Coal directly liquefied oil composition and preparation method thereof

A technology for direct coal liquefaction oil and composition, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., and can solve the problems of blending base oil without polyalphaolefin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

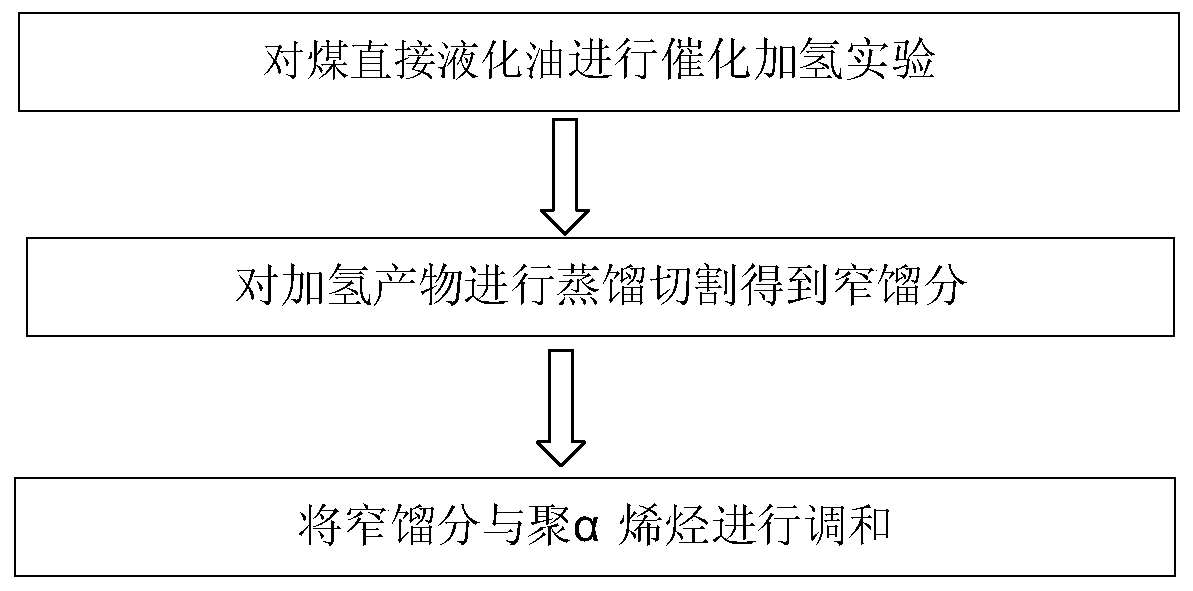

[0028] In order to solve the above problems, the present invention provides a method for preparing a coal direct liquefaction oil composition, such as figure 1 As shown, the preparation method includes the following steps: S1, catalytic hydrogenation of direct coal liquefaction oil to obtain hydrogenated product oil; S2, distillation and cutting of hydrogenated product oil to obtain multiple narrow fractions; and S3, the The narrow distillate oil is blended with polyalphaolefin to obtain a coal direct liquefaction oil composition.

[0029] The ratio of the viscosity of the narrow distillate oil to the polyalphaolefin used for blending is between about 10:1 and about 1:1000, for example, the ratio of the viscosity of the narrow distillate oil to be blended and the polyalphaolefin can be about 10:1 , about 1:1, about 1:2, about 1:5, about 1:10, about 1:20, about 1:30, about 1:40, about 1:50, about 1:100, about 1:200 , about 1:300, about 1:400, about 1:500, about 1:1000, etc., i...

Embodiment 1

[0058] Embodiment 1: the allocation of coal liquefied oil composition

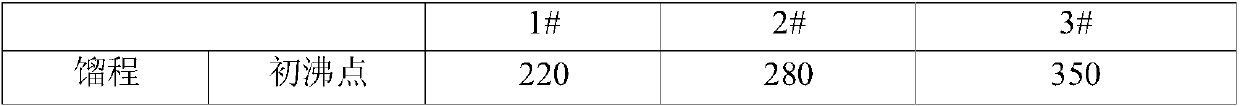

[0059] The solvent oil produced by direct liquefaction of 1# coal in Table 1 is used as the raw material. After the raw material oil and hydrogen are mixed, they enter the catalyst bed (the catalyst is Cat1 in Table 3), and then the hydrogenated products are cut at different temperature sections, and the obtained hydrogenated The hydrogen product was distilled under reduced pressure, and the narrow fractions obtained from the distillation were blended with 1#PAO, 2#PAO, and 3#PAO in Table 2 to finally obtain multiple coal direct liquefaction oil compositions. The experimental conditions and the properties of the obtained products are shown in Table 4.

[0060] Table 4, the coal direct liquefaction oil composition prepared by the present invention

[0061]

[0062] As above, polyalphaolefins can be selected over a broad range of kinematic viscosities, wherein the ratio of the viscosity of the narrow dis...

Embodiment 2

[0065] Embodiment 2: the allocation of coal liquefied oil composition

[0066] Using the 3# coal direct liquefaction distillate in Table 1 as the raw material, the raw material oil and hydrogen are mixed and enter the catalyst bed (the catalyst is Cat2 in Table 3), and then the hydrogenated product is cut at different temperature sections, and the obtained hydrogenated The product was distilled under reduced pressure, and the narrow fractions obtained from the distillation were blended with 3#PAO, 4#PAO, and 5#PAO in Table 2 to finally obtain multiple coal direct liquefaction oil compositions. The experimental conditions and the properties of the obtained products are shown in Table 5.

[0067] Table 5, the coal direct liquefaction oil composition prepared by the present invention

[0068]

[0069]

[0070] As above, the polyalphaolefin can be selected over a wide range of kinematic viscosities such that the viscosity ratio of the narrow distillate to be blended and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com