A kind of heat-conducting oil based on modified graphene and preparation method thereof

A graphene and heat transfer oil technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problem that dispersion stability and oxidation stability are not significantly improved, prone to sedimentation and agglomeration, and easy to desorb, etc. problems, to achieve the effect of delaying aging and coking, improving heat conduction efficiency, and good anti-oxidation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

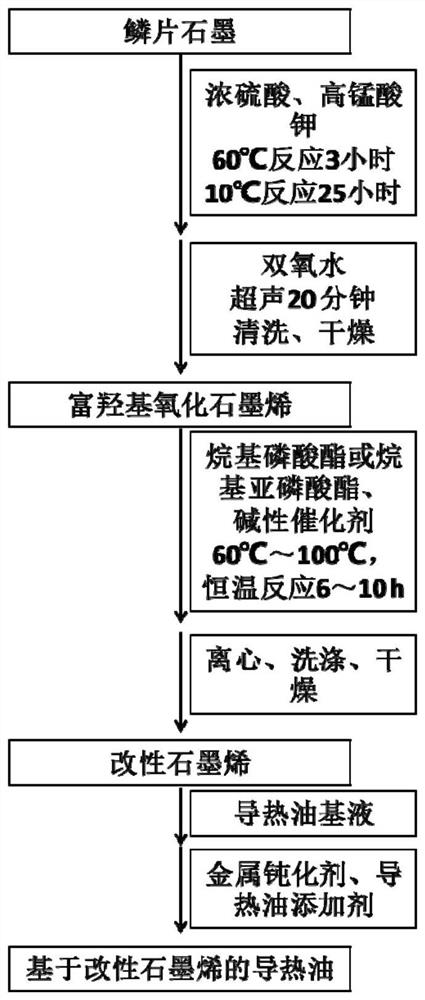

[0033] A preparation method based on modified graphene heat transfer oil, comprising the steps of:

[0034] (1) Take 1 part of flake graphite and disperse it in 25 parts of concentrated sulfuric acid, add 2.3 parts of potassium permanganate at 0°C, react at 60°C for 3 hours, cool down to 0°C, add 1 part of potassium permanganate, and keep at 10°C React for 30 hours; after the reaction, add 1.2 parts of hydrogen peroxide and ultrasonic for 20 minutes, and obtain hydroxyl-rich graphene oxide after cleaning and drying;

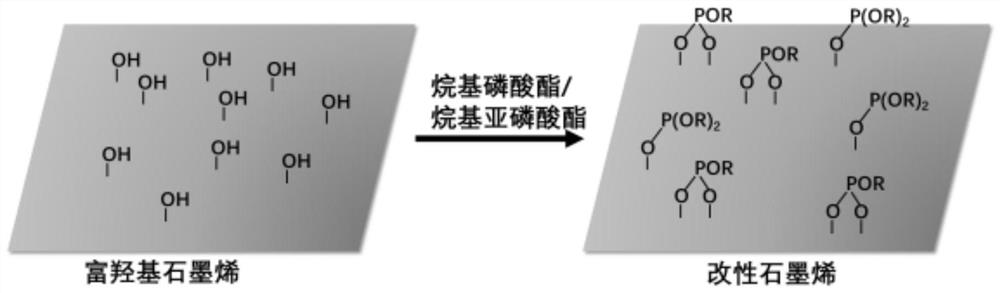

[0035] (2) Take 1 part of hydroxyl-rich graphene oxide prepared in step (1), 1 part of triethyl phosphite and 0.05 part of NaOH in 50 parts of solvent, heat and stir, heat up to 80 ° C, and react at constant temperature for 8 hours, After cooling down, centrifuge, redisperse and wash with water and ethanol, and obtain modified graphene after removing water;

[0036] (3) Take 0.05 parts of modified graphene, 0.01 parts of N,N′-disalicylidene-1,2-propylenediamine,...

Embodiment 2

[0038] A preparation method based on modified graphene heat transfer oil, comprising the steps of:

[0039] (1) Take 1 part of flake graphite and disperse it in 25 parts of concentrated sulfuric acid, add 2.3 parts of potassium permanganate at 0°C, react at 60°C for 6 hours, cool down to 0°C, add 1 part of potassium permanganate, and keep at 10°C React for 20 hours; after the reaction, add 1.2 parts of hydrogen peroxide and ultrasonic for 20 minutes, and obtain hydroxyl-rich graphene oxide after cleaning and drying;

[0040] (2) Take 1 part of hydroxyl-rich graphene oxide prepared in step (1), 1 part of triethyl phosphate and 0.05 part of KOH in 50 parts of solvent, heat and stir, heat up to 60 °C, and react at constant temperature for 10 h, After cooling down, centrifuge, redisperse and wash with water and ethanol, and obtain modified graphene after removing water;

[0041] (3) Take 0.5 part of modified graphene, 0.1 part of methyl benzotriazole, 0.1 part of heat transfer oi...

Embodiment 3

[0043] A preparation method based on modified graphene heat transfer oil, comprising the steps of:

[0044](1) Take 1 part of flake graphite and disperse it in 25 parts of concentrated sulfuric acid, add 2.3 parts of potassium permanganate at 0°C, react at 60°C for 5 hours, cool down to 0°C, add 1 part of potassium permanganate, and keep at 10°C React for 25 hours; after the reaction, add 1.2 parts of hydrogen peroxide and ultrasonic for 20 minutes, and obtain hydroxyl-rich graphene oxide after cleaning and drying;

[0045] (2) Get 1 part of hydroxyl-rich graphene oxide prepared in step (1), 1 part of tris (2-ethylhexyl) phosphite and 0.05 part of NaOCH 3 Place in 50 parts of solvent, heat and stir, heat up to 100 ℃ for 6 hours, cool down, centrifuge, redisperse and wash with water and ethanol, and obtain modified graphene after removing water;

[0046] (3) Take 0.2 part of modified graphene, 0.05 part of 2-amino-5-mercapto-1,3,4-thiadiazole, 0.07 part of heat transfer oil ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com