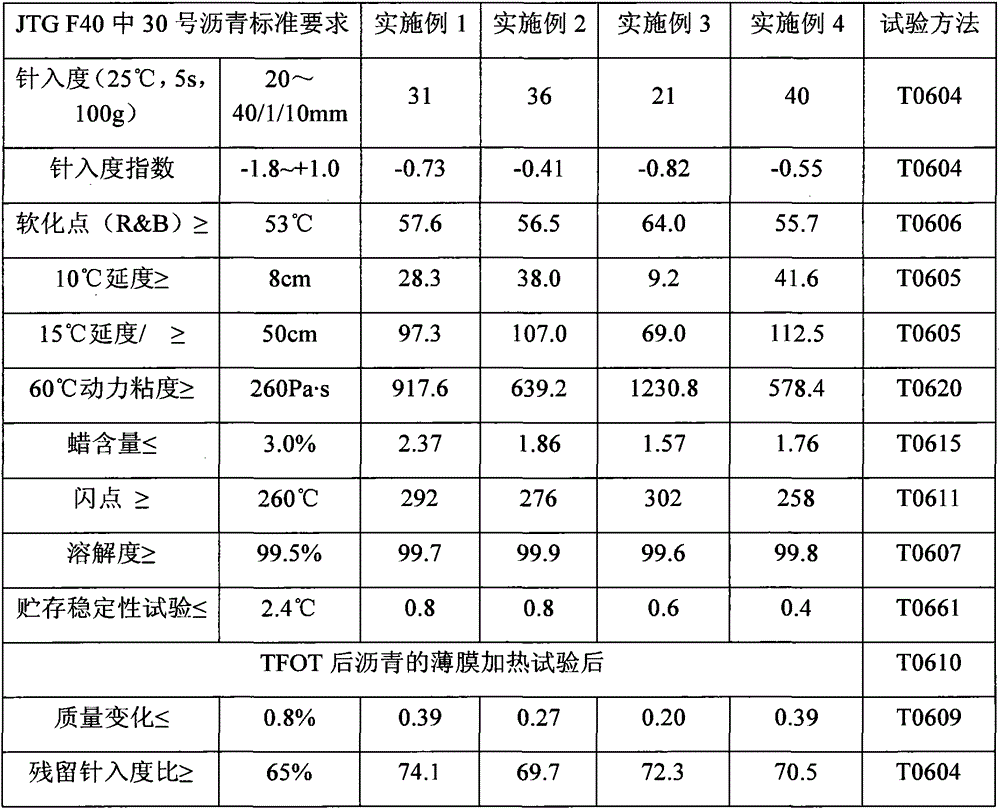

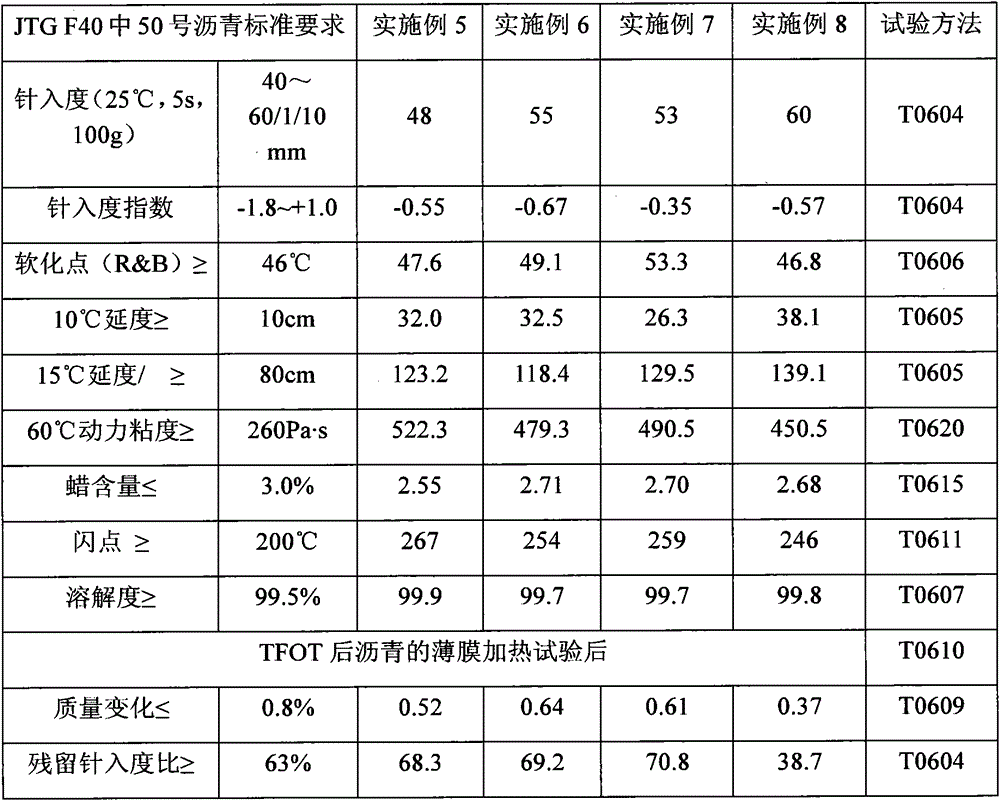

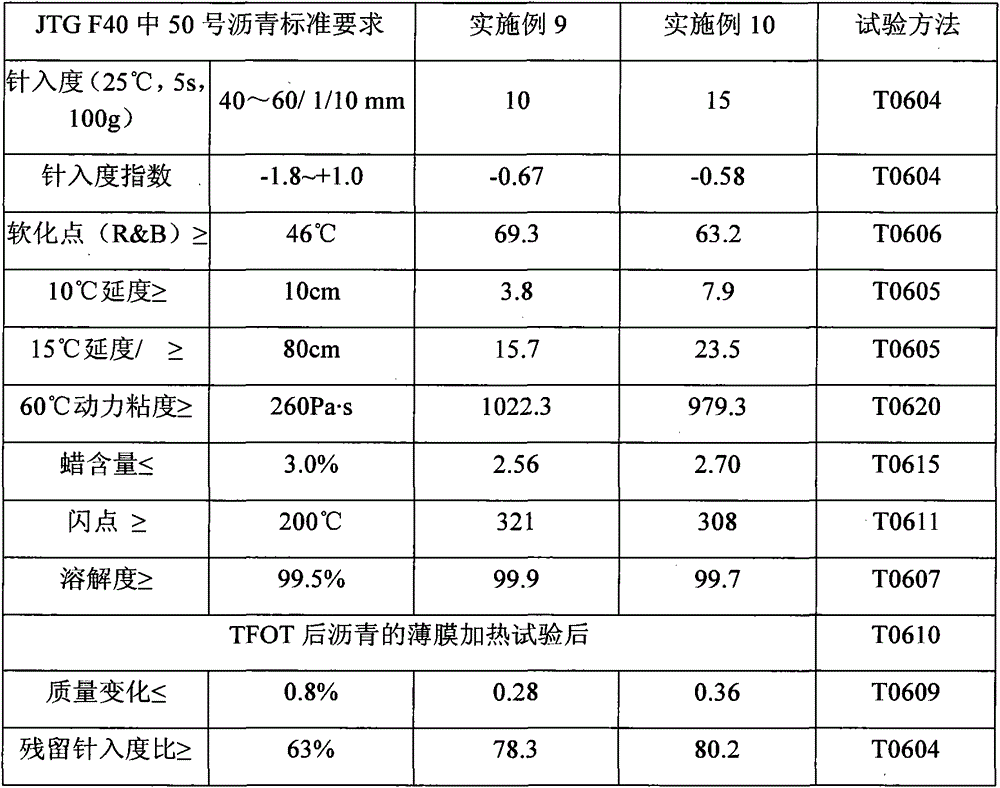

High-grade road hard asphalt and preparation method thereof

InactiveCN104650602AGood high and low temperature performanceImprove poor anti-aging performanceClimate change adaptationBuilding insulationsNeedle penetrationPolymer modified

The invention discloses high-grade road hard asphalt and a preparation method. The high-grade road hard asphalt is characterized by being prepared from the following raw materials in percentage by weight: 35-70 parts of degreased asphalt, 10-45 parts of reforming topped oil slurry, 8-20 parts of extract oil, 1-8 parts of a polymer modifying agent and 0.1-3.0 parts of an additive. The high-grade road hard asphalt disclosed by the invention has the advantages that the high temperature and low temperature performances of the asphalt are improved by adding the polymer modifying agent and the additive; high-grade road hard petroleum asphalt of which each index satisfies the JTGF40 index requirements of Traffic Department Road Asphalt Pavement Construction Technical Specifications and the needle penetration is within a range from 10-60 1 / 10mm can be prepared by regulating the ratio of the degreased asphalt to the reforming topped oil slurry to the extract oil and the doping ratio of the polymer modifying agent to the additive in the raw materials; the asphalt brand is adjustable and controllable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-efficiency purification energy-saving filter core

ActiveCN101780345AImprove qualityImprove the lubrication effectLoose filtering material filtersLubricant mounting/connectionCombustionVegetable oil

The invention relates to a high-efficiency purification energy-saving filter core which is manufactured by adopting the stems and the poles of various plants, pulverizing, screening, and bulking the stems and the poles, mixing the processed stems and the processed poles as filter materials (100 parts) with various chemical substances (6.43-11.56 parts), then adding special vegetable oil and a magnetic substance (15-25 parts) and finally packaging with an oil-resistant and high-temperature resistant fabric. The filter core of the invention is suitable for the lubricating oil purification of various internal-combustion engines or mechanical equipment, thereby not only leaching the impurities of more than 0.01mm in online engine oil, but also enhancing the lubricating efficacy, improving the quality and the use function of the engine oil, enabling lubricating oil not to deteriorate or age after long-term use, keeping the due physicochemical index thereof and really achieving the purposes of energy saving and emission reduction.

Owner:GANSU HENGTONG FILTER IND

Non-asphalt-based non-curing rubber waterproof coating and preparation method thereof

PendingCN112760037AExcellent high temperature heat resistance and low temperature flexibilityGood anti-aging performanceFireproof paintsWax coatingsRubberized asphaltPetroleum resin

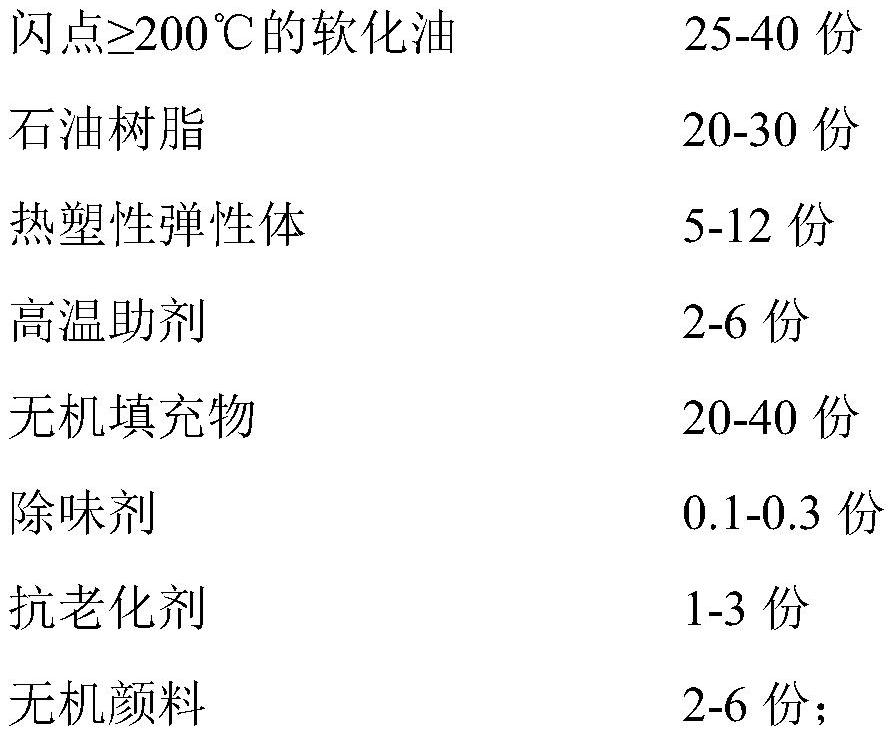

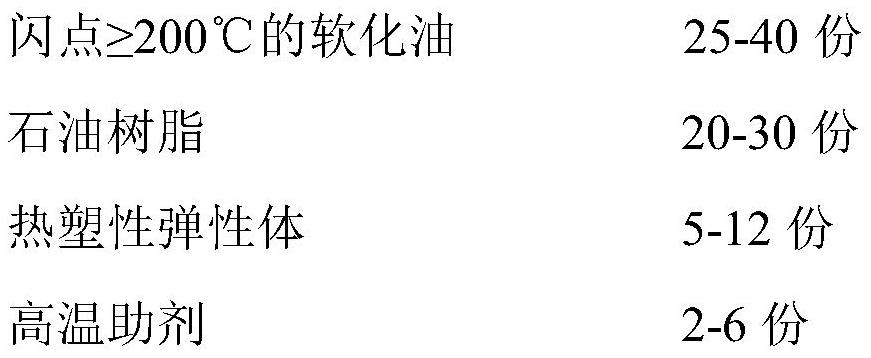

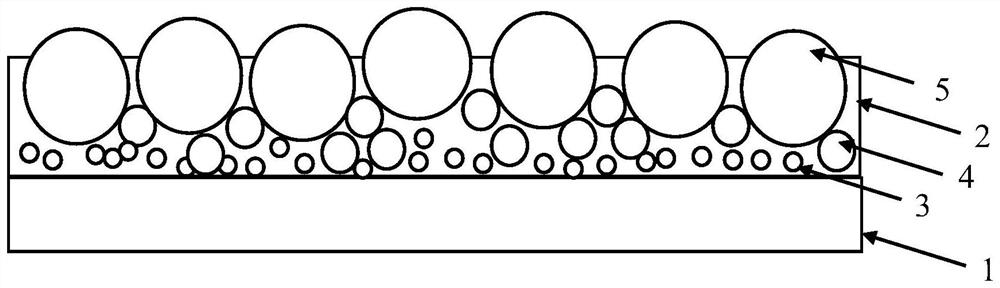

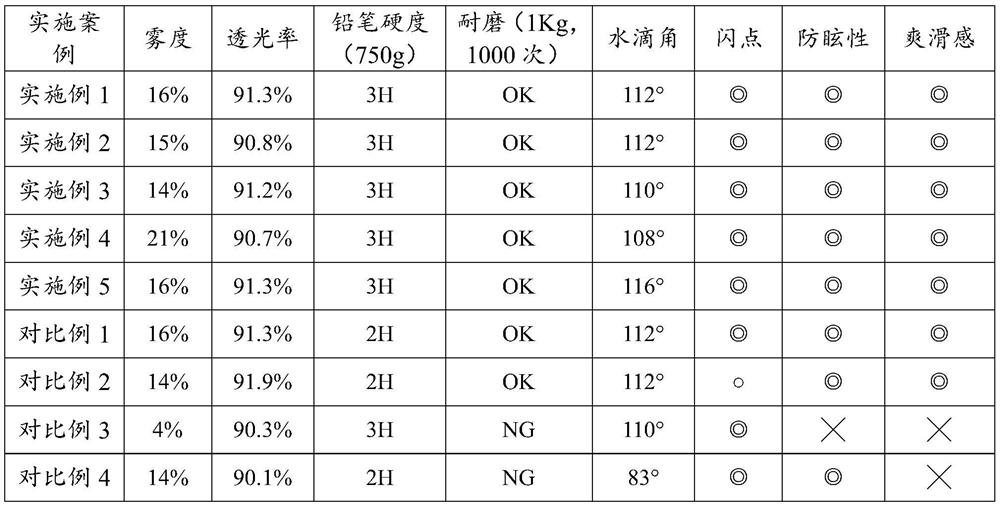

The invention relates to a non-asphalt-based non-cured rubber waterproof coating and a preparation method thereof, and the coating is mainly prepared from the following components in parts by weight, wherein the components are shown in the description. The invention overcomes the defects that the existing non-asphalt-based non-curing rubber waterproof paint takes rubber, asphalt and softening oil as main components, the anti-aging performance, the high-temperature heat resistance and the low-temperature flexibility are insufficient, and a large number of harmful substances are volatilized in the construction process; through the synergistic effect of the softening oil, the petroleum resin, the thermoplastic elastomer and the high-temperature additive and the cooperation of other components, the coating has the advantages of high temperature and low temperature performances, aging resistance, excellent bonding performance with a base layer and a waterproof coiled material, good construction performance, safety, environmental protection and no peculiar smell.

Owner:上海三棵树防水技术有限公司

High-wear-resistance and low-flash-point anti-glare film and preparation method thereof

PendingCN112375243AGood flashGood compatibilityPolyurea/polyurethane coatingsPrepolymerPhotoinitiator

The invention discloses a high-wear-resistance and low-flash-point anti-glare film and a preparation method thereof. The preparation method comprises the steps that S1, mixing the following componentsby weight percentage: 15%-70% of an acrylate prepolymer, 5%-40% of an acrylate monomer, 0.5%-10% of anti-glare particles, 1%-6% of a photoinitiator, 0.1%-0.5% of a dispersing agent, 0.1%-0.5% of a leveling agent, 0.1%-0.6% of a fluorine-containing auxiliary agent, and 20%-75% of a solvent; and S2, coating a base material with the anti-dazzle coating liquid, baking and drying, and carrying out UVcuring to obtain the anti-glare film with high wear resistance and low flash point. The anti-glare film provided by the invention has excellent properties of low flash point and high definition, and also has excellent wear resistance.

Owner:NUOVO FILM SUZHOU CHINA INC

Novel low carbon methanol diesel and additive and preparation method thereof

The invention relates to the field of energy, and in particular relates to a novel low carbon methanol diesel and an additive and a preparation method thereof. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: preparing the additive; adding and mixing the following components: 7 parts of surfactants, 10 parts of oleic acid, 25 parts of fatty acid methyl ester, 15 parts of vegetable oil, 10 parts of multi-carbon alcohol (C4-C8 linear chain fatty alcohol), 8 parts of fatty alcohol-polyoxyethylene ether, 15 parts of cyclohexane acid glyceride and 10 parts of organic nitrate (c-RONO2 for short); mixing and stirring for homogenization; putting statically so as to obtain uniform emulsion; mixing; weighing 1000 parts of methanol-diesel mixture fuel, wherein the mass ratio of the methanol and the diesel is 15:85, putting in a container; adding a composite additive according to the condition that the mass ratio of the methanol to the diesel mixture fuel is 200:1; and stirring till the microemulsion is clear and uniform.

Owner:陕西宝姜新能源技术研发有限公司

Biodiesel with low temperature liquidity and preparation method of biodiesel

InactiveCN103834446AGood fluidity at low temperatureGood pour point depressing effectBiofuelsLiquid carbonaceous fuelsProcess engineeringOxidation stability

The invention discloses a biodiesel with low temperature liquidity and a preparation method of the biodiesel. The biodiesel with low temperature liquidity comprises 2.5-30 percent by volume of direct coal liquefaction hydro-upgraded modified full-fraction oil and 70-97.5 percent by volume of illegal cooling oil biodiesel. The preparation method of the biodiesel comprises the step: after mixing the illegal cooking oil biodiesel and the direct coal liquefaction hydro-upgraded modified full-fraction oil, and standing for 8-12 hours to obtain the biodiesel with low-temperature liquidity. According to the biodiesel with low temperature liquidity, the pour point, the cloud point, the flash point, the kinematic viscosity, the oxidation stability, the heat value, the density and the acid value of mixed oil are detected according to the GB_T20828-2007, and accord with relevant requirements of EN14214 and ASTMD6751 for the technical performance of the biodiesel through detection. Compared with the illegal cooking oil biodiesel, the biodiesel has the advantages that the cloud point is reduced by 1-8 DEG C, the pour point is reduced by 2-10 DEG C, namely, the low temperature liquidity is remarkably improved, and the preparation method is simple and effective.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

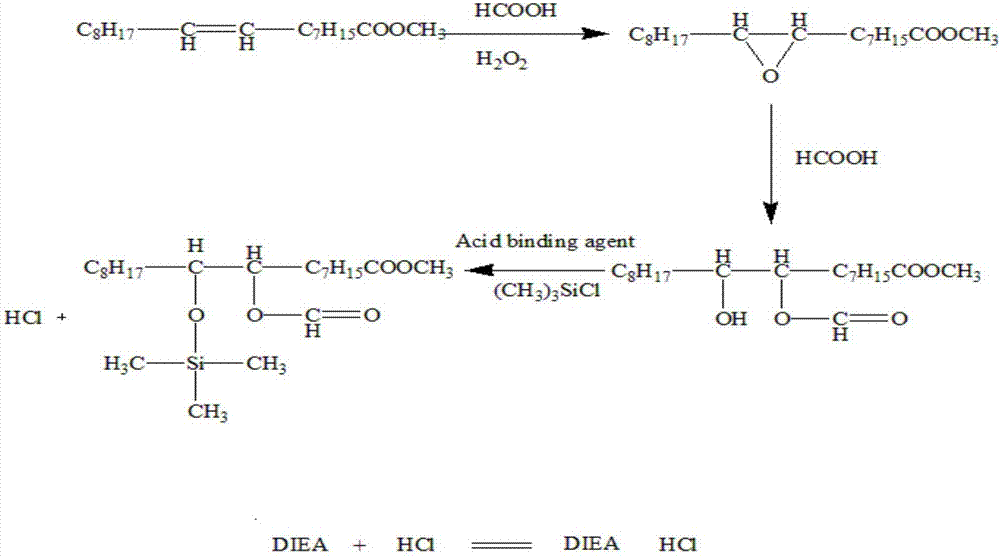

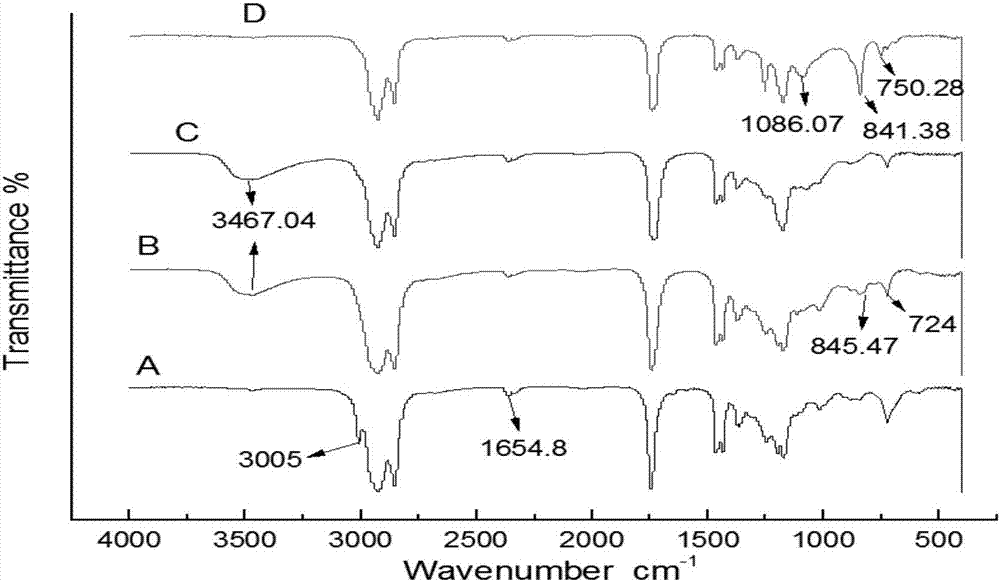

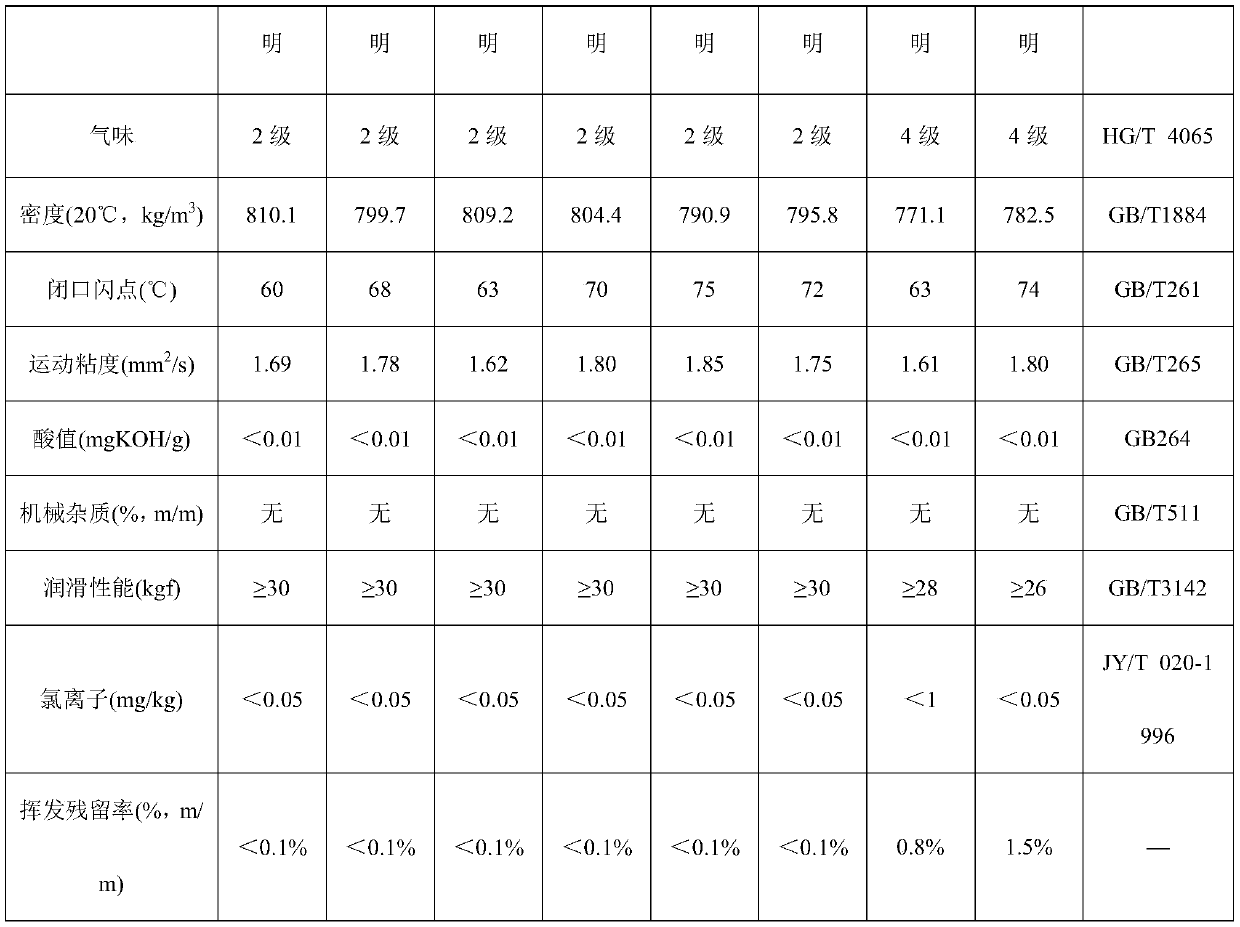

Method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester

The invention provides a method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester. The method comprises the following specific steps: mixing fatty acid ester with organic acid and a catalyst and adding the mixture into an epoxidation reaction kettle, dropwise slowly adding an oxidizing agent, reacting, standing for layering, fetching a supernatant liquid and distilling to obtain epoxidized aliphatic ester; carrying out a ring-opening reaction between epoxidized aliphatic ester and organic acid, washing to neutral level after the reaction and carrying out reduced pressure distillation to obtain a ring-opening product; stirring the ring-opening product and heating to reaction temperature, dropwise adding organosilicon and an acid binding agent according to requirements and carrying out a silylation reaction, directly carrying out reduced pressure distillation after the reaction, and separating a solid to obtain the silicon-based biolubricant base oil. By the above method, the disadvantage that biolubricant base oil produced by existing technologies has poor oxidation stability and poor viscosity-temperature characteristic is overcome. The production process is environment-friendly, and energy consumption is low. The industrial acid binding agent used in the method is low-cost such that cost of the product is reduced.

Owner:NANJING UNIV OF TECH

Biodegradable industrial gear oil and preparation method thereof

InactiveCN105907449AImprove Oxidation StabilityGood anti-seize propertiesLubricant compositionPulp and paper industryViscosity index

The invention relates to the technical field of lubricating oil, in particular to biodegradable industrial gear oil and a preparation method thereof. The biodegradable industrial gear oil is prepared from the following raw materials of extreme-pressure antiwear additive, phosphorous -containing antiwear additive, metal deactivator, oxidation and corrosion inhibitor, anti-rust agent and base oil. The biodegradable industrial gear oil has the advantages that the oxidizing stability and the seizure and biting resisting property are good, the viscosity index is higher, and the flash point and pour point are higher; the biodegradable industrial gear oil is suitable for more complicated use working condition and temperature change, the equipment can be well lubricated, the influence to equipment by water is avoided, the oil replacement cycle is prolonged, and the additional loss caused by frequent oil replacement is avoided; by adopting the biodegradable base oil and the environment-friendly additives, the biodegrading rate is higher, and the environment-friendly property is guaranteed on the basis of meeting the working requirements.

Owner:新疆金雪驰科技股份有限公司

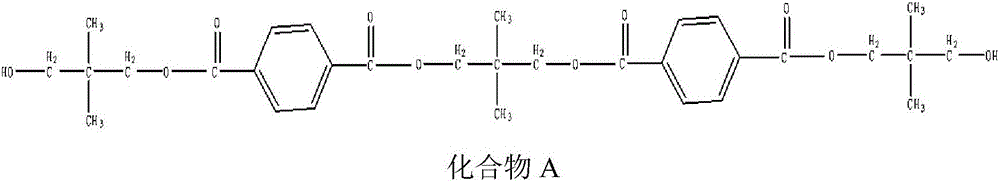

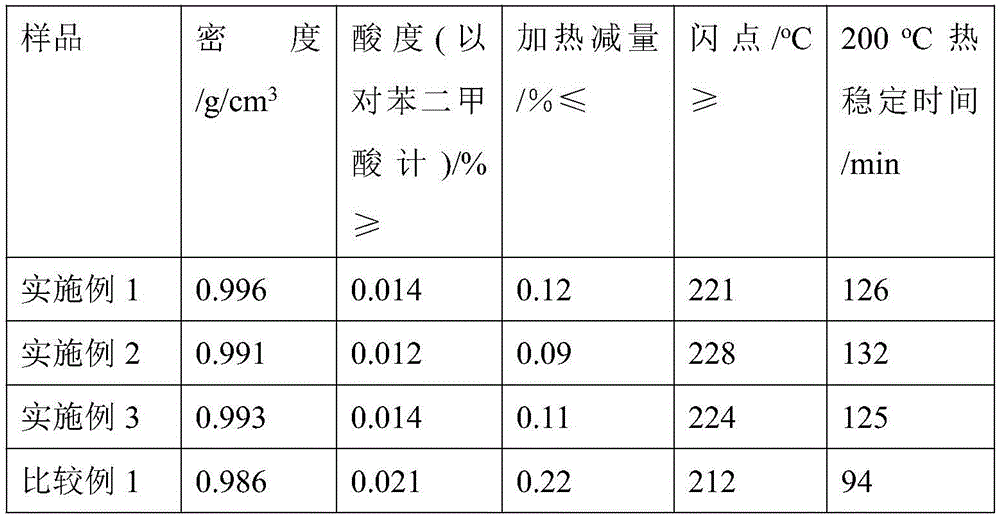

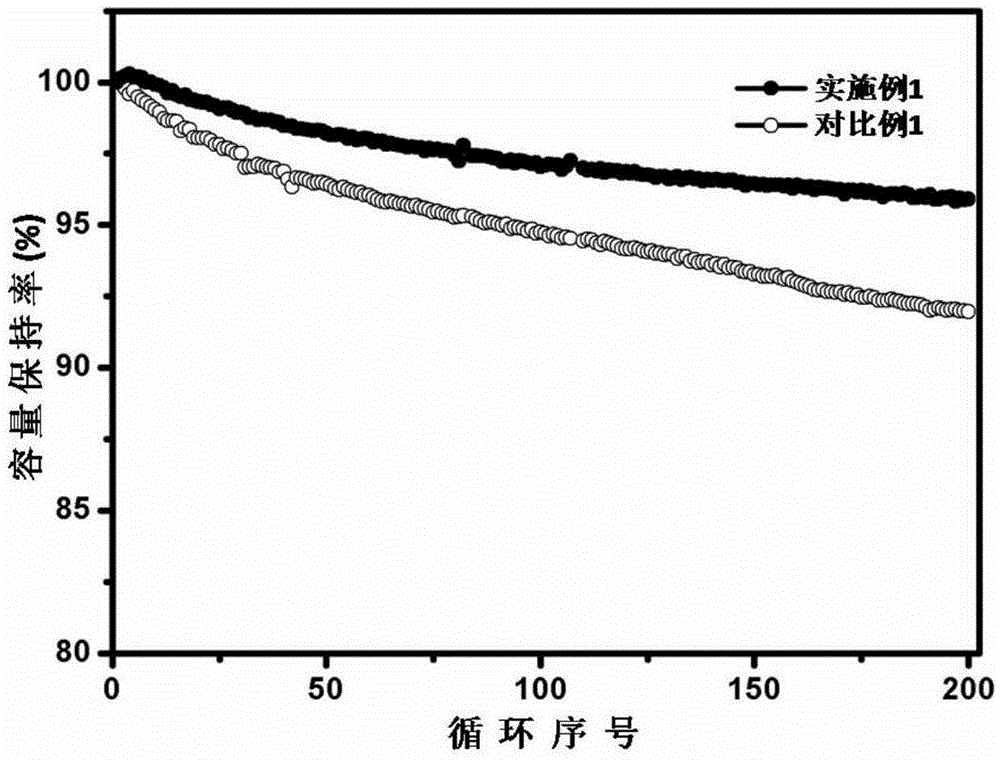

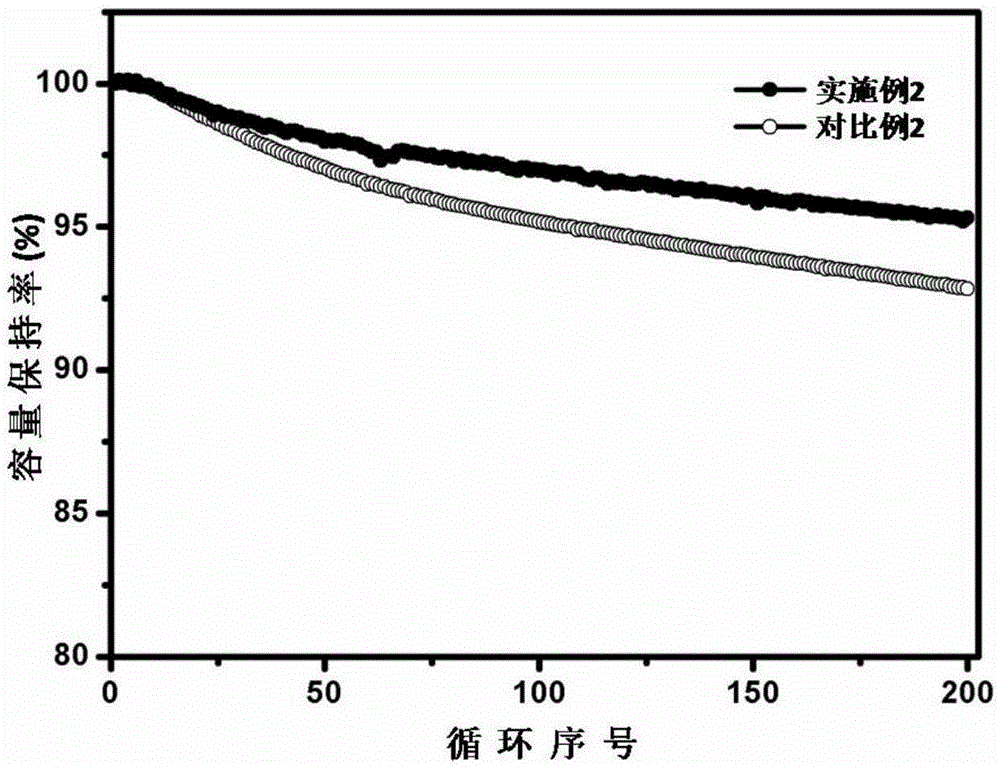

Mixed type polybasicester plasticizer and preparation method thereof

ActiveCN106349502AIncrease acidityImprove the heating effectOrganic compound preparationPreparation by ester-hydroxy reactionPolyesterPolyethylene terephthalate glycol

The invention discloses a method for comprehensively utilizing by-products generated in a trimellitic anhydride refining process. The method comprises the following steps: taking polyester waste as a raw material, taking 1,3-diethyl imidazole boron fluoborate as a catalyst, selecting the content and the process temperature of the catalyst, and regulating and controlling molecular size and distribution of a polyethylene terephthalate compound which is obtained by alcoholysis; and when the molecular size and the distribution are in a suitable range, adding refined residues of trimellitic anhydride and carrying out esterification / ester interchange reaction on the refined residues of the trimellitic anhydride and isooctanol to obtain a mixed type polybasicester plasticizer of which performance indexes such as acidity, heating loss and flashing point are good. Compared with the prior art, the mixed type polybasicester plasticizer has better performance indexes such as the acidity, the heating loss and the flashing point, has excellent heat resistance and processing convenience, and can meet requirements of plasticizers in the conventional field. Meanwhile, the preparation method is simple, easy to operate, low in cost of equipment and pollution-free; social benefit and economic benefit are huge; and the method is suitable for being generally popularized and used.

Owner:安徽泰达新材料股份有限公司

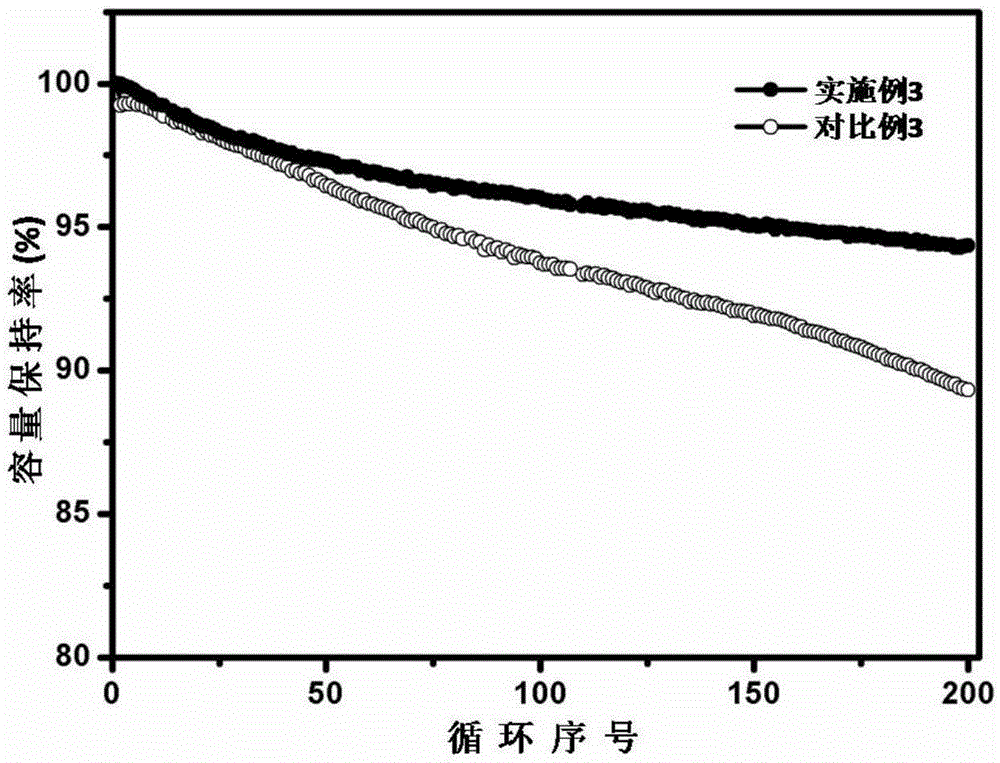

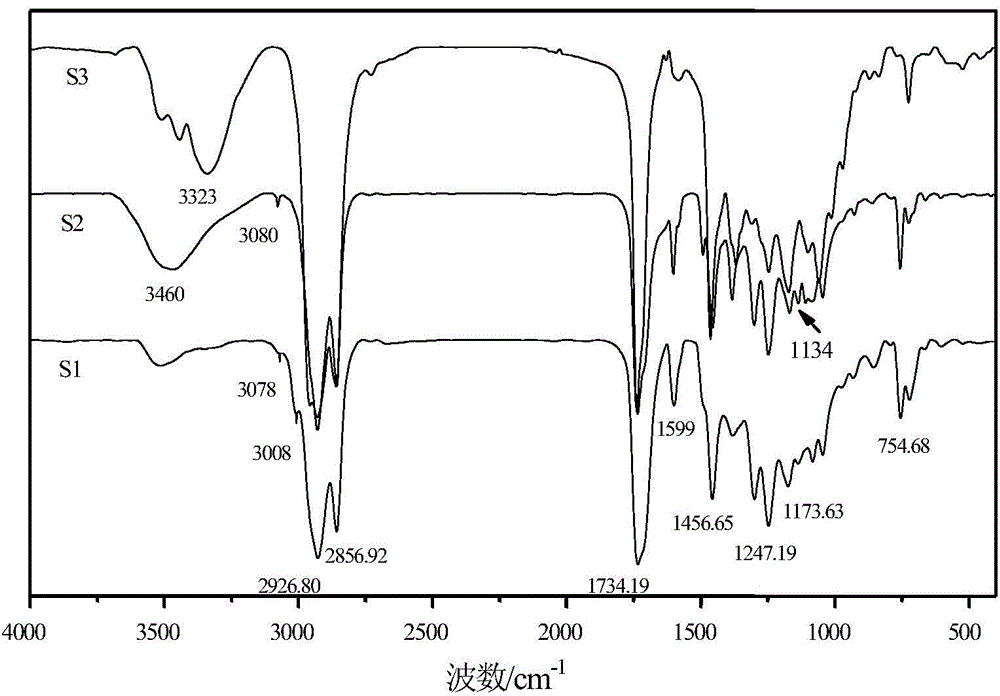

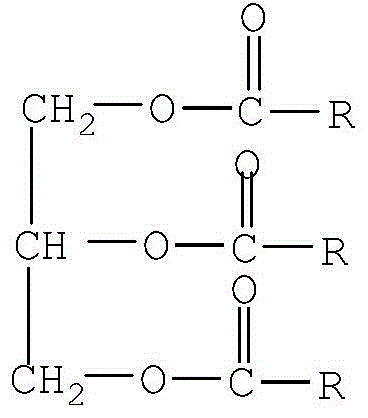

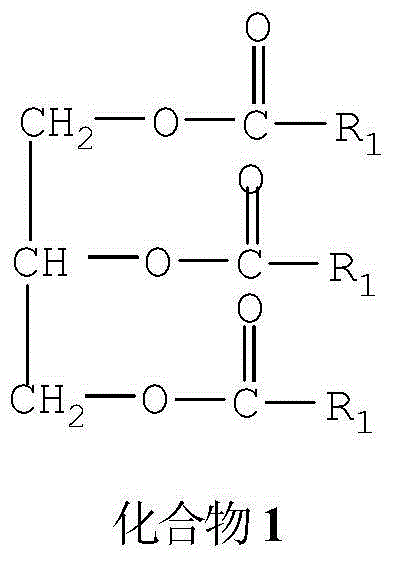

Lithium-ion battery electrolyte and lithium-ion battery containing electrolyte

InactiveCN105428716AGood gas productionReduce gas productionSecondary cellsOrganic electrolytesOrganic solventPhosphate

The invention discloses lithium-ion battery electrolyte. The electrolyte comprises LiPF6, a non-aqueous organic solvent and additives, wherein the additives comprise fluoroalkenyl phosphate compounds and LiBOB, the structural general formula of the fluoroalkenyl phosphate compounds is the general formula I or the general formula II shown in the specification; according to the general formula, when R1 represents alkyl with 1-5 carbon atoms, R2 represents fluoroalkenyl, and when R1 represents fluoroalkyl, R2 represents any one of alkenyl with 2-5 carbon atoms and fluoroalkenyl with 2-5 carbon atoms. The flammability of the lithium-ion battery electrolyte is low, the gas production capacity of the lithium-ion battery prepared from the electrolyte is small in the charging and discharging processes, and the battery can be effectively prevented from expanding and has excellent high-temperature cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

High-temperature-resistant lubricating oil base oil and preparation method thereof

InactiveCN104962341AHigh flash pointGood oxidation stabilityBase-materialsTemperature resistanceChemistry

The invention discloses high-temperature-resistant lubricating oil base oil and a preparation method thereof. The base oil is prepared from castor oil through three steps of modification including esterification, epoxidation and ring opening. The base oil prepared through the method is high in flashing point, oxidation stability and wear resistance, remarkable in high-temperature resistance, suitable for the high-temperature environment, green, environmentally friendly, capable of being used for various fields and wide in application prospect.

Owner:SHAANXI NORMAL UNIV

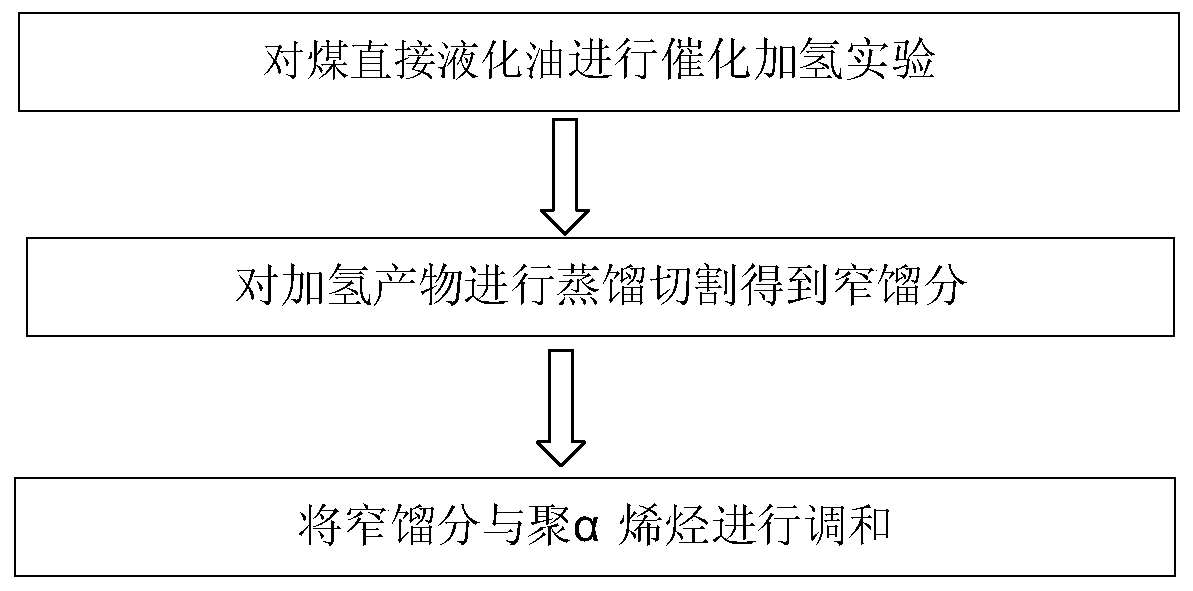

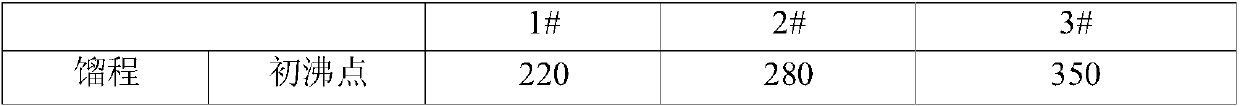

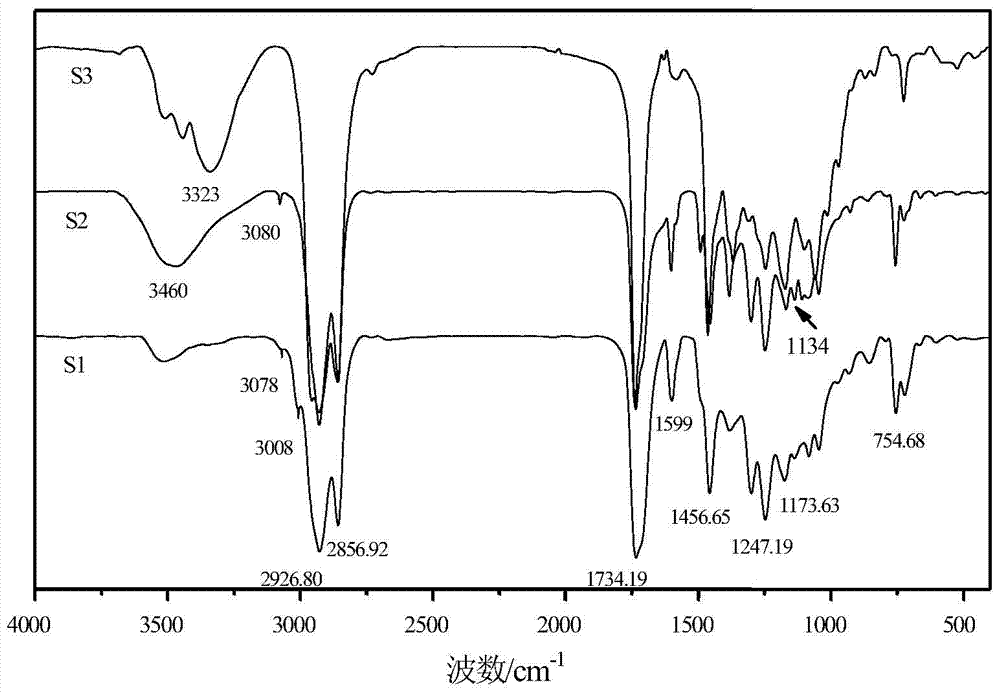

Coal directly liquefied oil composition and preparation method thereof

ActiveCN109825332AImprove physical and chemical propertiesImprove viscosity indexTreatment with hydrotreatment processesChemical compositionViscosity index

The invention provides a coal directly liquefied oil composition and a preparation method thereof. The preparation method comprises following steps: step one, catalytically hydrogenating coal directlyliquefied oil to obtain a hydrogenated oil product; step two, cutting the hydrogenated oil product by steam to obtain a plurality of narrow distillate oils; and step three, blending the narrow distillate oils with poly(alpha-olefin) to obtain the coal directly liquefied oil composition. The viscosity index, flash point, and low temperature properties of coal directly liquefied oil are improved effectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

A kind of high temperature resistant lubricating oil base oil and preparation method thereof

InactiveCN104962341BImprove flash pointImprove wear resistanceBase-materialsOxidation stabilityBase oil

The invention discloses a high temperature resistant lubricating oil base oil and a preparation method thereof. The base oil is prepared by modifying castor oil in three steps of esterification, epoxy and ring opening. The lubricating oil base oil prepared by the invention has a high flash point, good oxidation stability, good wear resistance, has remarkable high temperature resistance, is suitable for use in a high temperature environment, and the base oil is green and environmentally friendly, and can be used in various fields. with broadly application foreground.

Owner:SHAANXI NORMAL UNIV

Method for preparing environmentally-friendly chlorinated plasticizer from waste grease, and product produced therethrough

ActiveCN109971551AGood compatibilityHigh plasticizing efficiencyFatty oils/acids recovery from wasteFatty acid esterificationPlasticizerEthyl Chloride

The invention discloses a method for preparing an environmentally-friendly chlorinated plasticizer from waste grease. The method comprises the following steps: the waste grease, used as a raw material, and methanol undergo esterification and ester exchange to obtain a high-condensation point fatty acid methyl ester mainly containing saturated fatty acid methyl ester; and the high-condensation point saturated fatty acid methyl ester is post-treated under the action of a catalyst in the presence of introduced chlorine to obtain chloro fatty acid methyl ester. The environmentally-friendly chlorofatty acid methyl ester plasticizer prepared by the method of the invention has a good plasticizing effect, and makes PVC products have the advantages of difficult oil effusion, low condensation point, low price and good quality. The method has the advantages of simple preparation process, and suitableness for industrial production.

Owner:FUJIAN MINGZHOU ENVIRONMENTAL PROTECTION DEV

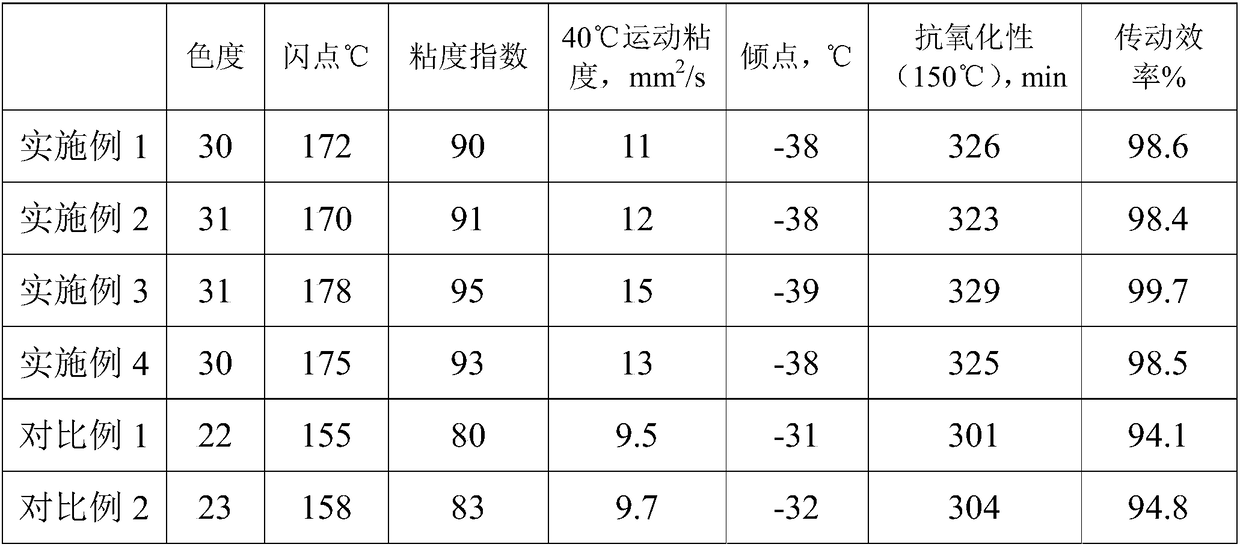

Preparation method of high speed engine base oil

ActiveCN109181767AHigh viscosity indexReduce transmission efficiencyTreatment with hydrotreatment processesPressure reductionCaking

The invention provides a preparation method of a high speed engine base oil. The preparation method comprises following steps: pre-heating, hydroisomerization, hydrofining, high and low pressure separation, normal pressure distillation, pressure reduction fractional distillation, and secondary adsorption refining with a composite adsorbent. The preparation method is capable of changing oil molecular size, structure, and arrangement mode, increasing ideal components, inhibiting catalyst caking carbon deposition, reducing generation of nonideal components such as polycyclic aromatic hydrocarbonsand asphaltene, improving oil product quality, removing impurities, improving oil product chroma, flash point, and oxidation resistance, widening oil product application range, and improving stability obviously. The obtained high speed engine base oil is high in flash point, high in viscosity index, low in pour point, high in oxidation resistance, and high transmission efficiency, and can be usedfor high speed engines preferably.

Owner:HAINAN HANDI SUNSHINE PETROCHEM

Method for preparing alkyl naphthalene from mixed olefins and application of alkyl naphthalene

The invention belongs to the technical field of high-quality lubricant base oil, and particularly discloses a method for preparing alkyl naphthalene from mixed olefins and application of the alkyl naphthalene. The preparation method comprises the following specific steps: mixing reaction raw materials, namely mixed alpha-olefins and naphthalene, adding a solid acid catalyst and a solvent, and performing a high-temperature reaction to obtain a product. According to the invention, a plurality of mixed alpha-olefins are used for replacing an olefin with a single carbon number in a traditional process, and the alkyl naphthalene product is prepared through synergism of the catalyst and reaction conditions; and the alkyl naphthalene product is improved in the aspects of viscosity, pour point, flash point, chromaticity, acid value, water content and the like, and overcomes the technical bias that the performance of alkyl naphthalene prepared from mixed olefins in the prior art is difficult to reach the performance index of alkyl naphthalene prepared from an olefin with a single carbon number.

Owner:SICHUAN LUTIANHUA +1

Corrosion inhibitor suitable for hydrochloric acid system with mass fraction of 20-28% and preparation method of corrosion inhibitor

ActiveCN113046046AEasy to coverGood synergyOrganic chemistryDrilling compositionOrganic acidOrganic solvent

The invention discloses a corrosion inhibitor suitable for a hydrochloric acid system with a mass fraction of 20-28%. The corrosion inhibitor is composed of a quinoline quaternary ammonium salt, an imidazoline quaternary ammonium salt, alkynol, an acid-soluble metal salt, a low-molecular organic acid, a surfactant, an organic solvent and deionized water. The corrosion inhibitor is suitable for production increase operation construction of an ultra-high concentration hydrochloric acid system acidification oil and gas well, and has the characteristics of simple formula, good dissolution and dispersion, better corrosion inhibition performance and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Printing equipment dedicated lubricating oil

InactiveCN104711083AHigh strengthImprove extreme pressure performanceLubricant compositionAntioxidantExtreme temperature

The invention belongs to the technical field of lubricating oil, and specifically relates to a printing equipment dedicated lubricating oil. The lubricating oil is characterized by being composed of the following raw materials in parts by weight: 75 to 85 parts of base oil, 1 to 3 parts of cleaning agent, 3 to 5 parts of antioxidant, 0.5 to 1 part of demulsifying agent, 0.3 to 0.5 part of antirust agent, 8 to 10 parts of friction improver, 2 to 4 parts of extreme pressure anti-wear agent, 3 to 5 parts of antioxidant antiseptic, 1 to 2 parts of antifoaming agent, 3 to 5 parts of pour point reducer, 1 to 3 parts of metal deactivator, 0.8 to 1.0 part of passivating agent, and 0.03 to 0.05 part of dye. The lubricating can be applied to machines such as stamping machine, die-cutting machine, and the like, can be used under heavy load, strong impact, and extreme temperatures, and in corrosive environment, has a good affinity on the metal surface, can improve the oil membrane's performance on preventing extreme pressure and wear, is capable of saving power loss by 10% or more, and can prolongs the service life of machines by 4 to 6 times or more.

Owner:张希顺

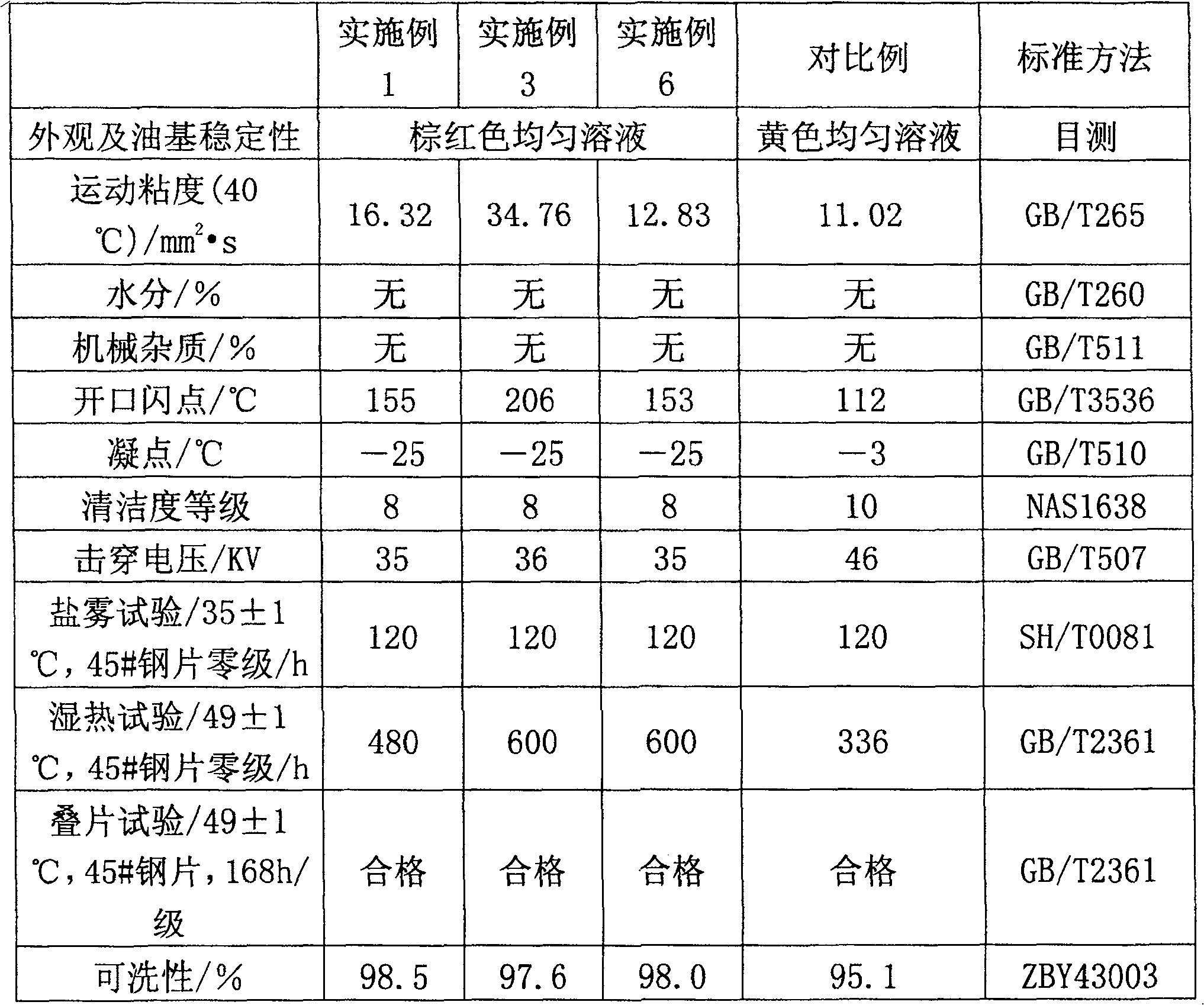

Electrostatic spraying antirust oil

The invention discloses an antirust oil for electrostatic spraying to solve the problem of corrosion on the surface of common carbon steel plates. The anti-rust oil consists of 70.0-90.0% by weight of base oil, 5.0-29.0% by weight of anti-rust agent, 0.1-5.0% by weight of atomization performance improver and 0.1-5.0% by weight of antioxidant. The antirust oil of the invention has the advantages of low production cost, high flash point, good washability, low surface tension and the like.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Environment-friendly volatile punching oil composition and application thereof

InactiveCN110862859ASmall smellNot easy to residueLubricant compositionTurpentine OilMachining process

The invention discloses an environment-friendly volatile punching oil composition and an application thereof and belongs to the technical field of metal piece punching. The volatile punching oil composition comprises the following ingredients in percentage by mass: 65%-85% of turpentine oil, 15%-30% of hydrocarbon solvent base oil and 0%-5% of volatile lubricant. According to the volatile punchingoil composition provided by embodiments of the invention, volatile punching oil, which is light in odor, difficult in residual, good in lubricating property and good in volatility and has a standards-compliant flashing point, can be prepared through employing a natural product, i.e., the turpentine oil and the hydrocarbon solvent base oil as main raw materials and employing the volatile lubricantas an additive. Compared with the traditional volatile punching oil, the volatile punching oil composition has the advantages that during use, environmental pollution can be reduced, and actions of lubricating, antirusting protection, corrosion prevention, workpiece surface cleaning and the like can be provided under the condition that a user does not change the existing production punching processing technology.

Owner:FOSHAN SHUNDE FUYANSHENG LUBRICANT

Process for production of MARPOL compliant bunker fuel from petroleum residues

ActiveUS20210246380A1Improve flash pointImprove stabilityThermal non-catalytic crackingTreatment with plural serial stages onlyProcess engineeringMarine fuel

This invention relates to production of low sulfur MARPOL compliant bunker fuel oil and distillates using high sulfur residue, low sulfur residue and / or blend of high and low sulfur residue feed stock. The invention also describes a method for production of a cutterstock stream having a lower paraffin and higher aromatic content than a feed stream using a paraffin separation section and its blending to produce bunker fuel.

Owner:INDIAN OIL CORPORATION

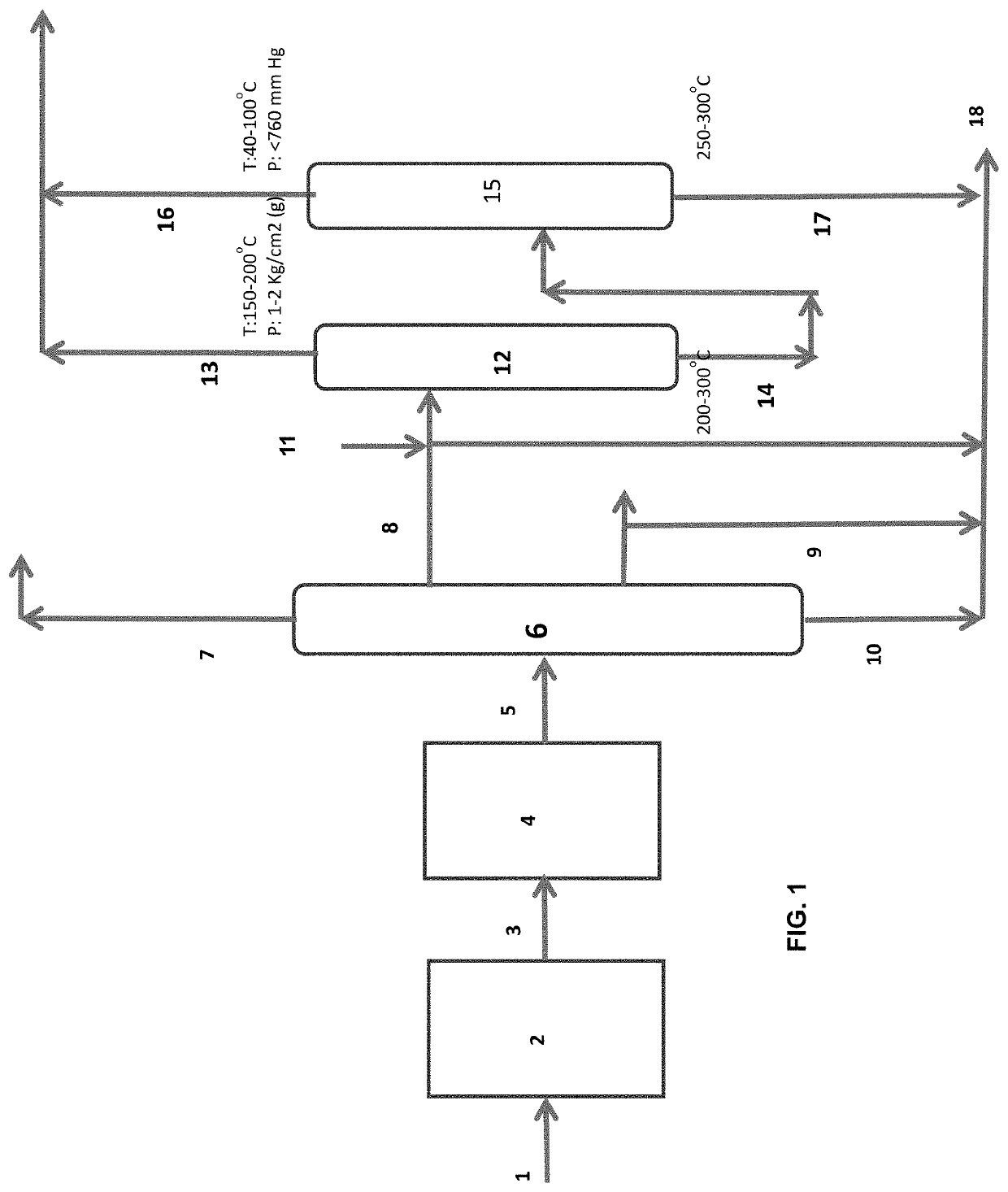

A kind of preparation method of aqueous phase suspension method cpvc resin

The invention discloses a CPVC resin preparation method by using a water phase suspension method, and belongs to the technical field of chemical raw materials. The preparation method is characterized in that the preparation steps comprise uniformly spraying a polyhydric alcohol aqueous solution on the surface of PVC resin by using a spraying device; then uniformly suspending the PVC resin which is sprayed with the polyhydric alcohol into a deionized water polymerizing kettle; adding an initiating agent and introducing chlorine gas for chlorination reaction; after the finish of introducing the chlorine gas, adding a chain terminating agent to stop the reaction; and performing washing and drying to obtain a product. The preparation method provided by the invention aims at the characteristics of CPVC resin production process by using the water phase suspension method, gives up the use of dispersing agents, first performs surface activating treatment on the PVC resin by using the polyhydric alcohol, and then performs the chlorination reaction. The prepared CPVC resin has high chlorine content and aging whiteness, has a good stability property, is easy to plasticize uniformly, and has good processability. As a chemical raw material, the CPVC resin can be widely used in preparing various products such as tubular materials, board materials, sectional materials, sheet materials, injection molded parts, foam materials and the like.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of preparation method of high-speed engine base oil

ActiveCN109181767BHigh viscosity indexReduce transmission efficiencyTreatment with hydrotreatment processesPtru catalystDistillation

The invention provides a preparation method of high-speed engine base oil, which is prepared by preheating, hydroisomerization, hydrofining, high and low pressure separation, atmospheric distillation, vacuum fractionation, and finally using a composite adsorbent for secondary adsorption refining. Get the target base oil. The invention changes the molecular size, structure and arrangement of oil products, increases ideal components, inhibits coking and carbon deposition of catalysts, reduces the generation of non-ideal components such as polycyclic aromatic hydrocarbons and asphaltenes, improves the quality of oil products, and removes impurities, so that The chromaticity, flash point, and oxidation resistance of the oil have been significantly improved, and the application range and stability of the oil have been significantly improved. The base oil prepared by the invention has the characteristics of high flash point, high viscosity index, low pour point, strong oxidation resistance and high transmission efficiency, and can be better applied to high-speed engines.

Owner:HAINAN HANDI SUNSHINE PETROCHEM

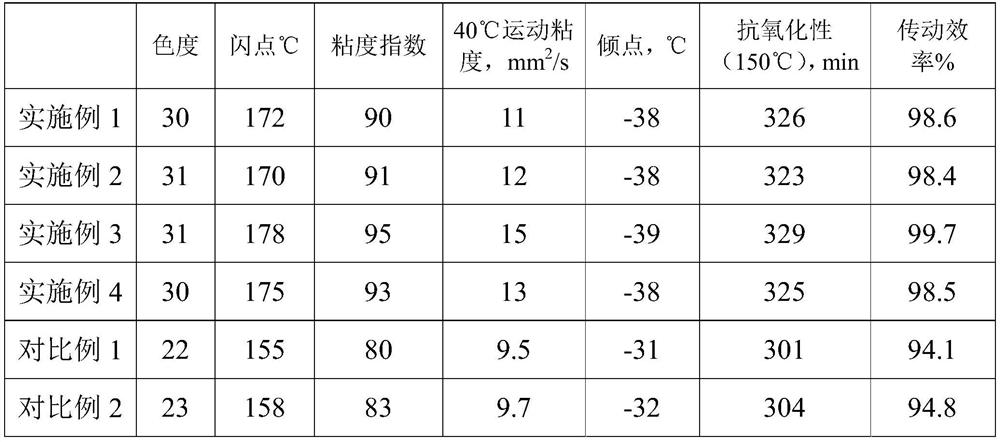

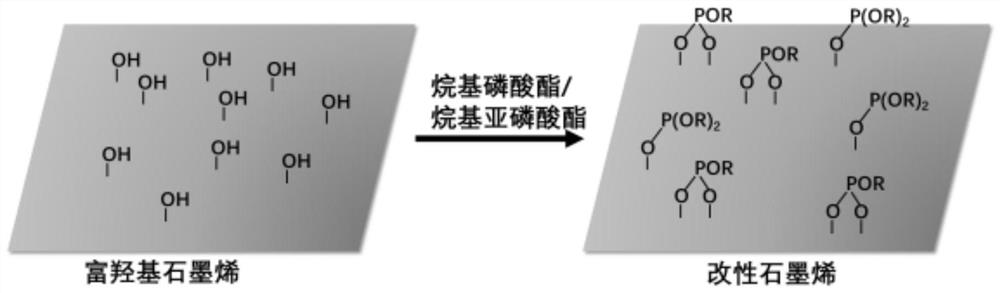

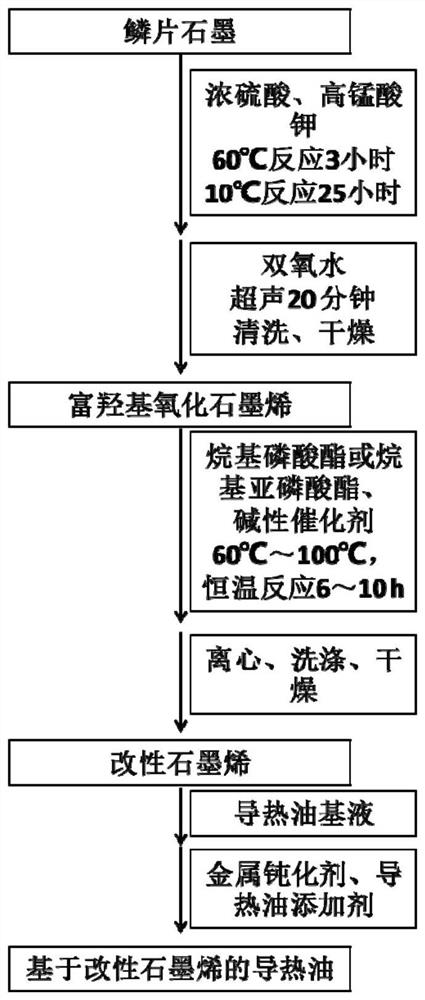

A kind of heat-conducting oil based on modified graphene and preparation method thereof

ActiveCN111410937BHigh thermal conductivityImprove heat transfer efficiencyHeat-exchange elementsPhosphorous acidAlkylphosphate

The invention discloses a modified graphene-based heat-conducting oil and a preparation method thereof. The components of the heat-conducting oil include modified graphene, a heat-conducting oil base liquid, a metal passivator, and a heat-conducting oil additive. The specific preparation method is as follows: firstly , prepare hydroxyl-rich graphene oxide by an optimized oxidation reaction method, react hydroxyl-rich graphene oxide with alkyl phosphate or alkyl phosphite compounds to obtain modified graphene, and then combine modified graphene with other components to obtain modified graphene. A certain proportion is prepared by ultrasonic-assisted shear dispersion process. The heat-conducting oil based on modified graphene provided by the invention has good dispersion uniformity and stability, improves the heat-conducting efficiency of the heat-conducting oil and at the same time improves its oxidation resistance, prolongs the service life of the heat-conducting oil, and saves energy and reduces consumption.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Multifunctional hydrocarbon cleaning agent and production method thereof

PendingCN113652310AImprove flash pointLow flash pointInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDodecaneN-dodecane

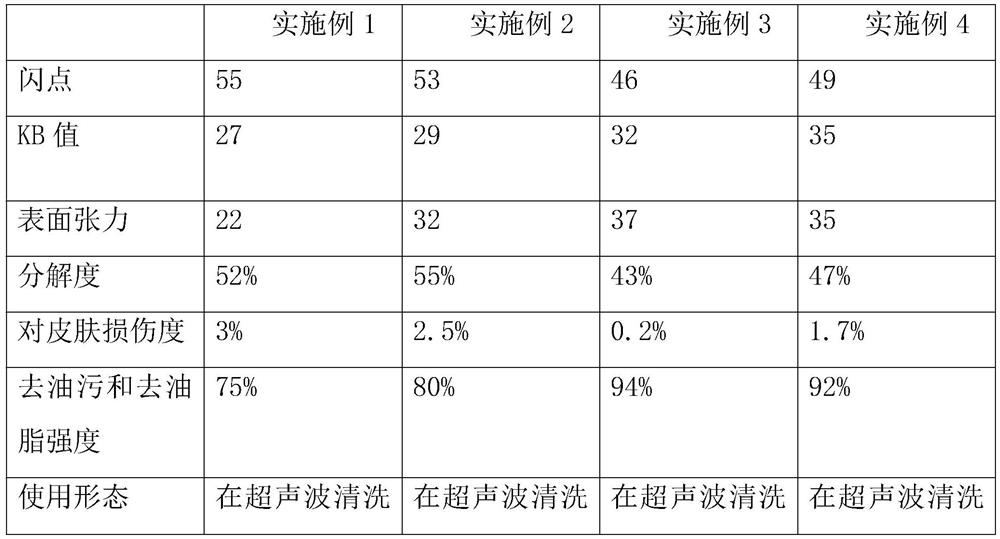

The invention belongs to the technical field of hydrocarbon cleaning agents, and particularly relates to a multifunctional hydrocarbon cleaning agent and a production method thereof.The multifunctional hydrocarbon cleaning agent is prepared from, in parts by weight, 30-50 parts of n-dodecane, 30-50 parts of undecyl alcohol, 20-40 parts of carbon trioxide, 20-40 parts of polyoxyethylene fatty alcohol sodium sulfate, 10-20 parts of sulfonic acid, 10-20 parts of sodium hydroxide, 5-10 parts of essence and 5-10 parts of an emulsifying agent. The hydrocarbon cleaning agent has the beneficial effects that the hydrocarbon cleaning agent is relatively low in flash point, not easy to burn, relatively high in capability of dissolving substances, relatively high in anti-pollution performance, relatively low in decomposition degree, not easy to automatically decompose in sunlight and air, easy to maintain, extremely low in skin damage degree, high in adaptability, relatively high in degreasing and degreasing strength, and can easily remove oil stains and grease; and more foam can be generated when the cleaning agent is used, and objects can be conveniently cleaned.

Owner:常州智高化学科技有限公司

Base oil for refrigerator oil, preparation method and application of base oil for refrigerator oil

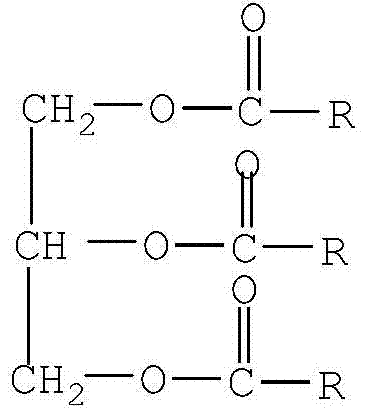

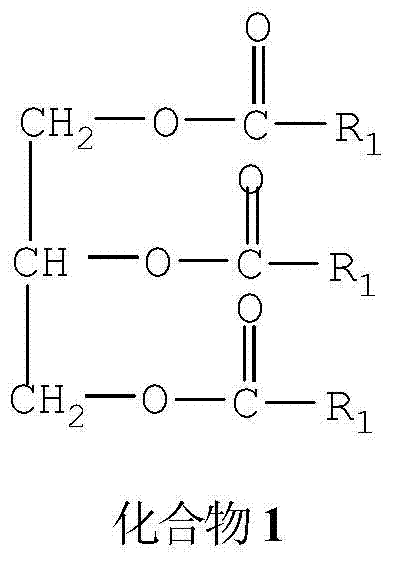

The invention discloses base oil for refrigerator oil, a preparation method and application of the base oil for the refrigerator oil. The preparation method comprises the following steps: trimethylolpropane and fatty acid are mixed to react with each other under effect of a catalyst; the catalyst contains silicate phosphate. The catalyst used in the preparation method has high substrate selectivity, low side product content and high catalysis efficiency; upon the end of the reaction, the catalyst can be removed through filtration, the preparation method has the advantages of simple and convenient operation, energy-saving and environment-friendly. The prepared base oil for refrigerator oil has a high stability and good viscosity, pour point and flash point and the like.

Owner:SHANGHAI DONGDA CHEM

A kind of refrigerating machine oil base oil and its preparation method and application

The invention discloses a refrigerating machine oil base oil, a preparation method and application thereof. The preparation method comprises: mixing trimethylolpropane and fatty acid, and reacting under the action of a catalyst; the catalyst contains silicon phosphate. The catalyst used in the preparation method of the invention has high selectivity to the substrate, low by-products and high catalytic efficiency; it can be removed by filtration after the reaction is finished, and the operation is simple, energy-saving and environment-friendly. The prepared refrigerating machine oil base oil has good stability and excellent properties such as viscosity, pour point and lightning.

Owner:SHANGHAI DONGDA CHEM

Novel low carbon methanol diesel and additive and preparation method thereof

Owner:陕西宝姜新能源技术研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com